Новини світу мікро- та наноелектроніки

Built myself a power supply with nixie tube display

| submitted by /u/U_A_beringianus [link] [comments] |

Introspect Technology Introduces LPDDR5/LPDDR5X Protocol Analyzer

Navitas celebrates tenth anniversary

Infineon highlights power solutions portfolio at APEC 2024

Tin my dad bought and rolled on a tape player spool exactly 45 years ago that I'm still using today, it never ends

| I'm using it for 10 years and it still doesn't end [link] [comments] |

Bought a microscope yesterday and holy smokes they’re a game changer

| submitted by /u/wastedhotdogs [link] [comments] |

Nuvoton’s New Microprocessors Target Industrial HMI Applications

Understanding the Significance of Dynamic Range and Spurious-Free Dynamic Range

Hotwire thermostat: Using fine copper wire as integrated sensor and heater for temperature control

Conventional thermostats are based on separate temperature sensor and heater devices with means for feedback between them. But in some recent EDN design ideas (DIs) we’ve seen thermostat designs that meld the functions of sensor and heater into a single active device (usually FET or BJT). The ploy can make a better fit to applications where the intended thermal load is physically small or has some other quirk of geometry that makes it inconvenient to apply the classic separate sensor/heater schema. This DI (see the figure) follows the melded concept but takes it in a somewhat different direction by using fine gauge copper wire (e.g., 40 AWG polyurethane insulated) as an integrated temperature sensor and heater.

Here’s how it works.

Miniature thermostat utilizing the tempco and I2R heating of 40 AWG copper wire as a melded sensor/heater.

Wow the engineering world with your unique design: Design Ideas Submission Guide

The resistance and temperature coefficient of a standard 40 AWG copper wire at 25 oC are generally spec’d at 1.07 Ω/foot and +0.393%/oC, respectively. Therefore, L feet of 40 ga can be expected to have an approximate resistance at a given temperature T of:

R(L,T) = 1.07 L(1 + 0.00393(T – 25)) (1)

R = 1.07 L + 0.00421 L T – 0.00421 L 25 (2)

T = (R – 1.07 L + 0.00421 L 25) / 0.00421 L (3)

T = (R – 0.965 L) / 0.00421 L (4)

Equation 4 holds well from R/L = 0.965 Ω/ft at 0o up to 1.6 Ω /ft at 155o (the recommended upper temperature limit for solderable polyurethane wire insulation).

Consider the implications for the use of fine copper wire as a combination temperature sensor and heater.

If a suitable length (between 5 and 15 feet) of wire is placed in a feedback loop driving current through it so as to dissipate enough I2R heating to raise and maintain a temperature that creates a preselected constant wire resistance, then said temperature, and the temperature of any thermal load thermally bonded to it, would likewise be constant! This is exactly what the circuit in the figure does.

Q1’s drain supplies heating; heating current I to the sensor/heater wire (please ignore for a moment the minor contribution from start-up resistor R2). The voltage induced between the terminals of the R wire resistance is then:

V = IR (5)

This causes the A1b, Q2 current source to output:

I2 = V/(R4 + R7) = IR/(R4 + R7) (6)

Which induces a voltage at pin 2 of A1b:

V2 = I2(R5 + R6) = IR(R5 + R6)/(R4 + R7) (7)

Meanwhile, Q1’s source current (also equal to I) sampling resistor R1 produces:

V3 = IR1 (8)

FET control amplifer A1a forces FET gate voltage and thereby R drive current such that:

V2 = V3 (9)

IR(R5 + R6)/(R4 + R7) = R1I (10)

R = R1(R4 + R7)/(R5 + R6) (11)

Thus, heater current, and therefore wire resistance and temperature, are forced to equilibrium values set purely by the resistance ratios listed in Equation 11, with the resultant constant temperature given by Equation 4.

About Q3. The thermostat circuit is intended to be as flexible as possible in regard to wire gauge, length and associated sensor/heater R resistance. To accommodate R < 10 Ω and consequent possibility of potentially damaging peak I values, Q3 removes Q1 gate drive when necessary and limits I to a safe ~1.4 A.

Setup and calibration. In further pursuit of flexibility in accommodating sensor/heater wire length and initial R, this simple calibration procedure is suggested for whenever the wire is replaced.

- Before first power up, allow sensor/heater to fully equilibrate to room temperature.

- Set R4 and R5 fully CCW.

- Push and hold the CAL NC pushbutton.

- Turn the power on.

- Slowly turn R4 clockwise until LED first flickers on.

- Release CAL.

Done. R5 is now “reasonably well” calibrated for a CCW to CW span of zero to 130oC above room temp.

Thermal coupling of the chosen length of sensor/heater wire to the desired thermal load (e.g., thermostated circuit component, test tube, petri dish, etc.) can be done by winding a meander of wire around the load, and securing it with polyimide tape, RTV silicone, or a similar heat tolerant adhesive.

