Feed aggregator

Enhance HMI User Experience with Built-in Large Memory MPU

Courtesy: Renesas

The HMI market continues to drive growth in better user experience and increased automation with the expansion of HMI applications. This results in a strong demand for improved functionality and performance in display-based applications, such as real-time plotting, smooth animation, and USB camera image capture, in affordable systems. Microprocessors (MPUs) with high-speed, large-capacity built-in memory that can be used like microcontrollers (MCUs) are gaining attention in the market. Renesas’ RZ/A3M MPU with a built-in 128MB DDR3L SDRAM and a compatible package for a two-layer PCB design is the ideal solution for realizing smooth animation and high-quality HMI at a reasonable system cost.

High-Performance HMI and Real-Time GraphicsIntegrating high-speed, large-capacity memory directly into the MPU package offers several advantages, including mitigating concerns about high-speed signal noise on the PCB and simplifying PCB design for the users. The large-capacity memory needed for high-performance HMIs is externally connected to the MPU in the conventional way. Additionally, PCBs equipped with DDR memory and high-speed signal interfaces require multi-layer PCB designs to account for signal noise, making it challenging to reduce PCB costs. Also, the common capacity of on-chip SRAM is typically between 1MB and 10MB, which is too small for high-performance HMIs that need to include a reasonable number of tasks in the near future. To overcome these issues, Renesas released an industry-leading RZ/A3M MPU with a large built-in 128MB DDR3L memory to support high-performance HMI and real-time graphics performance to enhance better and faster user experiences. Most importantly, the board does not require a high-speed signal interface and supports two-layer PCB design to reduce board noise and simplify system development for users.

Figure 1. Strengths of Built-in DDR Memory

Designing High-Performance PCBs at a Reasonable System CostThe number of PCB layers and the ease of design significantly impact the cost of system implementation and maintenance in user applications. As shown in Figure 2, using a wide pin pitch of 0.8mm allows for the layout of signal lines and placement of VIAs between the balls. Additionally, placing the balls handling the main signals in the outer rows of the 244-pin 17mm x 17mm LFBGA package and positioning the GND and power pins as inner balls allows for efficient routing of the necessary signal lines for the system (Figure 3). The RZ/A3M MPU is designed to build cost-effective systems with two-layer PCBs through its innovative packaging and pin assignments.

Figure 2. Signal Wiring and Ball Layout

Figure 3. Optimized Ball Arrangement for a Two-Layer Board Layout

User-Friendly Interface Enabling Smooth GUI DisplayThe high-resolution graphic LCD controller integrated into the RZ/A3M supports both parallel RGB and 4-lane MIPI-DSI interfaces, accommodating displays up to 1280×800. Additionally, the 2D graphics engine, high-speed 16-bit 1.6Gbps DDR3L memory, and 1GHz Arm Cortex-A55 CPU enable high-performance GUI displays, including smooth animations and real-time plotting that increase the possibility of automation in HMI applications. Connecting a USB camera to the USB 2.0 interface enables smooth capture of camera images, making it easy to check inside of an apparatus, for example, the doneness of the food in the oven or the condition in the refrigerator.

The EK-RZ/A3M is an evaluation kit for the RZ/A3M. It includes an LCD panel with a MIPI-DSI interface. With this kit, users can immediately start evaluation. Renesas also has several graphics ecosystem partners – LVGL, SquareLine Studio, Envox, Crank, RTOSX – who deliver GUI solutions utilizing the EK-RZ/A3M to further accelerate your development cycle.

Figure 4. High-Definition HMI Example with the EK-RZ/A3M

The RZ/A3M MPU, equipped with high-speed 128MB DDR3L memory and a 1GHz Arm Cortex-A55, excels in developing cost-effective HMI applications with real-time plot UIs, smooth animations, and USB camera capture. The integrated memory simplifies PCB design by removing the need for high-speed signal interface design.

The post Enhance HMI User Experience with Built-in Large Memory MPU appeared first on ELE Times.

Zonal Architecture 101: Reducing Vehicle System Development Complexity

Courtesy: Onsemi

Thirty years ago, cars were marvels of mechanical engineering, but they were remarkably simple by today’s standards. The only electronics in an entry-level car would have been a radio and electronic ignition. The window winders were manual. The dashboard had an electromechanical speedometer and some warning lights. Power flowed directly from the battery to the headlights via a switch on the dashboard. There was no ABS, no airbags, and no centralized computer. Everything was analog and isolated.

Fast forward to today, vehicles are packed with hundreds of features, many mandated by regulation or demanded by consumers. To implement these features, automakers bolted on electronic control units (ECUs) one after another. Each system (braking, lighting, infotainment, and more) gained its own ECU, software and wiring. Over time, this created an ever-more-complex web of over 100 to 150 ECUs in a single vehicle.

To break through this complexity, automakers are embracing software-defined vehicle (SDV) architectures. SDVs aim to centralize software control, making it easier to update, manage, and extend features. But even with this shift, the underlying wiring and distributed hardware can remain a bottleneck unless automakers also rethink the vehicle’s physical architecture.

Enter zonal architecture: a modern, location-based design strategy that complements SDV principles and dramatically simplifies vehicle systems.

What Is Zonal Architecture?Zonal architecture is a paradigm shift, organizing vehicle electronics by location instead of by function. Instead of assigning each subsystem its own dedicated ECU, zone controllers are installed in each region of the vehicle, such as the front-left corner, rear-right corner, or cabin. These controllers manage local devices like lights, switches, and sensors within their respective zones. Rather than each component running its own software, the zone controller acts as a hub, handling power distribution and data communications.

These zone controllers connect to a central computer, which houses the core software that defines how the vehicle behaves. So instead of having separate ECUs for central locking, lighting, or climate control, the central compute unit makes decisions, while zone controllers carry them out.

This shift replaces hundreds of point-to-point wires with a simpler, more manageable zonal layout. By doing so, it dramatically improves design clarity and system efficiency.

Real-World Challenges of Implementing Zonal ArchitectureWhile the benefits are compelling, implementing zonal architecture isn’t without its challenges. For one, not all edge modules can be completely stripped of intelligence. Some components, such as advanced lighting systems, still require local processing for performance, safety, or proprietary functionality. Tier 1 suppliers deliver these modules with built-in software because they possess specialized knowledge of how to program and control them.

This raises a core challenge for SDVs using zonal designs: balancing centralized control with localized flexibility. In many cases, carmakers handle the central compute software, while Tier 1s manage the embedded software for the modules they manufacture. A pure, software-only central brain is a goal, but compromises are often necessary.

The Role of Ethernet in Zonal DesignsTraditional ECUs used legacy communication protocols like CAN and LIN, which were adequate for isolated modules but became unwieldy when scaled across a zonal architecture. That’s where automotive Ethernet, specifically 10BASE-T1S, comes into play.

10BASE-T1S is a low-speed (10 Mbps), multi-drop Ethernet standard designed specifically for automotive use. It enables multiple nodes (think headlights, turn signals, and door locks) to share a single twisted pair of wires, reducing the need for expensive point-to-point connections.

