Feed aggregator

Powering the Future: How High-Voltage MLCCs Drive Efficiency in Modern Electronics

Courtesy: Murata Electronics

Power electronics is undergoing a profound transformation. Devices are now expected to operate faster, become smaller, and achieve unprecedented levels of efficiency.

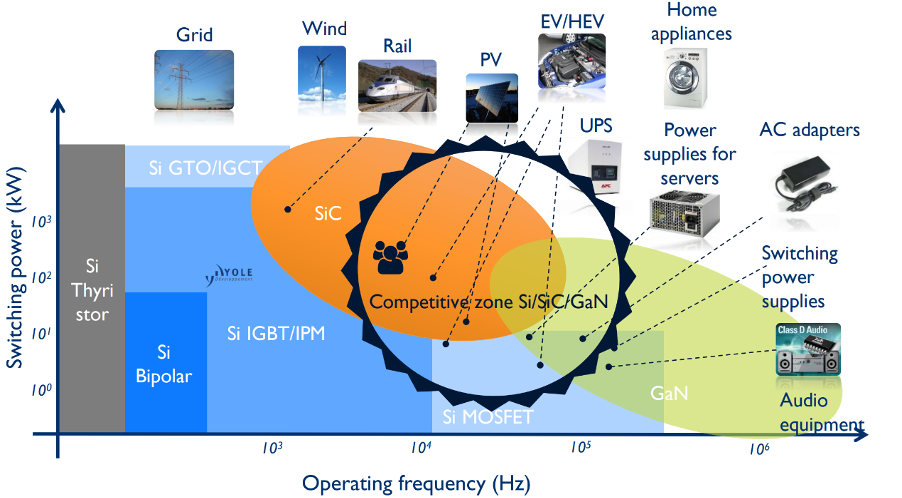

To meet these demands, wide-bandgap (WBG) semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), are increasingly adopted over silicon-based devices. These advanced materials enable significantly higher switching frequencies and increased voltage levels. This reduces system size and boosts power density.

Figure 1: The typical operating frequency and switching power of various semiconductor materials (Source: Yole Group) [see MURA200 for original images]At the same time, the rapid electrification of transport, industry, and energy infrastructure is driving an unprecedented expansion in power conversion applications. This evolution exposes designers to a far wider spectrum of operating conditions.

Figure 1: The typical operating frequency and switching power of various semiconductor materials (Source: Yole Group) [see MURA200 for original images]At the same time, the rapid electrification of transport, industry, and energy infrastructure is driving an unprecedented expansion in power conversion applications. This evolution exposes designers to a far wider spectrum of operating conditions.

Critical Challenges in High-Voltage Systems

These evolving expectations place significant stress not only on active devices but also on the passive components integral to these systems. Higher switching speeds, for instance, lead to sharp voltage transients and electromagnetic interference (EMI). Increased voltages impose strict demands on insulation and overall reliability.

Multilayer ceramic capacitors (MLCCs) play a vital role in suppressing high-frequency noise, absorbing transient spikes, and protecting semiconductor devices from overvoltage stress. Therefore, the advancement of MLCCs must align with the increased performance standards required by WBG devices, necessitating enhancements in dielectric compositions and creative packaging approaches.

Taming Transient Spikes

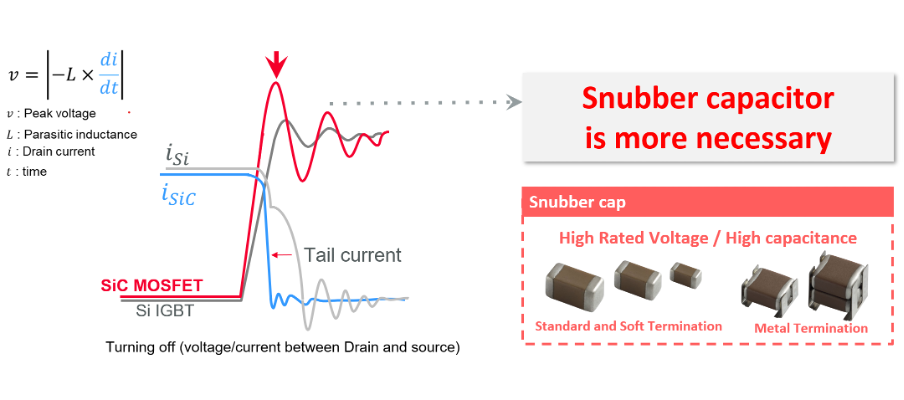

Snubber capacitors are essential in power electronics, especially where high-speed switching induces voltage overshoot and ringing. This is particularly critical during the turn-off transitions of MOSFETs or IGBTs. This issue is heightened in SiC and GaN power semiconductors, which exhibit greater surge voltages compared to traditional silicon IGBTs.

Figure 2: SiC MOSFETs exhibit a higher surge voltage than traditional Si IGBTs (Source: Murata) [see MURA200 for original images]A well-matched snubber capacitor effectively absorbs transient energy, suppresses peak voltages, and damps oscillations. Murata’s metal-termination MLCCs, such as the KC3 and KC9 series, are optimised for use in SiC-based circuits.

Figure 2: SiC MOSFETs exhibit a higher surge voltage than traditional Si IGBTs (Source: Murata) [see MURA200 for original images]A well-matched snubber capacitor effectively absorbs transient energy, suppresses peak voltages, and damps oscillations. Murata’s metal-termination MLCCs, such as the KC3 and KC9 series, are optimised for use in SiC-based circuits.

The post Powering the Future: How High-Voltage MLCCs Drive Efficiency in Modern Electronics appeared first on ELE Times.

Redefining the human experience with intelligent computing

Courtesy: Qualcomm

Enabling the devices, vehicles and machines that define tomorrow’s world.

What you should know:

- The next UI centres around you, with your AI agent seeing, hearing and acting on your behalf.

- We’re scaling AI to redefine the human experience—powering next-gen wearables and personal AI devices, and driving intelligence into robots, cars and smart homes.

- Our technologies enable extraordinary experiences that consumers and businesses depend on every day—bringing personal and physical AI everywhere.

Think of AI like coffee. You don’t walk into a café and ask for “a beverage brewed from roasted beans” — that’s assumed. You order the experience. Latte, half-pump vanilla, extra shot against a soundtrack of acoustic 90s alternative. The perfect mix to fuel your day, making you more productive, more creative, more you. AI works the same way. It’s a given, not a feature — the foundation of every experience, making each truly yours.

You are at the centre with your agent as your intelligent teammate. This is the next UI. Forget the seemingly endless scrolling and tedious tapping to complete one.single.thing only to do it again.and.again. Instead, your agent moves with you, learns from you and anticipates your needs. And thanks to AI processing on the device, it remains private, contextual and always-on. Like your favourite barista, who knows your order as soon as you walk in, including your (secret) treat every Friday.

