Feed aggregator

RTX unveils APG-82(V)X radar enhanced with gallium nitride

PWM buck regulator interface generalized design equations

A while back, I published the Design Idea (DI) “Simple PWM interface can program regulators for Vout < Vsense.” It showed some simple circuits for PWM programming of standard bucking-type regulator chips, both linear and switching, including applications that need an output voltage span that can swing well below the regulator’s sense voltage.

Wow the engineering world with your unique design: Design Ideas Submission Guide

Recent reader comments have shown interest in applying those designs to different applications and regulators. So, here’s a step-by-step procedure to make that process easier.

Note that it only works if Vx > 2Vs and Vl > Vs.

Figure 1 Ten discrete parts comprise a circuit for linear regulator programming with PWM.

Figure 1 Ten discrete parts comprise a circuit for linear regulator programming with PWM.

The steps are:

- Vs = U1 sense voltage from U1 datasheet (typically 0.5 to 1.25 V)

- Vl = available logic rail (typically 3 to 5 V)

- Vx = desired maximum output voltage at PWM duty factor = 100%

- Vpp = PWM peak to peak amplitude, typically Vl

- Fp = PWM rep rate

- N = PWM bits of resolution, N > 4

- R1 = recommended value from U1 datasheet example application

- R2 = R1(Vx/Vs – 1)

- R4 = R2Vl/Vs – R1 – R2

- R5 = (Vl – Q2vbe)Q2minbeta(R4 + R1 + R2)/Vl

- R3 = Vpp/(Vs/R1 + (Vl – Vs)/(R1 + R4))

- R3C3 = R2C2 = 2((N-2)/2)Fp-1

- C1 = C2R2/R1

Now, taking the inexpensive XLsemi XL4016 asynch buck converter as an example case for U1, and turning the crank for these givens gives you:

- Vs = 1.25 V

- Vl = 3.3 V

- Vx = 30 V

- Vpp = 3.3 V

- Fp = 10 kHz

- N = 8

- R1 = recommended value from U1 datasheet figure 4 = 3.3 kΩ

- R2 = 75 kΩ

- R4 = 120 kΩ

- R5 = 15 MΩ

- R3 = 8.2 kΩ

- C3 = 0.1 µF, C2 = 0.011 µF

- C2 = 0.27 µF

This yields Figure 2.

Figure 2 General design-accommodating parameters listed above. Note that U1-specific parts (e.g., inductor, capacitors, and power diode) are not shown.

Note that if the microamps and millivolts of residual zero offset that persist on the unloaded supply output at PWM = zero duty factor aren’t objectionable, then the Q2 R5 current sink is irrelevant and can be omitted.

Stephen Woodward’s relationship with EDN’s DI column goes back quite a long way. Over 100 submissions have been accepted since his first contribution back in 1974.

Related Content

- Simple PWM interface can program regulators for Vout < Vsense

- Revisited: Three discretes suffice to interface PWM to switching regulators

- Three discretes suffice to interface PWM to switching regulators

- Cancel PWM DAC ripple with analog subtraction

- Add one resistor to allow DAC control of switching regulator output

The post PWM buck regulator interface generalized design equations appeared first on EDN.

Aixtron ships its 100th G10-SiC system

Handling Signal Swings: Wide Common Mode Range in Action

Communication between devices must be reliable in modern industrial, automotive, and energy applications. Yet, engineers often encounter strange situations where everything seems to be connected well but the networks start acting strange out there in the field. Intermittent loss of communication and unexpected breakdown of nodes become tremendously expensive issues-a major reason for frustration, for such problems hardly pop their heads in the lab.

After more research, it is discovered that the sneaky evil is common mode voltage swings brought on by external circumstances. The swings push the signal outside the limits set in the original RS-485 standard, thereby maring the data exchange. Today’s extended CM range RS-485 transceivers are meant to protect networks against such eventualities.

When Noise Invades the Network

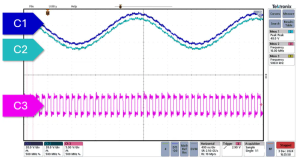

Figure 1: Scope Trace

A plain scope probe can narrate a grand story. At 500 kHz, it is not unusual to observe differential signals severely distorted due to external coupling. The transceiver receives data swathed in extraneous noise, and communication becomes unstable.

The 1983 EIA-485 standard provided for such situations by specifying a large common mode voltage range of -7 V to +12 V. Theoretically, this would be safe for signals. Practically, long cable lengths, wire resistance, and common mode external interference can move common mode levels far beyond that range.

Sources of Common Mode Swings:

A number of real-world conditions can inject interference currents into RS-485 networks:

- Motors and High-Voltage Power Supplies

Figure 2: Common Mode Swing Sources – Motors and High Voltage Power Supplies

Motors used in industry and switching power supplies produce powerful electromagnetic fields. These fields tend to couple readily into surrounding cabling, inducing unwanted RF interference on the data lines.

