ELE Times

Raptee Sets the Stage for Two-Wheeler EVs in India

Raptee is a full-stack two-wheeler EV startup with their flagship product highly tech-enabled and IoT-centred. The team began operations out of Chennai in 2019 with a mission to democratise electric mobility in India. They are crafting a two-wheeler EV that is more of an augmented machine which is intelligent, intuitive and safe with features like throttle mapping, blind-spot detection, and Bluetooth connectivity. So far, Raptee has over 31 technological patents in its name.

Mr. Dinesh Arjun, CEO & Cofounder, Raptee

Mr. Dinesh Arjun, CEO & Cofounder, Raptee

Rashi Bajpai, Sub-Editor at ELE Times spoke with Mr Dinesh Arjun, CEO and Co-founder at Raptee on various aspects of EV with a prime focus on the Indian market.

This is an excerpt from the conversation.

- Can you throw some light on the go-to features/ major USP of Raptee’s electric motorcycle?

Our bikes come with an onboard charger that plays an essential role in bidirectional charging modes thus making the riding experience hassle-free. Additionally, we stand out as the only electric two-wheeler company in India to leverage the ubiquitous CCS2 charging standard. This compatibility grants you access to the extensive public charging network, allowing you to top up your bike from 0 to 80% in a mere 45 minutes.

- What core technologies and concepts does the team Raptee work on? Please highlight your key expertise and core competencies.

As the sole electric two-wheeler (e2W) utilizing a high-voltage drivetrain, we deliver superior performance surpassing any internal combustion engine (ICE) counterparts. The seamless integration of VCU and cloud computing not only enhances rider experience with smoother acceleration and improved handling but also offers practical benefits like efficient trip planning through real-time battery status updates, showcasing Raptee’s commitment to innovation and practical functionality on the road.

- As India moves towards self-reliance in the area of information and technology, a wave of innovations and ideas has taken over the nation. How well is Raptee prepared to pursue development in the EV sector under the “Make in India” policy?

Raptee substantiates its alignment with the “Make in India” policy through its complete in-house design and development of all components. This comprehensive approach not only ensures technological sovereignty but also fosters a culture of innovation and expertise within the domestic industry. Additionally, Raptee’s establishment of a complete supply chain ecosystem from scratch addresses a critical gap in the market, particularly concerning high-voltage technology. This initiative not only reduces dependency on imports but also enhances the resilience and competitiveness of India’s EV sector.

- What is your view on EV battery swapping booths and can its implementation help India come closer to sustainable electric mobility?

As battery technology evolves, the range of EVs is steadily increasing, reducing the need for frequent charging. This improvement diminishes the perceived advantage of battery swapping, which is often promoted as a quick solution for limited-range EVs. As batteries become more energy-dense and charging times decrease, charging stations become more efficient and comparable in terms of convenience.

- India’s electric two-wheeler (E2W) sector is expected to cross the one million mark in 2024-what are the factors that will influence the market to reach the mark?

India’s E2W market is on an electric revolution, with sales expected to breach the one-million mark in 2024. This surge is driven by a customer-centric approach. Gone are the days of limited choices. Manufacturers are offering diverse options, from high-performance motorcycles to practical everyday rides, catering to every rider’s needs. Range anxiety is fading too, with advancements in battery technology and a rapidly expanding charging network. Additionally, robust customer support with readily available service and informative resources empowers riders, building trust and confidence in E2Ws. This focus on customer satisfaction, coupled with innovation and infrastructure development, is paving the way for a million E2Ws and a sustainable transportation future for India

- How can better implementation of the charging infrastructure accelerate the sales of EVs?

A well-developed charging infrastructure plays a pivotal role in accelerating electric vehicle (EV) sales by addressing critical consumer concerns. Firstly, it alleviates the fear of “range anxiety” among potential buyers by ensuring a widespread network of charging stations along highways and in urban areas, thereby assuring drivers they can recharge conveniently during their journeys. Secondly, the availability of fast-charging stations, such as those utilizing the CCS2 standard, significantly reduces charging times, making EVs more competitive with traditional gasoline vehicles. This not only enables quicker trips but also enhances overall convenience by minimizing wait times at charging stations. Moreover, a robust charging infrastructure sends a powerful message to the public, signaling that EVs are a practical and supported transportation choice. This reassurance can sway hesitant consumers, ultimately driving increased EV adoption.

- Tell us about Raptee’s goals and vision for the next decade.

Raptee’s vision is nothing less than a revolution in personal mobility. We are committed to accelerating the shift towards safe, smart, and sustainable transportation solutions, making them accessible to everyone. Fueled by a deep-tech core, we’re pioneering innovative technologies like HV drivetrains to achieve this ambitious goal.

Our focus isn’t limited to electric vehicles. We see ourselves as architects of the future of mobility, constantly exploring new product landscapes based on customer preferences and inventing disruptive technologies across different segments.

By the next decade, Raptee aspires to be a global leader in personal mobility, with a significant market share. This leadership will be built on the foundation of our unwavering commitment to safety, sustainability, and cutting-edge technological innovation.

The post Raptee Sets the Stage for Two-Wheeler EVs in India appeared first on ELE Times.

CEA-Leti Selected to Coordinate Two EU Projects for Developing ‘First-Class’ 6G Capabilities and Contributing to Standardization

Engaging Multiple EU Partners, the Projects Will Apply Intelligent Sensing and AI-enabled Learning Technologies

As part of the European Union’s drive to support a multifaceted approach to addressing 6G challenges and promises, CEA-Leti has been chosen to coordinate two projects to help build first-class 6G technology capabilities and boost standardization efforts across Europe.

The two projects were among 27 chosen in a competitive proposal process by an EU partnership that divided €130 million between the projects. “These projects present a significant stride towards advancing smart networks and services, offering breakthrough innovations, experimental platforms and large-scale trials, driving world-class research and shaping the world’s digital connected future,” said the group, called the Smart Networks and Services Joint Undertaking (SNS JU).

6G-DISAC (Distributed Intelligent Sensing and Communication) and 6G-GOALS (Goal-Oriented AI-enabled Learning and Semantic Communication Networks) launched their three-year projects in January with multiple EU collaborators.

The two projects mark the first time a single RTO or company has been chosen to coordinate two competitive EU proposals in the same initiative. CEA-Leti has coordinated several EU projects, including the recently completed RISE-6G project. That SNS JU effort developed a disruptive new concept as a service for wireless environments by dynamically controlling wireless communication for brief, energy-efficient and high-capacity communications on a variety of surfaces, such as such as walls, ceilings, mirrors and appliances.

6G-DISAC

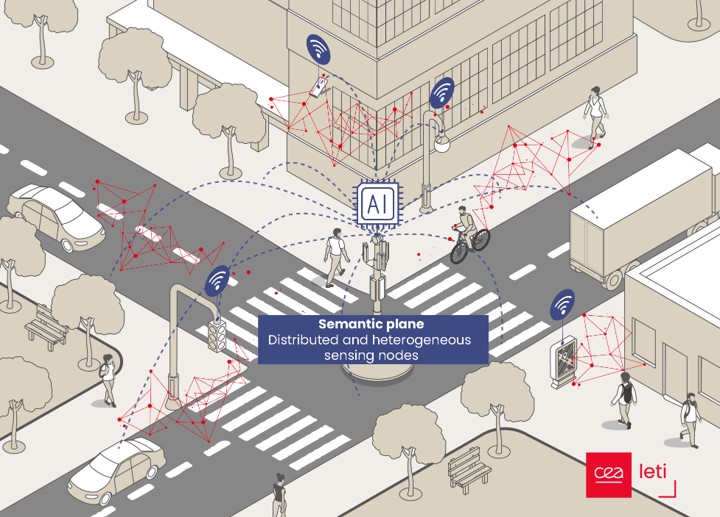

This project will develop and innovate on a widely distributed intelligent infrastructure compatible with both real-world integration constraints, new semantic and goal-oriented communication and sensing approaches, and the flexibility requirements of future 6G networks. It will apply theoretical approaches and operational and standards-compatible, distributed joint communication and sensing, by leveraging the expertise of world-leading network vendors, verticals, SMEs, research laboratories and academic institutions spanning the value chain.

Current approaches to integrated communication and sensing use centralized architectures and pass sensed information through a centralized controller.

“This project will bring the integrated sensing and communication (ISAC) vision into reality, going well beyond the usual restrictive standalone or localised scenarios, by adopting a holistic perspective, with large numbers of connected users and/or passive objects to be tracked,” said Emilio Calvanese Strinati, coordinator of the project and CEA-Leti’s smart devices & telecommunications strategy program director.