We’re leading the charge toward the future of intelligent computing — reimagining possibilities for not only consumers, but also enterprises and industries worldwide. We’re scaling intelligence from edge to cloud, bringing AI everywhere. Our Snapdragon and Qualcomm Dragonwing platforms enable the devices, vehicles and machines that define tomorrow’s world — and redefine the human experience.

And again, I can’t say this enough, it’s all about you. Or more precisely, an “ecosystem of you” where your agent can see, hear and act on your behalf across an emerging category of AI-first intelligent wearables, along with smartphones and AI PCs.

The newest entrant in our Snapdragon X Series Compute Platforms, Snapdragon X2 Plus, delivers agentic AI experiences to aspiring creators, professionals and everyday users — broadening the already-growing Windows PC community.

Your home, too, is transforming into a responsive, intuitive environment. Understanding you and your family, your home adapts to your needs, routines and comforts. Lights, climate, security and entertainment are now intelligent with Dragonwing Q-7790 and Q-8750 processors. The backbone of these AI-enabled experiences and home automation? Connectivity, brought to you by Qualcomm, the leading wireless innovator.

But AI isn’t just personal. It’s also physical, acting alongside you.

Your car is transforming into an adaptive companion, driven by intelligence. Snapdragon is redefining automotive experiences, from enhancing safety and comfort to immersive entertainment. Private, contextual AI — sensing, processing, acting in real time — makes every drive smarter, more efficient and connected.

Advanced autonomous capabilities are also being used to power the next generation of personal service robots, all the way through to industrial full-size humanoids. Thanks to our full-stack robotics system, they will deliver intuitive and impactful assistance with precision, enhancing daily life and industry. And I’m sure they’ll learn how to make your coffee perfectly.

This is truly an exciting time in how technology is evolving around us and for us. Our innovations already power billions of devices, enabling the extraordinary experiences that consumers and businesses depend on every day. And we can’t wait to bring you more.

The post Redefining the human experience with intelligent computing appeared first on ELE Times.

Звіт проректорки з навчальної роботи КПІ Тетяни Желяскової на засіданні Вченої ради 15 грудня 2025 року: "Освіта в КПІ за умов законодавчої трансформації 2025"

Освітня діяльність університету в 2025 році здійснювалася в умовах суттєвої законодавчої трансформації системи вищої освіти, триваючих безпекових викликів та необхідності збереження якості освітнього процесу.

The Forest Listener: Where edge AI meets the wild

Courtesy: Micron

Let’s first discuss the power of enabling. Enabling a wide electronic ecosystem is essential for fostering innovation, scalability and resilience across industries. By supporting diverse hardware, software and connectivity standards, organisations can accelerate product development, reduce costs and enhance user experiences. A broad ecosystem encourages collaboration among manufacturers, developers and service providers, helping to drive interoperability. Enabling an ecosystem for your customers is a huge value for your product in any market, but for a market that spans many applications, it’s paramount for allowing your customers to get to the market quickly. Micron has a diverse set of ecosystem partners for broad applications like microprocessors, including STMicroelectronics (STM). We have collaborated with STM for years, matching our memory solutions to their products. Ultimately, these partnerships empower our mutual businesses to deliver smarter, more connected solutions that meet the evolving needs of consumers and enterprises alike.

The platform and the kit

There’s something uniquely satisfying about peeling back the anti-static bag and revealing the STM32MP257F-DK dev board brimming with potential. As an embedded developer, I am excited when new silicon lands on my desk, especially when it promises to redefine what’s possible at the edge. The STM32MP257F-DK from STMicroelectronics is one of those launches that truly innovates. The STM32MP257F-DK Discovery Kit is a compact, developer-friendly platform designed to bring edge AI to life. And in my case, to the forest. It became the heart of one of my most exciting projects yet: the Forest Listener, a solar-powered, AI-enabled bird-watching companion that blends embedded engineering with natural exploration.

A new kind of birdwatcher

After a few weeks of development and testing, my daughter and I headed into the woods just after sunrise — as usual, binoculars around our necks, a thermos of tea in the backpack and a quiet excitement in the air. But this time, we brought along a new companion. The Forest Listener is a smart birdwatcher, an AI-powered system that sees and hears the forest just like we do. Using a lightweight model trained with STM32’s model zoo, it identifies bird species on the spot. No cloud, no latency, just real-time inference at the edge. My daughter has mounted the device on a tripod, connected the camera and powered it on. The screen lights up. It’s ready! Suddenly, a bird flutters into view. The camera captures the moment. Within milliseconds, the 1.35 TOPS neural processing unit (NPU) kicks in, optimised for object detection. The Cortex-A35 logs the sighting (image, species, timestamp), while the Cortex-M33 manages sensors and power. My daughter, watching on a connected tablet, lights up: “Look, Dad! It found another one!” A Eurasian jay, this time.

Built for the edge … and the outdoors

Later, at home, we scroll through the logs saved on the Memory cards. The system can also upload sightings via Ethernet. She’s now learning names, songs and patterns. It’s a beautiful bridge between nature and curiosity. At the core of this seamless experience is Micron LPDDR4 memory. It delivers the high bandwidth needed for AI inference and multimedia processing, while maintaining ultra-low power consumption, critical for our solar-powered setup. Performance is only part of the story: What truly sets Micron LPDDR4 apart is its long-term reliability and support. Validated by STM for use with the STM32MP257F-DK, this memory is manufactured at Micron’s dedicated longevity fab, ensuring a more stable, multiyear supply chain. That’s a game-changer for developers to build solutions that need to last — not just in home appliances, but in the harsh field environment. Whether you’re deploying an AI app in remote forests, industrial plants or smart homes, you need components that are not only fast and efficient but also built to endure. Micron LPDDR4 is engineered to meet the stringent requirements of embedded and industrial markets, with a commitment to support and availability that gives manufacturers peace of mind.

Beyond bird-watching

The Forest Listener is just one example of what the STM32MP257F-DK and Micron LPDDR4 can enable. In factories, the same edge-AI capabilities can monitor machines, detect anomalies, and reduce downtime. In smart homes, they can power face recognition, voice control and energy monitoring — making homes more intelligent, responsive and private, all without relying on the cloud.

The post The Forest Listener: Where edge AI meets the wild appeared first on ELE Times.

Eddy current in focus: A rapid revisit

Eddy currents are not just textbook curiosities; they are the hidden loops that appear whenever metal meets a changing magnetic field. From DIY levitation tricks to clever braking systems, these swirling paths of electrons keep finding new ways to surprise and inspire.

In this rapid revisit, we will zoom in on the essentials, highlight a few practical pointers, and remind ourselves why this classic effect still merits a place in every innovator’s playbook.

Eddy currents: From losses to brakes to rice cookers

Eddy currents are closed loops of electrical current induced in conductors by a changing magnetic field, as described by Faraday’s law of induction. These currents circulate in planes perpendicular to the applied magnetic field.

