Feed aggregator

ROHM adds compact top-view types to surface-mount near-infrared LED portfolio

Hot swap basics: Controllers, schematics, and design examples

How does a hot swap circuit work? What’s the role of a hot swap controller? What are the basic design considerations for selecting a hot swap controller or module? Here is a short tutorial explaining the inner functioning a hot swap device while outlining key design challenges. It also includes hot swap circuit schematics and design examples.

Read the full article at EDN’s sister publication, Planet Analog.

Related Content

- Making the Switch

- Introduction to Hot Swap

- Telecom hardware needs hot swap

- Hot-swap controllers: A programmable approach

- How does hot-swap capability improve isolated I2C interface?

The post Hot swap basics: Controllers, schematics, and design examples appeared first on EDN.

Singapore’s A*STAR’s inaugural Innovate Together event launches first industry-grade 200mm silicon carbide Open R&D Line

I know this is beating a dead horse, but this is ridiculous

| 2 orders, months apart. difference is one board is assembled. shipping went from $2 to $80. What the actual heck (no stencil, gust the boards with some smt components) [link] [comments] |

Single PCB Electronic Dice and Slot-Machine for trial apprentices

| Hey r/electronics, Sharing my final project for the third year as an apprentice, an electronic dice and slot-machine for trial apprentices. The main challenge was the multiplexing of the matrix and the logic behind it. It uses an AVR64DD14 to drive a 3x3 LED matrix (multiplexed) and reads a tilt sensor for shake detection. Powered by a 3V coin cell. Includes a basic dice function and a slot machine game, with potential for more animations. We're using a mix of THT and SMD components, aiming for beginner-friendly soldering. Its my first post here so if you want to know anything more about the project, please let me know! Submission is tomorrow, wish me luck :) [link] [comments] |

Освітньо-навчальна сесія в рамках проєкту «Єдиний простір»

У КПІ ім. Ігоря Сікорського відбулася освітньо-навчальна сесія в рамках проєкту «Єдиний простір», який реалізує благодійна організація «Побачимо Перемогу».

Всеукраїнська шкільна олімпіада «ЕкоГеній» в КПІ ім. Ігоря Сікорського

Всеукраїнська шкільна олімпіада «ЕкоГеній» в КПІ ім. Ігоря Сікорського на базі Навчально-наукового інституту енергозбереження та енергоменеджменту (НН ІЕЕ)

📰 Газета "Київський політехнік" № 21-22 за 2025 (.pdf)

Вийшов 21-22 номер газети "Київський політехнік" за 2025 рік

Platform helps secure in-vehicle connectivity

NXP’s OrangeBox 2.0 automotive connectivity domain controller features an upgraded CPU and embedded AI acceleration. This second-generation development platform facilitates secure connectivity between the vehicle’s gateway and its wired and wireless systems in domain- and zonal-based architectures.

Powered by the i.MX 94 applications processor, OrangeBox 2.0 delivers 4× the CPU performance of its predecessor. The processor integrates four Arm Cortex-A55 cores, two Cortex-M7 cores, two Cortex-M33 cores, and the NXP eIQ Neutron NPU. It also adds post-quantum cryptography acceleration along with enhanced AI, safety, and security capabilities. An integrated 2.5-Gbps Ethernet switch enables software-defined networking and supports the shift to software-defined vehicles (SDVs).

OrangeBox 2.0 builds on its predecessor with integrated NXP wireless technologies, including the SAF9100 for software-defined audio and the AW693 for concurrent Wi-Fi 6E and Bluetooth 5.4 to enable secure over-the-air updates. It supports smart car access via NXP’s latest BLE/UWB technology and an automotive-grade secure element.

The OrangeBox 2.0 automotive development platform is expected to be available in the second half of 2025.

The post Platform helps secure in-vehicle connectivity appeared first on EDN.