“With demonstrations that validate the vital 6G-DISAC concepts, the project will revolutionise various applications, from extended reality and robot-human interaction to vehicular-safety functions and improving communication key performance indicators (KPI) with sensing-aided communications,” he explained.

In addition to defining use cases and designing innovative network architecture, the 11 6G-DISAC partners will develop novel physical-layer waveforms, distributed sensing and communications methods, and optimised resource allocation methods and protocols.

Specific targets include:

- tracking connected user equipment (UE) and passive objects,

- performing ISAC with many distributed base stations, efficient distributed signal processing and machine learning for semantic ISAC, and

- incorporating extremely large multiple-input, multiple-output (MIMO) technologies and reconfigurable intelligent surfaces, and intelligent sensing activation.

“While addressing these fundamental and practical challenges, the team will focus on the distributed implementation of ISAC, unlocking real sensing applications and providing a multi-perspective view of networks in space and time for tangible communication gains,” Calvanese Strinati said.

6G-GOALS

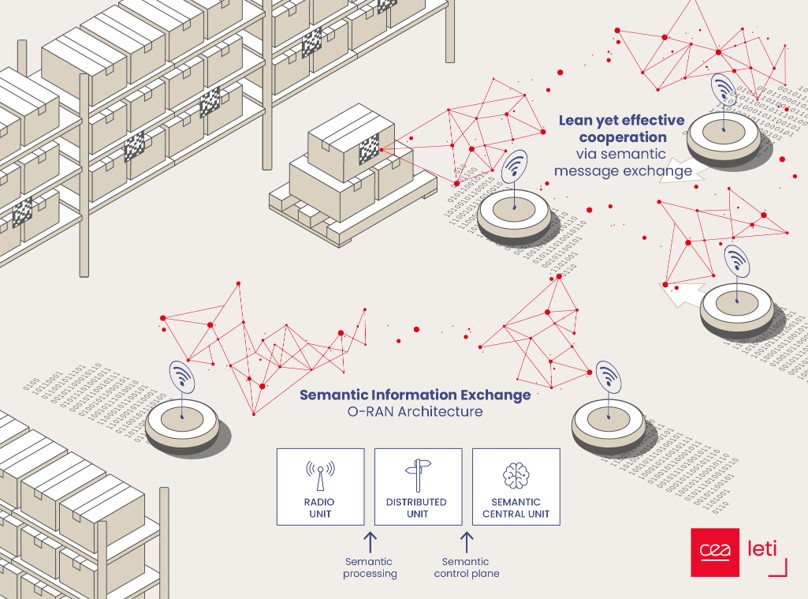

This project is designed to reduce data traffic by conveying only the most relevant information and produce data-efficient, robust and resilient protocols that can adapt to network conditions and communication objectives using modern AI/ML techniques.

“As wireless mobile communication requires ever-higher data rates and 5G’s scope expands to include massive and ultra-reliable low-latency links, wireless evolution has been pressed to solve the technical problem of reliable data exchange between two end-points,” said project coordinator Calvanese Strinati.

“The 6G-GOALS project will take the wireless system design to its next stage by considering the significance, relevance and value of the transmitted data and transforming the potential of the emerging AI/ML-based architectures into a semantic and goal-oriented communication paradigm, offering a solid step toward cooperative generative AI technologies,” he said.

Semantic communication is instrumental in inducing reasoning and shared understanding among intelligent agents by exchanging pragmatically selected information in which its meaning to the receiver is designed to efficiently accomplish a goal or a task. With current approaches, data is sensed and transferred from sensors to the destinations without prior semantic extraction functions.

A recent paper written by 6G-GOALS participants noted that advances in AI technologies have expanded device intelligence, fostering federation and cooperation among distributed AI agents. These advancements impose new requirements on future 6G mobile network architectures.

“To meet these demands, it is essential to transcend classical boundaries and integrate communication, computation, control, and intelligence,” the paper, “Goal-Oriented and Semantic Communication in 6G AI-Native Networks: The 6G-GOALS Approach”, reports.

“These projects are fundamental to explore the capabilities of AI/ML solutions on the networks of the future, especially dealing with joint communication and sensing and semantic communications,” said Mauro Boldi Renato, EU project program coordinator at TIM (Telcom Italia). “Working with CEA-Leti represents a solid basis for their success and for bringing European industry towards implementation of 6G around 2030.”

“The exploitation of 6G-DISAC and 6G-GOALS project results will represent a transformative step for manufacturers and 6G industrial players, like NEC Corporation, by fostering the development of distributed intelligent networks and semantic/AI-driven communication strategies,” said Vincenzo Sciancalepore, principal researcher at NEC Laboratories Europe GMBH/ Germany and a member of the 6G-DISAC team. “Such an unprecedented approach will enable more efficient, flexible, and responsive network infrastructures that can support advanced applications, such as extended reality and automated mobility, meeting the increasing demand for high-capacity, low-latency and sustainable communication.”

6G-DISAC Partners

- Coordinator: CEA-Leti/France

- Technical Manager: Chalmers Tekniska Hogskola AB/Sweden

- Innovation Manager: Nokia Networks/ France

- Telecom Italia Spa/Italy

- Orange S.A./France

- Ethniko Kai Kapodistriako Panepistimio Athinon/Greece

- Institut Polytechnique

De Bordeaux/France

- NEC Laboratories Europe GmbH/Germany

- NEC Italia S.P.A/Italy

- Robert Bosch GmbH/Germany

- RadChat AB/Sweden

6G-GOALS Partners

- Coordinator: CEA-Leti/France

- Technical Manager: Consorzio Nazionale Interuniversitario per le Telecomunicazioni/Italy

- Innovation Manager: NEC Laboratories Europe GMBH/ Germany

- NEC Italia S.p.A/Italy

- Telecom Italia S.p.A/Italy

- Eurecom GIE/France

- Aalborg Universitet/Denmark

- Hewlett-Packard/France

- Hewlett-Packard Italiana S.R.L/Italy

- Toshiba Europe Limited UK

- Imperial College of Science Technology and Medicine UK

- Singapore University of Technology and Design

The post CEA-Leti Selected to Coordinate Two EU Projects for Developing ‘First-Class’ 6G Capabilities and Contributing to Standardization appeared first on ELE Times.

maXTouch Touchscreen Controller Family Expands with Additional Security Features for Touchscreen Payment Systems

Microchip’s ATMXT2952TD 2.0 family of touch controllers offer cryptographic authentication and data encryption

As we see an increased number of electric vehicles (EVs) on the road, the necessary charging infrastructure must expand to meet the increased demand. Adding credit card payment options to EV chargers is becoming a standard practice in many countries—and is a mandate in the European Union—and chargers need to meet Payment Card Industry (PCI) security standards. To help EV charger designers protect their payment architectures, Microchip Technology has launched the MXT2952TD 2.0 family of secure touchscreen controllers.

Typical touch-enabled human-machine interface (HMI) and radio frequency identification (RFID) combination-based payment systems are vulnerable to hacking attacks via malicious software updates or man-in-the-middle attacks when a user enters their personal identification number (PIN) on the touchscreen. Physical mesh barriers and sensors are often used around these integrated circuits (ICs) for protection from hacking. Constant reflashing of software and device resets are used to help safeguard software integrity. The MXT2952TD 2.0 family is designed to encrypt touch data and cryptographically authenticate software updates to minimize risk and meet PCI certification compliance standards. When the RFID reader IC and the touchscreen controller are on different printed circuit boards (PCBs), it is especially difficult and expensive to build physical barriers for hack protection. Embedded firmware on the MXT2952TD 2.0 provides a more easily implemented solution for EV charger manufacturers to remain compliant with security regulations and avoid the cost of adding a second, expensive touchscreen payment module to the charger.

The outdoor nature of EV charger HMI demands they withstand harsh weather conditions, function accurately in the presence of moisture and are resistant to vandalism. MXT2952TD 2.0 touch controller-based touchscreens remain effective when designed with IK10 standard 6 mm-thick glass, anti-reflective, anti-glare and anti-fingerprint coatings and IR filter/UV filter layers. Microchip’s proprietary differential touch sensing delivers exceptional noise immunity for superior touch performance even when used with thick gloves.

“The maXTouch 2952TD 2.0 family provides EV charger designers with a cost-effective, secure design architecture for implementing credit card payments with PIN entry on their touchscreens,” said Patrick Johnson, senior corporate vice president overseeing Microchip’s human machine interface division. “Combined with the rugged, outdoor HMI touchscreen technology that Microchip’s maXTouch portfolio is known for, the new addition to the 2952TD family of touchscreen controllers offers our customers secure designs and the exceptional touch performance necessary for outdoor applications.”