By Lenz’s law, eddy currents generate their own magnetic field that opposes the change which created them. This opposition manifests as magnetic drag, joule heating, and energy conversion in conductive materials are exposed to time-varying fields.

The interaction between the applied field and induced currents resists motion. A classic demonstration is a magnet falling slowly through a copper tube—its descent dampened by the opposing magnetic force. As eddy currents circulate, they dissipate energy as heat due to the conductor’s resistance. This loss is problematic in devices such as transformers, motors, and induction coils, where unwanted heating reduces efficiency.

At the same time, eddy currents enable useful applications. In magnetic braking systems, for example, a moving object’s kinetic energy is deliberately converted into heat, providing smooth, contactless deceleration.

Figure 1 A generic eddy current brake is shown with rotor eddy currents resisting motion. Source: Author

Eddy currents embody both challenge and opportunity. In power systems, they waste energy as heat and demand careful design measures such as laminated transformer cores or specialized alloys to minimize losses. Yet the same principle enables precise, contactless control in magnetic braking, induction heating, and nondestructive testing.

Léon Foucault discovered eddy currents in the early 1850s; he also demonstrated Earth’s rotation with the Foucault pendulum. From Foucault’s copper disk to today’s rice cookers and industrial drives, eddy currents illustrate how a single electromagnetic effect can hinder efficiency while powering innovation. Their discovery remains a landmark in the history of electromagnetism.

Eddy currents at work: Quick insights

On paper, eddy currents arise from changing magnetic fields. They form when a conductor moves through a magnetic field or when the field around a stationary conductor varies. In short, any change in the intensity or direction of the magnetic field can drive circulating currents. Their strength scales with the rate of flux change, the loop area, and the field’s orientation, while higher conductor resistivity weakens them.

To grasp how this works, inertia makes a useful analogy. In classical mechanics, a moving body tends to keep moving, while a stationary one stays put. Electromagnetism shows a similar stubbornness: when a conductor encounters a changing magnetic field, it responds by generating an opposing flux through induction. That flux manifests as eddy currents. Picture them as invisible coils forming inside the conductor—the material itself acting like a “built-in electromagnet” that resists change.

A familiar example is the eddy current brake used in heavy vehicles and trains. These auxiliary brakes, often engaged on downhill runs, position electromagnets near a drum on the rotating axle. Once energized, the drum develops eddy currents that push back against the changing flux, creating drag. The beauty of this system lies in non-contact braking—no friction, no wear on drums or pads. Of course, the kinetic energy does not vanish; conservation of energy dictates it reemerges as Joule heating, dissipated as heat in the drum.

The same principle appears in everyday life. Induction cooktops and induction heating (IH) rice cookers rely on high-frequency currents in their coils to generate rapidly changing magnetic fields. These fields drive eddy currents in the conductive pot walls, producing Joule heat that cooks food directly and efficiently.

As a side note, eddy current brakes and electric retarders share the same physics but differ in role. An eddy current brake is a general device found in rail systems, roller coasters, or test rigs, providing smooth, non-contact braking. An eddy current electric/electromagnetic retarder, by contrast, is an auxiliary system integrated into heavy vehicles—buses, trucks, and coaches—to control speed on long descents.

Retarders ease the load on friction brakes, preventing overheating and wear, though they still demand cooling since induced currents generate substantial heat. In short, brakes emphasize stopping power, while retarders emphasize sustained drag torque for safe downhill control.

Figure 2 An electromagnetic retarder mounts mid-shaft and delivers non-contact braking for heavy vehicles. Source: Telma

Harnessing eddy currents in dynamometers

Dynamometers often rely on eddy current action in their background to absorb and measure power. In an eddy current dynamometer, a rotating metallic disc or drum is subjected to a magnetic field; as the engine drives the disc, circulating currents are induced in the metal. These eddy currents create a resistive force proportional to speed, effectively loading the engine while converting mechanical energy into heat.

The dynamometer’s role is to provide a controlled, repeatable load while precisely measuring torque and power, enabling accurate evaluation of engine or motor performance. Their application domain spans automotive testing, industrial machinery evaluation, and research laboratories where reliable power measurement is essential.

Figure 3 An eddy current dynamometer, delivering full power at high rotation speeds, is designed for fast-rotating motors. Source: Magtrol

Eddy current sensors: From magnetic fields to motion insight

An eddy current sensor, often referred to as a gap sensor, operates by generating a high-frequency magnetic field through a coil embedded in the sensor head. When a conductive measuring object approaches this field, eddy currents are induced on its surface, altering the impedance of the sensor coil.

By detecting these impedance changes, the sensor translates variations in transmission length into a precise relationship between displacement and output voltage. Their application fields span precision displacement measurement, vibration monitoring, and shaft run-out detection, with widespread use across the automobile, aerospace, and semiconductor industries.

Figure 4 An industrial-grade contactless proximity sensor measures position by interpreting eddy currents. Source: Messotron

Put another way, the eddy current method employs high-frequency magnetic fields generated by driving an alternating current through the coil in the sensor head. When a metallic target enters this field, electromagnetic induction causes magnetic flux to penetrate the object’s surface, producing circulating eddy currents parallel to that surface. These currents modify the coil’s impedance and eddy current displacement sensors detect the resulting oscillation changes to measure distance.

Figure 5 Drawing illustrates the core mechanism of an eddy current displacement sensor. Source: Author

At this point, it’s important to distinguish between an eddy current probe and an eddy current sensor. The probe is the coil assembly that induces and detects eddy currents, typically used in non-destructive testing (NDT), while the sensor integrates the probe with electronics to deliver calibrated displacement or vibration signals in industrial applications.

Also note that the sensing field of a non-contact sensor’s probe engages the target across a defined area, known as the spot size. For accurate measurement, the target must be larger than this spot size; otherwise, special calibration is required.

Spot size is directly proportional to the probe’s diameter. In eddy-current sensors, the magnetic field fully surrounds the end of the probe, creating a comparatively large sensing field. As a result, the spot size extends to many times the diameter of the probe’s sensing coil.

Wrap-up: Bridging theory and practice in eddy currents

Time for a quick break, yet so many details remain in the fascinating world of eddy currents. I am not covering every nuance here because eddy current methods are broad and specialized, with deeper dives best reserved for dedicated sections. To anchor the essentials: eddy current examination is a nondestructive testing method based on electromagnetic induction.

When applied to detect surface-breaking flaws in components and welds, it’s known as surface eddy current testing. Specially designed probes are used for this inspection, with coils mounted near one end of a plastic housing. During inspection, the technician guides the coil end of the probe across the surface of the component, scanning for variations that reveal discontinuities.

