Feed aggregator

Календар вступника КПІ

Слідкуйте за подіями щодо вступу до КПІ ім. Ігоря Сікорського в спеціальному гугл-календарі.

This mini DSO I got in the mail recently!

| submitted by /u/BlownUpCapacitor [link] [comments] |

📖 Конкурс на здобуття премій КПІ ім. Ігоря Сікорського за кращі видання

📢 Національний технічний університет України “Київський політехнічний інститут імені Ігоря Сікорського” оголошує конкурс на здобуття премій КПІ ім. Ігоря Сікорського за кращі видання.

📆 Термін подання документів до 15 квітня 2025 р.

Three discretes suffice to interface PWM to switching regulators

It’s remarkable how many switching regulator chips use the same basic two-resistor network for output voltage programming. Figure 1 illustrates this feature in a typical (buck type) regulator. See R1 and R2 where:

Vout = Vsense(R1/R2 + 1) = 0.8v(11.5 + 1) = 10v

Figure 1 A typical regulator output programming network with a basic two-resistor network for output voltage programming.

Figure 1 A typical regulator output programming network with a basic two-resistor network for output voltage programming.

Wow the engineering world with your unique design: Design Ideas Submission Guide

Quantitatively, the Vsense feedback node voltage varies from type to type and recommended values for R1 can vary too, but the topology doesn’t. Most conform faithfully to Figure 1. This defacto uniformity is useful if your application needs digital control of Vout via PWM.

Figure 2 shows the simplistic three-component solution it makes possible where:

Vout = Vsense(R1/(R2 + R3/DF) + 1) = 0.8v to 10v as DF = 0 to 1

All that’s required to add PWM control to Figure 1 is to split R2 into two equal halves, connect filter cap Cf to the middle of the pair, and add PWM switch Q1 in series with its ground end.

Figure 2 Simple circuit for regulator programming with PWM where Vout ranges from 0.8 V to 10 V as the duty factor (DF) goes from 0 to 1.

The Cf capacitance required for 1-lsb PWM ripple attenuation is 2(N-2)Tpwm/R2, where N is number of PWM bits and Tpwm is the PWM period. Since Cf will never see more than perhaps a volt, its voltage rating isn’t much of an issue.

A cool feature of this simple topology is that, unlike many other schemes for digital power supply control, only the regulator’s internal voltage reference matters to regulation accuracy. Precision is therefore independent of external voltage sources, e.g. logic rails. This is a good thing because, for example, the tempco of the TPS54332’s reference is only 15 ppm/oC.

Figure 3 graphs Vout versus the PWM DF for the Figure 2 circuit where the X-axis is DF, the Y-axis is Vout and,

Vout = Vsense(R1/(R2 + R3/DF) + 1)

Vout(min) = Vsense

Vout(max) = Vsense(R1/(R2 + R3) + 1)

R1/(R2 + R3) = Vout(max)/Vsense – 1

Figure 3 Graph showing Vout versus the Figure 2 PWM DF.

Figure 4 plots the inverse function with DF vs Vout where,

DF = R3/(R1/(Vout/Vsense – 1) – R2)

The nonlinearity of DF versus Vout does incur the cost of a bit of software complexity (two subtractions and three divisions) to do the conversion. But since it buys substantial circuitry simplification, it seems a reasonable (maybe zero) cost. Or, if the necessary memory is available, a lookup table is another (simple!) possibility.

Figure 4 DF versus Vout; the non-linearity necessitates a bit of software complexity to perform the conversion.

Stephen Woodward’s relationship with EDN’s DI column goes back quite a long way. Over 100 submissions have been accepted since his first contribution back in 1974.

Related Content

- Add one resistor to allow DAC control of switching regulator output

- Improve thermal airflow sensor PSRR with just two resistors

- Add one resistor to give bipolar LM555 oscillator a 50:50 duty cycle

- Peculiar precision full-wave rectifier needs no matched resistors

The post Three discretes suffice to interface PWM to switching regulators appeared first on EDN.