And about R2. Although not significant in the steady state function of the circuit, without R2 the thermostat might be vulnerable to a failure to start when first switched on and might simply sit looking stupid. Indefinitely. Don’t ask how I know this…

Stephen Woodward’s relationship with EDN’s DI column goes back quite a long way. Over 100 submissions have been accepted since his first contribution back in 1974.

Related Content

- ∆Vbe differential thermometer needs no calibration

- Fixing a fundamental flaw of self-sensing transistor thermostats

- Electromechanical relays: an old-fashioned component solves modern problems

- Low-cost precision adjustable current reference and application

- ∆Vbe differential thermometer needs no calibration

The post Hotwire thermostat: Using fine copper wire as integrated sensor and heater for temperature control appeared first on EDN.

EPC GaN FETs deliver power density and efficiency for computing, industrial and consumer DC/DC converters

EPC Space launches first rad-hard GaN power stage IC

NeoChromVG GPU, the 1st vector graphics accelerator for general-purpose MCUs enables single-chip designs

Author: STMicroelectronics

ST is announcing today the NeoChromVG GPU, the first vector graphics accelerator for general-purpose microcontrollers. Available on the upcoming STM32U5G9 and STM32U5F9, it builds on the Neochrom GPU, launched in 2023, and takes features like vector fonts, available on TouchGFX 4.23, to the next level by enabling a whole new type of optimization on embedded systems. Avid readers of the ST Blog will notice how NeoChromVG GPU is the culmination of our push into vector graphics in the hope of helping makers reduce their memory footprint. We even provide development kits and demos to help engineers know if this solution is right for their project.

Table of ContentsThe reason ST decided to release a specific hardware IP accelerating vector operations is because it was an increasingly popular demand from customers looking to reduce their dependency on external flash modules. Memory markets have always been volatile, but many analysts, according to Forbes, anticipate strong demand in flash during 2024, bolstered in part by new AI applications trying to create “all-flash object storage systems”. Consequently, smaller companies with less purchasing power could encounter serious issues sourcing modules or simply facing prices too high to make their products viable. Hence, many are looking to either reduce their external NAND needs or obliterate them altogether, which led us to offer NeoChromVG GPU in new STM32U5F9 and STM32U5G9 MCUs.

The NeoChromVG GPU solutionIn essence, NeoChromVG GPU is a traditional Neochrom GPU with a hardware unit accelerating vector graphics computations, such as quadratic Bézier curves, which are very common in vector fonts, Bézier tessellation to render surfaces, and vector calculations for vertex transformation, among other things, to rapidly draw vector graphics on screen. It still relies on the same texture mapper as the regular Neochrom GPU and has similar features like L8 compression. Vector graphic acceleration simply becomes an additional tool in a developer’s arsenal to optimize their UI. The feature also comes on the heels of TouchGFX 4.23, which just gained support for vector fonts. Hence, engineers see the overarching strategy ST is using to help with memory dependency.

NeoChromVG GPU will be available on the new STM32U5G9 and STM32U5F9, the former being the version housing a crypto core. Both will feature 3 MB of RAM and 4 MB of dual-bank flash. This hardware configuration has enabled some of our customers to move to a single-chip design that didn’t require external memory at all, while the increase in internal memory and vector graphics support helped others use smaller NAND devices. In both cases, it helps simplify the PCB design to move to only four layers and lower the bill of materials. Similarly, as embedded systems tend to map their NOR memory for greater optimization, not having to map anything above 32 MB becomes a significant time saver.

The best way to start using vector graphics on STM32Vector graphics aren’t for every system. Even with hardware acceleration, the performance penalty incurred by vector rendering may be too much in certain UIs. However, we are ensuring that developers get rapid prototyping tools to test NeoChromVG GPU in minutes. We are releasing the STM32U5G9J-DK, with a 480 x 480 display, and the STM32U5G9J-DK2 with an 800 x 480 screen, as well as a UI demo showing what developers can accomplish thanks to vector graphics. Even the ST Partner Riverdi, famous for its STM32 Embedded Displays, will soon offer a model with the STM32U5G9 to help develop and take advantage of the vector graphics accelerator.