Well, now switch on your eddy current soldering iron—or set up one yourself—and start doing something practical, like building your own probes, sensors, or experimental rigs. Hands-on exploration is the best way to connect theory with practice, and this is the perfect moment to make the leap from reading to making.

For curious makers, eddy current soldering irons are not just another tool, they are a gateway into experimenting with induction heating itself. A coil generates a rapidly changing magnetic field, inducing circulating currents in the conductive tip or sleeve. These eddy currents encounter resistance and dissipate energy as heat, delivering rapid warm-up and stable temperature exactly where it is needed.

Whether you pick up a ready-made station or build a DIY rig, you will be blending theory with practice in the most tangible way. It’s a perfect project to showcase how electromagnetic principles—Faraday’s law and Lenz’s law in action—can power real-world innovation.

T. K. Hareendran is a self-taught electronics enthusiast with a strong passion for innovative circuit design and hands-on technology. He develops both experimental and practical electronic projects, documenting and sharing his work to support fellow tinkerers and learners. Beyond the workbench, he dedicates time to technical writing and hardware evaluations to contribute meaningfully to the maker community.

T. K. Hareendran is a self-taught electronics enthusiast with a strong passion for innovative circuit design and hands-on technology. He develops both experimental and practical electronic projects, documenting and sharing his work to support fellow tinkerers and learners. Beyond the workbench, he dedicates time to technical writing and hardware evaluations to contribute meaningfully to the maker community.

Related Content

- Maxon: Inductive encoder is based on eddy currents

- The difference between inductive proximity, displacement, and eddy-current sensors

The post Eddy current in focus: A rapid revisit appeared first on EDN.

Nitride Global, USLLC and Axiom Space awarded NASA SBIR grant

Wolfspeed’s soft demand for EV application offset by 50% quarterly revenue growth for AI data-center application

Solution Suite Concept: Software-Based Refrigerator

Courtesy: Renesas

Imagine a world without cold storage—medicines would spoil, food would perish, and supply chains would collapse. Refrigeration systems are vital to modern life, from pharmaceutical coolers to large-scale warehouses. These systems form the backbone of the cold chain, ensuring products meet strict storage requirements.

To achieve durability and sustainability in these operations, embracing AI is essential for maximum performance optimisation. Renesas has been continuously innovating in this space, delivering a range of AI-driven solutions tailored for the refrigeration industry—helping businesses enhance efficiency, reliability, and energy savings.

Renesas Enablement for AI-powered Refrigeration Solutions

Renesas’ solution concept introduces a suite of AI-driven applications designed to tackle everyday challenges in refrigeration systems. These proposals focus on enhancing operational efficiency and reliability in key areas such as predictive maintenance, energy optimisation, and asset management, among others.

Refrigerant gas is crucial for maintaining stable cold temperatures in cooling systems. Over time, however, leaks can develop due to wear and tear in pipes or refrigerant circuits. To address this challenge, Renesas AI leverages advanced AI algorithms to detect anomalies by analysing changes in electrical current and compressor vibrations. This proactive approach enables timely maintenance, prevents costly breakdowns, and ensures optimal cooling efficiency.

Compressor Overheat Detection

Compressor overheating can result from issues such as low refrigerant levels or clogged filters, leading to potential system damage. Renesas AI HVAC solutions go beyond leak detection by continuously monitoring filter conditions and measuring intake airflow in real time. By analysing this data, the system predicts risks before they escalate, ensuring the cooling system operates efficiently and reliably.

Cooling Capacity Monitoring

Renesas HVAC solutions integrate advanced AI features to predict fan imbalances that directly impact cooling efficiency. Using AI models trained with electrical current data, these anomalies can be detected, enabling seamless and sensorless monitoring. This proactive approach enhances system reliability and ensures optimal cooling performance.

Assets Monitoring: Availability and Expiry Tracking

AI-powered object detection and classification enable real-time monitoring of stock levels and refrigerated assets. The system can automatically suggest restocking needs and estimate lead times for each item. Reducing the need for manual inventory checks and minimising the frequency of opening cooling units, it reduces energy consumption and improves operational efficiency.

Person Identification

AI-powered person identification enhances security and user experience in refrigeration systems. Authorised access can be ensured through two approaches:

- Vision-based authentication using an object detection model combined with on-device learning for custom face recognition.

- Voice-based authentication using a speaker identification model with a microphone sensor.

These methods can be combined for two-step authentication, which is especially critical in medical or industrial refrigeration environments. For home appliances, person identification enables context-aware interactions, such as personalised dietary recommendations or recipe suggestions, creating a smarter and more intuitive user experience.

By integrating real-time monitoring, predictive maintenance, and intelligent object detection, these systems deliver optimal performance, energy efficiency, and operational reliability. From detecting refrigerant leaks and airflow issues to predicting fan imbalances and automating inventory management, the Renesas solution concept offers a comprehensive, end-to-end approach to cooling system optimisation.

This seamless and sensorless monitoring capability not only extends system longevity but also drives significant energy savings. As demand for smarter, more efficient refrigeration systems grows, Renesas is leading the way, pioneering the next generation of intelligent cooling solutions.

The post Solution Suite Concept: Software-Based Refrigerator appeared first on ELE Times.

The V2X Revolution: Satellite Integration, Quantum Security, and 5G RedCap Reshape Automotive Connectivity

Imagine your car negotiating traffic with satellites, quantum-encrypted handshakes, and roadside infrastructure—all while you sip your morning coffee. This isn’t science fiction; it’s the V2X revolution unfolding in production vehicles by 2027. As the Vehicle-to-Everything market hurtles from $6.53 billion in 2024 toward a staggering $70.94 billion by 2032, three converging technologies are rewriting the rules of automotive connectivity: satellite-integrated networks that promise coverage where cell towers fear to tread, post-quantum cryptography racing against the quantum computing threat, and cost-optimised 5G RedCap systems making autonomous driving infrastructure economically viable. The question isn’t whether your next vehicle will be connected—it’s whether the ecosystem will be ready when it rolls off the line.

The Convergence Catalyst: When Satellites, Quantum, and RedCap Collide

The automotive industry has weathered countless transformations, but the V2X revolution of 2025-2026 represents something unprecedented: three disparate technologies—satellite connectivity, quantum cryptography, and 5G RedCap, converging into a single automotive imperative as the market accelerates toward $70.94 billion by 2032.

The strategic calculus facing OEMs isn’t simply about adopting V2X; it’s about choosing which technological bet defines their competitive position. Some prioritise satellite-integrated Non-Terrestrial Networks, banking on 5GAA’s 2025 demonstrations proving vehicles can maintain emergency connectivity where terrestrial infrastructure fails. Their roadmaps target 2027 commercial deployments, envisioning truly ubiquitous vehicle connectivity from urban centres to remote highways.