- Power and Data Bundled Together

Figure 3: Common Mode Swing Sources – Cables with Power and Data Bundled Together

Running AC power cables alongside RS-485 data cables within the same cable causes capacitive coupling, which injects currents directly into the communication network.

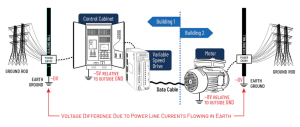

- Ground Potential Differences Between Buildings

Figure 4: Common Mode Swing Sources – Ground Potential Differences Between Buildings

Figure 5: Ground Voltage Differences Explained

When networking across buildings, ground potential differences can create large voltage shifts. Leakage currents from safety grounds or neutral wiring often raise the common mode voltage, pushing it outside the RS-485 tolerance.

Why Extended Common Mode Range Transceivers Help

Rather than depend solely on costly shielded cables, a better solution is to implement RS-485 transceivers that have wider common mode ranges. These chips are designed to maintain reliable data transfer even when external noise forces voltages well outside the legacy standard.

Examples include:

MAX33070E – MAX33074E: Half-duplex, 3.3 V to 5 V products with ±40 V common mode tolerance

LTC2862A and LTC2863: Half- or full-duplex products with improved noise immunity

Through the implementation of these resilient solutions, engineers are able to safeguard networks against downtime, minimize field failures, and lengthen the lifespan of industrial systems.

Conclusion:

Installing and operating RS-485 networks under regulated settings is nearly impossible. Motors, power supplies, bundled cables-if anything-shift voltages around in ways that disrupt communication.

With that said, the way to go will be to design with extended common mode range transceivers that offer a safety margin against any such disruptive swings and thus ensuring communication stays steady and reliable even in the harshest industrial weather.

(This article has been adapted and modified from content on Analog Devices.)

The post Handling Signal Swings: Wide Common Mode Range in Action appeared first on ELE Times.

Infineon’s CoolGaN power transistors incorporated into Universal Microelectronics’ 250W adapter for networking PoE applications

How Cloud-Integrated Printing is Revolutionizing Automotive Manufacturing

The automotive landscape has been witnessing a technological renaissance. Apart from EVs and autonomous driving, a quieter but profound change has been occurring: cloud-integrated printing. Hence, from rapid 3D prototyping to digitized supply chain management, cloud-based printing is defining new constraints in vehicle design, manufacturing, and maintenance. Analysts estimate an injection of unprecedented growth in the global cloud printing in the automotive market between 2025 and 2034; in turn, billions of dollars-worth of opportunities shall be disclosed. This means that the transformation is not only about efficiency but about sustainability, agility, and rethinking the whole concept of a factory floor for manufacturers.

Cloud Printing: With cloud printing being a mainstay of office workflows, it has now become central to automotive production. Merging next-generation hardware with managed services and cloud-based software, automotive firms can:

- Prototype cars at unprecedented velocities.

- Label and track thousands of parts globally across diverse supply chains.

- Digitize technical manuals, blueprints, and marketing collateral.

- Streamline workflows between manufacturing plants around the globe.

The cloud layer introduces a revolutionary aspect: frictionless integration anywhere, elastic production, and secure protection of sensitive designs with private or hybrid cloud models.

Market Highlights:

- North America: Holds its 30% market share in 2025 underpinned by high EV uptake and top OEMs such as Tesla, Ford, and Rivian.

- Asia-Pacific: Set to experience the quickest growth by 2034 with China, Japan, and India’s growing automotive and EV industries.

- Hardware vs. Software: Hardware has a commanding 45% market share, but cloud-based software platforms are swiftly catching up.

- Printing Types: 2D printing comprises 55% of use, but 3D printing is becoming the real growth driver.

- Applications: Parts labeling and traceability dominate, but cloud-based vehicle prototyping is the most rapidly increasing segment.

- Deployment Models: Private cloud adoption holds steady at 50%, although hybrid solutions are quickly gaining traction.

- End-Users: OEMs account for 60% of adoption, with manufacturers increasingly using 3D printing for sophisticated parts.

Trends Driving Adoption:

- Collaboration and Partnerships: Partnerships are driving faster adoption. As an example, Sharp collaborated with directprint.io in February 2025 to grow cloud printing solutions throughout the UK.

- AI-Driven Printing: AI is becoming more and more integrated into cloud platforms. Infosys and Telstra Group’s August 2025 partnership in Australia shows how machine learning is powering smarter manufacturing workflows.

- Regional Hardware Expansion: To address booming demand, Seiko Epson and other firms are increasing production, with the company opening a large-capacity printer plant in Chennai, India, in July 2025.

Hardware and Software:

Though hardware such as 3D printers and high-end scanners are seen as visible drivers of innovation, software is emerging as the real differentiator:

- Hardware: Facilitates custom part fabrication, sophisticated prototyping, and aids EV component manufacturing.

- Software: Cloud-based design systems and additive manufacturing software simplify vehicle design, enable better traceability, and enhance operational effectiveness.