Compound semiconductor market growing at nearly 13% CAGR to $25bn by 2030

Real (left) vs Fake (right) ST mosfets

| Left one is bought from Mouser for about 6$ each and the right one was less than 1$ from Alibaba. Right one couldnt handle 200V drain to source. While its rated for 600V. I know they are not the same part but watch out for culprits when buying mosfets. I read some legit suppliers got fake ICs back when there was silicon shortage. [link] [comments] |

Understanding Reflow Soldering: Definition, Process, Working, Uses & Advantages

Reflow soldering is a widely used technique in electronics manufacturing for assembling surface-mount devices (SMDs) onto printed circuit boards (PCBs). This method involves applying solder paste to the board, placing components on top of it, and then heating the assembly in a controlled manner to melt and solidify the solder. The process ensures strong and reliable solder joints, making it a preferred method for mass production in the electronics industry.

Unlike wave soldering, which is typically used for through-hole components, reflow soldering is designed for SMDs, allowing for higher component density and miniaturization of electronic circuits. The precision and efficiency of reflow soldering make it ideal for modern electronic manufacturing, where consistency and high reliability are critical.

How Reflow Soldering WorksThe reflow soldering process consists of several carefully controlled stages to ensure optimal soldering results. Each stage plays a crucial role in preventing defects such as solder bridging, tombstoning, or incomplete solder joints. The main steps include:

- Solder Paste Application

The process begins with the application of solder paste, a mixture of powdered solder alloy and flux, onto the PCB. This is typically done using a stencil and a squeegee to ensure uniform deposition. The accuracy of solder paste application is critical as it determines the quality of the solder joints.

- Component Placement

Once the solder paste is applied, surface-mount components are carefully placed on the PCB using automated pick-and-place machines. These machines use vision systems to precisely position components, ensuring alignment with the solder paste deposits.

- Preheating Stage

The assembled board is then gradually heated in a reflow oven. The preheating stage raises the temperature of the PCB and components at a controlled rate to prevent thermal shock. This phase also activates the flux in the solder paste, which removes oxidation and improves wetting.

- Thermal Soaking

After preheating, the PCB enters a thermal soaking phase where the temperature is maintained at a specific range to ensure uniform heat distribution. This helps in stabilizing the components and further activating the flux.

- Reflow Zone (Peak Temperature Stage)

In this stage, the temperature reaches its peak, typically between 220°C and 250°C, depending on the solder alloy used. This is the critical moment where the solder paste melts, creating reliable electrical and mechanical connections between the components and the PCB.

- Cooling Phase

Once the solder has melted and formed solid connections, the PCB is gradually cooled in a controlled manner. Controlled cooling prevents thermal stress and ensures the formation of strong, defect-free solder joints.

Reflow Soldering Uses & ApplicationsReflow soldering is widely used in various industries, primarily in the manufacturing of electronic devices. Some key applications include:

- Consumer Electronics: Smartphones, laptops, tablets, and gaming consoles all rely on reflow soldering to ensure compact and efficient circuit assemblies.

- Automotive Electronics: Modern vehicles contain complex electronic systems, including engine control units (ECUs), infotainment systems, and safety sensors, all of which use SMD technology and reflow soldering.

- Medical Devices: High-precision medical equipment, such as diagnostic devices and portable health monitors, require reliable soldering for seamless functionality.

- Industrial Electronics: Industrial automation, control systems, and robotics benefit from reflow soldering due to its ability to create robust and durable electronic circuits.

- Aerospace & Defense: High-reliability electronics for satellites, avionics, and defense applications depend on precise and high-quality soldering techniques like reflow soldering.

Reflow soldering offers several advantages that make it the preferred method for assembling SMD components:

- High Precision: Automated solder paste application and component placement result in accurate soldering with minimal defects.

- Consistency and Reliability: Controlled heating profiles ensure strong and uniform solder joints, reducing the chances of failure.

- Mass Production Efficiency: The process is highly automated and scalable, making it suitable for high-volume manufacturing.

- Compatibility with Small Components: Reflow soldering supports miniaturized electronics, enabling the development of compact and lightweight devices.

- Improved Aesthetic and Functionality: Unlike wave soldering, reflow soldering does not leave excess solder, resulting in cleaner circuit boards with better electrical performance.

Despite its benefits, reflow soldering also has some limitations:

- Complex Equipment Requirements: Reflow ovens and pick-and-place machines are expensive, making the initial setup costly for small manufacturers.

- Component Sensitivity: Some temperature-sensitive components may get damaged if exposed to high temperatures during the reflow process.

- Risk of Defects: Issues such as tombstoning (where small components lift on one side) or solder bridging (where excess solder creates unintended connections) can occur if process parameters are not optimized.

- Limited Use for Through-Hole Components: While hybrid techniques exist, reflow soldering is primarily designed for surface-mount devices, requiring additional methods for through-hole components.