“Connectivity is becoming more and more important for vehicles. No connection is not an option. Satellite came to our attention 3 to 5 years ago, and then it was costly and proprietary with large terminals,” said Olaf Eckart, Senior Expert, Cooperations R&D / Engineering Lead, NTN, BMW

Others race against the quantum threat timeline. With NIST finalising quantum-resistant standards including CRYSTALS-Kyber and CRYSTALS-Dilithium, these companies face an uncomfortable truth: today’s vehicle encryption could be obsolete within a decade. Their 18-24 month roadmaps aren’t about adding features; they’re about future-proofing against a cryptographic paradigm shift most consumers don’t yet understand.

The pragmatist camp focuses on 3GPP Release 17’s RedCap specifications entering mass production. These organisations see cost-effective 5G variants as critical enablers for vehicle-road-cloud integration architectures, making L2+ autonomous driving economically viable at scale.

What’s remarkable isn’t the diversity of approaches; it’s that all three are simultaneously correct. The V2X ecosystem emerging in 2026-2027 won’t be defined by a single winner but by seamless integration of all three domains. Vehicles rolling off 2027 production lines will need satellite backup for coverage gaps, quantum-resistant security for longevity, and RedCap efficiency for cost-effectiveness.

The question keeping executives awake isn’t which technology to choose; it’s whether their organisations can master all three fast enough to remain relevant.

Engineering Reality Check: Breaking Through the Technical Bottlenecks

Every breakthrough technology comes with footnotes written in engineering challenges, and V2X is no exception. The gap between demonstrations and production-ready systems is measured in thousands of testing hours and occasional failures that never reach press releases.

Consider satellite-integrated V2X’s deceptively simple promise: connectivity everywhere. Reality involves achieving seamless terrestrial-to-Non-Terrestrial Network handovers while maintaining sub-100ms latency that safety-critical applications demand. When vehicles at highway speeds switch from cellular towers to LEO satellite constellations, handovers must be invisible and instantaneous. Engineers are discovering that 3GPP Release 17/18 standards provide frameworks, but real-world implementation requires solving synchronisation challenges that textbooks barely address.

Post-quantum cryptography presents an even thornier dilemma. CRYSTALS-Kyber and CRYSTALS-Dilithium aren’t just longer keys—they’re fundamentally different mathematical operations consuming significantly more processing power than today’s RSA or ECC algorithms. Automotive-grade ECUs, designed with tight power budgets and cost constraints, weren’t built for quantum-resistant workloads. Development teams wrestle with a trilemma: maintain security standards, meet latency requirements, or stay within thermal envelopes. Pick two.

The integration paradox compounds complexity. Can existing vehicles receive V2X capabilities through OTA updates and modular hardware? Sometimes, a 2024 model with appropriate sensor suites might support RedCap upgrades via software. But satellite antenna arrays and quantum-capable security modules often require architectural changes that can’t be retrofitted; they need initial platform integration.

The coexistence problem adds another layer. Many vehicles must support multiple V2X standards simultaneously: legacy DSRC, C-V2X, and emerging satellite connectivity. Ensuring these systems don’t interfere while sharing antenna space and processing resources is creative problem-solving happening in testing facilities at 3 AM.

What separates vapourware from production-ready solutions isn’t the absence of challenges; it’s how engineering teams respond when elegant theory collides with messy reality.

NXP’s Post Quantum Cryptography chips use on-chip isolation so that “in the event of an identified attack, the technology doesn’t let the attack spread to other chips and controllers in the vehicle,” said the NXP Semiconductors, Engineering Team, Marius Rotaru (Software Architect) & Joppe Bos (Senior Principal Cryptographer).

Beyond the Vehicle: Infrastructure, Ecosystems, and the Path to Scale

The most sophisticated V2X technology becomes an expensive paperweight without supporting ecosystems. This truth is reshaping automotive development models, forcing OEMs beyond the vehicle into infrastructure challenges they’ve historically ignored.

The infrastructure gap is staggering. Satellite-integrated V2X requires ground stations for orbit tracking and handover coordination. Post-quantum security needs certificate authorities upgraded with quantum-resistant algorithms across entire PKI hierarchies. RedCap-enabled vehicle-road-cloud architectures demand roadside units at sufficient density, plus edge computing infrastructure processing terabytes of sensor data with minimal latency.

No single company can build this alone, spawning partnership models from traditional supplier relationships into complex consortia. Automotive OEMs partner with telecom operators on spectrum allocation, governments on roadside infrastructure and regulatory frameworks, and satellite operators, cloud providers, and cybersecurity firms; often simultaneously, sometimes competitively.

Regulatory landscapes add complexity. V2X touches spectrum allocation, data privacy, cybersecurity standards, and safety certification, each governed by different agencies with different timelines. Europe swung toward C-V2X after years of DSRC mandates. China receives state-backed vehicle-road-cloud infrastructure investment. United States approaches vary by state, creating fragmented deployment landscapes complicating nationwide rollouts.

When does this reach mainstream production? RedCap systems enter vehicles now, in 2025-2026, leveraging existing cellular infrastructure. Satellite integration likely reaches commercial deployment by 2027-2028 for premium vehicles and emergency services. Post-quantum security faces longer timelines; threats aren’t imminent enough to justify computational overhead across fleets.

Three factors will accelerate or delay timelines: infrastructure deployment speed, regulatory harmonisation, and killer applications making V2X tangible to consumers. V2X reaches mainstream adoption when it solves problems people actually have.

Looking toward 2027-2030, the competitive landscape splits between integrated mobility providers mastering the full vehicle-infrastructure-cloud stack and specialised component suppliers. Winners will be organisations that built ecosystems delivering end-to-end experiences. In the V2X era, the vehicle is just the beginning.

by: Shreya Bansal, Sub-Editor

The post The V2X Revolution: Satellite Integration, Quantum Security, and 5G RedCap Reshape Automotive Connectivity appeared first on ELE Times.

Building a programmable DC-DC Power Supply with I2C Interface (I2C-PPS). Part 1 - Idea

| I was lurking through DigiKey catalog and found a TI buck-boost controller with I²C interface - BQ25758S. The controller allows to create a programmable power supply with quite impressive output specs - voltage 3.3-26V and current up to 20A. Decided to give it a try and create a compact board for my RPI Zero. I don't think I'll go above 3A input (which means only 500mA@26V give or take some efficiency) and it's a bit of a shame that the controller doesn't go below 3.3V (much better would be at least 1.8V). For starter created an umbrella repository - github.com/condevtion/i2c-pps. Any "well, actually" are very welcome! [link] [comments] |

My first project: Universal Traction Control System for Motorcycles!!

| I really like motorcycles, specially old sports bikes, but, they do come with a terrible thing, they don't have any safety electronics at all, ABS, TCS, nothing, completely barebones, and I consider myself a pretty new rider, so I'm starting a project where I'm gonna make my own traction control, using hall effect sensors and laser cut tone wheels for sensing both of the wheels rotation, so the ESP32 inside the main PCB can do the math, alongside the MPU6050 GY-512, so it correct the "slipage rate" as the bike inclines from side to side into turns in the twisties, it's definitely not gonna be perfect from the get go, but I'm really hopeful that this thing can work properly. If you're wondering, they don't act directly on the brakes, but rather using the relay to shut off the ignition coil for a few microseconds as the bikes takes grip again, hopefully this will be able to help both me and several other riders ride their dream bikes more safely! Everything is at a very starting phase, but I did already order all the PCBs from JLCPCB and the components I bought locally, so excited to see how it turns out! [link] [comments] |

Modifying the INA226 Current Sensor for High-Power Applications

| I’d like to share my experience building a "rough gauge" for my LiFePO4 battery pack. Instead of using an off-the-shelf Smart BMS, I chose the DIY route to better understand the underlying physics and processes. Stock INA226 modules come with a 100 mΩ shunt resistor, which limits the current measurement to a measly 800 mA. This is far too low for a power battery.