2D vs. 3D Printing:

- 2D Printing: Remains the vital use cases such as documentation, blueprints, and marketing material.

- 3D Printing: The game-changer, facilitating lightweight EV components, on-demand spare parts, and quicker prototyping cycles, with growth outpacing all other segments.

Applications Driving Market Growth:

- Parts Labeling & Traceability: Critical to supply chain transparency and regulatory compliance.

- Vehicle Prototyping & Design: The most rapidly growing segment, owing to cloud-based 3D prototyping speeding up the design-to-production process.

Deployment Models: Private vs. Hybrid Cloud:

- Private Cloud: Provides control, customization, and security for proprietary IP.

- Hybrid Cloud: Fuses scalability, cost-effectiveness, and effortless data management, emerging as the preferred model for contemporary EV ecosystems.

Leading the Adoption Curve:

- OEMs represent 60% of all adopting for innovation and authentic part quality maintenance.

- In the rise: Tier-1 and 2 suppliers are increasingly turning to cloud print, particularly 3D printing, for easy and complex methods of cost-efficient part production.

Regional Outlook:

- North America as a powerhouse: Leader in cloud print adoption driven by EVs and tech-conscious OEMs.

- Asia Pacific: As fastest-growing, is nurtured by China’s EV boom and by Japan’s mature component design, with India gearing up to be an automotive manufacturing and R&D hub. Such expansions as the May 2025 launch of Konica Minolta in Australia exemplify this recent flow of energy into the region.

The Way Forward:

In the very next ten years, automotive manufacturing will be redefined. Cloud-integrated printing is more than just a tool of productivity-it stands for sustainability, innovation, and agile transformation. As 3D, AI, and hybrid cloud models converge, automakers and suppliers would rather become active in shaping the industry rather than playing catch-up.

Going Cloud-Integrated Printing today means setting the standards of tomorrow for automotive innovation.

(This article has been adapted and modified from content by Laxmi Narayan, Research Analyst, Towards Automotive.)

The post How Cloud-Integrated Printing is Revolutionizing Automotive Manufacturing appeared first on ELE Times.

A crash course in 3D IC technology

What’s 3D IC, and what’s causing the shift from 2D IC to 3D IC? How does this new technology relate to heterogeneous integration and advanced packaging? What is required for a successful 3D IC implementation? EDN recently published a three-article series to cover multiple facets of this advanced packaging technology.

Below is a sneak peek at this three-article series, which explains 3D IC fundamentals, microarchitectures, toolkits, and design use cases.

Part one, titled “Making your architecture ready for 3D IC”, provided essential context and technical depth for design engineers working toward highly integrated, efficient, and resilient 3D IC systems. It explains 3D IC microarchitectures that redefine how data and controls move through a system, how blocks are partitioned and co-optimized across both horizontal and vertical domains, and how early-stage design decisions address the unique challenges of 3D integration.

Making your architecture ready for 3D IC

Part two, titled “Putting 3D IC to work for you”, outlines the challenges and opportunities in adopting 3D IC technology. It demonstrates how 3D IC enables efficient chiplet integration and reuse, accelerates innovation, and guarantees manufacturability across organizational boundaries. The article also provides a detailed examination of 3D IC design toolkits and workflows, as well as their incorporation of AI technology.

The third and final part, titled “Automating FOWLP design: A comprehensive framework for next-generation integration”, presents fan-out wafer-level packaging (FOWLP) as a case study, showing how automation frameworks manage the inherent complexity of advanced packaging and the scale of modern layouts, racking up millions of pins and tens of thousands of nets. It also demonstrates how effective frameworks promote collaboration among package designers, layout specialists, signal and power integrity analysts, and thermal and mechanical engineers.

Automating FOWLP design: A comprehensive framework for next-generation integration

Related Content

- 3D IC Design

- Thermal analysis tool aims to reinvigorate 3D-IC design

- Heterogeneous Integration and the Evolution of IC Packaging

- Tighter Integration Between Process Technologies and Packaging

- Advanced IC Packaging: The Roadmap to 3D IC Semiconductor Scaling

The post A crash course in 3D IC technology appeared first on EDN.

CEA-Leti and CRHEA present step toward full-color AR/VR micro-displays at MicroLED Connect Conference

✅ Оголошується конкурс на заміщення посад

Національний технічний університет України "Київський політехнічний інститут імені Ігоря Сікорського" оголошує конкурс на заміщення вакантних посад. Термін подання документів до 26.10.2025 року.

Конкурс на заміщення вакантної посади завідувача кафедри

Конкурс на заміщення вакантних посад професорів

Конкурс на заміщення вакантних посад доцентів, викладачів

Photon Design exhibiting product range at ECOC 2025

Socomec Launches COUNTIS P new range of Smart AC/DC Energy Meters for Efficient Energy Management

From design to commissioning, Socomec guarantees high-performance, sustainable electrical installations

Socomec announced the launch of its latest innovation: COUNTIS P, a next-generation range of smart energy meters designed to meet the evolving needs of modern infrastructure. With over three decades of industry expertise, this launch reinforces Socomec’s commitment to innovation, sustainability, and excellence in energy efficiency and digital transformation.