Reflow soldering is a highly efficient and precise method for assembling surface-mount components on PCBs. With applications ranging from consumer electronics to aerospace, it remains a crucial technique in modern electronic manufacturing. While the process requires careful temperature control and specialized equipment, its benefits in terms of reliability, efficiency, and scalability make it indispensable. As technology advances, improvements in solder paste formulations and reflow oven designs continue to enhance the effectiveness of reflow soldering, ensuring its relevance in the ever-evolving electronics industry.

The post Understanding Reflow Soldering: Definition, Process, Working, Uses & Advantages appeared first on ELE Times.

As a child, I made such an electronic canary using this circuit, and surprisingly everything worked.

| submitted by /u/nkaysss [link] [comments] |

Довідка про результати публічного громадського обговорення проєкту Професійного стандарту Професіонал з енергетичного менеджменту

Розробником Національним технічним університетом України «Київський політехнічний інститут імені Ігоря Сікорського» відповідно до Порядку розроблення, введення в дію та перегляду професійних стандартів, затвердженого постановою Кабінету Міністрів України від 31.05.2017 р. № 373 (далі – Порядок), завершено процес публічного громадського обговорення проєкту Професійного стандарту «Професіонал з енергетичного менеджменту».

Altum RF achieves ISO 9001 registration for Sydney design center

Top 10 3D Printer Manufacturers in India

India’s 3D printing industry has experienced significant growth, with numerous companies emerging as key players in the field. Here’s an overview of the top 10 3D printer manufacturers in India as of 2025:

- Divide By Zero Technologies

Established in 2013 and based in Maharashtra, Divide By Zero Technologies is a prominent 3D printer manufacturer catering to small and medium enterprises. The company aims to make 3D printing affordable and reliable, providing solutions to renowned clients such as Samsung, L’Oreal, GE Healthcare, Godrej, and Mahindra. Their product lineup includes models like Accucraft i250+, Aion 500 MK2, Aeqon 400 V3, and Alpha 500. Notably, their patented Advanced Fusion Plastic Modeling (AFPM) technology ensures consistent quality through intuitive automation.

- Make3D

Founded in 2014 in Gujarat, Make3D specializes in manufacturing 3D printers and scanners. Their Pratham series caters to both hobbyists and industrial users, featuring models like Pratham Mini and Pratham 6.0. They also offer the Eka Star DLP Printer and EinScan Pro 2X scanner. Committed to enhancing the accessibility of additive manufacturing, Make3D provides products known for quality and durability, alongside educational courses on 3D printing.

- Mekuva Technologies (POD3D)

Based in Hyderabad and established in 2021, Mekuva Technologies offers a range of 3D printers, including the AKAR series (300 Pro, 600 Basic, 200 Desktop, and 200 Pro). Beyond manufacturing, they provide services like 3D design, printing, scanning, CNC machining, sheet metal operations, and injection molding, serving as a comprehensive solution provider for various industries. Their printers are compatible with materials such as PLA, ABS, and carbon fiber.

- IMIK Technologies

Operating since 2007 in Tamil Nadu, IMIK Technologies supplies a wide range of 3D printers, including their own FDM printer, IMIK 3DP, and models from brands like Creality, Flashforge, and Ultimaker. They cater to sectors such as defense, textiles, robotics, agriculture, and medicine, offering products suitable for educational, industrial, and personal use. Additionally, they provide 3D prototyping services.

- Printlay

Established in 2015 in Tamil Nadu, Printlay specializes in 3D printing and scanning services. They assist clients from prototyping to end-use parts production, ensuring precision and accuracy. Their services extend to CNC machining and injection molding, catering to diverse industries with a reputation for quick turnaround times and quality service.

- A3DXYZ

Founded in 2018 in Maharashtra, A3DXYZ offers 3D printing services, including FDM printing, stereolithography, CAD modeling, digital light processing, and vacuum casting. They serve industries such as architecture, aerospace, healthcare, and medicine, and have introduced the A3DXYZ DS200 3D printer, known for its robust design and high-quality output.

- Boson Machines

Based in Maharashtra and established in 2017, Boson Machines is a leading 3D printing manufacturer utilizing technologies like FDM, SLA, and SLS. They offer services such as part production, injection molding, and CNC machining, providing comprehensive solutions from design to production.