Figure 1. Example of 10BASE-T1S multi-drop connections

This approach simplifies cabling, lowers cost, and leverages Ethernet’s mature ecosystem, including time synchronization and error recovery, without the overhead of higher-speed Ethernet like 100BASE-T1 or gigabit Ethernet, which are unnecessary for low-bandwidth devices.

Smart Switches in Power DistributionZonal controllers not only relay data, but also distribute electrical power to the components in their zone. This means they play a critical role in system safety and diagnostics. onsemi’s smart switches go far beyond basic circuit protection. These intelligent devices offer:

- Voltage and current monitoring for each channel

- Support for automotive safety standards such as ASIL B and ASIL D

- Fail-safe and fail-operational modes, ensuring continuity of function even when faults are detected

For example, in the event of a malfunction, a smart switch can reduce power, isolate the fault, or enter a safe fallback mode rather than shutting down critical systems like headlights entirely. This level of insight and control is critical and mandatory for higher levels of automated driving.

Figure 2. Typical zonal power distribution architecture

Benefits of Zonal ArchitectureZonal architecture delivers five major advantages across vehicle development, production and operation:

- Reduced wiring harness complexity and weight: Fewer wires and connectors reduce both vehicle weight and build time.

- Lower cost of materials and assembly: Simplified wiring means reduced manufacturing cost and easier maintenance.

- Improved scalability: New features can be added or changed via software, without reengineering hardware layouts.

- Centralized software control: Streamlines development and enables over-the-air (OTA) updates, a key enabler of SDVs.

- Smarter feature coordination: Take lighting as an example. In legacy vehicles, flashing the headlights upon unlock required integrating multiple ECUs. In zonal designs, the central computer sends a single command, and the appropriate zone controller executes it—no redundant wiring or separate lighting logic required.

Zonal architecture represents a paradigm shift in how vehicles are designed and built. By grouping functions by physical location and leveraging Ethernet-based communications, automakers significantly reduce system complexity, wiring costs and maintenance challenges.

When combined with software-defined vehicle principles, zonal designs pave the way for faster innovation, greater customization, and smarter diagnostics.

With enabling technologies like 10BASE-T1S, Remote Control Protocol ICs, and intelligent power distribution, onsemi is helping carmakers bring this vision to life, delivering scalable, safe, and efficient zonal solutions that meet the evolving demands of modern mobility.

The post Zonal Architecture 101: Reducing Vehicle System Development Complexity appeared first on ELE Times.

Foxconn Taps NVIDIA to Accelerate Physical and Digital Robotics for Global Healthcare Industry

Courtesy: Nvidia

The world’s largest electronics manufacturer is building smart hospital solutions using NVIDIA technologies from the data center to the edge.

The global healthcare system is expected to face a shortage of 4.5 million nurses by 2030— and one of the main causes is high burnout. Manufacturing giant Foxconn is helping ease the burden with NVIDIA-accelerated solutions like Nurabot, a collaborative nursing robot that offloads time-consuming, fatiguing tasks such as transporting medication and samples across the hospital.

Nurabot is just one of Foxconn’s smart hospital applications developed using NVIDIA technologies and deployed by Taiwan’s leading medical centers. Its other tools include AI models to support patient health monitoring and digital twins of hospital facilities to help management teams with design and planning.

Together, these applications can transform medical centers into smart hospitals powered by NVIDIA physical AI and its three-computer solution. First, massive AI models are trained and fine-tuned on supercomputers. Next, in simulation, digital twins are used for planning, testing and robotics training — and third, edge computing systems enable rapid AI inference on robots and sensors.

Taichung Veterans General Hospital (TCVGH), Baishatun Tung Hospital – Mazu Hospital, and Cardinal Tien Hospital are among the Taiwan-based healthcare institutions adopting Foxconn’s smart hospital solutions to support clinicians and advance patient care.

“Taiwan has a highly developed healthcare infrastructure with a strong push toward digital health transformation, creating the ideal environment for robotic integration,” said Shu-Fang Liu, deputy director of the nursing department at TCVGH, which is currently conducting a field trial with Nurabot. “Robots are augmenting our capabilities so we can provide more focused, meaningful care.”

Recognized as one of the world’s top 100 smart hospitals, TCVGH is developing multiple solutions to address the severe shortage of nursing personnel in Taiwan. In addition to implementing welfare policies to retain talent, the hospital is harnessing AI technology to ease the burden on frontline staff, noted Dr. Yun-Ching Fu, the hospital’s superintendent.

The hospital began working with Foxconn last year to codevelop the Nurabot collaborative nursing robots as part of its smart healthcare initiative led by Dr. Shih-An Chen, honorary superintendent at TCVGH.

Supporting Smart Hospitals From the Data Center to the EdgeFoxconn’s smart hospital solution begins in the data center, where high-performance compute is applied to develop large AI foundation models — like FoxBrain, a large language model (LLM) developed using the NVIDIA NeMO framework. Trained on NVIDIA Hopper GPUs, FoxBrain is capable of text-to-speech, automatic speech recognition and natural language processing.

The company is also using its Honhai Super AI Computing Center 1, which features NVIDIA DGX systems, to develop healthcare-specific AI models. Offered through Foxconn’s CoDoctor AI platform, powered by NVIDIA AI, these models improve diagnostic accuracy and optimize clinical workflows for tasks including retinal imaging, vital sign monitoring, arrhythmia screening and cancer screening.

Clinicians in the radiology department at Tungs’ Taichung MetroHarbor Hospital use Foxconn’s CoDoctor AI platform for medical imaging workflows. Credit: Foxconn

Foxconn is also working with medical centers to integrate the NVIDIA AI Blueprint for video search and summarization, which can analyze real-time video data to alert healthcare workers of medical events and generate visual summaries for hospital management teams.

It will contribute CoroSegmentater, its AI model for coronary artery segmentation, to the MONAI open-source medical imaging platform pioneered by NVIDIA and leading academic medical centers. The model, powered by MONAI’s Auto3DSeg framework for 3D medical image segmentation, can be used to support diagnostics, preoperative planning and patient education.

Clinical teams can use FoxConn’s CoroSegmentater model with NVIDIA Omniverse platform to visualize the heart in 3D. Credit: Foxconn

Clinical teams can visualize these segmentations on 3D visualizations of the heart and vascular system running on NVIDIA OVX servers with NVIDIA Isaac for Healthcare, built on the NVIDIA Omniverse platform. Foxconn has also used Omniverse to develop a tool that can simulate the effects of drug treatments on the tumors of breast cancer patients.

Beyond simulating biology, Foxconn is working with TCVGH, Baishatun Tung Hospital – Mazu Hospital, and Cardinal Tien Hospital to simulate healthcare facilities using NVIDIA Omniverse. With these physically accurate simulations, the hospitals are planning out the design of new facilities, making data-driven decisions to optimize operations and building simulations to train robots.

Digital twins of TCVGH, Baishatun Tung Hospital – Mazu Hospital, and Cardinal Tien Hospital facilities. Credit: Foxconn

TCVGH, for instance, built a digital twin of one of its nursing stations and wards as a training ground for Nurabot — enabling the robotic system to practice navigating through virtual hallways before testing in the real world.