To find the exact resistance value, I ran a series of tests and compared the readings with a UNI-T UT61 multi meter. The calculated precision value is 4.392 mΩ.

The biggest challenge is heat. At currents above 10 A, the shunt begins to warm up noticeably. This creates Therm-EMF (the Seebeck effect), which causes "phantom" readings of about 50 mA on the screen for several minutes after the load is disconnected, until the node cools down. More details here: https://en.neonhero.dev/2026/02/modifying-ina226-from-08a-to-high-power.html [link] [comments] |

Test if the diodes work (Silly power supply for a lone lamp update)

| A long anticipated update for "Silly power supply for a lone lamp" post :) The original post showed a simple set of low power batteries connected in parallel supplying a 12V/50mA lamp. The schematic featured a diode per battery to prevent them from feeding each other. Here, I decided to check experimentally if the diodes indeed work as expected. I used an STM32F103 module as multichannel ADC, a set of resistors to scale down from 0-18V to 0-3V and a RPi Zero 2W as a 5V power supply and to collect data. Potentiometers were set to 20k creating 6 100k/20k voltage dividers (pic 3). First, measured lamp and batteries voltages with a fresh set batteries. They held around 3 hours 45 minutes. The set had voltage around 12.6V fresh without load. Upon switching on the load they immediately dropped to 12V and then spent most of the time going from 10.5 to 8.5V as the pic 4 shows. The diodes took about 350mV so lamp's voltage went clearly below batteries. Then I mixed 3 fresh and 3 used batteries and actually was really surprised with how clearly it showed when used batteries kicked in. The last pic shows voltage drop across diodes and comparing with the previous one you can see that the diodes for used batteries open as voltage reaches around 200mV. Which is a great real-world demo of how low is cut-in (or knee) voltage for a Schottky diode can be (here SD103A used). [link] [comments] |

I hear we like to sort stuff here? How about a gallon of resistance?

| submitted by /u/mofomeat [link] [comments] |

Weekly discussion, complaint, and rant thread

Open to anything, including discussions, complaints, and rants.

Sub rules do not apply, so don't bother reporting incivility, off-topic, or spam.

Reddit-wide rules do apply.

To see the newest posts, sort the comments by "new" (instead of "best" or "top").

[link] [comments]

NUBURU activates Q1 production ramp for 40 high-power blue laser systems

Звіт першого проректора КПІ Михайла Безуглого на засіданні Вченої ради 12 січня 2026 року

Функціонування університету в умовах визначеної невизначеності: причини для адаптації чи виклик новим можливостям

Safe operating area

Any semiconductor has limits on how much voltage, how much current, and for how much time combinations of voltage and current can be supported in normal usage. Sometimes that information is provided as part of the device’s datasheet, and sometimes that information is NOT provided. In either case, though, there ARE limits which MUST be observed.

Any switching semiconductor device must address voltage and current issues. Drive considerations aside, from the standpoint of “safe operating area” or SOA, the voltage Vds and the current Ids of a power MOSFET and the Vce and Ic of a bipolar transistor are at issue.

Please consider the following unwisely designed circuit in Figure 1.

Figure 1 A badly designed switching circuit requiring the 2N2222 at Q1 to repeatedly dump the charge of capacitor C1 of 0.01 µF. Source: John Dunn

Figure 1 A badly designed switching circuit requiring the 2N2222 at Q1 to repeatedly dump the charge of capacitor C1 of 0.01 µF. Source: John Dunn

What we’ve done wrong here is require the 2N2222 at Q1 to repeatedly dump the charge of capacitor C1 of 0.01 µF. The Vce and the Ic versus time burdens on Q1 are as shown. The current peak of nearly 500 mA is pretty big, and to our dismay, it occurs while the value of Vce is still fairly high, which means that there is a substantial peak power dissipation demand placed on Q1.

Having constructed a Lissajous pattern of Vce versus Ic as shown in Figure 2, we process that pattern.

Figure 2 The voltage versus current Lissajous pattern for Q1. Source: John Dunn

Just one comment about obtaining that Lissajous pattern. The oscilloscope simulations in the Multisim-SPICE I was using do not support “x” versus “y” capability, and therefore cannot provide the Lissajous pattern. I made the pattern you see here by reading out the voltage and current values at each time step of the oscilloscope display and then plotting them using GWBASIC. There were 240 datums for each, a total of 480 readings, which were pretty tedious to acquire. Ordinarily, I can’t concentrate on work and listen to music at the same time, but this time, listening to some Petula Clark recordings through all of this did help to ease the monotony.

In all my years of acquaintance with the 2N2222, I have never seen any specification or any datasheet that presented the SOA boundaries for that device. In fact, I’ve never seen the SOA boundaries for any TO-18 packaged device. In the TO-5 and TO-39 packages, the one and only time I have ever come across SOA boundary information was for the 2N3053 and 2N3053A, and even today, some datasheets omit that information.

As a result, we just have to make do with what we’ve got, which for now is this partial reconstruction of the 2N3053 and 2N3053A SOA chart taken from a very old datasheet from RCA that I stashed away long ago (Figure 3).

Figure 3 Safe operating area reconstruction of the 2N3053 and 2N3053A SOA chart taken from a very old datasheet from RCA. Source: John Dunn

We replot the Vce versus Ic data using logarithmic scaling, and then we overlay that result with the SOA boundaries of our NPN, but we encounter a difficulty (Figure 4).

Figure 4 SOA examination using logarithmic scaling. Source: John Dunn

The 2N2222 has a peak power rating of 1.2 watts, while the 2N2219, a first cousin to the 2N2222, has a peak power rating of 3 watts, versus a 7 watts rating for the 2N3053. I would therefore imagine that the 2N2222 SOA boundaries are quite a bit lower than those of the 2N3053. We note that the SOA curve of Q1 operating in this circuit moves outside of the DC operating boundary for the 2N3053 and thus, in all likelihood, it moves well outside of the 2N2222 equivalent limits.