- 3Ding

Operating since 2013 in Tamil Nadu, 3Ding supplies a variety of 3D printers, PCB printers, printing materials, and scanners. They distribute products from brands like 3D Systems, Fab X, Voltera, Formlabs, and Creality, and offer rental options. Their services include 3D design, printing, and scanning, along with workshops and training programs. They have branches in Chennai, Bangalore, Hyderabad, and Mumbai.

- Precious 3D

Established in 2017 in Tamil Nadu, Precious 3D offers 3D design, printing, CNC machining, and injection molding services. They utilize technologies like SLS, FDM, DLP, and Polyjet, serving industries such as automotive and healthcare. Their clientele includes brands like Renault, Ford, Verizon, and Nippon Paint, and they provide consultation services for material selection.

- Imaginarium

Based in Mumbai, Imaginarium stands as India’s largest 3D printing and rapid prototyping company. They offer design validation, prototyping, batch production, and various techniques such as SLA (Stereolithography), SLS (Selective Laser Sintering), VC (Vacuum Casting), CNC machining, injection molding, and scanning. Serving industries such as jewelry, automotive, and healthcare, Imaginarium utilizes 20 industrial 3D printers and 140 different materials, making them a key player in the field.

These companies exemplify the rapid advancement and diversification of India’s 3D printing industry, offering a wide range of products and services to meet the evolving needs of various sectors.

The post Top 10 3D Printer Manufacturers in India appeared first on ELE Times.

For some reason, I just love doing this fancy shit. No one will probably ever see the PCB except me lol

| submitted by /u/No_Pilot_1974 [link] [comments] |

ROHM launches 650V GaN HEMT in compact, high-heat-dissipation TOLL package

📢 Тиждень математики в КПІ ім. Ігоря Сікорського!

Тема Тижня математики в КПІ ім. Ігоря Сікорського у 2025 році - «Математика для всіх: математика, мистецтво та креативність»

🎥 Defense Expo Day в КПІ ім. Ігоря Сікорського

На початку травня спільно з Мінстратегпромом було проведено «Defense Expo Day. День кар'єри в оборонній сфері». Чудово, що саме наші студенти серед перших мають можливість спілкуватися з представниками провідних оборонних підприємства України, дізнаватися про можливості подальшої роботи у ОПК і допомоги державі!

How AI is changing the game for high-performance SoC designs

The need for intelligent interconnect solutions has become critical as the scale, complexity, and customizability of today’s systems-on-chip (SoC) continue to increase. Traditional network-on-chip (NoC) technologies have played a vital role in addressing connectivity and data movement challenges, but the growing intricacy of designs necessitates a more advanced approach. Especially, when high-end SoC designs are surpassing the human ability to create NoCs without smart assistance.

The key drivers for this demand can be summarized as follows:

- Application-specific requirements: Many industries and applications, such as automotive, Internet of Things (IoT), consumer electronics, artificial intelligence (AI), and machine learning (ML), require highly specialized hardware tailored to unique workloads, such as real-time processing, low latency, or energy efficiency. Off-the-shelf chips often fall short of providing the precise blend of performance, power, and cost-efficiency these applications need.

- Cost and performance optimization: Custom SoCs allow companies to integrate multiple functions into a single chip, reducing system complexity, power consumption, and overall costs. With advanced process nodes, custom SoCs can achieve higher levels of performance tailored to the application, offering a competitive edge.

- Miniaturization and integration: Devices in areas like wearables, medical implants, and IoT sensors demand miniaturized solutions. Custom SoCs consolidate functionality onto a single chip, reducing size and weight.

- Data-centric and AI workloads: AI and ML require processing architectures optimized for parallel computation and real-time inferencing. Custom SoCs can incorporate specialized processing units, like neural network accelerators or high-bandwidth memory interfaces, to handle these demanding tasks.

The market now demands a next-level approach, one that leverages AI and ML to optimize performance, reduce development time, and ensure efficient data movement across the entire system. Today’s high-end SoC designs are necessitating smarter, automated solutions to address evolving industry needs.

The solution is the introduction of a new type of smart NoC interconnect IP that can leverage smart heuristics using ML and AI technology to dramatically speed up the creation and increase the quality of efficient, high-performance SoC designs.

Today’s NoC technologies

Each IP in an SoC has one or more interfaces, each with its own width and frequency. A major challenge is the variety of standard interfaces and protocols, such as AXI, AHB, and APB, used across the industry. Adding to this complexity, SoCs often integrate IPs from multiple vendors, each with different interface requirements.