Mr. Meenu Singhal, Regional Managing Director – Greater India, Socomec Innovative Power Solutions, emphasized the significance of the launch, stating, “As the energy consumption becomes increasingly complex across sectors, organizations are under pressure to manage usage more efficiently while ensuring compliance and sustainability. COUNTIS P offers a smarter, simpler way to manage energy through its compact design, AC/DC compatibility, and seamless integration with digital platforms. It empowers businesses to gain real-time insights, improve cost allocation, and drive meaningful progress toward energy efficiency goals”. He stated that this innovation demonstrates Socomec’s ongoing efforts to deliver intelligent, sustainable solutions that support customers in navigating today’s energy challenges while preparing for tomorrow’s opportunities.

The COUNTIS P range delivers precision metering, modular design, and advanced connectivity, including Modbus RTU/TCP protocols. Designed for versatility, COUNTIS P is compatible with both AC and DC systems and operates seamlessly across single-phase and complex three-phase networks. Built to perform in harsh environments, it maintains high accuracy even under extreme temperature conditions. Its plug-and-play QuickConnect installation simplifies deployment, reducing time and complexity for installers and integrators.

When integrated with Socomec’s digital monitoring platforms, COUNTIS P provides real-time energy insights that help customers track consumption, identify inefficiencies, make data-driven decisions, reduce operational costs, and support their sustainability goals. These capabilities make COUNTIS P a future-ready solution for organizations looking to optimize energy use and meet tightening regulatory standards.

In many sectors, managing sub-billing remains a critical challenge. Accurate sub-metering enables fair and transparent rebilling of energy consumption across tenants or business units. COUNTIS P meters are MID-certified, ensuring reliable accuracy and full compliance with regulatory requirements. This makes them an ideal solution for organizations seeking to avoid billing errors and ensure transparency in energy cost allocation. With features like QuickConnect technology, AC/DC compatibility, and MID certification, COUNTIS P is ideal for buildings, industry, infrastructure, and EV charging stations.

Socomec supports its customers throughout the entire lifecycle — from design to commissioning — ensuring high-performance, compliant, and sustainable electrical installations. As energy consumption becomes a critical issue for businesses, reducing kilowatt-hour usage not only lowers costs but also minimizes environmental impact. In this context, COUNTIS P stands out as a smart, reliable, and efficient tool for modern energy management.

The post Socomec Launches COUNTIS P new range of Smart AC/DC Energy Meters for Efficient Energy Management appeared first on ELE Times.

Setting Up PCM and I2S Formats for Reliable SCO Loopback Transmission

In the contemporary wireless audio industry, providing crystal-clear uninterrupted sound is such a major and recurrently faced problem. Depending on the nature of Bluetooth headsets ethereally connecting with other apparatus modules over wireless ambience or in the car for in-roads communication purposes, or in gaming devices, it is imperative that, from the engineers’ standpoint, audio signals need to stay unstuck from distortion. To validate and optimize further, SCO (Synchronous Connection-Oriented) loopback transmissions can be put to use.

In this manual, loopback mode is described. Why do we need loopback testing in Bluetooth audio? And how does one configure PCM or I2S for an SCO loopback using the Infineon AIROC Bluetooth controllers?

What is a Loopback Mode?

Loopback mode is a constraint and verification method for wireless audio. Rather than train the audio signal back to a set destination (e.g., speakers, headphones, etc.), the signal is looped back to the originating source. This allows the developers to check the signal quality, such as verifying hardware configurations and troubleshooting towards identifying any mismatch, without dependence on external devices for tests.

Normal vs. Loopback Mode:

Normal Mode: Audio is transmitted to the output device.

Loopback Mode: Audio is redirected back to the source for testing.

Test Environment

To configure SCO loopback transmission, you’ll need:

AIROC CYW20706 headset demo (PCM_OUT source) → GitHub demo project

Linux mbt tool for HCI command input → GitHub mbt tool

AIROC CYW89072 (or any supported Infineon Bluetooth controller) with firmware

Step-by-Step Setup for SCO Loopback Transmission

Step 1: Program the CYW20706 and Bring Up the Demo

- Flash the CYW20706 using ModusToolbox.

- Use the client control tool to run the demo.

- Pair a phone with the CYW20706 and start playback.

Step 2: Connect Hardware

Wire the CYW20706 PCM_OUT pin to the CYW89072 PCM_IN pin.