MCU enables neuromorphic processing at the edge

As Innatera’s first mass-market neuromorphic MCU, Pulsar delivers intelligence at the edge by emulating the brain’s neural networks. It uses Spiking Neural Networks that process only changes in input—enabling real-time decision making with significantly reduced energy and latency. According to Innatera, Pulsar achieves up to 100× lower latency and 500× lower energy consumption compared to conventional AI processors.

The Pulsar chip combines neuromorphic computing with conventional signal processing. In addition to its Spiking Neural Networks (SNNs), it integrates a RISC-V CPU and dedicated accelerators for Convolutional Neural Networks (CNNs) and Fast Fourier Transform (FFT). By processing data intelligently at the sensor level, Pulsar reduces reliance on power-hungry edge processors or cloud infrastructure for interpreting sensor input.

With sub-milliwatt power consumption, Pulsar enables always-on intelligence in power-constrained devices—from sub-millisecond gesture recognition in wearables to energy-efficient object detection in smart home systems. It provides real-time responsiveness with power budgets as low as 600 µW for radar-based presence detection and 400 µW for audio scene classification.

Pulsar is available now, supported by Innatera’s Talamo SDK for neuromorphic application development.

The post MCU enables neuromorphic processing at the edge appeared first on EDN.

PSU combines GaN and SiC for hyperscale AI

Navitas announced a production-ready 12-kW PSU reference design that achieves 97.8% efficiency for hyperscale AI data centers with 120-kW rack densities. The design incorporates three-phase interleaved TP-PFC and FB-LLC stages, implemented using Gen-3 Fast SiC MOSFETs and 4th-generation high-power GaNSafe ICs, respectively. The GaNSafe ICs integrate control, drive, sensing, and essential protection functions, while IntelliWeave digital control enhances overall performance.

IntelliWeave uses a hybrid strategy combining Critical Conduction Mode (CrCM) and Continuous Conduction Mode (CCM) to optimize efficiency from light to full load. This approach simplifies the design, reduces component count, and lowers power losses by 30% compared to conventional CCM-only solutions.

The PSU meets Open Rack v3 (ORv3) and Open Compute Project (OCP) standards, with dimensions of 790×73.5×40 mm. It operates from 180 VAC to 305 VAC and delivers up to 50 VDC, supplying 12 kW above 207 VAC and 10 kW below. Features include active current sharing and protection against overcurrent, overvoltage, undervoltage, and overtemperature. It operates from –5°C to +45°C, provides ≥20 ms hold-up time at 12 kW, and limits inrush current to ≤3× steady-state current for <20 ms. Cooling is provided by an internal fan.

For more information about the 12-kW PSU reference design, click here.

The post PSU combines GaN and SiC for hyperscale AI appeared first on EDN.

Toshiba shrinks SiC MOSFETs with DFN package

Toshiba has released four 650-V third-generation SiC MOSFETs in compact 8×8-mm DFN packages. The surface-mount DFN reduces volume by over 90% compared to leaded packages such as TO-247 (3-terminal) and TO-247-4L(X) (4-terminal). It also enables smaller parasitic impedance components, helping to lower switching losses.

The package’s flat, leadless design enables a Kelvin connection for the gate-drive signal-source terminal, minimizing source wire inductance. This improves switching speed and efficiency. For example, the TW054V65C achieves about 55% lower turn-on loss and 25% lower turn-off loss compared to Toshiba’s existing products.

Well-suited for industrial applications, the devices can be used for switch-mode power supplies, EV charging stations, and photovoltaic inverters. Key specifications include:

Toshiba has begun volume shipments of the TW031V65C, TW054V65C, TW092V65C, and TW123V65C 650-V SiC MOSFETs in the 8×8-mm DFN package.

Toshiba Electronic Devices & Storage

The post Toshiba shrinks SiC MOSFETs with DFN package appeared first on EDN.