NoC technology helps manage this complexity by assigning a network interface unit (NIU) to each IP interface. For initiator IPs, the NIU packetizes and serializes data for the NoC. For target IPs, it de-packetizes and de-serializes incoming data.

Packets contain source and destination addresses, and NoC switches direct them to their targets. These switches have multiple ports, allowing several packets to move through the network at once. Buffers and pipeline stages further support data flow.

Without automation, designers often add extra switches, buffers, or pipeline stages as a precaution. However, too many switches waste area and power, excessive buffering increases latency and power use, and undersized buffers can cause congestion. Overusing pipeline stages also adds delay and consumes more power and silicon.

Existing NoC interconnect solutions provide tools for manual optimization, such as selecting topology and fine-tuning settings. However, they still struggle to keep pace with the growing complexity of modern SoCs.

Figure 1 SoC design complexity which has surpassed manual human capabilities, calls for smart NoC automation. Source: Arteris

Smart NoC IP

The typical number of IPs in one of today’s high-end SoCs ranges from 50 to 500+, the typical number of transistors in each of these IPs ranges from 1 million to 1+ billion, and the typical number of transistors on an SoC ranges from 1 billion to 100+ billion. Furthermore, modern SoCs may comprise between 5 to 50+ subsystems, all requiring seamless internal and subsystem-to-subsystem communication and data movement.

The result of all this is that today’s high-end SoC designs are surpassing human ability to create their NoCs without smart assistance. The solution is the introduction of a new type of advanced NoC IP, such as FlexGen smart NoC IP from Arteris. The advanced IP can leverage smart heuristics using ML technology to dramatically speed up the creation and increase the quality of efficient, high-performance SoC designs. A high-level overview of the smart NoC IP flow is illustrated in Figure 2.

Figure 2 A high-level overview of the FlexGen shows how smart NoC IP flow works. Source: Arteris

Designers start by using an intuitive interface to capture the high-level specifications for the SoC (Figure 2a). These include the socket specifications, such as the widths and frequencies of each interface. They also cover connectivity requirements, defining which initiator IPs need to communicate with which target IPs and any available floorplan information.

The designers can also specify objectives at any point in the form of traffic classes and assign performance goals like bandwidths and latencies to different data pathways (Figure 2b).

FlexGen’s ML heuristics determine optimal NoC topologies, employing different topologies for different areas of the SoC. The IP automatically generates the smart NoC architecture, including switches, buffers, and pipeline stages. The tool minimizes wire lengths and reduces latencies while adhering to user-defined constraints and performance goals (Figure 2c). Eventually, the system IP can be used to export everything for use with physical synthesis (Figure 2d).

NoC with smart assistant

The rapid increase in SoC complexity has exceeded the capabilities of traditional NoC design methodologies, making it difficult for engineers to design these networks without smart assistance. This has driven the demand for more advanced solutions.

Take the case of FlexGen, a smart NoC IP from Arteris, which addresses these challenges by leveraging intelligent ML heuristics to automate and optimize the NoC generation process. The advanced IP delivers expert-level results 10x faster than traditional NoC flows. It reduces wire lengths by up to 30%, minimizes latencies typically by 10% or more, and improves PPA metrics.

Streamlining NoC development accelerates time to market and enhances engineering productivity.

Andy Nightingale, VP of product management and marketing at Arteris, has over 37 years of experience in the high-tech industry, including 23 years in various engineering and product management positions at Arm.

Andy Nightingale, VP of product management and marketing at Arteris, has over 37 years of experience in the high-tech industry, including 23 years in various engineering and product management positions at Arm.

Related Content

- SoC Interconnect: Don’t DIY!

- What is the future for Network-on-Chip?

- SoC design: When is a network-on-chip (NoC) not enough

- Network-on-chip (NoC) interconnect topologies explained

- Why verification matters in network-on-chip (NoC) design

The post How AI is changing the game for high-performance SoC designs appeared first on EDN.