Taichung Veterans General Hospital Pilots Collaborative Nursing RobotNurabot — built by Foxconn and Japanese multinational company Kawasaki Heavy Industries — uses the FoxBrain LLM, virtual training with Isaac for Healthcare and onboard compute powered by the NVIDIA Holoscan sensor processing platform running on an NVIDIA Jetson Orin device.

Foxconn estimates that when deployed in clinical applications for delivering medication, transporting specimens and patrolling wards, Nurabot can reduce the workload of nurses by up to 30%.

“In one of our wards, we are using Nurabot to deliver wound care kits and health education materials to patient bedsides,” said Liu. “For nurses, having a robot assistant reduces physical fatigue, saving them multiple trips to supply rooms and allowing them to focus more on patients.”

TCVGH is conducting a field trial with Nurabot. Credit: TCVGH, Foxconn, Kawasaki Heavy Industries

During visiting hours, Nurabot helps guide patients and visitors through the ward, reducing the administrative workload for frontline staff. And during night shifts, where hospitals operate with fewer staff, it can help pick up the slack.

Liu hopes the nursing robots will also be able to soon converse with patients in multiple languages, recognize individuals to enable personalized interactions, and help nurses move patients.

Someone with a lung condition, for example, may need the help of two nurses to get up from their hospital bed and move to a chair to perform breathing exercises. With the help of an assistant like Nurabot, the task might be accomplished with a single nurse, allowing the other to focus on caring for the rest of the ward.

The post Foxconn Taps NVIDIA to Accelerate Physical and Digital Robotics for Global Healthcare Industry appeared first on ELE Times.

How to get great results with an infrared thermometer

Courtesy: Fluke

Temperature, Fundamentals

Infrared (IR) thermometers enable you to measure temperature quickly, at a distance, and without touching the object you’re measuring. They are so useful, easy, and even fun to use that they have become as common in kitchens as they have on factory floors. Infrared thermometers are often used to find overheated equipment and electrical circuits, but they have hundreds of other uses.

Measurement spot diameters of a Fluke 63 Infrared Thermometer at three distances.

However, there are a few “gotchas” when using an infrared thermometer that can generate readings that are misleading or just plain wrong. Fortunately, these sources of error are easy to avoid or work around.

Common uses for infrared thermometers in industry

- Finding faulty terminations in high power electrical circuits

- Locating overloaded circuit breakers

- Identifying fuses at or near their current rated capacity

- Identifying problems in electrical switch gear

- Monitoring and measuring bearing temperatures in large motors or other rotating equipment

- Identifying “hot spots” in electronic equipment

- Identifying leaks in sealed vessels

- Troubleshooting steam traps

- Finding faulty insulation in process pipes or other insulated processes

- Capturing process temperature readings

Every infrared thermometer has a “distance-to-spot” (D:S) ratio that tells you the diameter of the area being measured compared to the distance from the target. For example, if your thermometer has a distance-to-spot ratio of 12:1, it measures an approximately one-inch-diameter spot when it’s 12 inches from the target (about 2.5 cm at 30 cm). If you try to use that thermometer to measure a two-inch (5-cm) area from even just a few feet (1 m) away, you’re not going to get an accurate result because the thermometer will also be measuring the temperature outside the area you want to measure.

Distance-to-spot ratios vary a lot (from about 1:1 on the least expensive thermometers to about 60:1 on top-of-the-line models) and vary slightly with distance, so be sure to check the label on your thermometer or in the manual.

2. Lead Astray by the Laser?Most handheld infrared thermometers have laser pointers that show the approximate center of the measurement area. It’s important to know that the laser is only a pointer and not used for the actual temperature measurement. Another common misconception is that the thermometer is measuring the area illuminated by the laser beam. The measurement spot is always wider.

3. Confused by Bright Shiny Objects?Infrared thermometers have good accuracy when measuring most objects, but shiny, reflective surfaces can be a challenge. You should be especially wary when measuring the temperature of shiny metal objects, but even reflections off of glossy paint can affect accuracy. Putting a piece of non-reflective tape (such as electrical tape) over the shiny surface or applying some flat paint gives you a target from which you can get a better measurement.

Taking measurements on non-reflective tape or flat paint helps avoid errors caused by shiny surfaces.

The reason for this is that not all materials emit the same amount of infrared energy when they are at the same temperature. In general, most materials emit more infrared energy than shiny metals do – they have higher “emissivity.” (Emissivity is expressed as a number between 0 and 1, with 0 being non-emissive and 1 being perfectly emissive). Reflective surfaces are less emissive than dull surfaces. Weathered or oxidized metals are more emissive than polished, shiny metals.

If you need to take temperature readings on low emissivity objects regularly, consider an IR thermometer that enables you to compensate for variations in emissivity. For example, the Fluke 561 Infrared Thermometer enables you to set emissivity to “High” (for measuring most surfaces, such as wood, paint, rubber, plaster, or concrete), “Medium” (for oxidized metals or granite, for example), or “Low” (for shiny metals).

4. Obscured Optics?Where you use your infrared thermometer can also affect its accuracy. For example, if there is steam or dust in the between the target and the thermometer, some of the IR energy may be deflected before reaching the thermometer. Similarly, a dirty or scratched lens on your IR thermometer may impair its ability to “see” the IR energy that it needs to make a measurement. A lens that has fogged when the thermometer is brought into a warm room from a colder environment can also affect accuracy.

5. Temperature Shocked?Finally, for highest accuracy, it’s best to allow some time (about 20 minutes is usually enough) for your IR thermometer to come to the temperature of its surroundings when bringing the thermometer into surroundings that are significantly warmer or colder than where it has been stored.

Noncontact infrared thermometers offer a great combination of speed, convenience, and accuracy, but only when they’re used correctly.

To get the best results possible, remember to:- Know your IR thermometer’s distance-to-spot ratio, and get close enough to the target so your thermometer reads only the area that you want it to measure.

- Watch out for (and compensate for) shiny, “low emissivity” objects.

- Remember that steam or dust can affect the accuracy of IR thermometers.

- Keep the lens of your thermometer clean and free of scratches.

- To get the most accurate results, allow some time for the thermometer to come to the temperature of its surroundings.

The post How to get great results with an infrared thermometer appeared first on ELE Times.

Simulations à la Carte: Infusing SPICE Models for a Tasty Design Experience

Courtesy: Infineon

Have you ever noticed how the simplest dishes become unforgettable with just the right seasoning? As an Ecuadorian, I’ve learned this firsthand. A touch of “ají”—a traditional chili sauce—can transform any meal into something extraordinary. The tamarillo-based hot sauce is my personal favorite. It’s not just a condiment; it’s an experience. And when it comes to power electronics, I’ve come to see SPICE models in the same way. They’re the secret ingredient that can take your circuit simulations from bland to brilliant.

Let me show you how adding a bit of SPICE to your simulations can make all the difference.