Step 3: Download Firmware

./mbt download [filename].hcd –minidriver

Step 4: Enable Loopback Mode

./mbt input_command 24fc0101

PCM Configuration

8K PCM

./mbt input_command 1cfc050001000101

./mbt input_command 24fc0101

16K PCM

./mbt input_command 7efc03010200

./mbt input_command 6dfc0400010102

./mbt input_command 1cfc050002000101

./mbt input_command 1efc050000030000

./mbt input_command 24fc0101

I2S Configuration

8K I2S

./mbt input_command 7efc03000200

./mbt input_command 6dfc0401010001

./mbt input_command 24fc0101

16K I2S

./mbt input_command 7efc03010200

./mbt input_command 6dfc0401010102

./mbt input_command 24fc0101

Pin Configuration Notes

For controllers like CYW555xx or CYW43xx, an additional command may be required to route PCM/I2S to default pins:

./mbt input_command 61fc0501b9b8b8b8

By default, the setup assumes TDM2 pins are in use. If you are using alternative pins, adjust the commands accordingly.

Key Takeaway

SCO loopback transmission is an invaluable tool for validating wireless audio performance. By configuring PCM or I2S formats with Infineon’s AIROC Bluetooth controllers, engineers can easily verify signal integrity, fine-tune system performance, and ensure a smooth end-user audio experience.

(This article has been adapted and modified from content on Infineon Technologies.)

The post Setting Up PCM and I2S Formats for Reliable SCO Loopback Transmission appeared first on ELE Times.

Looking Into What Makes Glasses Smart: A Guide to the Flexible PCBs in Smart Glasses

As emerging glasses and systems bring the virtual and physical worlds closer together than ever before, making navigation, entertainment, and even gaming way easier and more exciting, it is the power of electronics that makes it happen. In such a scenario, let’s examine the technology that makes it possible, seamless, and modern. As we move into the topic, it’s essential to emphasize that the PCB is the most crucial central platform that connects and organizes all the electronic components in a smart glass or an AR/VR device.

What type of PCB is used in Smart Glasses?

Due to the need for flexibility, adaptability, and reliability, the majority of smart glasses today are manufactured using Flexible Printed Circuit Boards (FPCBs). These are thin, lightweight circuit boards made from pliable materials that bend easily without breaking. As opposed to the rigid circuit boards, FPCBs are made with the intent to empower technology with convenience.

What makes FPCBs the go-to Choice?

PCBs enable engineers to redefine electronics with unique shapes. As it can withstand repeated bending cycles, by default, it becomes an ideal choice for compact and curved designs of smart glasses or AR/VR gear. It is a prime example of how technology integrated with aesthetics and need can empower a whole segment of innovation and seamlessness.

Smart Glasses and FPCBs are a match made in heaven, as FPCBs not only constitute the central platform, which is what a PCB usually does, but also enable the engineers to render various specific characteristics of glasses into the segment of Smart Glasses.

Electrical yet Appealing & Convenient: Secrets

To make a device fitted with so many components, yet maintain it for optimal use as a glass, necessitates a plethora of considerations to be ticked. This takes us to the next part of our story, which is the types of FPCBs depending on the materials it is made of. These materials render significant properties to the FPCBs, enabling them to not only facilitate technology but also combat its ills.

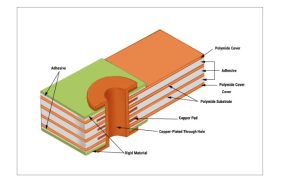

Structure of an FPCB

Structure of an FPCB

Primary materials used in these applications are:

- Polyimide (PI): The most commonly used substrate for flexible PCBs, polyimide offers outstanding thermal stability (up to 400 °C) and high mechanical strength. It can withstand thousands of bending cycles, making it ideal for the constantly moving and compact environment of smart eyewear.

- Polyester (PET): A more economical alternative to polyimide, PET provides decent flexibility but is less durable. It works best in static or low-bend applications, and is often chosen for simpler or less demanding wearable designs.

- Copper Foil: Copper is the standard conductor in flexible PCBs. Among the types, rolled-annealed (RA) copper is preferred over electrodeposited (ED) copper because of its superior flexibility and fatigue resistance—key for handling repeated bends in devices like smart glasses.

- Adhesives and Coverlays: Adhesives secure the layers of a flexible PCB, while coverlays (thin protective films) safeguard the circuitry. Both must retain flexibility and adhesion under stress to prevent issues like delamination during everyday use.

Engineers frequently favor polyimide-based substrates for their durability, particularly in premium AR glasses where long-term reliability is essential. Beyond strength, the choice of material also influences signal performance—polyimide’s low dielectric loss makes it well-suited for high-frequency applications such as 5G connectivity in smart devices.

Design Considerations with FPCBs

Since smart glasses can be subjected to repeated bending and need proper signals to enable their proper usage, it is important to design them accordingly to suit future needs. In engineering terms following considerations rank the highest:

Bending Radius:

- Maintain ≥10× PCB thickness for dynamic bends, ≥3× for static.

- Example: 0.1 mm PCB → 1 mm minimum dynamic bend radius.

Trace Layout & Spacing:

- Route traces perpendicular to bend lines.

- Avoid vias/components in bend zones.

- Keep ≥0.1 mm spacing to prevent shorts during flexing.