PCIe card provides FPGA-based data acceleration

Powered by the Achronix Speedster 7t1500 FPGA, the VectorPath 815 PCIe accelerator card meets the performance demands of AI and HPC workloads. Speedster FPGAs integrate machine learning processors to deliver a massively parallel architecture, customizable data paths, and efficient processing of sparse and irregular computations.

“The VectorPath 815 card delivers greater than 2000 tokens per second with 10-ms inter-token latency (LLAMA 3.1-8B Instruct) for unmatched generative AI inferencing performance — enabling customers to accelerate bandwidth-intensive, low-latency applications with a greater than 3× total cost of ownership (TCO) advantage vs. competitive GPU solutions,” said Jansher Ashraf, director of AI Solutions Business Development at Achronix.

The Speedster 7t1500 FPGA features 2560 machine learning processors, a 2D network-on-chip, 692k LUTs, and 32 SerDes lanes supporting PCIe Gen5 ×16 and dual 400G Ethernet. The VectorPath 815 card builds on this by integrating 32 GB of GDDR6 memory for 4-Tbps bandwidth, 16 GB of DDR4 memory, dual QSFP-DD ports, and a PCIe Gen5 interface.

VectorPath 815 accelerator cards are now in volume production.

The post PCIe card provides FPGA-based data acceleration appeared first on EDN.

NUBURU reveals TEKNE as targeted defense-tech acquisition

eevBLAB 128 - Why Dont I Go OFF-GRID Solar/Battery?

Altum RF showcasing products and expertise at IMS 2025

KLA opens $138m R&D and manufacturing facility in Newport, Wales

TEG energy harvesting: hype or hope?

I like to follow energy-harvesting research developments and actual installations, as there are many creative approaches and useful applications. In many cases, harvesting has solved a power-source problem effectively and with reasonable cost versus benefit.

At the same time, however, I see energy harvesting as often being oversold at best and overhyped at worst. There’s a real glow with the concept of getting something for (almost) nothing that is often associated with it, when the harsh reality is you may be getting very little energy for a much higher cost and complexity than what was promoted. That tradeoff may be acceptable if you are desperate or have no viable alternative, but often that is not the case.

Perhaps the strangest non-conventional harvesting scheme I saw was a specialized coating that could be applied as wall paint (see References 1 and 2). That coating used humidity in the air to harvest energy, with the speculative projections that maybe you could power a house using this paint. Of course, beyond the obvious issues of physical-connection wiring, there was the near-trivial actual available output. The power density output of 0.0001-0.05 watts/meter2 was quite modest (to be polite) in both absolute and relative terms and certainly wouldn’t power your house or even a smartphone.

Tailpipe TEGA good example of a more practical harvesting arrangement is a recent thermoelectric generator (TEG) story I saw in the Wall Street Journal, of all places (Reference 3). A research team at Pennsylvania State University developed a TEG that fits into the exhaust tailpipe of an internal combustion engine (ICE) vehicle and uses the exhaust waste heat to generate up to about 40 watts (Figure 1).

Figure 1 (a) 3D schematic diagram of the TEG system. The geometry of the exhaust gas pipeline can vary. (b) Power (P) and (c) power density (ω) for automobile and high-speed object conditions. Source: Pennsylvania State University

Figure 1 (a) 3D schematic diagram of the TEG system. The geometry of the exhaust gas pipeline can vary. (b) Power (P) and (c) power density (ω) for automobile and high-speed object conditions. Source: Pennsylvania State University

While that’s enough to power or recharge a small electronic device, it’s a fairly modest amount of power in the context of the power of the engine of a car, small airplane, or helicopter. One of their claimed innovations in this implementation is that it is optimized to work better when there is cooling airflow around the moving tailpipe, yielding a larger temperature differential and thus greater output. The design has been modeled, a prototype built and tested, and the collected data is in line with the expectations (Reference 4).

So far, so good. But then it the storyline goes into what I call extrapolation mode, as the “free energy” and “something for almost nothing” aspects start to overtake reality. How much does this harvester cost as a single unit, or perhaps as a mass-produced item? How long will it last in the tailpipe, which is a harsh environment? What’s the effect on engine exhaust flow and back pressure? What’s the developed energy density, by weight and volume?