In addition to EV chargers, the MXT2952TD 2.0 family is well-suited for most unattended outdoor payment terminals such as parking meters, bus ticketing meters and other types of point-of-sale (POS) systems. The 2952TD 2.0 is specifically optimized for 20” screen sizes and its sister part, the MXT1664TD, is available for 15.6” screen sizes.

The post maXTouch Touchscreen Controller Family Expands with Additional Security Features for Touchscreen Payment Systems appeared first on ELE Times.

STMicroelectronics Reports 2024 First Quarter Financial Results

- Q1 net revenues $3.47 billion; gross margin 41.7%; operating margin 15.9%; net income $513 million

- Q1 free cash flow $(134) million after Net Capex1 of $967 million

- Business outlook at mid-point: Q2 net revenues of $3.2 billion and gross margin of 40%

STMicroelectronics, a global semiconductor leader serving customers across the spectrum of electronics applications, reported U.S. GAAP financial results for the first quarter ended March 30, 2024. This press release also contains non-U.S. GAAP measures (see Appendix for additional information).

ST reported first-quarter net revenues of $3.47 billion, a gross margin of 41.7%, an operating margin of 15.9%, and a net income of $513 million or $0.54 diluted earnings per share.

Jean-Marc Chery, ST President & CEO, commented:

- “Q1 net revenues and gross margin both came in below the midpoint of our business outlook range, driven by lower revenues in Automotive and Industrial, partially offset by higher revenues in Personal Electronics.”

- “On a year-over-year basis, Q1 net revenues decreased 18.4%, operating margin decreased to 15.9% from 28.3% and net income decreased 50.9% to $513 million.”

- “During the quarter, Automotive semiconductor demand slowed down compared to our expectations, entering a deceleration phase, while the ongoing Industrial correction accelerated.”

- “Our second quarter business outlook, at the mid-point, is for net revenues of $3.2 billion, decreasing year-over-year by 26.0% and decreasing sequentially by 7.6%; gross margin is expected to be about 40%.”

- “We will now drive the Company based on a revised plan for FY24 revenues in the range of $14 billion to $15 billion. Within this plan, we expect a gross margin in the low 40’s.”

- “We plan to maintain our Net Capex1 plan for FY24 at about $2.5 billion focusing on our strategic manufacturing initiatives.”

Quarterly Financial Summary (U.S. GAAP)

| (US$ m, except per share data) | Q1 2024 | Q4 2023 | Q1 2023 | Q/Q | Y/Y |

| Net Revenues | $3,465 | $4,282 | $4,247 | -19.1% | -18.4% |

| Gross Profit | $1,444 | $1,949 | $2,110 | -26.0% | -31.6% |

| Gross Margin | 41.7% | 45.5% | 49.7% | -380 bps | -800 bps |

| Operating Income | $551 | $1,023 | $1,201 | -46.1% | -54.1% |

| Operating Margin | 15.9% | 23.9% | 28.3% | -800 bps | -1,240 bps |

| Net Income | $513 | $1,076 | $1,044 | -52.4% | -50.9% |

| Diluted Earnings Per Share | $0.54 | $1.14 | $1.10 | -52.6% | -50.9% |

First Quarter 2024 Summary Review

Reminder: On January 10, 2024, ST announced a new organization which implied a change in segment reporting starting Q1 2024. Comparative periods have been adjusted accordingly. See the Appendix for more details.

| Net Revenues by Reportable Segment (US$ m) | Q1 2024 | Q4 2023 | Q1 2023 | Q/Q | Y/Y |

| Analog products, MEMS and Sensors (AM&S) segment | 1,217 | 1,418 | 1,400 | -14.2% | -13.1% |

| Power and discrete products (P&D) segment | 820 | 965 | 909 | -15.1% | -9.8% |

| Subtotal: Analog, Power & Discrete, MEMS and Sensors (APMS) Product Group | 2,037 | 2,383 | 2,309 | -14.5% | -11.8% |

| Microcontrollers (MCU) segment | 950 | 1,272 | 1,448 | -25.3% | -34.4% |

| Digital ICs and RF Products (D&RF) segment | 475 | 623 | 486 | -23.8% | -2.1% |

| Subtotal: Microcontrollers, Digital ICs and RF products (MDRF) Product Group | 1,425 | 1,895 | 1,934 | -24.8% | -26.3% |

| Others | 3 | 4 | 4 | – | – |

| Total Net Revenues | 3,465 | 4,282 | 4,247 | -19.1% | -18.4% |

Net revenues totalled $3.47 billion, representing a year-over-year decrease of 18.4%. Year-over-year net sales to OEMs and Distribution decreased 11.5% and 30.8%, respectively. On a sequential basis, net revenues decreased 19.1%, 320 basis points lower than the mid-point of ST’s guidance.

Gross profit totalled $1.44 billion, representing a year-over-year decrease of 31.6%. Gross margin of 41.7%, 60 basis points below the mid-point of ST’s guidance, decreased 800 basis points year-over-year, mainly due to the combination of sales price and product mix, unused capacity charges and reduced manufacturing efficiencies.

Operating income decreased 54.1% to $551 million, compared to $1.20 billion in the year-ago quarter. ST’s operating margin decreased 1,240 basis points on a year-over-year basis to 15.9% of net revenues, compared to 28.3% in the first quarter of 2023.

By reportable segment, compared with the year-ago quarter:

In Analog, Power & Discrete, MEMS and Sensors (APMS) Product Group:

Analog products, MEMS and Sensors (AM&S) segment:

- Revenue decreased by 13.1% mainly due to a decrease in MEMS and Imaging.

- Operating profit decreased by 44.8% to $185 million. Operating margin was 15.2% compared to 23.9%.

Power and Discrete products (P&D) segment:

- Revenue decreased by 9.8% mainly due to a decrease in Discrete.

- Operating profit decreased by 41.6% to $138 million. Operating margin was 16.8% compared to 26.0%.

In Microcontrollers, Digital ICs and RF products (MDRF) Product Group:

Microcontrollers (MCU) segment:

- Revenue decreased 34.4% mainly due to a decrease in GP MCU.

- Operating profit decreased by 66.7% to $185 million. Operating margin was 19.5% compared to 38.3%.

Digital ICs and RF products (D&RF) segment:

- Revenue decreased 2.1% due to a decrease in ADAS more than offsetting an increase in RF Communications.

- Operating profit decreased by 8.2% to $150 million. Operating margin was 31.8% compared to 33.9%.

Net income and diluted Earnings Per Share decreased to $513 million and $0.54 respectively compared to $1.04 billion and $1.10 respectively in the year-ago quarter.

Cash Flow and Balance Sheet Highlights

| Trailing 12 Months | ||||||

| (US$ m) | Q1 2024 | Q4 2023 | Q1 2023 | Q1 2024 | Q1 2023 | TTM Change |

| Net cash from operating activities | 859 | 1,480 | 1,320 | 5,531 | 5,577 | -0.8% |

| Free cash flow (non-U.S. GAAP)[1] | (134) | 652 | 206 | 1,434 | 1,715 | -16.4% |

Net cash from operating activities was $859 million in the first quarter compared to $1.32 billion in the year-ago quarter.

Net Capex (non-U.S. GAAP)1 was $967 million in the first quarter compared to $1.09 billion in the year-ago quarter.

Free cash flow (non-U.S. GAAP)1 was negative at $134 million in the first quarter, compared to positive $206 million in the year-ago quarter.

Inventory at the end of the first quarter was $2.69 billion, compared to $2.70 billion in the previous quarter and $2.87 billion in the year-ago quarter. Days sales of inventory at quarter-end was 122 days compared to 104 days in the previous quarter and 122 days in the year-ago quarter.

In the first quarter, ST paid cash dividends to its stockholders totalling $48 million and executed an $87 million share buy-back as part of its current share repurchase program.

ST’s net financial position (non-U.S. GAAP)1 was $3.13 billion as of March 30, 2024, compared to $3.16 billion as of December 31, 2023, and reflected total liquidity of $6.24 billion and total financial debt of $3.11 billion. Adjusted net financial position (non-U.S. GAAP)1, taking into consideration the effect on total liquidity of advances from capital grants for which capital expenditures have not been incurred yet, stood at $2.78 billion as of March 30, 2024.

Business Outlook

ST’s guidance, at the mid-point, for the 2024 second quarter is:

- Net revenues are expected to be $3.2 billion, a decrease of 7.6% sequentially, plus or minus 350 basis points.

- Gross margin of 40%, plus or minus 200 basis points.

- This outlook is based on an assumed effective currency exchange rate of approximately $1.08 = €1.00 for the 2024 second quarter and includes the impact of existing hedging contracts.