Voltage and current excursions toward the upper right of this diagram are NOT a good thing.

The 2N2222 as used here can well be expected to fail, maybe sooner, maybe later, but it is set up for eventual calamity. Regardless of other factors that may apply to this design, remedial SOA measures should be considered.

The first is to reduce the capacitance of C1 (Figure 5).

Figure 5 The effects of reducing the capacitance of C1. Source: John Dunn

Using a smaller value of C1, or perhaps using no C1 at all, will lower the peak collector current and will make the switching events occur more quickly. This will take us away from the upper right corner of the SOA plot, and from that standpoint, this is a very good thing to do.

Adding R3, as shown in Figure 6, can also reduce the peak collector current.

Figure 6 The effects of including a collector resistance. Source: John Dunn

Although using R3 will slow down the C1 discharge rate for each discharge event, doing so will keep the peak collector current down, and that is a desirable SOA outcome.

If, for some reason, C1 has to be there, omitting R3 is not a good idea.

John Dunn is an electronics consultant and a graduate of The Polytechnic Institute of Brooklyn (BSEE) and of New York University (MSEE).

Related Content

- Safe operating area of linear MOSFETs extended

- SOA, Watts Up, Transistor?: A Mystery of Self-Destructing MOSFETs

- The application guides the MOSFET selection process

- Practical Considerations of Trench MOSFET Stability

The post Safe operating area appeared first on EDN.

A tutorial on instrumentation amplifier boundary plots—Part 2

The first installment of this series introduced the boundary plot, an often-misunderstood plot found in instrumentation amplifier (IA) datasheets. It also discussed various IA topologies: traditional three operational amplifier (op amp), two op amp, two op amp with a gain stage, current mirror, current feedback with super-beta transistors, and indirect current feedback.

Part 1 also included derivations of the internal node equations and transfer function of a traditional three-op-amp IA.

The second installment will introduce the input common-mode and output swing limitations of op amps, which are the fundamental building blocks of IAs. Modifying the internal node equations from Part 1 yields equations that represent each op amp’s input common-mode and output swing limitation at the output of the IA as a function of the device’s input common-mode voltage.

The article will also examine a generic boundary plot in detail and compare it to plots from device datasheets to corroborate the theory.

Op-amp limitations

For an op amp to output a linear voltage, the input signal must be within the device’s input common-mode range specification (VCM) and the output (VOUT) must be within the device’s output swing range specification. These ranges depend on the supply voltages, V+ and V– (Figure 1).

Figure 1 Op-amp input common-mode (green) and output swing (red) ranges depend on supplies. Source: Texas Instruments

Figure 2 depicts the datasheet specifications and corresponding VCM and VOUT ranges for an op amp, such as TI’ OPA188, given a ±15V supply. For this device, the output swing is more restrictive than the input common-mode voltage range.

Figure 2 Op-amp VCM and VOUT ranges are shown for a ±15 V supply of the OPA188 op amp. Source: Texas Instruments

The boundary plot

The boundary plot for an IA is a representation of all internal op-amp input common-mode and output swing limitations. Figure 3 depicts a boundary plot. Operating outside the boundaries of the plot violates at least one input common-mode or output swing limitation of the internal amplifiers. Depending on the severity of the violation, the output waveform may depict anything from minor distortion to severe clipping.

Figure 3 Here is how an IA boundary plot looks like for the INA188 instrumentation amplifier. Source: Texas Instruments

This plot is specified for a particular supply voltage (VS = ±15 V), reference voltage (VREF = 0 V), and gain of 1 V/V.

Figure 4 illustrates the linear output range given two different input common-mode voltages. For example, if the common-mode input of the IA is 8 V, the output will be valid only from approximately –11 V to +11 V. If the common-mode input is mid supply (0 V), however, an output swing of ±14.78 V is available.

Figure 4 Output voltage range is shown for different common-mode voltages. Source: Texas Instruments

Notice that the VCM (blue arrows) ranges from –15 V to approximately +13.5 V. Both the mid-supply output swing and VCM ranges are consistent with the op-amp ranges depicted in Figure 2.

Each line in the boundary plot corresponds to a limitation—either VCM or VOUT—of one of the three internal amplifiers. Therefore, it’s necessary to review the internal node equations first derived in Part 1. Figure 5 depicts the standard three-op-amp IA, while Equations 1 through 6 define the voltage at each internal node.

Figure 5 Here is how a three-op-amp IA looks like. Source: Texas Instruments

(1) (2)

(2)  (3)

(3)  (4)

(4)  (5)

(5)  (6)

(6) ![]() In order to plot the node equation limits on a graph with VCM and VOUT axes, solve Equation 6 for VD, as shown in Equation 7:

In order to plot the node equation limits on a graph with VCM and VOUT axes, solve Equation 6 for VD, as shown in Equation 7:

(7)

Substituting Equation 7 for VD in Equations 1 through 6 and solving for VOUT yields Equations 8 through 13. These equations represent each amplifier’s input common-mode (VIA) and output (VOA) limitation at the output of the IA, and as a function of the device’s input common-mode voltage.

(8) ![]()

(9) ![]()

(10) ![]()

(11) ![]()

(12) ![]()

(13)

One important observation from Equations 8 and 9 is that the IA limitations from the common-mode range of A1 and A2 depend on the gain of the input stage, GIS. These output limitations do not depend on GIS, however, as shown by Equations 11 and 12.

Plotting each of these equations for the minimum and maximum input common-mode and output swing limitations for each op amp (A1, A2 and A3) yields the boundary plot. Figure 6 depicts a generic boundary plot. The linear operation of the IA is the interior of all plotted equations.

Figure 6 Here is an example of a generic boundary plot. Source: Texas Instruments

The dotted lines in Figure 6 represent the input common-mode limitations for A1 (blue) and A2 (red). Notice that the slope of the dotted lines depends on GIS, which is consistent with Equations 8 and 9.

Solid lines represent the output swing limitations for A1 (blue), A2 (red) and A3 (green). The slope of these lines does not depend on GIS, as shown by Equations 11 through 13.

Figure 6 doesn’t show the line for VIA3 because the R2/R1 voltage divider attenuates the output of A2; A2 typically reaches the output swing limitation before violating A3’s input common-mode range.

The lines plotted in quadrants one and two (positive common-mode voltages) use the maximum input common-mode and output swing limits for A1 and A2, whereas the lines plotted in quadrants three and four (negative common-mode voltages) use the minimum input common-mode and output swing limits.

Considering only positive common-mode voltages from Figure 6, Figure 7 depicts the linear operating region of IA when G = 1 V/V. In this example, the input common-mode limitation of A1 and A2 is more restrictive than the output swing.