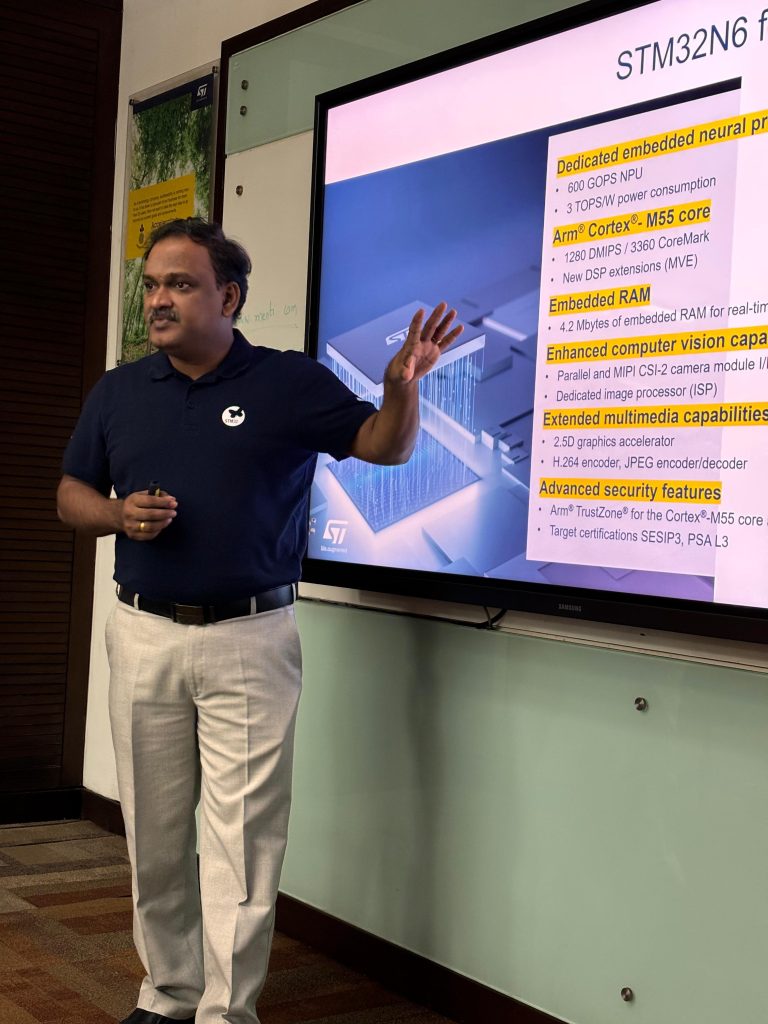

STMicroelectronics enables unmatched edge AI performance on MCU with STM32N6

In an era where artificial intelligence (AI) is rapidly transforming edge computing, STMicroelectronics is leading the charge with its groundbreaking STM32N6 series, featuring the Neural-ART Accelerator. This next-generation microcontroller delivers 600 times more AI performance than previous STM32 MCUs, redefining real-time AI processing for embedded systems.

Sridhar Ethiraj, Technical Marketing – General Purpose MCU at STMicroelectronics India

Sridhar Ethiraj, Technical Marketing – General Purpose MCU at STMicroelectronics India

In this exclusive interview, Rashi Bajpai from ELE Times sits down with Sridhar Ethiraj, Technical Marketing – General Purpose MCU at STMicroelectronics India, to explore the technological breakthroughs behind the STM32N6. We discuss the challenges of integrating high-performance AI with ultra-low power consumption, the real-world impact of AI-accelerated MCUs in industries like automotive, healthcare, and smart devices, and how ST’s Edge AI Suite is simplifying AI deployment for developers worldwide.

With industry giants like LG, Lenovo, and Alps Alpine already leveraging the STM32N6, this conversation unveils how AI-powered microcontrollers are shaping the future of intelligent embedded systems.

Excerpts:

STMicroelectronics has introduced the STM32N6 MCU with the Neural-ART Accelerator, delivering 600 times more machine-learning performance than previous high-end STM32 MCUs. What key challenges did ST overcome to integrate such advanced AI capabilities into a microcontroller while maintaining power efficiency?

Ans: STMicroelectronics faced several key challenges while integrating the Neural-ART Accelerator into the STM32N6 MCU. The need for high computing power for advanced AI features clashed with power efficiency goals was a major hurdle. ST tackled this by creating its own neural processing unit (NPU) to handle most AI tasks while keeping power use low. Making the system work with different AI frameworks and models also proved tough, but ST fixed this by supporting common frameworks like TensorFlow Keras, and the ONNX ecosystem. ST also had to tweak the hardware to run neural networks for computer vision and audio in real-time. This meant building a computer vision pipeline and special image processing abilities. In the end, all this work resulted in the STM32N6 MCU, which offers 600 times better machine-learning performance than earlier top-end STM32 MCUs, while still being very power-efficient.