- The second quarter will close on June 29, 2024.

Conference Call and Webcast Information

ST will conduct a conference call with analysts, investors and reporters to discuss its first quarter 2024 financial results and current business outlook today at 9:30 a.m. Central European Time (CET) / 3:30 a.m. U.S. Eastern Time (ET). A live webcast (listen-only mode) of the conference call will be accessible at ST’s website, https://investors.st.com, and will be available for replay until May 10, 2024.

Use of Supplemental Non-U.S. GAAP Financial Information

This press release contains supplemental non-U.S. GAAP financial information.

Readers are cautioned that these measures are unaudited and not prepared in accordance with U.S. GAAP and should not be considered as a substitute for U.S. GAAP financial measures. In addition, such non-U.S. GAAP financial measures may not be comparable to similarly titled information from other companies. To compensate for these limitations, the supplemental non-U.S. GAAP financial information should not be read in isolation, but only in conjunction with ST’s consolidated financial statements prepared in accordance with U.S. GAAP.

See the Appendix of this press release for a reconciliation of ST’s non-U.S. GAAP financial measures to their corresponding U.S. GAAP financial measures.

Forward-looking Information

Some of the statements contained in this release that are not historical facts are statements of future expectations and other forward-looking statements (within the meaning of Section 27A of the Securities Act of 1933 or Section 21E of the Securities Exchange Act of 1934, each as amended) that are based on management’s current views and assumptions, and are conditioned upon and also involve known and unknown risks and uncertainties that could cause actual results, performance or events to differ materially from those anticipated by such statements due to, among other factors:

- changes in global trade policies, including the adoption and expansion of tariffs and trade barriers, that could affect the macro-economic environment and adversely impact the demand for our products;

- uncertain macro-economic and industry trends (such as inflation and fluctuations in supply chains), which may impact production capacity and end-market demand for our products;

- customer demand that differs from projections;

- the ability to design, manufacture and sell innovative products in a rapidly changing technological environment;

- changes in economic, social, public health, labor, political, or infrastructure conditions in the locations where we, our customers, or our suppliers operate, including as a result of macroeconomic or regional events, geopolitical and military conflicts, social unrest, labor actions, or terrorist activities;

- unanticipated events or circumstances, which may impact our ability to execute our plans and/or meet the objectives of our R&D and manufacturing programs, which benefit from public funding;

- financial difficulties with any of our major distributors or significant curtailment of purchases by key customers;

- the loading, product mix, and manufacturing performance of our production facilities and/or our required volume to fulfill capacity reserved with suppliers or third-party manufacturing providers;

- availability and costs of equipment, raw materials, utilities, third-party manufacturing services and technology, or other supplies required by our operations (including increasing costs resulting from inflation);

- the functionalities and performance of our IT systems, which are subject to cybersecurity threats and which support our critical operational activities including manufacturing, finance and sales, and any breaches of our IT systems or those of our customers, suppliers, partners and providers of third-party licensed technology;

- theft, loss, or misuse of personal data about our employees, customers, or other third parties, and breaches of data privacy legislation;

- the impact of intellectual property (“IP”) claims by our competitors or other third parties, and our ability to obtain required licenses on reasonable terms and conditions;

- changes in our overall tax position as a result of changes in tax rules, new or revised legislation, the outcome of tax audits or changes in international tax treaties which may impact our results of operations as well as our ability to accurately estimate tax credits, benefits, deductions and provisions and to realize deferred tax assets;

- variations in the foreign exchange markets and, more particularly, the U.S. dollar exchange rate as compared to the Euro and the other major currencies we use for our operations;

- the outcome of ongoing litigation as well as the impact of any new litigation to which we may become a defendant;

- product liability or warranty claims, claims based on epidemic or delivery failure, or other claims relating to our products, or recalls by our customers for products containing our parts;

- natural events such as severe weather, earthquakes, tsunamis, volcano eruptions or other acts of nature, the effects of climate change, health risks and epidemics or pandemics in locations where we, our customers or our suppliers operate;

- increased regulation and initiatives in our industry, including those concerning climate change and sustainability matters and our goal to become carbon neutral by 2027 on scope 1 and 2 and partially scope 3;

- epidemics or pandemics, which may negatively impact the global economy in a significant manner for an extended period of time, and could also materially adversely affect our business and operating results;

- industry changes resulting from vertical and horizontal consolidation among our suppliers, competitors, and customers; and

- the ability to successfully ramp up new programs that could be impacted by factors beyond our control, including the availability of critical third-party components and performance of subcontractors in line with our expectations.

Such forward-looking statements are subject to various risks and uncertainties, which may cause actual results and performance of our business to differ materially and adversely from the forward-looking statements. Certain forward-looking statements can be identified by the use of forward-looking terminology, such as “believes”, “expects”, “may”, “are expected to”, “should”, “would be”, “seeks” or “anticipates” or similar expressions or the negative thereof or other variations thereof or comparable terminology, or by discussions of strategy, plans or intentions.

Some of these risk factors are set forth and are discussed in more detail in “Item 3. Key Information — Risk Factors” included in our Annual Report on Form 20-F for the year ended December 31, 2023 as filed with the Securities and Exchange Commission (“SEC”) on February 22, 2024. Should one or more of these risks or uncertainties materialize, or should underlying assumptions prove incorrect, actual results may vary materially from those described in this press release as anticipated, believed or expected. We do not intend, and do not assume any obligation, to update any industry information or forward-looking statements set forth in this release to reflect subsequent events or circumstances.

Unfavorable changes in the above or other factors listed under “Item 3. Key Information — Risk Factors” from time to time in our Securities and Exchange Commission (“SEC”) filings, could have a material adverse effect on our business and/or financial condition.

The post STMicroelectronics Reports 2024 First Quarter Financial Results appeared first on ELE Times.

Rohde & Schwarz and IPG Automotive unveil a complete Hardware-in-the-Loop automotive radar test solution

Rohde & Schwarz has teamed up with IPG Automotive, a pioneer in virtual test driving, to redefine automotive radar Hardware-in-the-Loop (HIL) integration testing thereby reducing the cost by bringing Autonomous Driving (AD) testing from the proving ground to the development lab. Combining the CarMaker simulation software from IPG Automotive with the R&S AREG800A radar object simulator and the R&S QAT100 advanced antenna array provides vehicle manufacturers with the ability to simulate ADAS/AD scenarios like those defined in the Euro NCAP in a controlled, safe, time-efficient and cost-reducing way. This combination provides automotive OEMs and radar sensor suppliers with a comprehensive radar sensor testing platform. It is applicable for validation and real-time, closed-loop characterization of radar sensors and enables compliance with Association for ASAM standards.

IPG Automotive’s CarMaker simulation solution is designed for the development and end-to-end testing of cars and light commercial vehicles at all development stages from MIL/SIL to HIL and VIL. The open integration and test platform allows vehicle manufacturers, engineering services companies and Tier 1 suppliers to implement virtual test scenarios in the application areas of powertrain, vehicle dynamic chassis functions and ADAS/AD functions. Thanks to a high-resolution 3D engine, the simulation of the complete sensor stack is possible in very high detail. Seamless integration into existing tool landscapes is also possible with a variety of supported standards and interfaces like the ASAM Open Standards.

The R&S AREG800A, in conjunction with the R&S QAT100, generates multiple artificial objects, each with independent range, Radar Cross Section (RCS), angle (azimuth/elevation) and radial velocity. The Open Simulation Interface (ASAM OSI) links R&S AREG800A with the CarMaker HIL test automation, creating a comprehensive test setup, proving extremely valuable for realistic driving scenario assessment within radar HIL testing. Moreover, the solution includes a Scenario Editor, specifically designed for non-simulation experts. This feature greatly simplifies the process of testing maneuver-based driving scenarios and their associated complex traffic-related configurations and makes it accessible to a wider range of professionals.

The simulation solution CarMaker features an advanced Test Manager, capable of building and running automated test sequences. It can run tests individually or simultaneously, locally or in the cloud, providing flexibility and scalability. Additionally, it automates the calculation and evaluation of Key Performance Indicators (KPIs) and generates reports automatically, thereby saving considerable time and effort.

The Model Manager CarMaker helps to define the configuration of virtual vehicle prototypes. This enhances the realism and accuracy of simulations, making them more useful for testing and development.

Andreas Höfer, Chief Technology Officer at IPG Automotive: “With the collaboration between Rohde & Schwarz and IPG Automotive, we intend to provide the automotive industry with a comprehensive Hardware-in-the-Loop integration test solution, bringing tests from the proving ground into the lab, resulting in significant time and cost savings in the development process.”