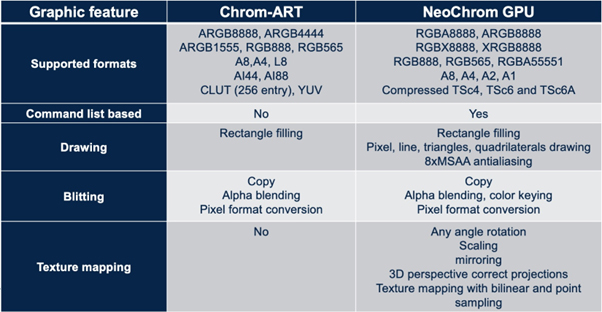

From Chrom-ART to NeoChrom GPU What Are Chrom-ART and NeoChrom GPU?Readers familiar with ST technologies can guess that NeoChrom GPU is the next evolution of Chrom-ART. The latter is a 2D accelerator (DMA2D) embedded inside several STM32 MCUs that optimizes memory access to manipulate images faster. Many tools and products from ST partners use it, such as Storyboard from Crank, Microvisor from Twilio, or interfaces from PsiControl, a TouchGFX Implementer, to only name three. Comparatively, NeoChrom GPU draws from the same philosophy while offering a greater scope of optimizations. Thanks to texture mapping with bilinear and point sampling, the new technology provides new drawing acceleration and supports animations. Hence, what used to require a Desktop PC GPU card can now run on a microcontroller.

Comparing specs between Chrom-ART and NeoChrom

How Does NeoChrom GPU Integrate Into the TouchGFX Ecosystem?Historically, Chrom-ART represented one of ST’s first forays into graphical optimizations. Since then, we acquired TouchGFX and built an entire ecosystem with TouchGFX Designer, Simulator, and Generator. As a result, ST is integrating NeoChrom GPU into these tools right from the start. TouchGFX Designer contains demos showing a smooth animation running at 60 FPS on a circular display. More importantly, it shows the impact on the frame rate when NeoChrom GPU is off to help decision-makers grasp its importance. Similarly, the texture mapping widget will automatically use the new GPU if the MCU supports it. Hence, the immediate integration of the new IP within TouchGFX serves as a witness to ST’s cohesive ecosystem instead of a simple feature list.

From NeoChrom GPU to Real-World Performance What Are the Challenges to Graphical Performances?

The STM32U5

There exist two main challenges to graphical performances: an instructions-per-clock limitation and a memory issue. The first one often follows architectural innovations. Microcontrollers have ALU and FPU restrictions due to their size and low power consumption, but improvements in manufacturing processes allow for more transistors capable of handling more operations. NeoChrom GPU follows such trends with a hardware IP accelerating more types of graphical calculations. The second challenge is trickier but all the more critical because memory will always remain a scarce resource. While the STM32U599 will come with 2.5 MB of internal RAM capable of storing two frame buffers, many embedded systems need external RAM. The problem is that it comes with significant performance penalties.

What Are Unique STM32 Implementations?To solve this second challenge, NeoChrom GPU comes with hardware optimizations specific to STM32 MCUs. For instance, the STM32U5 relies on either an 8-bit Octal Serial Peripheral Interface (OSPI) or a 16-bit high-speed interface (HSPI) at 200 MHz to external memory modules to hasten fetching operations to the L2 cache. Similarly, the L1 cache can directly access two 832 KB frame buffers in the internal RAM. As a result, tessellation is significantly faster thanks to quick access to all the data necessary to render the image in real-time. Put simply, our engineers optimized performance by working on reducing the time it takes to access textures and other assets, ultimately accelerating rendering by up to six times.

What’s Next?The first industry feedback around NeoChrom GPU has been very positive. While many MCU makers have similar IPs to accelerate graphical computations, the specific STM32 optimizations and the TouchGFX ecosystem led many early alpha testers to adopt NeoChrom GPU instead of competing solutions. The new technology is already supported within TouchGFX 4.19, and a few alpha customers have already worked on production-ready UIs using an upcoming STM32U599 development kit. ST will also include NeoChrom GPU in other upcoming microcontrollers and we’ll update this blog post as they become public.

- Contact us to learn more about NeoChrom GPU

- Start a UI that will take advantage of NeoChrom GPU with TouchGFX Designer

- Check all the major features of the TouchGFX framework

The post NeoChromVG GPU, the 1st vector graphics accelerator for general-purpose MCUs enables single-chip designs appeared first on ELE Times.

Generative AI Meets Its Computing Match in Nvidia’s New GPU

Hand-held biosensor detects breast cancer biomarkers from saliva

The perfect multimeter doesn't exi...

| submitted by /u/chataou [link] [comments] |

Siemens Rolls Out Multi-Discipline Simulation Tool for EV Designs

UK tech firms start commercial negotiations at SEMICON Korea

CSA Catapult’s achievements over 2018–2023 outlined in independent report

Indoor solar cells spur design-option reassessments

Conventional solar cells are just that: photovoltaic devices which, by their physics, extract and transform energy from the sun. Their sensitivity and efficiency are matched to the optical-energy spectrum of radiated and received power from the Sun to the extent possible, Figure 1.

Figure 1 The solar optical spectrum is complex and the available power per wavelength is a function of many factors. Source: Pennsylvania State University

In many small-scale applications, these same solar cells are used indoors and powered by ambient light from source’s overhead fixtures (which may be fluorescent or LEDs of various color temperatures), incandescent lamps (yes, some are still out there), diffuse or shaded natural light, and even specialized light such as halogen sources.