The foundation for a flavorful design: Compact modelsThink of a compact model as your base recipe. It’s the essential framework that captures the behavior of a semiconductor device. As shown in Fig.1, a good compact model blends all the critical elements: electrical characteristics, parasitic effects, and even thermal dynamics.

For example, a compact model typically includes three layers:

– Chip model: The core of the device, accounting for its on-state and off-state characteristics, capacitances, and thermal behavior.

– Parasitic model: This layer considers resistive, inductive, and capacitive effects from the package—factors that can influence performance.

– Thermal model: It simulates how heat flows through the device, giving you insight into self-heating effects during operation.

Fig.1. A simplified structure of a compact model is shown for a SiC MOSFET in a TO247-4 package.

When these models come together, they provide a detailed picture of how a semiconductor behaves in real-world conditions. But, as with any recipe, the quality of the outcome depends on the precision and care put into each ingredient.

In the land of flavors, spicy is the king: Spice modelsIn the world of circuit simulations, SPICE models are the trusted seasoning. They’re incredibly detailed and flexible, making them perfect for analyzing switching behavior under various conditions. But just like too much chili in a dish, there’s a tradeoff: SPICE simulations can be time-consuming, especially for long-term scenarios, like a solar inverter operating over a full day.

To speed things up, designers sometimes use simplified thermal-loss models based on datasheet data. These are faster to work with but come with limitations. They often represent how a device performs on a specific test bench rather than in real-life applications, which can lead to less accurate results. A brief comparison between both abstraction levels is depicted on Fig.2.

Fig.2. Comparison of spice model and thermal-loss description models

It’s a bit like cooking with pre-made sauces—quick and convenient, but not quite as satisfying as making everything from scratch.

When life gives you chilies, make it hot: Infineon’s approachSo, how do you get the best of both worlds? How do you achieve simulations that are both fast and accurate? At Infineon, we asked these same questions, and we’ve worked hard to deliver the answers.

Our SPICE SiC MOSFET models are like your fresh, high-quality ingredients. Designed for accuracy, they provide detailed insights into dynamic response and performance. And here’s the best part: we’ve built an automated workflow that takes these models to the next level.

Using our SPICE simulator, we’ve created a system that extracts switching waveforms under various conditions, calculates energy losses, and translates them into a thermal-loss format (XML files), a simplified flow scheme is shown in the Fig. 3. This makes it easy to incorporate high-quality data into system-level simulations without sacrificing speed. Imagine having a perfectly balanced sauce ready to enhance any dish—that’s what we’re offering for your circuit designs.

Fig.3. Flow diagram to design custom thermal models using spice simulations

The finishing touchLike a great meal, a successful power converter design is all about balance. You need the right ingredients, careful preparation, and attention to detail. At Infineon, we’re passionate about helping you get it just right.

With our SPICE models and simulation tools, you’ll gain deeper insights into how our products perform in your specific applications. You’ll save time, reduce costs, and open the door to faster innovations—all while improving system performance and reliability. And let’s not forget the big win: a reduced carbon footprint, thanks to more efficient designs.

So, the next time you’re working on a simulation, remember this: a little SPICE can go a long way. Explore our tools, try our models, and see how they can transform your designs. After all, every great creation—whether it’s a dish or a circuit—deserves the perfect touch.

The post Simulations à la Carte: Infusing SPICE Models for a Tasty Design Experience appeared first on ELE Times.

Protect Your Critical Timing Applications with TimeProvider XT Extension Shelf

Courtesy: Microchip

Communications network operators who are struggling to support legacy SSU and BITS systems can now migrate to a newer platform that supports E1/T1/CC critical timing services as well as next-generation network-based timing services using PTP, NTP and Synchronous Ethernet.

The Importance of Timing ConnectionsIn today’s rapidly evolving telecommunications landscape, maintaining precise and reliable timing is crucial for the seamless operation of central office environments. Timing connections that support synchronization, timing or timestamps related to signaling information are critical. Even something as simple as NTP timing services for credit card transactions is vital.

Transitioning to Modern PlatformsNow is the time to migrate from legacy Synchronization Supply Units (SSU) and Building Integrated Timing Supply (BITS) technologies to newer platforms. These modern platforms support next-generation network-based timing services using PTP, NTP and Synchronous Ethernet as well as legacy SONET/SDH TDM synchronization.

Traditional SSU and BITS timing equipment is becoming outdated and reaching end-of-life, posing significant challenges for maintaining reliable timing services. The TimeProvider 4×00 and TimeProvider XT Extension System addresses these challenges by providing advanced timing capabilities and supporting next-generation network-based timing services. Below are several use cases outlining the value of migrating legacy synchronization to a modern platform.

Use Cases Use Case 1: Enhancing Holdover CapabilitiesIn this use case, the TimeProvider 4×00 system with dual time provider oscillators serves as the holdover oscillators for the SSU or BITS clock application. We remove the oscillators in the SSU/BITS shelf and we drive the outputs directly from the inputs. This approach is cost-effective and ensures resiliency, as many older oscillators are expensive to repair and often no longer available. The holdover hierarchy, supported by Rubidium atomic clock oscillators, meets Stratum one and G.811 requirements for synchronous Ethernet use cases. This adds holdover capability as well as next generation packet-based timing services to your offices with a very low cost and a way to ensure resiliency moving into the future. (see figure 1)

Figure 1

The Model 2 + 2 use case demonstrates the use of PTP timing services with APTS flow between two locations (e.g., central offices or mobile switching offices) A and B. This setup allows for a PTP APTS flow from location A to B and vice versa. With only one antenna per location, if a GNSS antenna fails, location A can back up location B and vice versa. By implementing this model, customers can build confidence in PTP/APTS technology and prepare for future PTP use cases. (see Figure 2)

Figure 2

The TimeProvider 4×00 and TimeProvider XT Expansion Shelf can be used to overlay legacy SSU and BITS platforms. Many of our customers have extremely old DCD or SSU and BITS platforms in place that are no longer reliable and near end of life. So, it is in the best interest of our customers to migrate the critical timing services in an office that supports signaling, transmission or high volumes of network services over to a more modern reliable platform like the Time Provider 4×00 and XT extension. (see Figure 3)

Figure 3

The final use case involves completely replacing legacy SSU BITS equipment with a TimeProvider grandmaster and XT Extension shelves that support legacy outputs. This approach is beneficial for several reasons:

- Older products are often at the end of their lifecycle.

- Customers may not need the high number of outputs provided by older platforms.

- Modern platforms consume less power, reducing overall power consumption.

- High replacement and repair costs for end-of-life SSU and BITS platforms can be avoided.

Moving to a more modern, reliable platform can actually save money in the long term related to repairs and end of life scenarios. Additionally, replacing legacy systems can help clean up office wiring issues, providing a more organized and efficient setup. (see Figure 4)

Figure 4

The good news is that it is very easy to replace a legacy office SSU/BITS with a new TimeProvider 4×00 grandmaster and XT extension. Each XT shelf has 40 individually configurable E1/T1/CC outputs, and up to five shelves can be connected, providing 200 outputs per system. This solution is backwards compatible; legacy wirewrap and patch output panels can be left in place. During a service window, simply disconnect the cable from the SSU/BITS equipment and attach it to TimeProvider XT shelf (see Figure 5).