Tear-Drop Pads:

- Use tear-drop geometry at trace–pad junctions to minimize stress concentration and cracking.

Layer Stack-Up:

- Use symmetrical stack-ups to keep the neutral axis centered.

- Reduces stress on multilayer FPCs, especially in curved frame designs.

In AR glasses, an FPC can route signals from the microdisplay in the lens to the control unit in the frame, flexing around corners without adding bulk. This ability to combine compact routing with mechanical flexibility makes FPCs fundamental to wearable design.

Is it all Always Good with FPCBs?

To give a straight answer, no. Neither is the case with any technology in the world. Let’s look into certain challenges that FPCBs have to offer when it comes to Smart Glasses:

- Maintaining Signal Integrity: With FPCBs having thin dielectric layers, high-frequency signals for wireless connectivity can face significant challenges. To counter this, manufacturers often turn towards low-loss materials like modified polyimide and ensure precise impedance control, targeting values like 50 ohms for optimal performance.

- Ensuring Bend Durability: Repeated flexing can fatigue copper traces. Mitigation strategies include using rolled-annealed (RA) copper and reinforcing bend zones with stiffeners or extra coverlay layers to better distribute mechanical stress.

- Miniaturization: Smart eyewear requires ultra-compact PCBs with high-density interconnects. Techniques like laser-drilled microvias (as small as 0.05 mm) enable dense, high-performance circuit layouts.

By leveraging these methods, manufacturers can deliver flexible PCBs that meet the strict demands of smart eyewear—combining durability, miniaturization, and high-speed signal integrity where Flexible PCBs are central to smart eyewear, enabling sleek, lightweight designs. Success depends on material choice, proper bend-radius design, and precise rigid-flex assembly—key factors for building reliable, innovative wearables

The post Looking Into What Makes Glasses Smart: A Guide to the Flexible PCBs in Smart Glasses appeared first on ELE Times.

For more secure AI and ML models: Infineon’s OPTIGA Trust M backs Thistle Technologies’ Secure Edge AI solution

Infineon Technologies AG provides its OPTIGA Trust M security solution to Thistle Technologies for its new cryptographic protection for on-device AI models to its security software platform for embedded computing products based on the Linux operating system (OS) or on a microcontroller. The new capabilities in the Thistle Security Platform for Devices, along with Infineon OPTIGA Trust M security solution as tamper-resistant hardware-based root-of-trust, protect the valuable intellectual property (IP) in the AI models deployed in edge AI applications, and in the training data sets on which they are based.

The Thistle Security Platform for Devices that includes the Infineon OPTIGA Trust M security solution, provides ready-made, cloud-managed security components which integrate seamlessly into Linux OS-based devices and microcontrollers. Instead of building and maintaining a one-off cybersecurity stack, OEMs can deploy a proven, continuously updated foundation in hours, and scale it across large, heterogeneous fleets of devices. The Security Platform enables both secured boot and over-the-air (OTA) updating, and is compatible with a broad range of microprocessors, systems-on-chip (SoCs) and microcontrollers. Infineon OPTIGA Trust M security controller enables secured key provisioning, tamper-resistant key storage, and efficient cryptographic operations for encryption and decryption, taking care that only trusted, authenticated, and verified AI models are deployed in edge AI applications.

Thistle has extended its solution to include built-in protection for on-device AI models and data, using cryptographic keys stored in Infineon’s tamper-resistant security controllers, OPTIGA Trust M. The three key features of the new Thistle Secure Edge AI solution are:

- Hardware-backed model encryption – AI model encryption key is secured by OPTIGA Trust M security solution. Each device has a unique AES 256-bit key securely stored in OPTIGA Trust M, which is used to secure the AI Model encryption key. This means that the AES key is used for encryption and decryption inside the OPTIGA Trust M only. Even if a device is lost, decommissioned, or disassembled, the manufacturer’s IP embedded in the model is still efficiently protected. At launch, this feature is enabled on the Infineon OPTIGA Trust M security solution.

- Secured model provenance – in OTA updates, the Thistle platform enables cryptographically signed, tamper-evident delivery of AI models and firmware directly from the training platform to the device, taking care that every installed instance of a model can be traced and verified.

- Signed data and data lineage – device-generated or collected data can be signed on-device and tagged with provenance metadata. This means that downstream systems which might use the data to train or refine AI models can check the provenance of the data, and of the version of the model that the device was running when it generated the data.

Animesh Ranjan, Head of Partnerships & Ecosystem at Infineon says: “At Infineon, we are pleased to expand our collaboration with Thistle Technologies to deliver stronger protection for AI models running at the edge. By combining the OPTIGA Trust M security solution with the Thistle Security Platform, we enable device makers to safeguard their AI with hardware-anchored security that is both practical and scalable.”

Window Snyder, Chief Executive Officer of Thistle Technologies, says: “It is always our goal to make robust security capabilities accessible for device makers. With Infineon’s OPTIGA Trust M and the Thistle Security Platform, manufacturers can protect AI models and data with proven cryptography and deploy at scale quickly. Together we give customers a straightforward way to ship devices that can securely verify, encrypt, and update AI models.”