Given the indoor situation, two things are obvious:

- The designation as “solar” is somewhat of a misnomer since the Sun is no longer the source and so “photovoltaic” (PV) would be more accurate—but that’s the widely used, colloquial way of describing these cells.

- The energy spectrum of these indoor lighting sources is mismatched to the responsiveness of the solar cells, so efficiency is low.

While there have been some smaller, less-critical indoor products using solar power alone such as small calculators, such harvesting of ambient indoor optical energy is generally limited in its usefulness.

That situation may be changing as several companies have developed solar cells (we’ll stick with that misnomer) based on technologies which are very different from those used by conventional “real” solar cells. These indoor-optimized cells use complex layers of dyes along with specialized physical and chemical processes to achieve their indoor-optimized results.

Both Ambient Photonics (Scotts Valley, CA) and Exeger Operations AB (Stockholm) use variations of dye sensitized solar cell (shortened to DSC or DSSC) technology to produce light-sensitive cells which are optimized for indoor settings. The production process is a high-volume printing-like operation rather than the furnace-based process used for conventional solar cells.

Ambient says they have reinvented the chemistry of the dye sensitized solar cell (DSSC) with novel, proprietary molecules, using light-sensitive dyes to collect photons and convert them into electrons. In their electrochemical system, these light-sensitive dye molecules harvest and produce energy, with the dyes functioning similar to how chlorophyll behaves during photosynthesis in converting photons into energy.

They maintain that their energy-harvesting technology can harness photons across the light spectrum, yielding more than 90 percent conversion efficiency in low-light condition, even when compared to standard DSSC cells, Figure 2. They also function effectively despite the dynamic, changing indoor low-light conditions which are largely a function of the time of day.

Figure 2 Ambient says their DSSC process yields results which are superior to conventional film-based PV cells. Source: Ambient Photonics

Exeger’s dye sensitized solar cell uses a new architecture which they say improves real-life performance, provides greater flexibility, and offers seamless integration possibilities. In their approach, a unique conductive electrode material has replaced the traditional expensive and inefficient indium-tin-oxide (ITO) layer, Figure 3.

Figure 3 The Exeger’s process requires multiple layers of sophisticated materials and films and is compatible with mass production. Source: Exeger Operations AB

Dubbed Powerfoyle, it is flexible and durable and so can be integrated on curved surfaces such as headbands, Figure 4. It can be produced in sizes from 15 cm² to 500 cm², and therefore integrated into products ranging from small IoT sensors to speakers and larger accessories.

Figure 4 A bendable, flexible solar cell opens up new design-in and application opportunities. Source: Exeger Operations AB

For most design engineers, how these companies have achieved their indoor-friendly solar cells is not as important as what these innovations may do with respect to design options and degrees of freedom. Do power sources such as these enable increased consideration of IoT devices (sensors, trackers, shelf labels, and even remote controls) which do not need battery replacement, yet require more power other harvesting schemes (such as ambient RF-harvesting) support? For example, electronic door locks in hotels are an interesting possibility, as they are continually exposed to indoor lighting and used relatively infrequently; in theory, that’s a good combination of harvesting and use cycles.

Applications do not have to be limited to such small devices, either; Exeger has an agreement with a headphone manufacturer for ambient-powered units with the headband capturing ambient light. The same idea can be used for providing power to safety vests and alarm devices.

Of course, the energy source itself is only part of the harvesting chain. For designers, the dominant issue is not “how did they do it” but instead “what can it perhaps do for me?”; “what new opportunities does it provide?”; and “what do I need to do in my design to make use of this power source?”

For example, designers will have to decide on a suitable energy-storage and charging arrangement, whether using a rechargeable battery and the issues of limits on viable charge/discharge cycles, or a supercapacitor and the unique issues of using these non-chemical storage cells.

It will be interesting to see if these indoor-friendly solar cells become a standard part of the design-in possibilities, or if they have downsides which only become apparent when you get into the nitty-gritty design details of product design, manufacturing, use patterns, and long-term performance.

Do you see a viable energy-harvesting role for these non-Sun-driven solar cells? Would they allow you to create something you haven’t been able to do thus far? What possible design-in issues do you see?

Bill Schweber is an EE who has written three textbooks, hundreds of technical articles, opinion columns, and product features.

Related Content

- Keep solar panels clean from dust, fungus

- Are solar-powered cars the ultimate electric vehicles?

- Home solar-supply topologies illustrate tradeoff realities

- Enough With the Solar Power ‘Magic,’ Please!

- Solar Energy Harvesting: A Great Solution, Except When It’s Not

The post Indoor solar cells spur design-option reassessments appeared first on EDN.