Figure 5

Below is a simplified five-step process to replace a legacy SSU/BITS with a new TimeProvider 4×00 grandmaster and TimeProvider XT shelf fan-out.

- Install and configure the TimeProvider 4×00 grandmaster clock and XT shelve(s) in the rack near the legacy SSU/BITS.

- Install and connect the new rooftop antenna for the TimeProvider 4×00 system. Note: that the TimeProvider 4×00 system is not compatible with the legacy SSU antenna electronics.

- Confirm that the TimeProvider 4×00 system with XT shelves are fully locked to GNSS and alarm free.

- Schedule maintenance window time to disconnect output panels from the legacy BITS/SSU and reconnect them to the TimeProvider XT shelves. Or, network elements can be moved individually from the SSU/BITs equipment to the XT shelves.

- The BITS/SSU systems will switch to backup references or enter holdover with associated alarms when the legacy SSU/BITS is disconnected. Confirm that the XT shelves E1/T1/CC outputs are functioning, and all alarms have cleared.

Microchip has developed detailed procedures for exact equipment replacement scenarios. Please contact your Microchip representative for examples of detailed procedures.

TimeProvider 4×00 Grandmaster Overview and Comparison to a Legacy SSU/BITSTable 1 provides a full side by side comparison of the TimeProvider 4×00 grandmaster with XT Expansion Shelf to a legacy SSU 2000/2000e. Figure 6 is an overview of the TimeProvider XT Extension Shelf.

Table 1. Legacy SSU/BITS vs. TimeProvider 4×00 with XT extension shelf

| Functionality | DCD, SSU 2000/2000e, TP1x00, TSG-3800, TimeHub | TimeProvider 4×00 Grandmaster and XT shelf |

| Node clocks in synchronization networks ITU-T G.812 | Yes | Yes |

| Composite clock ITU G.703 | Yes | Yes |

| Input filtering of wander and jitter ITU-T G.824 | Yes | Yes |

| PRTC ITU-T G.8272 | Yes (PRTC-A and PRTC-B) | |

| ePRTC ITU-T G.8272.1 | Yes (when deployed with a collocated cesium standard ePRC clock) | |

| GNSS | GPS only | Full GNSS (GPS, Galileo, GLONASS, Beidou, QZSS, NaviC user selectable) and multi-band L1/L2/E5B/L5 support |

| BlueSky GNSS spoofing and jamming protection | Yes | |

| T1/E1/CC outputs | Yes | Yes |

| NTPr v4 and v6 with MD5 security | Yes | |

| IEEE 1588 PTP | Yes (input and output) | |

| SyncE ITU-T G.8261 | Yes |

Figure 6

The TimeProvider 4×00 and TimeProvider XT Expansion Shelf is a powerful solution for protecting and enhancing critical timing applications in central office environments. By migrating from outdated SSU and BITS technologies to modern platforms that support PTP, NTP and synchronous Ethernet, organizations can ensure the accuracy and reliability of their timing infrastructure. The use cases presented here demonstrate the versatility and benefits of the TimeProvider XT Extension Shelf, making it an essential component for any central office looking to future-proof its timing services.

Migrate your critical services timing needs to a new modern platform that can serve your existing and future requirements as you evolve your timing and network infrastructure.

The post Protect Your Critical Timing Applications with TimeProvider XT Extension Shelf appeared first on ELE Times.

Breaking the Barriers – Why Buildings Need DAS for Cellular Connectivity

Courtesy: Analog Devices

In the digital age, reliable and high-speed wireless connectivity is no longer a luxury but a necessity. From bustling urban centers to remote rural areas, the demand for seamless communication is ever-increasing. This series will delve into the world of cellular distributed antenna systems (DAS) and how integrated solutions are revolutionizing wireless coverage. This first part of the series introduces the basics of cellular DAS, its importance, and the challenges it addresses.

Enhancing Connectivity in Challenging EnvironmentsDefinition of Cellular DAS: Modern commercial buildings are marvels of engineering, but they’re also notorious for blocking cellular signals. Materials like reinforced concrete, steel, and energy-efficient glass are excellent for sustainability and safety, but they act as RF shields, severely weakening or blocking mobile signals. A cellular DAS is a network of spatially separated antenna nodes connected to a common source through fiber optic cables, which provides wireless service within a geographic area or structure. It is designed to improve cellular coverage and capacity in areas where traditional macrocell solutions are insufficient. DAS systems are particularly useful in environments with high user density, such as large buildings, stadiums, and dense urban areas.

Importance of Cellular DAS: In today’s connected world with rising expectations for always-on mobile connectivity, poor cellular signal inside buildings is no longer acceptable. Reliable wireless coverage is crucial for both personal and business communications. Cellular DAS ensures that users can maintain high-quality connections, even in challenging environments. It is essential to maintain productivity, enhance user experience, and support critical applications such as emergency services and healthcare.

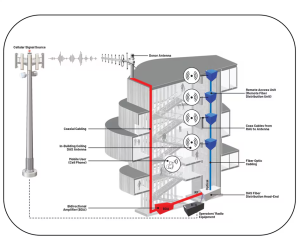

Challenges Addressed by Cellular DAS: Traditional macrocell solutions often struggle with indoor coverage, capacity limitations, and interference. These challenges can lead to dropped calls, poor data speeds, and unreliable connections. Cellular DAS addresses this challenge by extending and boosting signals inside buildings. A DAS is a network of antenna nodes distributed across a facility, all connected to a central source (often through a donor antenna and head-end equipment) to ensure even, reliable cellular coverage. These nodes amplify and redistribute the incoming signal to mobile users across multiple floors or large spaces. In short, cellular DAS overcomes these challenges by providing a robust, scalable, and flexible solution that can be tailored to specific needs. Figure 1 shows a typical fully DAS architecture.

Figure 1: A Hybrid DAS Architecture

Key Components of Cellular DAS

The main components of a cellular DAS include:

- Head-End: The head-end is the central unit that connects to the base station and processes the signals. It is responsible for converting the signals from the base station into a format that the remote units can distribute.

- Transport Medium: The transport medium, such as fiber optic cables or coaxial cables, carries the signals from the head-end to the remote units. Fiber optic cables are preferred for their high bandwidth and low signal loss.

- Remote Units (Antennas): The remote units, or antennas, distribute the signals throughout the coverage area. They can be placed in strategic locations to ensure optimal coverage and capacity.

Benefits of Cellular DAS

Some of the key benefits of cellular DAS include:

- Improved Signal Strength: DAS systems can significantly improve signal strength–reducing the number of dropped calls and improving call quality.

- Enhanced Data Speeds: DAS systems can support higher data speeds by providing a more reliable and robust connection, which is essential for data-intensive applications.

- Better User Experience: Users benefit from a more consistent and reliable connection, which enhances their overall experience and satisfaction.