The post Rohde & Schwarz and IPG Automotive unveil a complete Hardware-in-the-Loop automotive radar test solution appeared first on ELE Times.

STMicroelectronics reveals high-performance, state-of-the-art wireless microcontrollers ready for incoming cyber-protection regulations

Highly integrated chips support multiple wireless technologies and the latest security standards, perfectly addressing requirements for smart industrial, medical, and consumer devices

STMicroelectronics, a global semiconductor leader serving customers across the spectrum of electronics applications, has revealed the next generation of its short-range wireless microcontrollers. These innovative, all-in-one components enable wearables and smart objects including smart home devices, health monitors, and smart appliances to become ever more miniaturized, easy to use, secure and affordable.

Short-range wireless technologies like Bluetooth LE, Zigbee and Thread (popular in smart meters and smart buildings) are the fabric connecting smart devices to home bridges, gateways, and controllers including smartphones. As we all seek solutions for making life more economical, sustainable, and comfortable, vendors are looking to bring creative and high-performing new solutions to market more quickly, within tight cost constraints. They need to be stylish, too: tiny, low-profile, or even embedded out of sight in other equipment, such as in smart bulbs. Going wireless is a part of this trend, for freedom, flexibility, and fashion.

Wireless microcontrollers like ST’s new STM32WBA5 product line allow a one-chip solution that’s extremely compact, reduces the bill of materials, and shortens the time to market by relieving wireless design challenges. Also, being compatible with the development tools and software packs of the STM32 microcontroller development ecosystem, the new line simplifies migrating existing products designed for wired connections.

The new series’ flagship STM32WBA55 microcontroller can communicate using multiple wireless standards concurrently, including low-energy Bluetooth LE 5.4, Zigbee, Thread, and Matter (Thread RCP). Matter border router is a perfect match with the STM32WBA5 for this new open-source connectivity standard for smart-home and IoT (Internet of Things) devices. In this way, the STM32WBA55 supports a great user experience while simplifying hardware and software engineers’ development journey, aiding affordability and time to market for the new product.

With this new generation, ST has also introduced support for the recently completed Bluetooth LE Audio specifications that enable exciting and innovative new products for richer listening and hearing experiences. These include the new Bluetooth Auracast feature, which opens the door to a new world of audio broadcasting applications.

“Lead customers are already appreciating the enhanced wireless performance, flexibility, and security of our latest STM32WBA wireless microcontrollers. They are creating diverse products including smart thermostats, tracking devices, smart chargers, headsets, power tools, and smart meters,” said Benoit Rodrigues, Wireless MCU Division General Manager, STMicroelectronics. “The extensive software ecosystem that provides communication stacks, microcontroller-specific software packs, sample code, and tools helps developers bring new products to market based on these MCUs quickly and efficiently.”

The STM32WBA series is the first wireless MCU in the market to achieve the important SESIP (Security Evaluation Standard for IoT Platforms) Level 3 security certification. With this, smart devices containing STM32WBA microcontrollers are ready to satisfy the US Cyber Trust Mark and EU Radio Equipment Directive (RED) regulations due to become mandatory in 2025.

“We work with smart asset tracking devices which are connected through Bluetooth to mobiles and through mobile apps to the cloud, enabling us to deliver complete asset tracking management for our customers. ST’s microcontrollers bring wireless connectivity to our multi-mode trackers,” said Olivier Hersent, CEO, Abeeway (Actility Group). “We have selected the new wireless connectivity product, STM32WBA5, for its enhanced performance with ultra-low power radio capabilities, which is key for our battery-powered devices. They ensure stable connectivity in the harsh industrial environment where we operate, combined with security that meets the highest industry standards.”

“We believe that gaming peripherals should be as unique and accessible as the gaming community itself,” said Tom Roberts, CTO, Performance Designed Products (PDP). “ST and PDP have worked together through several Video Game generations, and we have used STM8 and STM32 devices for many years. ST products consistently provide the features we need in our highly competitive market segment. We recently selected ST’s short-range wireless connectivity product, the STM32WBA5, based on the integrated MCU and Bluetooth low-energy technology, as the right solution for a new, groundbreaking game controller. The STM32WBA offered us an ideal combination of performance, peripherals, cost efficiency and ecosystem support that enabled simple and fast development.”

Sample requests and pricing information are available from local ST sales offices. ST will introduce a ready-to-use module containing the STM32WBA, integrated with necessary external components including power-supply and antenna-balancing circuitry, in June 2024.

The post STMicroelectronics reveals high-performance, state-of-the-art wireless microcontrollers ready for incoming cyber-protection regulations appeared first on ELE Times.

Rohde & Schwarz introduces new R&S SMB100B microwave signal generator for analog signal generation up to 40 GHz

Available with four frequency options each covering from 8 kHz to 12.75 GHz, 20 GHz, 31.8 GHz or 40 GHz, the new R&S SMB100B microwave signal generator from Rohde & Schwarz brings excellent output power, spectral purity, very low close-in phase noise, and practically no wideband noise to analog microwave signal generation.

The new R&S SMB100B analog microwave signal generator from Rohde & Schwarz offers outstanding, market-leading performance for analog signal generation up to 40 GHz in the midrange class. Thanks to its easy operation and comprehensive functionality, the versatile R&S SMB100B is now the first choice for all applications requiring clean analog signals or high output power from 8 kHz to 40 GHz. Typical applications include testing radar receivers, semiconductor components, upconverters, downconverters or amplifiers. The

high output power and low phase noise make it ideal as a source for simulating interferers for blocking tests.

The R&S SMB100B microwave signal generator features a signal purity which combines very low single sideband (SSB) phase noise, excellent non-harmonics suppression, and low wideband noise for all carrier frequencies. For users seeking even better close-in phase noise and frequency stability, and less temperature-based variation in performance, in addition to the standard OXCO reference oscillator, a higher performance version is available for all frequency ranges. In addition to the conventional 10 MHz reference

frequency, users can choose optionally 1 MHz to 100 MHz as well as 1 GHz reference frequency signals. Optional high output power of measured 25 dBm at 20 GHz and 19.5 dBm at 40 GHz is activated by keycode, so users can install it at any time. Considering the microwave frequency range covered by the instrument, the R&S SMB100B microwave signal generator is light (10.7 kg) and compact, fitting in a 19” rack and only two rack units in height.

The level accuracy of the output directly from an R&S SMB100B itself is excellent. With each increase in the frequency of the required signal, the challenge of obtaining the correct level input to a device increases: The R&S SMB100B supports two additional features to compensate for path losses and variations in the signal caused by setups with additional test fixtures, cables or amplifiers. These features help to provide the wanted power level at the reference plane i.e. at the input of the device under test. One of them, the user correction function (UCOR), compensates if the frequency response of the setup is known and stable. However, there are still unknown factors especially if the setup includes additional active devices such as an amplifier. Then 1/2 the frequency response of the setup with an external additional amplifier can vary over level or temperature. Closed-loop power control can compensate for all these variations by continuously measuring the input level to the DUT i.e. at the wanted reference plane with a suitable R&S NRP power sensor feeding its measured level back to the generator to adjust the output power accordingly. More details about this use case can be found in the application note 1GP141.

The R&S SMB100B is user-friendly in every detail. Users can create their own customized menus, so that the parameters they most use are always available. They can generate code to automate measurements first made manually with the SCPI macro recorder while the measurements are set up and run, then use the code generator to export the instructions in languages such as MATLAB. Thanks to R&S Legacy Pro, the R&S SMB100B (and other Rohde & Schwarz test equipment) can be used to emulate other instruments such as

R&S SMB100A or competitor instruments directly, as a drop-in replacement using the existing code.

The new R&S SMB100B microwave signal generator up to 40 GHz is now available from Rohde & Schwarz and expands the R&S SMB100B analog signal generator family with its established RF models up to 6 GHz.

The post Rohde & Schwarz introduces new R&S SMB100B microwave signal generator for analog signal generation up to 40 GHz appeared first on ELE Times.

Tata Elxsi is Improving Aircraft Manufacturing Performance Through its Industry 4.0 solutions

Having delivered 13% revenue growth in FY24, Tata Elxsi is among the world’s leading design and technology service providers across industries including Automotive, Broadcast, Communications, Healthcare, and Transportation. They mark high competence in servicing through design thinking and development in digital technologies like IoT, Cloud, Mobility, Virtual Reality, and AI.

Jayaraj Rajapandian, Head of Avionics, Transportation, Tata Elxsi

Jayaraj Rajapandian, Head of Avionics, Transportation, Tata Elxsi

Rashi Bajpai, Sub-Editor at ELE Times spoke with Jayaraj Rajapandian, Head of Avionics, Transportation, Tata Elxsi on various aspects of aerospace/ aviation – from what’s trending to what the future holds for the industry.