The post For more secure AI and ML models: Infineon’s OPTIGA Trust M backs Thistle Technologies’ Secure Edge AI solution appeared first on ELE Times.

New Investments Flowing Into Photonics—Part 1: Trends Pointing Upwards

I'm in love with this build123d + KiCad workflow for parametric CAD

This parametric case is described in <150L of Python and it loads the board edge and footprint positions straight from the KiCad PCB file. In the video I also load the exported KiCad STEP 3d model just for visual inspection. Source here for the curious.

[link] [comments]

🏆 МОН оголошує конкурс наукових проєктів молодих учених!

📢 Міністерство освіти і науки України своїм наказом від 16.09.2025 №1253 17 вересня 2025 року оголосило конкурсний відбір проєктів фундаментальних наукових досліджень, прикладних наукових досліджень та науково-технічних (експериментальних) розробок молодих учених, які працюють (навчаються) у зак

🚀 Реєстрація на найбільший у світі космічний хакатон NASA Space Apps Challenge

🚀 КПІшники, реєструйтеся на найбільший у світі космічний хакатон NASA Space Apps Challenge, який щороку проходить під егідою NASA у різних державах.

Протягом 48 годин команди вирішують практичні завдання. Цьогоріч їх 19!

Optical Chip Beats Counterparts in AI Power Efficiency 100 Fold

Meta Connect 2025: VR still underwhelms; will smart glasses alternatively thrive?

For at least as long as Meta’s been selling conventional “smart” glasses (with partner EssilorLuxottica, whose eyewear brands include the well-known Oakley and Ray-Ban), rumors suggested that the two companies would sooner or later augment them with lens-integrated displays. The idea wasn’t far-fetched; after all, Google Glass had one (standalone, in this case) way back in early 2013:

Meta founder and CEO Mark Zuckerberg poured fuel on the rumor fire when, last September, he demoed the company’s chunky but impressive Orion prototype:

And when Meta briefly, “accidentally” (call me skeptical, but I always wonder how much of a corporate mess-up versus an intentional leak these situations often really are) published a promo clip for (among other things) a display-inclusive variant of its Meta Ray-Ban AI glasses last week, we pretty much already had our confirmation ahead of the last-Wednesday evening keynote, in the middle of the 2025 edition of the company’s yearly Connect conference:

Yes, dear readers, as of this year, I’ve added yet another (at least) periodic tech-company event to my ongoing coverage suite, as various companies’ technology and product announcements align ever more closely with my editorial “beat” and associated readers’ interests.

But before I dive fully into those revolutionary display-inclusive smart glasses details, and in the spirit of crawling-before-walking-before-running (and hopefully not stumbling at any point), I’ll begin with the more modest evolutionary news that also broke at (and ahead of) Connect 2025.

Smart glasses get sportyWithin the midst of my pseudo-teardown of a transparent set of Meta Ray-Ban AI Glasses published earlier this summer:

I summarized the company’s smart glasses product-announcement cadence up to that point. The first-generation Stories introduced in September 2020:

was, I wrote, “fundamentally a content capture and playback device (plus a fancy Bluetooth headset to a wirelessly tethered smartphone), containing an integrated still and video camera, stereo speakers, and a three-microphone (for ambient noise suppression purposes) array.”

The second-generation AI Glasses unveil was led three-plus years later in October 2023, which I own—two sets of, in fact, both Transitions-lens equipped:

make advancements on these fundamental fronts…They’re also now moisture (albeit not dust) resistant, with an IPX4 rating, for example. But the key advancement, at least to this “tech-head”, is their revolutionary AI-powered “smarts” (therefore the product name), enabled by the combo of Qualcomm’s Snapdragon AR1 Gen 1, Meta’s deep learning models running both resident and in the “cloud”, and speedy bidirectional glasses/cloud connectivity. AI features include real-time language Live Translation plus AI View, which visually identifies and audibly provides additional information about objects around the wearer.

And back in June (when published, written early May), I was already teasing what was to come:

Next-gen glasses due later this year will supposedly also integrate diminutive displays.

More recently, on June 20 (just three days before my earlier coverage had appeared in EDN, in fact), Meta and EssilorLuxottica released the sports-styled, Oakley-branded HTSN new member of the AI Glasses product line:

The battery life was nearly 2x longer: up eight hours under typical use, and 19 hours in standby. They charged up to 50% in only 20 minutes. The battery case now delivered up to 48 operating hours’ worth of charging capacity, versus 36 previously. The camera, still located in the left endpiece, now captured up to 3K resolution video (albeit the same 12 Mpixel still images as previously). And the price tag was also boosted: $499 for the initial limited-edition version, followed by more mainstream $399 variants.