Keras, and the ONNX ecosystem. ST also had to tweak the hardware to run neural networks for computer vision and audio in real-time. This meant building a computer vision pipeline and special image processing abilities. In the end, all this work resulted in the STM32N6 MCU, which offers 600 times better machine-learning performance than earlier top-end STM32 MCUs, while still being very power-efficient.

With AI inference moving to the edge, how does the STM32N6 differentiate itself from other AI-enabled MCUs in terms of performance, memory, and AI software support?

Ans: The STM32N6 series redefines AI-enabled microcontrollers with its Neural-ART Accelerator, a custom neural processing unit (NPU) delivering up to 600 GOPS for real-time neural network inference. Built on the Arm Cortex-M55 core running at 800 MHz, it leverages Arm Helium vector processing to enhance DSP performance. With 4.2 MB of built-in RAM and high-speed external memory interfaces, it excels in AI and graphics-intensive applications. Backed by a comprehensive AI software ecosystem—including STM32Cube.AI, ST Edge AI Developer Cloud, and the STM32 model zoo—it simplifies model optimization and deployment. This seamless blend of hardware acceleration and software support makes the STM32N6 a powerful and scalable solution for edge AI workloads.

The STM32N6 has been tested and adopted by industry leaders like LG, Lenovo, and Alps Alpine. Can you share some real-world applications where this MCU is making a significant impact?

Ans: The STM32N6 MCU is driving innovation across multiple industries. In automotive, it powers advanced driver assistance systems (ADAS) by enabling real-time processing of camera and sensor inputs for collision avoidance and lane-keeping. In smart home technology, companies like LG and Lenovo use it in security cameras and smart doorbells, leveraging its AI capabilities for motion detection and facial recognition. In healthcare, it enhances medical devices by accurately processing patient data for diagnostics and continuous monitoring. These real-world applications highlight how the STM32N6 delivers high-performance AI processing, improving safety, efficiency, and user experience across industries.

AI at the edge is evolving rapidly, particularly in vision, audio processing, and sensor-based analytics. How does ST’s Edge AI Suite support developers in optimizing AI models for the STM32N6, and what industries stand to benefit the most from this innovation?

Ans: Through three main tools in the Edge AI Suite from ST, developers gain complete functionality to improve AI models for the STM32N6 platform: STM32Cube.AI and ST Edge AI Developer Cloud and STM32 model zoo. The tools in this platform optimize AI model deployment on the Neural-ART Accelerator of STM32N6 while supporting the entire process from data preparation to code generation. The STM32N6 has the potential to revolutionize multiple sectors including automotive production, automotive components and consumer electronics together with healthcare and industrial automation markets. The STM32N6 allows advanced driver assistance systems (ADAS) in automotive applications as it provides healthcare products with real-time data analysis capabilities. Through their suite developers can build effective edge AI solutions which operate throughout numerous applications.

Looking ahead, how does STMicroelectronics envision the future of AI-accelerated microcontrollers, and what role will the STM32N6 series play in shaping next-generation embedded systems?

Ans: STMicroelectronics envisions a future where AI-accelerated microcontrollers like the STM32N6 series play a pivotal role in edge computing, enabling smarter, more efficient, and autonomous embedded systems. The STM32N6, with its Neural-ART Accelerator, is designed to handle complex AI tasks such as computer vision and audio processing with exceptional efficiency. Its energy-optimized AI processing will drive advancements across automotive, healthcare, consumer electronics, and industrial automation, enabling real-time data analysis, improved user experiences, and enhanced operational efficiency. As AI at the edge continues to evolve, the STM32N6 series will be instrumental in shaping intelligent, responsive, and secure next-generation embedded systems.

Sources:

STMicroelectronics to boost AI at the edge with new NPU-accelerated STM32 microcontrollers – ST News

STM32N6 series – STMicroelectronics

STM32N6-AI – AI software ecosystem for STM32N6 with Neural-ART accelerator – STMicroelectronics

Microcontrollers-stm32n6-series-overview.pdf

The post STMicroelectronics enables unmatched edge AI performance on MCU with STM32N6 appeared first on ELE Times.

EEVblog 1673 - JBL Partybox 310 Repair - Part 2 (SPOILER)

Diy 3 channel equalizer. First audio project

| submitted by /u/gdma2004 [link] [comments] |