The WSJ reporter covering this story seemed to be a non-technical journalist who basically repeated what the researchers said—which is certainly a valid starting point—but didn’t ask any follow-up questions. That’s the problem with most energy-harvesting stories, especially the free-heat TEG ones: they are so attractive and feel-good in concept that the realities of the design and installation are not brought up in polite conversation while the benefits are touted.

I’m not saying that this TEG harvesting scheme is of no value. It may, in fact, be useful in specific and well-defined situations. There are many examples of viable waste-heat recovery installations in industrial, commercial, and residential settings to prove that point. But as will all designs, there are hard and soft costs as well as short- and long-term implications that shouldn’t be ignored.

Small-scale TEGThere are also smaller-scale TEG-type harvesting success stories out there. For example, for many decades, gas-fired home water heaters used their own always-pilot light (no longer allowed in many places due to energy mandates) to heat an array of thermocouples. This array then provided power to activate and turn on the gas valve and ignite the gas to heat the water in the tank (Figure 2).

If the pilot light was out for any reason, turning on the gas valve to heat that water would be extremely dangerous. However, the gas-heated thermocouple system is self-protecting and fail-safe: in the absence of that pilot light that ignites the gas and heats the thermocouples, there is no power to actuate the valve, thus the gas flow would be shut off. As an additional benefit, no electrical wiring of any type was needed by the water heater. It was a plumbing-only (water and gas) installation with no external electricity needed.

Figure 2 This schematic of a gas-fired water heater shows the bottom thermocouple assembly whose electrical output controls fail-safe actuation for the gas-flow valve. Source: All Trades Las Vegas

Harvesting hubbubMy sense is that harvesting gets so much favorable attention because it is so relatable and appears to offer no/low-cost benefits with little downside, at least at first glance. There’s little doubt that the multifaceted attraction of TEG and other energy-harvesting approaches attracts a lot of positive attention and media coverage, as this one did. That’s a big plus for these researchers as they look for that next grant.

Engineers know that reality is usually different. When it comes to generating, capturing, and using energy and power, the old cliché that “there’s no such thing as a free lunch” usually applies. The real question is the cost of that lunch.

Have you used TEG-based harvesting in any project? What were the expected and unexpected issues and benefits? Did you stick with it, or do you have to go with another approach?

Bill Schweber is an EE who has written three textbooks, hundreds of technical articles, opinion columns, and product features.

Related Content

- Niche Energy Harvesting: Intriguing, Innovative, Probably Impractical

- Underwater Energy Harvesting with a Data-Link Twist

- Clever harvesting scheme takes a deep dive, literally

- Is triboelectricity the next harvesting source?

- Tilting at MEMS Windmills for Energy Harvesting?

- Energy harvesting gets really personal

- Lightning as an energy harvesting source?

References

- Nature, “Generic Air-Gen Effect in Nanoporous Materials for Sustainable Energy Harvesting from Air Humidity”

- Nature, Supplement to “Generic Air-Gen Effect in Nanoporous Materials for Sustainable Energy Harvesting from Air Humidity”

- The Wall Street Journal, April 18, 2025, “The Heat Coming Out of Your Car’s Tailpipe? Some Can Be Turned Into Electricity”

- ACS Applied Materials & Interfaces, January 7, 2025, “Thermoelectric Energy Harvesting for Exhaust Waste Heat Recovery: A System Design” (behind paywall, but it is also posted here at ResearchGate)

The post TEG energy harvesting: hype or hope? appeared first on EDN.

Fraunhofer ISE and III/V-Reclaim develop 150mm InP-on-GaAs substrates that can replace prime InP wafers

Nuvoton Releases 4th Generation of “Gerda,” the Automotive HMI Display IC Series in 3 Variants

Nuvoton Technology Corporation Japan (NTCJ) will start a series production of automotive

HMI display IC “Gerda”, 4th generation, which are 3 types (Gerda-4M/ Gerda-4L/ Gerda-4C).