A precursor retrofit and sports-tailored expansionFast forward to last week, and the most modest news coming from the partnership is that the Oakley HTSN enhancements have been retrofitted to the Ray-Ban styles, with one further improvement: 1080p video can now be captured at up to 60 fps in the Gen 2 versions. Cosmetically, they look unchanged from the Gen 1 precursors. And speaking of looks, trust me when I tell you that I don’t look nearly as cool as any of these folks do when donning them:

Meta and EssilorLuxottica have also expanded the Oakley-branded AI Glasses series beyond the initial HTSN style to the Vanguard line, in the process moving the camera above the nosepiece, otherwise sticking with the same bill-of-materials list, therefore specs, as the Ray-Ban Gen 2s:

And all of these, including a welcome retrofit to the Gen 1 Ray-Ban AI Glasses I own, will support a coming-soon new feature called conversation focus, which “uses the glasses’ open-ear speakers to amplify the voice of the person you’re talking to, helping distinguish it from ambient background noise in cafes and restaurants, parks, and other busy places.”

AI on displayAnd finally, what you’ve all been waiting for: the newest, priciest (starting at $799) Meta Ray-Ban Display model:

Unlike last year’s Orion prototype, they’re not full AR; the display area is restricted to a 600×600 resolution, 30 Hz refresh rate, 20-degree lower-right portion of the right eyepiece. But with 42 pixels per degree (PPD) of density, it’s still capable of rendering crisp, albeit terse information; keep in mind how close to the user’s right eyeball it is. And thanks to its coupling to Transitions lenses, early reviewer feedback suggests that it’s discernible even in bright sunlight.

Equally interesting is its interface scheme. While I assume that you can still control them using your voice, this time Meta and EssilorLuxottica have transitioned away from the right-arm touchpad and instead to a gesture-discerning wristband (which comes in two color options):

based on very cool (IMHO) surface EMG (electromyography) technology:

Again, the initial reviewer feedback that I’ve seen has been overwhelmingly positive. I’m guessing that at least in this case (Meta’s press release makes it clear that Orion-style full AR glasses with two-hand gesture interface support are still under active development), the company went with the wristband approach both because it’s more discreet in use and to optimize battery life. An always-active front camera, after all, would clobber battery life well beyond what the display already seemingly does; Meta claims six hours of “mixed-use” ( ) between-charges operating life for the glasses themselves, and 18 hours for the band.

) between-charges operating life for the glasses themselves, and 18 hours for the band.

Longstanding silicon-supplier partner Qualcomm was notably quieter than usual from an announcement standpoint last week. Back in June, it had unveiled the Snapdragon AR1+ Gen 1 Platform, which may very well be the chipset foundation of the display-less devices launched last week. Then again, given that the aforementioned operating life and video-capture quality advancements versus their precursor (running the Snapdragon AR1) are comparatively modest, they may result mostly-to-solely from beefier integrated batteries and software optimizations.

The Meta Ray-Ban Display, on the other hand, is more likely to be powered by a next-generation chipset, whether from Qualcomm—the Snapdragon AR1+ Gen 1 or perhaps even one of the company’s higher-end Snapdragon XR platforms—or another supplier. We’ll need to wait for the inevitable teardown-to-come (at $799, not from yours truly!) to know for sure. Hardware advancements aside, I’m actually equally excited (as will undoubtedly also be the software developers out there among my readership) to hear what Meta unveiled on day 2: a “Wearables Device Access Toolkit” now available as a limited developer preview, with a broader rollout planned for next year.

Pending more robust third-party app support neatly leads into my closing topic: what’s in all of this for Meta? The company has clearly grown beyond its Facebook origin and foundation, although it’s still fundamentally motivated to cultivate a community that interacts and otherwise “lives” on its social media platform. AI-augmented smart glasses are just another camera-plus-microphones-and-speakers (and now, display) onramp to that platform. It’ll be interesting to see both how Meta’s existing onramps continue to evolve and what else might come next from a more revolutionary standpoint. Share your guesses in the comments!

p.s…I’m not at all motivated to give Meta any grief whatsoever for the two live-demo glitches that happened during the keynote, given that the alternative is a far less palatable fully-pre-recorded “sanitary” video approach. What I did find interesting, however, were the root causes of the glitches; an obscure, sequence-of-events driven software bug not encountered previously as well as a local server overload fueled by the large number of AI Glasses in the audience (a phenomenon not encountered during the comparatively empty-venue preparatory dress rehearsals). Who would have thought that a bunch of smart glasses would result in a DDoS?

—Brian Dipert is the Editor-in-Chief of the Edge AI and Vision Alliance, and a Senior Analyst at BDTI and Editor-in-Chief of InsideDSP, the company’s online newsletter.

Related Content

- Smart glasses skepticism: A look at their past, present, and future(?)

- Ray-Ban Meta’s AI glasses: A transparency-enabled pseudo-teardown analysis

- Apple’s Spring 2024: In-person announcements no more?

The post Meta Connect 2025: VR still underwhelms; will smart glasses alternatively thrive? appeared first on EDN.