- Support for Multiple Carriers and Frequencies: DAS systems can support multiple carriers and frequency bands, making them highly versatile and future-proof.

Real-World Applications

Cellular DAS is widely used in various real-world applications, including:

- Large Buildings: In large office buildings, shopping malls, and other commercial spaces, DAS systems ensure reliable coverage and capacity for a large number of users.

- Stadiums and Arenas: DAS systems are essential for providing coverage to tens of thousands of spectators during events in large venues such as stadiums and arenas.

- Transportation Hubs: Airports, train stations, and other transportation hubs rely on DAS systems to ensure reliable communication for travelers and staff.

- Healthcare Facilities: Hospitals and other healthcare facilities use DAS systems to support critical communication and data transmission for patient care.

Conclusion

Understanding the fundamentals of cellular DAS is essential for grasping its significance in modern wireless networks. Cellular DAS plays a crucial role in ensuring reliable and high-speed connectivity by improving coverage and capacity. In the next part of this series, we will explore the different types of cellular DAS and their specific applications, providing a deeper understanding of how these systems can be tailored to meet various needs.

The post Breaking the Barriers – Why Buildings Need DAS for Cellular Connectivity appeared first on ELE Times.

TIL that there is no such thing as a "full bridge rectifier". It's a "bridge rectifier" or a "full wave rectifier".

Watch out when using ceramic capacitors a 100uF 6.3V capacitor can easily be 48uF when being used at 3.3V

| Hi everyone, I've put together a Jupyter Notebook to help analyze and visualize the common issue of DC bias derating in ceramic capacitors (MLCCs). If you've ever been curious (or frustrated) about how much capacitance you're really getting from a capacitor once it's under a DC voltage, this tool might be helpful for you! The data is from Murata's SimSurfing tool at 10mV rms. You can find the project on GitHub here: https://github.com/CDFER/Ceramic-Capacitor-Derating [link] [comments] |

X-Ray of electronics and X-Ray machine teardown by Michael (Buy It, Fix It)

| submitted by /u/jonathan__34 [link] [comments] |

Weekly discussion, complaint, and rant thread

Open to anything, including discussions, complaints, and rants.

Sub rules do not apply, so don't bother reporting incivility, off-topic, or spam.

Reddit-wide rules do apply.

To see the newest posts, sort the comments by "new" (instead of "best" or "top").

[link] [comments]

I modified my cheap mouse to autoclick

| I used a very simple astable multivibrator to switch a transistor on and off which sends current through the buttons its very simple and it works well.(sorry for bad quality this was shot on a 12 year old digital camera) [link] [comments] |

EEVblog 1689 - ANOTHER Dumpster Diving A3 Colour Photocopier!

Sampler project I'm working on

| Attempting to make a tiny sampler inspired by several ones or there. It's been fun working on something like this. Got to rewire a few things, but having fun with it! [link] [comments] |

Looking for the future of autonomous driving? It’s in your car today

Courtesy: Texas Instruments

How today’s semiconductors are powering the current and future landscape of autonomous driving

Semiconductors are crucial to designing new and evolving vehicles; a vehicle today has between 1,000 and 3,500 semiconductors. As drivers continue to prioritize features such as advanced driver assistance systems (ADAS), the importance of semiconductors in the vehicles of today – and tomorrow – will only increase. Looking ahead, more than 50 percent of vehicles in the US are estimated to have a full suite of ADAS features by 2050, potentially helping prevent 37 million crashes over a 30-year period.

Given this projected growth, how are today’s semiconductors powering the current and future landscape of autonomous driving?

To show off current ADAS, highlight future capabilities of these systems and discuss the semiconductors that make them possible, Mike Pienovi, general manager for high-performance processors, and Sneha Narnakaje, business manager for automotive radar, took a car with these features out for a test drive.

Enhanced sensing capabilities

Cars with ADAS functions need to see further in front and behind in order to better perceive and respond to the world around them. The driver assistance systems in these vehicles use a combination of semiconductors for sensing, processing, in-vehicle communication and power management.

Serving as the eyes and ears of these new vehicles, sensing integrated circuits enable enhanced angular and distance resolution sensing, whether on the road or in a parking lot. These vehicles use a combination of sensor modules (radar, lidar and cameras) to actively gather data from around the vehicle, with each type of sensor and their supporting sensing semiconductors best suited for particular driving or weather conditions.

Pairing these sensors with high-speed interface solutions facilitates the transfer of the rapidly growing volume of data about the vehicle’s surroundings to advanced embedded processors.

TI has portfolios of innovative highly precise automotive radar sensors as well as embedded processors with edge artificial intelligence capabilities. For camera-based systems, we continue to invest in high-speed FPD-Link SerDes interface technology, which is capable of transferring high-resolution, uncompressed video data and control information over lightweight automotive coaxial cables.

Meeting regulations and functional safety requirements for automotive systems

Manufacturers are striving to expand the capabilities and features of their vehicles while also complying with current and future safety regulations for new vehicles.

Selecting semiconductors that are designed, qualified and certified according to automotive, functional safety and cybersecurity standards is crucial to meeting the stringent demands of these regulations. Our automotive-qualified devices are designed to not only help manufacturers create safer vehicle systems, but also to provide the advanced capabilities and scalability they need to meet current and future design requirements while differentiating from their competition in terms of features and safety.

Driving closer to the future of vehicle autonomy

With portfolios like TI’s, manufacturers can elevate the ADAS features in cars while setting expectations for the future of autonomous driving. Semiconductors are enabling this journey by making it easier for manufacturers to implement ADAS such as parking and lane assistance, collision monitoring, adaptive cruise control and automatic emergency braking across new vehicles.

These enhanced semiconductors, including sensors, processors, power components and interface devices, are the building blocks for innovation. They can help manufacturers reduce design complexity and more easily meet regulatory requirements in current automotive systems while also planning for the future.

From current features like lane and parking assist to the enhanced Level 3 environmental detection capabilities now hitting the market, each innovation, no matter how seemingly minor, moves us closer to full vehicle autonomy, one mile and one parking space at a time.

The post Looking for the future of autonomous driving? It’s in your car today appeared first on ELE Times.

They messed up my Breadboard!

| The producer/s somehow misaligned the number print and it disorientes me!! They managed to do this on both sides... [link] [comments] |

Inside the AI & Sensor Technology Underpinning Level 3 Driving: Beyond ADAS

From simple driver aid technologies to extremely clever, semi-autonomous cars, the automobile industry is changing quickly. The transition from conventional ADAS to Level 2+ and Level 3 autonomous driving, made possible by developments in artificial intelligence, sensor fusion, edge computing, and functional safety, is at the core of this evolution. The fundamental engineering advancements that not only enable Level 3 autonomy but also make it feasible for mass production are examined in this article.

Level 3 systems still anticipate the driver to take control when the system requests it, in contrast to Level 4 systems, which may function without a steering wheel or pedals and don’t require driver participation inside their designated operational domains. The technological advancement from Level 2 and the constraints that set Level 3 apart as a stage of transition toward complete autonomy are both highlighted in this comparison.

