Feed aggregator

Ashwini Vaishnaw Inaugurates India’s first Lithium-Ion Battery Manufacturing Hub With ₹3,000 Crore Investment

Electronics and IT Minister Ashwini Vaishnaw, inaugurated India’s first large-scale lithium-ion battery manufacturing facility at Sohna in Haryana. The project, set up by TDK Corporation with an investment of nearly ₹3,000 crore, under the Centre’s Electronics Manufacturing Cluster (EMC) scheme, is envisaged to play a crucial role in fulfilling the domestic demand for advanced battery technology in India.

The plant is to produce around 20 crore battery packs every year, which is around 40% of the country’s requirement of 50 crore cell packs each year. These batteries would be used in smartphones, laptops, smartwatches, earphones, and other wearables, thereby limiting imports and strengthening the self-reliance factor of the nation in electronics manufacturing.”

During the launch, Vaishnaw highlighted the government’s vision of creating a robust electronics ecosystem in the country. “Whether it is semiconductors, PCB assemblies, batteries, or camera modules-every component will be Made in India in the coming years; establishment of such great technology facilities is a huge milestone for self-reliance,” he said.

The initial phase of production at Sohna would begin in the last quarter of 2025, with the operations slowly scaling up to reach full capacity. The project will create a large set of employment opportunities, and about 5,000 direct jobs will be created. Training of the workforce has already started at the TDK At Bawal facility in Haryana.

TDK, a worldwide leader in electronic components with manufacturing facilities in over 30 countries, has brought its expertise to India through this investment. Acknowledging the support of the Haryana government, Vaishnaw said the state has been instrumental in facilitating new electronics manufacturing projects.

The inauguration was hailed as a significant turning point in India’s development into a global electronics hub in an official statement. It was claimed that any project, whether in PCB assemblies, batteries, or semiconductors, would lessen the nation’s dependency on imports while enhancing its expanding position in global value chains.

The post Ashwini Vaishnaw Inaugurates India’s first Lithium-Ion Battery Manufacturing Hub With ₹3,000 Crore Investment appeared first on ELE Times.

Electronics Manufacturing Surges to ₹11.5 Lakh Crore Industry, Generates 25 Lakh Jobs: Vaishnaw

The growth of electronics manufacturing in India is unprecedented, having emerged out as one of the leading industries with a market size of ₹11.5 lakh crore, Union Minister for Electronics and Information Technology Ashwini Vaishnaw stated.

Addressing a press conference at the BJP headquarters, the minister said production in the sector has increased almost six times in the last 11 years, while exports have increased eight times. This growth, he said, has also created direct and indirect employment opportunities for more than 25 lakh people across the country.

The Minister explained how India has moved towards self-reliance in electronics and can almost make any component that goes inside devices like mobile phones. “From glass and casings to chips, PCBs, and camera modules, all are being manufactured domestically,” he added.

Highlighting a new plant set up in Sohna, Haryana, the minister added that the facility will be manufacturing smartphone batteries. The plant alone is expected to produce nearly 20 crore battery packs, helping meet the nation’s demand of around 50 crore units annually.

According to the minister, the momentum of Swadeshi is forming, and a higher acceptance will build up the spirit of a self-reliant India. Encouraging people to purchase Indian goods, he said.

From the economic perspective, Vaishnaw associated the growth of the sector with the recent GST rationalisation, which has simplified tax slabs and lowered rates for household electronics. He said that consumers can expect lower prices in the near future on TVs, refrigerators, microwave ovens, dishwashers and power banks.

“With the GST reforms, Prime Minister Modi has given considerable relief to the middle-class families by easing the tax burden on daily essentials as well as household appliances,” said the minister.

The post Electronics Manufacturing Surges to ₹11.5 Lakh Crore Industry, Generates 25 Lakh Jobs: Vaishnaw appeared first on ELE Times.

Exclusive Feature, Part 1: “We’re Using AI to Help Us Make Better, Faster, and More Accurate Decisions,” says DigiKey’s Ken Paxton

| Mr Ken Paxton, Director, Advanced Semiconductor, DigiKey

Ken Paxton serves as the director of advanced semiconductor at DigiKey, where he leads the company’s relationships with top semiconductor suppliers. His team is dedicated to building supplier partnerships and creating innovative market strategies that support mutual growth. Ken’s focus is to help suppliers position their products to meet the latest customer needs, ensuring fast market introduction and connecting them with DigiKey’s broad network of engineers and designers. |

“We are enhancing our logistics to offer products manufactured in India and distributed directly within the country, using local currency,” says Ken Paxton, Director of Advanced Semiconductor for DigiKey, in an exclusive conversation with the ELE Times. As the industries across the globe embrace AI either as agents or as a tool, it becomes more important than ever to check how the companies empowering this revolution are themselves adopting the change. Furthermore, as India’s semiconductor ambitions soar high and the country marches to gain a good piece of the global semiconductor market, ELE Times takes the hot seat with DigiKey’s Ken Paxton to unravel the AI-specific and India-specific strategy of the world’s 5th largest electronics component distributor.