Figure 7 The input common-mode range limit of A1 and A2 defines the linear operation region when G = 1 V/V. Source: Texas Instruments

Increasing the gain of the device changes the slope of VIA1 and VIA2 (Figure 8). Now both the input common-mode and output swing limitations define the linear operating region.

Figure 8 The input common-mode range and output swing limits of A1 and A2 define the linear operating range when G > 1 V/V. Source: Texas Instruments

Regardless of gain, the output swing always limits the linear operating region when it’s more restrictive than the input common-mode limit (Figure 9).

Figure 9 The output swing limit of A1 and A2 define the linear operating region independent of gain. Source: Texas Instruments

Datasheet examples

Figure 10 illustrates the boundary plot from the INA111 datasheet. Notice that the output swing limit of A1 and A2 define the linear operating region. Therefore, the output swing limitations of A1 and A2 must be equal to or more restrictive than the input common-mode limitations.

Figure 10 Boundary plot for the INA111 instrumentation amplifier shows output swing limitations. Source: Texas Instruments

Figure 11 depicts the boundary plot from the INA121 datasheet. Notice that the linear operating region changes with gain. At G = 1 V/V, the input common mode must limit the linear operating region. However, as gain increases, the linear operating region is limited by both the output swing and input common-mode limitations (Figure 8).

Figure 11 Boundary plot is shown for the INA121 instrumentation amplifier. Source: Texas Instruments

Third installment coming

The third installment of this series will explain how to use these equations and concepts to develop a tool that automates the drawing of boundary plots. This tool enables you to adjust variables such as supply voltage, reference voltage, and gain to ensure linear operation for your application.

Peter Semig is an applications manager in the Precision Signal Conditioning group at TI. He received his bachelor’s and master’s degrees in electrical engineering from Michigan State University in East Lansing, Michigan.

Related Content

- Instrumentation amplifier input-circuit strategies

- Discrete vs. integrated instrumentation amplifiers

- New Instrumentation Amplifier Makes Sensing Easy

- Instrumentation amplifier VCM vs VOUT plots: part 1

- Instrumentation amplifier VCM vs. VOUT plots: part 2

The post A tutorial on instrumentation amplifier boundary plots—Part 2 appeared first on EDN.

20 Years of EEPROM: Why It Matters, Needed, and Its Future

ST has been the leading manufacturer of EEPROM for the 20th consecutive year. As we celebrate this milestone, we wanted to reflect on why the electrically erasable programmable read-only memory market remains strong, the problems it solves, why it still plays a critical role in many designs, and where we go from here. Indeed, despite the rise in popularity of Flash, SRAM, and other new memory types, EEPROM continues to meet the needs of engineers seeking a compact, reliable memory. In fact, over the last 20 years, we have seen ST customers try to migrate away from EEPROM only to return to it with even greater fervour.

Why companies choose EEPROM today? Granularity Understanding EEPROM

Understanding EEPROM

One of the main advantages of electrically erasable programmable read-only memory is its byte-level granularity. Whereas writing to other memory types, like flash, means erasing an entire sector, which can range from many bytes to hundreds of kilobytes, depending on the model, an EEPROM is writable byte by byte. This is tremendously beneficial when writing logs, sensor data, settings, and more, as it saves time, energy, and reduces complexity, since the writing operation requires fewer steps and no buffer. For instance, using an EEPROM can save significant resources and speed up manufacturing when updating a calibration table on the assembly line.

PerformanceThe very nature of EEPROM also gives it a significant endurance advantage. Whereas flash can only support read/write cycles in the hundreds of thousands, an EEPROM supports millions, and its data retention is in the hundreds of years, which is crucial when dealing with systems with a long lifespan. Similarly, its low peak current of a few milliamps and its fast boot time of 30 µs mean it can meet the most stringent low-power requirements. Additionally, it enables engineers to store and retrieve data outside the main storage. Hence, if teams are experiencing an issue with the microcontroller, they can extract information from the EEPROM, which provides additional layers of safety.

ConvenienceThese unique abilities explain why automotive, industrial, and many other applications just can’t give up EEPROM. For many, giving it up could break software implementation or require a significant redesign. Indeed, one of the main advantages of EEPROM is that they fit into a small 8-pin package regardless of memory density (from 1 Kbit to 32 Mbit). Additionally, they tolerate high operating temperatures of up to 145 °C for serial EEPROM, making them easy to use in a wide range of environments. The middleware governing their operations is also significantly more straightforward to write and maintain, given their operation.

ResilienceSince ST controls the entire manufacturing process, we can provide greater guarantees to customers facing supply chain uncertainties. Concretely, ST offers EEPROM customers a guarantee of supply availability through our longevity commitment program (10 years for industrial-grade products, 15 years for automotive-grade). This explains why, 40 years after EEPROM development began in 1985 and after two decades of leadership, some sectors continue to rely heavily on our EEPROMs. And why new customers seeking a stable long-term data storage solution are adopting it, bolstered by ST’s continuous innovations, enabling new use cases.

Why will the industry need EEPROM tomorrow? More storage EEPROM vs. Page EEPROM

EEPROM vs. Page EEPROM

Since its inception in the late 70s, EEPROM’s storage has always been relatively minimal. In many instances, it is a positive feature for engineers who want to reserve their EEPROM for small, specific operations and segregate it from the rest of their storage pool. However, as serial EEPROM reached 4 Mbit and 110 nm, the industry wondered whether the memory could continue to grow in capacity while shrinking process nodes. A paper published in 2004 initially concluded that traditional EEPROMs “scale poorly with technology”. Yet, ST recently released a Page EEPROM capable of storing 32 Mbit that fits inside a tiny 8-pin package.

The Page EEPROM adopts a hybrid architecture, meaning it uses 16-byte words and 512-byte pages while retaining the ability to write at the byte level. This offers customers the flexibility and robustness of traditional EEPROM but bypasses some of the physical limitations of serial EEPROM, thus increasing storage and continuing to serve designs that rely on this type of memory while still improving endurance. Indeed, a Page EEPROM supports a cumulative one billion cycles across its entire memory capacity. For many, Page EEPROMs represent a technological breakthrough by significantly expanding data storage without changing the 8-pin package size. That’s why we’ve seen them in asset tracking applications and other IoT applications that run on batteries.

New featuresST also recently released a Unique ID serial EEPROM, which uses the inherent capabilities of electrically erasable programmable read-only memory to store a unique ID or serial number to trace a product throughout its assembly and life cycle. Usually, this would require additional components to ensure that the serial number cannot be changed or erased. However, thanks to its byte-level granularity and read-only approach, the new Unique ID EEPROM can store this serial number while preventing any changes, thus offering the benefits of a secure element while significantly reducing the bill of materials. Put simply, the future of EEPROM takes the shape of growing storage and new features.

The post 20 Years of EEPROM: Why It Matters, Needed, and Its Future appeared first on ELE Times.