Introduction to Level 3 AutonomyLevel 3 autonomy, or “Conditional Automation” as defined by SAE J3016, allows the driver to relinquish active control under certain circumstances, allowing the vehicle to take over dynamic driving responsibilities. Suppose the Operational Design Domain (ODD) is satisfied. In that case, Level 3 systems can control lane changes, acceleration, braking, and environmental perception without human interaction, in contrast to Level 2, which necessitates continuous driver supervision.

With the help of UNECE standards, nations such as China, Japan, and Germany have begun to approve Level 3 deployments (R157). This change necessitates a strong technical base that combines real-time decision-making algorithms, ultra-low latency processing, and sensor redundancy.

The Level 3 Vehicle ArchitecturePlatforms for Centralized Computing

Centralized computation systems that can process more than 20 sensor inputs in real-time are replacing legacy distributed ECUs. Level 3 vehicles are increasingly being driven by high-performance SoCs like of the Qualcomm Snapdragon Ride Flex, NVIDIA DRIVE Thor, and Mobileye EyeQ Ultra. These SoCs are based on real-time safety islands, ISPs (Image Signal Processors), and AI accelerators. Controlling power consumption and heat dissipation becomes a crucial engineering challenge as these compute platforms incorporate numerous high-throughput pipelines and AI inference engines. Advanced thermal management techniques, such as power gating, dynamic voltage/frequency scaling (DVFS), heat sinks, and active cooling, must be used by designers to guarantee system dependability, efficiency, and adherence to automotive-grade operating temperature ranges.

Combining LiDAR, Radar, and Camera SensorsLevel 3 cars use a redundant set of sensors:

- cameras for semantic segmentation and object classification.

- Radar for tracking velocity and depth in all weather conditions.

- LiDAR for object contour identification and high-resolution 3D mapping.

Using deep neural networks (DNNs), Bayesian networks, and Kalman filters, sensor fusion techniques combine multi-modal data to provide a logical environmental model. Avoiding obstacles and maintaining situational awareness depend on this. However, problems including cross-sensor synchronization under dynamic settings, sensor calibration drift over time, and different environmental influences on sensor dependability are introduced by real-world deployment. For the sensor suite to operate consistently, engineers must guarantee accurate temporal alignment and strong error correction.

Safety & Redundant ActuationDesigns that adhere to ISO 26262 guarantee fail-operational capabilities. Redundant power, steering, and braking systems are essential, particularly in situations where human override is delayed. At this level, ASIL-D certified systems and functional safety monitoring are non-negotiable.

Perception and Planning Driven by AIThe Level 3 AI stack consists of:

- Perception: To identify lanes, people, cars, and signs, DNNs were trained on millions of edge cases.

- Prediction: Probabilistic models and recurrent neural networks (RNNs) assess paths and intent.

- Planning: To create safe, driveable routes, path planning modules employ optimization solvers, RRT (Rapidly-exploring Random Trees), and A* search.

Real-time OS kernels and hypervisors are now a feature of compute platforms to control the separation of safety-critical and non-critical workloads.

Localization and High-Definition (HD) MapsLevel 3 systems use SLAM (Simultaneous Localization and Mapping) and GNSS corrections to integrate sensor data with HD maps that are centimeter-accurate. Real-time map streaming is available from map providers such as HERE, TomTom, and Baidu. Using fleet learning algorithms, some OEMs are experimenting with crowdsourced localization.

Real-Time Inference & Edge AIFor Level 3, inference latency is a bottleneck. On-chip AI accelerators (such as NPU and DSP cores) enable real-time neural network inference at over 30 frames per second with latency at the millisecond level. AI models can be deployed on embedded automotive platforms more efficiently thanks to widely used frameworks like ONNX Runtime and NVIDIA TensorRT. These toolkits aid in the optimization, quantization, and compression of models for effective real-time operation.

Mixed precision (INT8, FP16) is supported by new SoCs to balance energy efficiency and performance. Automotive-grade Linux or QNX-based systems and zero-downtime OTA updates are essential for maintaining the system’s security, responsiveness, and compliance. For Level 3, latency is a bottleneck. On-chip AI accelerators (such as NPU and DSP cores) enable real-time neural network inference at over 30 frames per second with latency at the millisecond level. Mixed precision (INT8, FP16) is supported by new SoCs to balance energy efficiency and performance.

Automotive-grade Linux or QNX-based systems and zero-downtime OTA updates are essential for maintaining the system’s security, responsiveness, and compliance.

Challenges AheadA single essential point that concerns the implementation strategy for Level 3 vehicles is the absence of standardised regulations across all regions. Unlike the European Union or Japan, and China, which have put in place systems for endorsing and managing Level 3 systems (i.e., UNECE R157), the United States still does not have overarching federal guidelines. Approvals are still left to states, which creates inconsistency at the central level. These inconsistencies impact OEM planning calendars, compliance validation testing, and strategies for market entrance.

- ODD Constraints: Most Level 3 systems have geo-fencing or speed limitations.

- Cost & Power: Sensor suites and compute platforms escalate the BOM, budget and thermal envelope.

- Cybersecurity: Robust security measures are needed for real-time V2X communication.

- Driver Handover: UX and regulation remain significant challenges for smooth transition from AI driver to human control.

In Level 3 autonomy, a milestone in automotive engineering progress is AI, mechatronics, embedded systems, and regulatory science working together. Level 4/5 complete autonomy may still be years away, but Level 3 demonstrates and paves the way for a future where cars not only provide assistance but drive themselves under supervision and sophisticated control.

The post Inside the AI & Sensor Technology Underpinning Level 3 Driving: Beyond ADAS appeared first on ELE Times.

Breaking Through AI’s Invisible Barrier With Molybdenum

Courtesy: Lam Research

- AI’s evolution could be thwarted by electrical resistance in 3D architectures

- Molybdenum, a breakthrough material, reduces resistance, improves performance

Lam Research’s ALTUS Halo is designed to address the unique challenges of molybdenum implementation in leading-edge integrated circuit types.

The AI revolution faces an invisible barrier: electrical resistance. As artificial intelligence (AI) demands ever-increasing compute, the semiconductor industry has responded by building upward, creating dense 3D architectures that pack more computing power into each square millimeter.

But this vertical scaling creates an unprecedented engineering challenge: every electrical connection through these towering structures must be perfect at the atomic scale, or AI performance degrades catastrophically.

Advanced 3D Integration and Metallization Barriers in AI Chip ManufacturingTraditional metallization approaches are reaching their physical limits.

In conventional chip designs, creating electrical pathways meant depositing metal into dielectric etched features. These methods relied on barrier layers (e.g., titanium nitride, TiN) to prevent unwanted interactions between metals and surrounding materials.

While necessary, these barriers add electrical resistance—acceptable in simpler chips, but a fundamental roadblock in 3D architectures where signals must (soon) travel through up to 1,000 NAND layers of vertical connections.

The narrowing of lines caused by device shrinking drives the need for new materials with shorter mean-free paths—the distance electrons can travel before colliding—that match line length to achieve lower resistance.