Distributors and AI

“We’ve embedded AI capabilities across DigiKey, not as isolated projects, but as an integrated approach to innovation. We’re using AI to help us make better, faster, and more accurate decisions, serving customers and suppliers more efficiently and effectively,” Mr. Paxton says in response to the AI question. He underlines that to DigiKey, AI is not just about financial parameters but a fundamental commitment to reimagining what is possible.

He further underlines DigiKey’s ultimate vision to be an AI-driven innovator where customer experiences shape the future of the industry.

Underlining India’s commitments to semiconductor growth and innovations are the India Semiconductor Mission (ISM) with an outlay of Rs 76,00 Crore and the Design Linked Incentive (DLI) with an outlay of Rs 1,000 Crore, to name a few. Among the schemes, the DLI scheme caters specifically to the design engineers with an aim to foster the semiconductor design ecosystem in India. To that effect, it is important to ensure that the design engineers are provided with the components they need on time with quality assurance.

That’s where DigiKey comes into India’s semiconductor foray.

“India represents a strategic growth region for DigiKey, with a dynamic engineering community that can capitalize on our robust stocking positions,” Ken Paxton says. Recognizing India’s design potential, Mr. Paxton underlines DigiKey’s close collaboration with the Indian supplier community. He says that the collaboration helps DigiKey in getting a comprehensive understanding of manufacturing capabilities and logistics specific to the Indian market.

DigiKey’s India Approach

As the Indian market evolves and the government as well as the private sector get on the nerves, it’s important to track how the distribution giants like DigiKey are responding to the same. To this, Mr. Paxton says, “DigiKey is constantly monitoring evolving opportunities in supplier distribution areas that could help enhance our reach within India to grow the electronics and technology market,” indicating a positive and uplifting scenario for the prospects of the industry.

He also goes on to add about the various other initiatives of DigiKey that aim to empower the design engineers community in India. “Beyond the products that drive technological innovation, DigiKey provides engineers with robust digital solutions, tools, and technical content to enhance their work,” he adds.

Emerging Technologies

Apart from adopting the emerging technologies like AI and automation in internal functioning, DigiKey also purveys the newest technologies and components for building the machines and devices that lead the future. It can range from sectors like healthcare and AI to energy, industrial automation, sustainability, and IoT. “We specialize in maintaining robust inventory across virtually all emerging technologies offered by our suppliers,” adds Mr. Paxton.

India-Specific Customization

Sharing an India-specific example, Mr. Paxton spotlights one instance of their collaboration with a supplier that has recently relocated its manufacturing operations to India. Consequently, DigiKey is enhancing its logistics to offer products manufactured in India and distributed directly within the country, using local currency. Mr. Paxton explained that DigiKey has been engaging with suppliers on developing products tailored to regional technical requirements.

He further explained that the company also provides power products in formats beyond the US standard to ensure Indian users enjoy a seamless, out-of-the-box experience.

Focus on India.

Mr. Paxton explained that India and the broader APAC region will continue to remain a priority for DigiKey, given the strong concentration of technological advances emerging from this part of the world. He further explained that the company’s focus in the region also extends to education and maker products, with an aim to provide cutting-edge technology in user-friendly formats to support aspiring engineers. He added that DigiKey will continue to partner with and promote suppliers committed to these areas.

“Engineering activity is high, and innovation is strong as we move into the second half of the year. We’re thrilled to help support our suppliers as they bring NPIs to market,” says Mr. Paxton as he wraps up the conversation.

| India’s semiconductor ambitions are backed by initiatives like the ₹76,000 crore ISM and the ₹1,000 crore DLI scheme, which focuses on fostering a strong design ecosystem. A critical part of this effort is ensuring design engineers get timely access to quality components.

To highlight how distributors are enabling this, we present our exclusive series — “Powering the Chip Chain” — featuring conversations with key industry players. |

The post Exclusive Feature, Part 1: “We’re Using AI to Help Us Make Better, Faster, and More Accurate Decisions,” says DigiKey’s Ken Paxton appeared first on ELE Times.

Light level detection

| submitted by /u/Bobert_DaZukin [link] [comments] |

Removing the "Keyboard" from the Cloud-B tranquil turtle.

IC Double Event

| Bullsxit [link] [comments] |

Improving the Frequency Deviation and Stability of a Direct FM Generator

World Radio History (large archive of electronics magazines, schematics, etc.)

Weekly discussion, complaint, and rant thread

Open to anything, including discussions, complaints, and rants.

Sub rules do not apply, so don't bother reporting incivility, off-topic, or spam.

Reddit-wide rules do apply.

To see the newest posts, sort the comments by "new" (instead of "best" or "top").

[link] [comments]

Finally, my White Whale eludes me no more.

| After a long time trying to make a circuit board in house for a QFN package, I have a working ATtiny 841 blinking an LED. QFN unlocked!! [link] [comments] |

TDK Boosts DC Voltage of SMT Gate Driver Transformers

Designing a Custom LCD & Switch Membrane

| submitted by /u/Icoso_Labs [link] [comments] |

Пам'яті Поповича Олексія Валерійовича

На війні загинув випускник нашого університету Попович Олексій Валерійович (17.07.1982 – 30.08.2025)...