This lineup features image processing technology, security, and display safety functions for the various HMI devices which are progressing under expectation to support the higher level of safety requirement. And it contributes to realizing the HMI solutions which enhance vehicle safety and comfort.

Achievements:

- By producing the high visibility of interior display utilities such as electronic mirrors, AR-HUD, and cluster meters, “Gerda” assists comfort and fatigue-resistant safe driving by system.

- By high-speed and large capacity memory built in “Gerda” allows customers to develop the high-functional HMI systems with advanced display capability without external memory at reasonable cost in system.

- “Gerda” features OTA (Over-The-Air software updating) and secure boot functions, and contributes to the safe and comfort systems by mitigating the risks of on-vehicle cyber security and supporting the functional safety level ASIL-B.

Features:

- Refined visibility and comfort of HMI equipment is realized with unique image processing engine.

Our video processing technology is ideal for electronic mirrors, AR-HUDs, and cluster meters, which are becoming widely spread due to digitization of equipment installed in cars, to create a safe and comfortable driving environment.

– Features for electronic mirrors

The issue with conventional e-mirrors had issues with reduced visibility, especially in night time camera images, due to glare caused by headlight light and white blown out/blacked out due to big gap in brightness.

With Gerda-4M, it is possible to improve the visibility by adjusting the picture contrast locally, in response to the brightness distribution by area (“local contrast” function), can be achieved with low-latency processing of 1 frame.

– Features for AR-HUD

It is essential with AR-HUD that the display naturally kept shown in the driver’s eyesight by harmonizing the displayed contents to the windshield shape.

For this, displaying image needs to be projected in low latency, and flexible deformed to fit the windshield. Image warping engine allows free deformation to fit the screen at lower latency than 1 frame. And it supports “dual projection HUD” with single chip, which both 2 images are projected in near and far focuses.

– Features for cluster meters

It is essential with cluster-meter that multiple assisting information is conducted to drivers accurately and intuitively. And its design needs to flexibly match the interior. Nuvoton’s Gerda has 2.5D GFX engine which allows customers to design the screen with cubic effects like depth and shades added to the design by 2D objects. It provides the display with higher visibility and contributes to the accurate decision of drivers. And by combination with the image compression engine, displaying images at as high resolution as WXGA@60FPS which enables the higher-grade cockpit design.

- Multi-functional HMI system is realized at reduced system cost with built-in high speed/ large size memory.

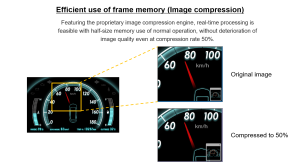

In general, construction of high-performance HMI systems requires external memories the system. Nuvoton’s lineup of Gen.4 is embedded with the memory of high speed and large capacity, which makes external memory unnecessary, and contributes to reduce the component counts and system cost. And Gerda-4L has built-in the dedicated image compression engine which enables the real-time processing at half memory usage than normal use, and it realizes high resolution image display as WXGA@60FPS only with the built-in memory.

- Supporting Functional Safety ASIL-B, and contributing to the risk mitigation of vehicle cyber security

Gen.4 Gerda features the display safety functions as video signal monitoring, alert display monitoring etc., and contributes to realize the system of Functional Safety ASIL-B by supporting the functions as fail-safe, real-time monitoring. And the built-in HSM which supports EVITA-Full achieves the software update via network (OTA) and secure boot, which allows only trusted software to boot up. It helps to mitigate the risk of vehicle cyber security.

NTCJ developed the 3 types of 4th generation of HMI display IC “Gerda” series which is equipped with a wide range of image processing technologies and advanced security functions and has started its mass production.

The post Nuvoton Releases 4th Generation of “Gerda,” the Automotive HMI Display IC Series in 3 Variants appeared first on ELE Times.