The surge in compute demand compounds the challenge. Every suboptimal connection, every additional barrier layer, creates performance bottlenecks and thermal management challenges that can degrade overall AI system capability.

Molybdenum Innovation Provides a Breakthrough Material for Advanced AI Chip ArchitectureLam’s leadership in metallization innovation spans decades of industry inflections. Our pioneering work with tungsten atomic layer deposition (ALD) enabled the revolutionary shift from planar to 3D NAND memory. Now, as device features continue to shrink, we’re driving another fundamental transition with molybdenum—a material uniquely suited for today’s confined spaces.

Molybdenum (Mo) emerges as a transformative material for advanced metallization because its shorter mean-free path makes it uniquely suited for today’s confined spaces.

And unlike tungsten and other metals, Mo doesn’t need an adhesion or barrier layer (like TiN), simplifying the manufacturing process while significantly reducing overall resistance.

The transition to molybdenum echoes another historic industry inflection point: the shift from aluminum to copper interconnects in the early 2000s, which Lam led. Just as that transition fundamentally changed semiconductor manufacturing, today’s move to Mo represents a similar watershed moment.

Advanced ALD Solutions for AI-Era ChipsMaterial selection alone isn’t enough. Our latest innovation, ALTUS Halo, represents a convergence of atomic-scale engineering and practical manufacturing solutions. The platform brings specific innovations for each critical application:

- For 3D NAND it enables void-free lateral and barrier-less fill through advanced ALD technology and precise wafer temperature control.

- For DRAM applications it drives metallization innovation with selective and conformal fill capabilities.

- For logic it offers both thermal and plasma ALD options with an integrated interface cleaning process.

The implications extend far beyond material selection and manufacturing processes.

Lam’s advances in deposition technology and grain engineering enable optimal molybdenum integration across all leading-edge applications—from 3D NAND wordlines to advanced logic interconnects and DRAM structures.

Initial atomic layers in ALD are critical for interface engineering and subsequent film growth, serving as the template for the material’s properties. The ALTUS Halo quad station module architecture is ideal for creating the most advanced fill processes with the highest productivity due to its flexibility of running different wafer temperatures, process steps and chemistry at each station.

As the industry pushes toward increasingly complex architectures, this precision engineering at the atomic scale becomes even more critical.

A Semiconductor Industry Transformation in Memory and LogicThe semiconductor industry stands at a crucial juncture. Data-intensive AI applications demand significant advancements in both memory and logic technologies. These next-generation devices require unprecedented precision in metallization, where even small improvements in resistance and thermal performance can have outsized impacts on overall system capability.

Through innovations like ALTUS Halo, Lam is enabling a fundamental transition across NAND, DRAM, and logic. As the semiconductor industry pushes physics and chemistry to their limits, our manufacturing-ready solutions will help define the future of AI computing.

The post Breaking Through AI’s Invisible Barrier With Molybdenum appeared first on ELE Times.

Виставка викладача ВПІ Сергія Гулєвича в художньому музеї

Жити в Україні й оминути тему війни неможливо. Дослідити парадокси і карколомні повороти людського життя у кризові часи покликана виставка графіки "Долаючи морок", що була розгорнута в Хмельницькому обласному художньому музеї. Автор робіт – молодий художник, викладач кафедри графіки НН ВПІ Сергій Гулєвич.

Transform Your Safety Strategy: Introducing Logix SIS for Enhanced Protection and Efficiency

Courtesy: Rockwell Automation

Introducing Logix SIS, a safety instrumentation system from Rockwell Automation.

“The only way of discovering the limits of the possible is to venture a little way past them into the impossible.”

This quintessential quote by Arthur C. Clarke appropriately foreshadows and encapsulates the spirit of innovation and progress that has driven humanity to push past conceivable boundaries. More than ever, people look to their resources, neighbors and leaders for intuitive and adaptable solutions to their persisting problems. Today, in the realm of safety, Rockwell Automation answers the call, standing at the precipice of a new era, where the limitations of the past are giving way to future possibilities.

Barriers of Traditional Safety Systems

Complexities abound in our dynamic world of modern industry, and safety is paramount. From robust oil refineries and chemical plants to intricate manufacturing facilities, ensuring the well-being of personnel, protecting valuable assets and safeguarding the environment are at the forefront of business priorities.

Traditional safety systems, while essential, have often needed help to keep pace with the evolving demands of industry. Their implicit complexity, inflexibility and integration challenges can create barriers, hinder productivity and even compromise safety itself. The need for a more streamlined, adaptable and cost-effective approach to safety has never been more apparent.

Enter Logix SIS: A New Era of Safety

Rockwell Automation, a pioneer in industrial automation and digital transformation, has risen to this challenge with the introduction of Logix SIS. This cutting-edge safety instrumented system redefines the landscape of industrial safety.

Logix SIS is more than merely an incremental improvement over existing solutions — it’s a paradigm shift, a bold leap into the future of safety that empowers a connected approach to how businesses achieve unprecedented levels of protection, efficiency and productivity.

Unlike traditional safety systems that operate in isolation, Logix SIS seamlessly integrates with Rockwell Automation’s Integrated Architecture®, leveraging a common platform for both safety and process control. This simplification reduces the need for separate engineering and maintenance staff, which in turn reduces complexity and can help accelerate project timelines. With familiar Logix programming tools and a streamlined configuration process, you can easily design, implement and maintain your safety system.

Key Features and Benefits of Logix SIS:

- High Availability & SIL 2 /SIL 3 Certification: Logix SIS is engineered for the most demanding safety applications, achieving Safety Integrity Level (SIL) 2 and SIL 3 certifications, the gold standards in industrial safety. This means you can trust Logix SIS to provide robust protection against even the most critical hazards, achieving the safety of your people, assets and environment.

- Scalability and Flexibility: Logix SIS is built to adapt and grow with your business. Its modular design allows you to quickly expand or modify your system as your needs evolve, confirming your safety infrastructure remains practical and relevant in the face of change. Whether you’re adding new processes, equipment, or safety zones, Logix SIS can scale to meet your requirements, providing the flexibility and agility you must stay ahead of the curve.

- Cost Efficiency and ROI: Logix SIS is not just a safety solution; it’s a strategic investment in your business. By leveraging existing Rockwell Automation hardware and software, eliminating the need for additional licenses, and streamlining engineering processes, Logix SIS helps you reduce the total cost of ownership and achieve a compelling return on investment.

- Improved Productivity and Uptime: Downtime is the enemy of productivity. Logix SIS’s high availability architecture, combined with advanced diagnostics and predictive maintenance capabilities, helps minimize safety-related stoppages and unplanned downtime. This delivers continuous operation, maximizes output and helps protect your bottom line.

Tomorrow’s Safety, Today

Logix SIS represents a bold step forward in industrial safety, offering a comprehensive, integrated and future-ready solution that empowers businesses to achieve their safety and operational goals. It’s a testament to the spirit of innovation and progress that has always defined Rockwell Automation.

The post Transform Your Safety Strategy: Introducing Logix SIS for Enhanced Protection and Efficiency appeared first on ELE Times.