This is an excerpt from the interaction.

ELE Times: What are some of the latest trends in Aerospace electrification?

Jayaraj Rajapandian: The aerospace industry is rapidly evolving, with many innovations redefining the field. One of the latest advancements is in aerospace electrification. This is a major boost to meet the UN sustainable development goals set for the Aerospace industry. It involves implementing electric propulsion technologies such as electric motors and turbo-electric propulsion by using electric energy to power the aircraft fully or in hybrid mode.

The electrification of propulsion systems made Urban Air Mobility (UAM) vehicles a reality and it is a step closer to commercial operation. Smaller aircraft and drones provide decreased emissions, quieter operation, and improved efficiency. Electrical actuators drive fuel efficiency and are replacing the hydraulic-driven actuators.

Hybrid-electric propulsion systems combine traditional fuel-powered engines with electric propulsion systems. The larger aircraft adapts them to increase fuel efficiency and reduce emissions.

Sustainable Aviation Fuels (SAFs) can be used to reduce aviation’s environmental impact. However, the investment to scale the SAF production is to be monitored against aviation demands.

Electric Vertical Takeoff and Landing (eVTOL) vehicles enable vertical takeoff and landing, which reduces the dependency on infrastructure like a dedicated runway. Vertiport unlocks the potential for urban air mobility. These vehicles will be incorporated more for logistics and aerial combat vehicles.

Moreover, advancements in battery technologies are seeing exponential growth in fuel cells for storage, effective power conversion, and distribution, necessitating effective battery management solutions. Lithium polymer batteries enable long-endurance owing to their lower weight and higher power storage.

ELE Times: Give us some insights into the future innovations in Unmanned Air Systems.

Jayaraj Rajapandian: Unmanned Air Systems (UAS) have been incredibly useful in improving efficiency, reducing costs, reaching remote and inaccessible areas, improving defence systems, and, most importantly, enhancing safety. The primary focus is to improve autonomous navigation and control by incorporating cutting-edge technologies such as Artificial Intelligence (AI) and Machine Learning (ML) to operate effectively in complex environments and all-weather conditions and push the endurance for extended missions.

Currently, commercial usage of UAVs is being monitored by regulators, mainly when operating beyond the visual line of sight (BVLOS). However, advanced sensor and payload technologies such as LiDAR and thermal imaging systems could help improve the availability and reliability.

Unmanned Combat Systems consist of aerial, land, and underwater drones. Unmanned aerial vehicles are used to gather intelligence, conduct surveillance, and reconnaissance (ISR), and carry munitions. Governments worldwide recognize Unmanned Combat Systems as an asset comparable to manned fighter jets as they consume a significant portion of defence budgets. Researchers are exploring swarm intelligence to enable several drones to work together and operate collectively, ensuring the mission is never compromised, even if many UAVs are lost.

ELE Times: Elaborate on some of the latest technologies in avionics development for advanced navigation and control.

Jayaraj Rajapandian: In the past couple of decades, satellite-based navigation and communications systems have become more widespread, electronic systems have become more scalable, and higher redundancy has become more common in recent aircrafts. Fly-by-wire flight control systems have replaced mechanical controls with electronic interfaces, allowing for precise and adaptive control of aircraft flight surfaces. Using a single pane of glass in the cockpit flight decks turned the operation to be more seamless. However, by the mid-2030s, ICAO predicts that airspace will witness double the current traffic and the industry requires more than incremental innovation, a transformation is needed.

Currently, the focus is on bringing compact form factors and platforming the systems. Aerospace OEMs and technology partners are collaborating on this next journey. RISC-V-based processing units are gaining attention for their security features and custom-built capabilities that meet OEMs’ needs. The collaboration on Avionics such as FMS, used in different aircraft supplied by various vendors, to create a unified family of products signifies a strategic move towards standardization and interoperability in the aviation industry. This reduces inventory costs for OEMs and the training costs of airlines.

Innovations to counter deceived sensors to manage spoofing, anti-jamming and to distinguish friends from foes, and security in communications are gaining attention. A growing number of regional players are developing Avionics for UAVs, breaking the technology entry barrier. To stay competitive and relevant, defense OEMs require transformational effort to reduce cycle time which typically takes 5 to 7 years. Digital Twin, Investment in Big-Data processing with High Processing Computing capability can accelerate this cycle time.

Tata Elxsi’s advanced process flow can be used in the development of a cloud-based Digital Twin of a sub-system. The features developed from the Digital Twin are scalable and can be used for multiple systems simultaneously.

ELE Times: How can AI/ML be adopted for aerospace design and maintenance?

Jayaraj Rajapandian: With AI and ML capabilities, aerospace design and maintenance can improve efficiency, reduce downtime, and improve the health of systems. AI and ML can analyze extensive datasets from simulations, past designs, and real-world operations to pinpoint the most effective configurations for aircraft components, structures, and systems.

AI and ML tools also help to build virtual prototyping and testing of aircraft systems and components. It generates precise simulations using high-processing computers, anticipating performance traits, and fine-tuning design parameters. More importantly, AI and ML algorithms also help in predictive maintenance. These algorithms can analyze sensor data from aircraft systems and components to detect anomalies, predict failures, and schedule maintenance proactively. AI and ML tools also help in care for health monitoring systems and analysis of root causes. We will soon see certifications through simulations of numerous scenarios exercised on the system models.

Our solution accelerator for TEDAX- Tata Elxsi’s big data platform is being used to build system models and visualize the data. Tata Elxsi’s AI-based Video Analytics AIVA resolves complex scenarios in real-time.

ELE Times: How is Tata Elxsi enhancing aircraft production efficiency?

Jayaraj Rajapandian: The aerospace industry is picking up the pace in demand post-slowdown due to the COVID-19 pandemic. With the boost in demand, OEMs will need to enhance their production efficiency by tapping into advanced manufacturing technologies, adding cost-effective suppliers, and integrating product lifecycle management techniques. Technologies like 3D printing, robotics, digital twins, and automated assembly systems can enhance aircraft production.

Tata Elxsi designs and implements Industry 4.0 solutions, improving manufacturing performance. We are also working with OEMs in identifying suppliers to source raw materials, build-to-spec, and certify their products.

The post Tata Elxsi is Improving Aircraft Manufacturing Performance Through its Industry 4.0 solutions appeared first on ELE Times.

NORD DRIVESYSTEMS at ACHEMA 2024

NORD drive solutions for the process industry

From 10 to 14 June 2024, NORD will be presenting a wide range of products at ACHEMA in Frankfurt am Main. The focus is on ATEX-compliant drive concepts for the process industry and the robust heavy-duty MAXXDRIVE® industrial gear unit, in particular for agitator and mixer applications. Further focal points at the trade fair will be the new decentralised NORDAC ON/ON+ frequency inverters, the revolutionary DuoDrive geared motors and IE5+ synchronous motors as well as the NORDCON APP with NORDAC ACCES BT. Interested trade visitors can find out more about NORD’s wide range of solutions at the trade fair grounds in Frankfurt am Main in Hall 8.0, Stand B52.

Whether in the chemical, pharmaceutical or food industries: Companies that extract, transport or process raw materials require industry-specific, innovative drive solutions. As a system supplier, NORD offers matched drive systems consisting of gear unit, motor and drive electronics that are tailored to the respective requirements of the customer application.

ATEX drives for explosion-protected areas Flammable gases and dust in processing industries create serious safety risks. NORD has decades of experience with gas and dust explosion protection and offers particularly robust electric motors with powers from 0.12 to 200 kW especially for this field of use. The explosion-protected electric motors can be operated in category 2D or 3D dust atmospheres (zones 21 and 22) as well as in category 2G or 3G gas atmospheres (zones 1 and 2) and are approved according to ATEX and HazLoc. The dust-protected motors feature the ignition protection category “Protection by enclosure” (tD). Depending on the requirements, the motors in the gas explosion protection version are available in the following ignition protection classes: increased safety

(e), pressure-resistant encapsulation (d/de) and non-sparking design.

Industrial gear units for high torque applications NORD’s MAXXDRIVE® industrial gear units power heavy-duty applications such as agitators, mixers and grinders in food or cosmetic production. The parallel and right-angle gear units cover a speed ratio range from 5.54:1 to 400:1 – and with a first-stage gear unit, even up to 30,000:1. They feature:

• High output torques from 15 to 282 kNm for reliable operation even under extreme conditions

• Torsionally rigid, one-piece UNICASE housing for a longer bearing life and efficient power transmission

• Large low-friction roller bearings for extremely high radial and axial load capacities and a long service life

• High-precision axis alignment for guaranteed quiet running

For mixer and agitator applications, the industrial gear units can also be equipped with a SAFOMI-IEC

adapter:

• The adapter is available for parallel gear units and in sizes 7 to 11, i.e. for maximum output torques from 25

to 75 kNm.