Олексій закінчив університет 2006 року за спеціальністю «Адміністративний менеджмент» (на той час Факультет соціології).

Take Our 2025 EETech Engineering Insights Survey

My 3$ VFD (Vacuum fluorescent display) driver

| I bought this display from Alibaba, and then created PCB with JLCPCB. Refresh rate 60Hz with STM32. [link] [comments] |

An e-mail delivery problem, Part 2

For decades, I have used my IEEE alias address for both incoming and outgoing emails with no difficulties; however, this is no longer the case. The IEEE alias address is no longer workable for outgoing e-mails that are destined for any “gmail.com” recipient.

If I put ambertec@ieee.org in the “From” line of such an outgoing message, I get an immediate message rejection reply that looks like this:

If the content of the “From” line does not match the actual sending address, rejection occurs. In this case, the intended recipient was my own cell phone, but this kind of message comes my way when trying to send any email to any Gmail.com user.

I have neither the time nor the energy to wade into the bureaucratic techno-drivel of the “DMARC policy” or of the “DMARC initiative.” I simply cite my own experience as a signal that you and other IEEE members who read this will know that you are not alone.

John Dunn is an electronics consultant and a graduate of The Polytechnic Institute of Brooklyn (BSEE) and of New York University (MSEE).

Related Content

- An e-mail delivery problem

- What it means to be an IEEE HKN member

- The IEEE Code of Ethics

- Why do problems come in pairs?

- The First Spam Email: History & Fun Facts

The post An e-mail delivery problem, Part 2 appeared first on EDN.

Nichia launches µPLS Mini and DominoPLS at ISAL 2025

Lumileds’ LUXEON HL1Z Color Line simplifies multi-color LED application development with chip-scale packaging and uniform focal length

CSA Catapult appoints Caroline O’Brien as CEO

Decision Tree Learning Architecture Definition, Types and Diagram

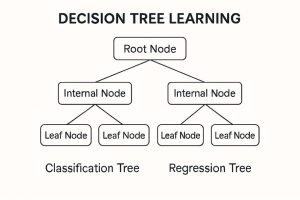

Decision Tree Learning’s architecture is a tree-like, hierarchical structure employed in both classification and regression in supervised machine learning. It starts with a root node, which is the complete dataset and the starting point of the first split according to a chosen feature. From there, the tree splits into internal decision nodes, where each of them is a test on an attribute, and branches, which represent the results of those tests. The algorithm repeats recursively, splitting the data into subsets until reaching leaf nodes, where the terminal output is represented as either a class label or a numeric value.

Such an architecture is constructed based on algorithms such as CART (Classification and Regression Trees), which select the optimal splits based on evaluation of criteria such as Gini impurity or entropy. The aim is to produce a model imitating human decision-making by posing a series of questions that progressively give more particular conclusions. The ease of interpretability and simplicity of this organization make decision trees widely used in predictive analytics and data mining.

Types of Decision Tree Learning:

- Classification Tree

A Classification Tree is created to solve problems where the output variable is a category, i.e., it is a member of a particular class or category. The tree divides the data based on feature values that can best distinguish the categories. For each node, the algorithm selects the feature that gives the maximum information gain or decreases Gini impurity most. This goes on until the data has been separated into pure subsets, or leaf nodes, which are the final class prediction. For instance, it can distinguish between emails and non-spams.

- Regression Tree

A Regression Tree is employed when the target variable is continuous, i.e., it has numerical values. Rather than dividing data into categories, it estimates a numeric value by averaging the values in each leaf node. The tree splits data according to features that reduce the variance or mean squared error in the target variable. Each split is designed to produce subsets as homogeneous as possible based on the numerical output. For example: Predicting house prices, forecasting sales.

Decision Tree Learning Diagram:

The figure shows the decision tree learning architecture, a supervised learning machine model that applies to both classification and regression learning. At the apex is the root node, which symbolizes the entire data set and makes the first decision based on a chosen feature. It divides into internal nodes, each symbolizing a point of decision which further divides the data along specific feature values. These internal nodes subsequently branch out to leaf nodes that give the terminal output either a class label for a classification tree or a numerical value for a regression tree. The left half of the diagram illustrates a classification tree where the decisions end up in discrete categories, and the right half illustrates a regression tree where the outputs are continuous values. The framework is binary and symmetrical, highlighting the way data recursively splits in order to make a predictive judgment. The graphical framework serves to demystify how decision trees work through the gradual elimination of possibilities based on feature divisions.

Conclusion:

Decision trees are not only model they’re reasoning frameworks. Their readability, interpretableness, and flexibility make them a starting point for data science, particularly when understanding and actionable results are paramount. From classifying emails to forecasting real estate values, decision trees provide a step-by-step, logical process to comprehend the data.

The post Decision Tree Learning Architecture Definition, Types and Diagram appeared first on ELE Times.