• The adapter is compact and simple in design and has an integrated oil expansion volume; oil tanks and hoses as well as the radial shaft seal that is subject to leakage and wear between gear unit and IEC cylinder are therefore not required.

The NORDAC ON frequency inverters are part of the NORD modular system and can be optimally combined with the manufacturer’s motors.

• NORDAC ON was designed for applications with asynchronous motors,

• NORDAC ON+ was designed for the combination with highly efficient IE5+ synchronous motors.

The inverters are designed for power ranges from 0.37 to 3 kW.

The IE5+ motor generation from NORD DRIVESYSTEMS guarantees the highest level of efficiency and operational reliability, thanks to IE5+ technology. The motors are available as a TENV smooth-surface motor, as a TEFC motor with cooling fins and as an integrated DuoDrive motor. The latter combines a highefficiency IE5+ motor and a single-stage helical gear unit in one housing. The IE5+ synchronous motors with motor efficiencies of up to 95% are available in the TEFC version with a power of up to 4.0 kW, in the TENV

version with up to 2.2 kW and in the DuoDrive version with up to 3.0 kW.

With the NORDCON APP for mobile maintenance and commissioning of NORD frequency inverters, NORD enables the diagnosis, analysis, parametrisation and monitoring of the drive systems via a mobile terminal device for service use. The NORDAC ACCESS BT is a Bluetooth stick that is used directly with the frequency inverter – this ensures convenient mobile access to the drive data while at the same time access control.

NORD will present its comprehensive range of solutions at ACHEMA in Hall 8.0, Stand B52.

The post NORD DRIVESYSTEMS at ACHEMA 2024 appeared first on ELE Times.

Rohde & Schwarz expands footprint in India by opening new state-of-the-art facility in Bengaluru

On April 22, Rohde & Schwarz inaugurated a new facility center in Bengaluru’s Manyata Tech Park, housing R&D, system integration as well as calibration and repair services. The opening marks a strategic milestone for the technology company: it not only increases its presence in the third-largest city in India, but also strengthens its commitment to the Make in India initiative of the government by fostering innovation across the automotive, telecom, semiconductor, electronics, aerospace and defense sectors.

Rohde & Schwarz India, the Indian subsidiary of the German-based, global technology company Rohde & Schwarz, celebrated the grand opening of its new future-oriented facility located in the heart of Bengaluru’s prestigious Manyata Tech Park.

Andreas Pauly, President and Chief Technology Officer (CTO) of Rohde & Schwarz

Andreas Pauly, President and Chief Technology Officer (CTO) of Rohde & Schwarz

While inaugurating the new offices, Andreas Pauly, President and Chief Technology Officer (CTO) of Rohde & Schwarz, said: “We are proud to expand our presence in Bengaluru. For Rohde & Schwarz, India is not merely a growth market but a vital component of our global strategy. The new facility marks a significant milestone in our journey toward strengthening our position as a trusted partner in India’s evolving technological landscape. Moreover, it reflects our contribution to the Make in India initiative through a large team of highly skilled engineers.”

For more than 90 years, Rohde & Schwarz has had a tradition of innovation, helping to develop current and future cutting-edge technologies. By expanding R&D activities in India, Rohde & Schwarz is able to enhance technological excellence for the highly dynamic Indian market. The R&D team in Bengaluru is involved in developing next-generation solutions for the company’s Test and Measurement Division.

Yatish Mohan, Managing Director Rohde & Schwarz India

Yatish Mohan, Managing Director Rohde & Schwarz India

Yatish Mohan, Managing Director, Rohde & Schwarz India, added: “For the past 25 years, we have fostered technological advancement in India through strategic partnerships with government agencies, training institutes and technology firms. Our presence spans multiple locations throughout the country, encompassing tier-II cities directly and via our extensive channel partner network. We are excited about the opportunities that our new facility brings, allowing us to enhance our services to the Indian technology industry and facilitate innovation in the electronics, semiconductor, automotive and telecommunications sectors.”

The new facility houses an ISO 9001 and ISO17025 (NABL) accredited calibration and repair service center, offering precision services to meet the rigorous quality standards of the industry. This addition reinforces the commitment of Rohde & Schwarz to delivering high-quality products and services to its customers across India and beyond. Furthermore, the facility will also encompass sales, applications, systems integration and a dedicated demo display area showcasing various test and measurement equipment and test solutions. This strategic move underscores the company’s intention to enhance customer experience and accessibility, providing clients with hands-on experiences and seamless access to cutting-edge technology solutions.

The post Rohde & Schwarz expands footprint in India by opening new state-of-the-art facility in Bengaluru appeared first on ELE Times.

Renesas’ New FemtoClock 3 Timing Solution Delivers Industry’s Lowest Power and Leading Jitter Performance of 25fs-rms

- Industry-leading 25fs-rms jitter exceeds next-generation 112Gbps and 224Gbps SerDes reference clock requirements

- Up to 4 frequency domains allow all system clocks to be generated from a single device

- Device variants with jitter attenuation, synchronization and clock generation capabilities and with 8 or 12 outputs

- Low power dissipation of 1.2W and operating a single 1.8V supply

- Integrated non-volatile memory allows for device customization in factory at no additional cost to customer

- Small 7 x 7mm 48-pin VFQFPN and 9 x 9mm 64-pin VFQFPN packages

- Compliant with ITU-T G.8262 and G.8262.1 for enhanced synchronous Ethernet

- Single chip with multiple operating modes simplifies overall clock tree

, VersaClock, buffer and oscillator portfolio of timing solutions to address challenging timing needs for their high-performance wireline infrastructure and data center designs.

, VersaClock, buffer and oscillator portfolio of timing solutions to address challenging timing needs for their high-performance wireline infrastructure and data center designs.The post Renesas’ New FemtoClock 3 Timing Solution Delivers Industry’s Lowest Power and Leading Jitter Performance of 25fs-rms appeared first on ELE Times.

STMicroelectronics Powers Up the Intelligent Edge with Second-Generation STM32 Microprocessors, Bringing Performance Boost and Industrial Resilience

- New STM32MP2 MPUs with 64-bit processing and edge AI acceleration

- Built for speed, security, and reliability

- Leverage the STM32 ecosystem for rapid development and secure provisioning

STMicroelectronics, a global semiconductor leader serving customers across the spectrum of electronics applications, is releasing new devices from the second generation of its industrial microprocessors (MPUs), the STM32MP2 series, to drive future progress in smart factories, smart healthcare, smart buildings, and smart infrastructure.

Digital transformation is happening everywhere, driving improvements including greater business productivity, better healthcare, and enhanced safety and energy management throughout buildings, utilities, and transport networks. Critical enabling technologies include cloud computing, data analytics, artificial intelligence (AI), and the Internet of Things (IoT). ST’s new STM32MP2 MPUs will power the next generations of equipment that create the fabric of this evolving digital world. These include industrial controllers and machine-vision systems, scanners, medical wearables, data aggregators, network gateways, smart appliances, and industrial and domestic robots.

“Our embedded MPUs address the trend that’s pushing more workloads and greater demands to smart devices, often deployed at the IoT edge, for faster response and increased efficiency,” said Stephane Henry, General Purpose MPU Division General Manager, STMicroelectronics. “The new STM32MP2 devices we are announcing today extend the performance trajectory, introducing our most powerful processing engine, now adding edge AI, and supported by the STM32 ecosystem to accelerate product development.”

Architected for demanding and time-sensitive workloads, AI inferencing, and communication, and featuring state-of-the-art cyber security, the STM32MP2 MPUs are built to withstand up to 10 years of continuous operation.

State-of-the-art security of the new STM32MP2 devices leverages ST’s proprietary secure hardware, anti-tamper controls, protected firmware, and secure provisioning, working with Arm’s TrustZone architecture, to keep sensitive data and keys secret. Certification to SESIP Level 3, the leading security test methodology for IoT devices and compliance, is ongoing for STM32MP2 MPUs to satisfy forthcoming tougher cyber-protection requirements in key territories worldwide. These include the US CyberTrust mark and stipulations in the EU’s Radio Equipment Directive that are due to become mandatory in 2025.

“Together with ST, we tackled the challenge of connecting our devices to the cloud. From opening locks remotely to granting new access rights, our products are shaping the future of access management,” said Marco Temporiti, R&D Software Manager, ISEO. “Thanks to the STM32MP2 microprocessor with its strong encryption capabilities, we are able to build an industrial-grade gateway with unmatched reliability and security. The seamless integration with Yocto Linux has streamlined our development process, allowing us to innovate with ease. And, ST’s 10-year longevity program also ensures a long product lifecycle at reduced cost, setting a new standard in the industry.”

“We worked with ST to build a 2-channel network audio adapter, leveraging the STM32MP1 series microprocessors to handle tasks like converting network digital audio signals for transmission and reception. The robust processing power, Ethernet connectivity and adaptable audio output interfaces were key considerations in choosing the STM32MP1 series for integration into our products,” said Yue XIONG, CEO, S-TRACK. “Now, we’re enthusiastic about the possibilities presented by ST’s latest MPUs, particularly the STM32MP2 series, which deliver improved power efficiency, enabling us to minimize cooling requirements in our enclosed casings. Additionally, the integrated Cortex-M co-processor eliminates the need for a separate microcontroller, and support for Gigabit Ethernet with precision time protocol (PTP) enables accurate data transfer and synchronization among devices. With this advanced technology, our goal is to broaden our product range to include 16-channel offerings.”

The first STM32MP2 MPUs are scheduled to enter volume production in June 2024. Sample requests and pricing information are available from local ST sales offices.

The post STMicroelectronics Powers Up the Intelligent Edge with Second-Generation STM32 Microprocessors, Bringing Performance Boost and Industrial Resilience appeared first on ELE Times.

Infineon provides FOXESS with power semiconductors to improve efficiency and power density of energy storage applications

Infineon Technologies AG supplies its power semiconductor devices to FOXESS, a fast-growing leader in the green energy industry and a manufacturer of inverters and energy storage systems. The two sides aim at promoting the development of green energy. Infineon will provide FOXESS with its CoolSiC MOSFETs 1200 V, which will be used with EiceDRIVER gate drivers for industrial energy storage applications. At the same time, FOXESS’ string PV inverters will use Infineon’s IGBT7 H7 1200 V power semiconductor devices.

The global market for photovoltaic energy storage systems (PV-ES) has grown at a high speed in the last years. As competition in the PV-ES market accelerates, improving power density has become key to success, and how to improve efficiency and power density for energy storage applications has attracted much attention. Infineon’s CoolSiC MOSFET 1200 V and IGBT7 H7 1200 V series power semiconductor devices adopt the latest semiconductor technologies and design concepts that are tailored to industrial applications.

Mr. Yu Daihui, Senior Vice President and Head of Industrial & Infrastructure of Infineon Technologies Greater China said, “As an industry leader in power semiconductors, we are proud to work closely with FOXESS. We will continue to drive decarbonization by enabling higher power density and more reliable systems for PV-ES applications.”

Mr. Zhu Jingcheng, Chairman of FOXESS, said, “Thanks to the support of Infineon’s advanced components, FOXESS’ products have been significantly improved in terms of reliability and efficiency. This has been an important driving force for FOXESS’ growth. Infineon’s technical support and product quality have not only strengthened our competitiveness, but also expanded our presence in the market. We are confident about the future and look forward to further cooperation with Infineon to jointly promote the development of the industry and create greater value for our customers.”

With a high power density, Infineon’s CoolSiC MOSFETs 1200 V can reduce losses by 50 percent and provide ~2 percent additional energy without increasing the battery size, which is especially beneficial for high-performance, lightweight, and compact energy storage solutions. FOXESS’ H3PRO 15 kW-30 kW energy storage series uses Infineon’s CoolSiC MOSFETs 1200 V for all models. Thanks to Infineon’s excellent performance, the H3PRO series has achieved an efficiency of up to 98.1 percent and excellent EMC performance; with superior performance and reliability, the H3PRO series has seen rapid sales growth in the global market.

Infineon’s TRENCHSTOP IGBT7 H7 650 V / 1200 V series has lower losses and helps improve the overall efficiency and power density of inverters. In high-power inverter projects, high-current mold packaged discrete devices with current handling capability above 100 A can reduce the number of IGBTs in parallel and replace the IGBT module solution, further improving system reliability and reducing costs; in addition, the H7 series has become an industry benchmark for its high-quality performance and greater resistance to humidity. At present, FOXESS’ main industrial and commercial model, the R Series 75-110 kW, redefines the overall design of the 100 kW model by using IGBT7 H7 series discretes, and the efficiency of the whole machine can reach up to 98.6 percent. Thanks to the low power loss and high power density of the IGBT7 H7 series in discrete packages, technical problems such as current sharing in the paralleling process can be simplified and optimized.

Every power device needs a driver, and the right driver can make the design a lot easier. Infineon offers more than 500 EiceDRIVER gate drivers with typical output currents of 0.1 A~18 A and comprehensive protection functions including fast short-circuit protection (DESAT), active Miller clamp, shoot-through protection, fault reporting, shutdown, and overcurrent protection, suitable for all power devices including CoolSiC and IGBTs.

The post Infineon provides FOXESS with power semiconductors to improve efficiency and power density of energy storage applications appeared first on ELE Times.

Integrated Actuation Power Solution Aims to Simplify Aviation Industry’s Transition to More Electric Aircraft

Microchip introduces configurable family of companion driver boards using its Hybrid Power Drive modules available in silicon carbide (SiC) or silicon (Si) technology

The aviation industry’s requirements for the latest, most efficient and lowest-emission aircraft is propelled by an overarching goal towards sustainability and decarbonization. To satisfy these goals, aviation power systems developers are transitioning to electric actuation systems as the trend towards More Electric Aircraft (MEA) continues to grow. To provide the aviation industry with a comprehensive electric actuation solution, Microchip Technology (Nasdaq: MCHP) today announces a new integrated actuation power solution that combines companion gate driver boards with our expansive Hybrid Power Drive (HPD) modules in silicon carbide or silicon technology with a power range of 5 kVA to 20 kVA.

The new integrated actuation power solution maintains the same footprint regardless of the power output. The companion gate driver boards are designed to be integrated with Microchip’s HPD modules to provide an all-in-one motor drive solution for the electrification of systems such as flight controls, braking and landing gear. Microchip’s power solutions are designed to scale based on the requirements of the end application, from smaller actuation systems for drones to high-power actuation systems for Electric Vertical Take-Off and Landing (eVTOL) aircraft, MEA and all-electric aircraft.

“We developed the companion gate driver boards to be used with our existing HPD modules to bring to market a plug-and-play power solution for MEA,” said Leon Gross, vice president of Microchip’s discrete product group. “With this solution, customers no longer need to design and develop their own drive circuitry, which can reduce design time, resources and cost.”

These high-reliability devices are tested to conditions outlined in DO-160, “Environmental Conditions and Test Procedures for Airborne Equipment.” There are multiple protection features including shoot-through detection, short circuit protection, desaturation protection, Under Voltage Lock Out (UVLO) and active miller clamping.

The gate driver boards are designed to be driven with external PWM signals based on Low Voltage Differential Signaling (LVDS) compliant with TIA/EIA-644 for low Electromagnetic Interference (EMI) and good noise immunity. The gate driver board provides differential outputs for telemetry signals like DC bus current, phase current and solenoid current by taking feedback from shunts present in the HPD module and DC bus voltage. It also provides direct output of two PT1000 temperature sensors available in the HPD power module.

The companion gate driver boards are low-weight, low-profile and compact solutions to optimize size and power efficiency of actuation systems. The gate drivers are designed to operate throughout the temperature range of −55°C to +110°C, which is critical for aviation applications that are often exposed to harsh environments.

The isolated companion gate driver boards only require a single 15V DC input for the control and drive circuit; all additional voltages needed are generated on the card. This significantly reduces the number of system components and simplifies system cabling.

Microchip provides comprehensive solutions for MEA by integrating power products with FPGAs, microcontrollers, security, memory and timing. Microchip’s solutions are designed to help customers speed up their development, reduce costs and get to market faster.

Support and ResourcesThe companion gate driver boards are supported with detailed data sheets and device models.

Pricing and AvailabilityThe companion gate driver boards and accompanying HPD modules are available in production quantities. For additional information, contact a Microchip sales representative.

ResourcesHigh-res images available through Flickr or editorial contact (feel free to publish):

- Application image: http://www.flickr.com/photos/microchiptechnology/53415024168/sizes/l

The post Integrated Actuation Power Solution Aims to Simplify Aviation Industry’s Transition to More Electric Aircraft appeared first on ELE Times.

Vishay Intertechnology Blue and True Green LEDs in MiniLED Package Deliver High Brightness in a Small Size