ELE Times

STMicroelectronics and Qualcomm enter strategic collaboration in wireless IoT

- Strategic collaboration will pair STMicroelectronics’ market-leading STM32 microcontroller ecosystem and Qualcomm’s world-leading wireless connectivity solutions.

- Seamless integration into existing STM32 developer ecosystem to allow simple, fast, and cost-effective design of next-gen industrial and consumer IoT applications augmented by edge AI.

STMicroelectronics, a global semiconductor leader serving customers across the spectrum of electronics applications, and Qualcomm Technologies International, Ltd., a subsidiary of Qualcomm Incorporated, has announced a new strategic collaboration for the next generation of industrial and consumer IoT solutions augmented by edge AI. This highly complementary collaboration will see the two companies integrate Qualcomm Technologies’ leading AI-powered wireless connectivity technologies, starting with Wi-Fi/Bluetooth/Thread combo system-on-a-chip (SoC), with the market-leading microcontroller (MCU) ecosystem from ST. Through this collaboration, developers will enjoy seamless connectivity software integration into STM32 general-purpose MCUs, including software toolkits, facilitating quick and broad adoption via ST’s world-wide sales and distributor channels.

Remi El-Ouazzane, President, Microcontrollers, Digital ICs and RF Products Group, for STMicroelectronics said: “Wireless connectivity is key to the fast pervasion of edge AI across an ever-growing variety of use cases in enterprise, industrial and personal applications. This is why we are establishing a strategic collaboration with Qualcomm Technologies on wireless connectivity today, starting with Wi-Fi/BT/Thread combo SoC, and already considering next steps, complementing our existing multi-protocol Bluetooth Low Energy, Zigbee, Thread and sub-GHz products portfolio. We envision wireless connectivity products based on technology from Qualcomm Technologies augmenting any of our STM32 products, bringing significant value to our more than 100,000 STM32 customers globally.”

Rahul Patel, Group General Manager, Connectivity, Broadband and Networking Business Unit for Qualcomm Technologies, Inc. said: “Qualcomm Technologies’ research and development leadership has helped drive the evolution of wireless IoT, ranging from pioneering 4G/5G, to high performance Wi-Fi, to micropower connectivity solutions. Our collaboration with STMicroelectronics pairs Qualcomm Technologies’ best-in-class connectivity offerings with ST’s leading STM32 microcontroller ecosystem and will help drive a significant acceleration of feature-rich capabilities across the IoT. Together, we are setting new developer experiences for IoT applications, supporting seamless integration and optimal performance for developers and end-users alike.”

Focusing on the broader market, ST plans to introduce self-contained modules utilizing Qualcomm Technologies’ Wi-Fi/Bluetooth/Thread combo SoC portfolio, which can be system-level integrated with any STM32 general-purpose microcontrollers. Wireless connectivity optimized and made available to ST’s developer ecosystem through ST’s well established software platform will contribute to reducing development time and time-to-market. The initial product offerings resulting from this collaboration are expected to be available to OEMs in Q1 2025, with broader availability to follow. This is a first step in a collaboration that envisions a roadmap of Wi-Fi/Bluetooth/Thread combo SoC products over time, with the intention to extend into cellular connectivity for industrial IoT applications.

Andrew Zignani, Senior Research Director, ABI Research, commented “With the installed base of consumer, commercial and industrial connected devices expected to reach well over 80 billion units by 2028, the proliferation of high-performance wireless connectivity solutions combined with a diverse suite of microcontrollers will be fundamental in enabling this next wave of wireless IoT innovation. This collaboration between STMicroelectronics and Qualcomm Technologies is a perfect match thanks to ST’s leading microcontroller ecosystem and Qualcomm Technologies’ R&D leadership in wireless connectivity, and the growing availability of these combined solutions will enable companies to address this dynamic IoT market more simply, more quickly, and more cost-effectively in the years to come.”

The post STMicroelectronics and Qualcomm enter strategic collaboration in wireless IoT appeared first on ELE Times.

RF Connectors for Autonomous Mobile Robots

Factory floors look much different than they did in the past. Today, robots assemble products, think on their feet to navigate complex environments, take on new tasks, and make real-time decisions. And they do plenty of this without human supervision.

Early industrial robots advanced manufacturing by taking over redundant and dangerous tasks but were still confined to straightforward and pre-programmed actions. Things have changed. Autonomous mobile robots (AMRs) are equipped with cutting-edge microelectronics, high-performance batteries, and advanced wireless connectivity.

While these robots are not self-aware, they still visualize and interpret the environment around them. Gathering information from various sensors, they respond to changing conditions and adapt their actions to accomplish assigned tasks. Navigating their way through a busy factory environment, these AMRs act autonomously by employing a form of artificial intelligence called machine learning.

Autonomous robots are playing a vital role in the lights-out factory. Also known as the dark factory, these facilities require very little human activity., Lights-out manufacturing is becoming more possible since AMRs are equipped with advanced sensors that enable them to operate in the dark. AMRs also play a crucial role in production, delivering raw materials around the factory. Their ability to act independently allows them to calculate the safest route through the dynamic environment. Any change in the production schedule is communicated to the fleet of AMRs, ensuring that the correct parts are in the right place at the right time.

To effectively navigate industrial settings, AMRs rely on sensors, vision systems, and machine learning to understand their environment. Like many industrial machines, these robots need to process vast volumes of data while working in harsh conditions. To help with this, radio frequency (RF) connectors provide communication from the sensor to the processor, delivering high data rates while withstanding the vibration and shock of the industrial environment.

Radio Frequencies for RobotsAn essential component of the AMR communication process involves RF signals. Every device that transmits or receives data wirelessly uses RF signals to carry information. RF signals are carried around the equipment using coaxial cables and connectors constructed with a single central conductor surrounded by an outer conductive shield. The inner and outer conductors are separated by an insulator called a dielectric, whose dimensions are critical to allow for efficient transmission of an RF signal.

While 5G wireless communication uses relatively low frequencies, up to 6GHz, many applications require higher performance. Modern precision RF connectors can transmit signals with frequencies greater than 80GHz. These higher frequencies allow AMRs to wirelessly send enormous amounts of information, forming part of a dynamic network in which information is shared with other nearby equipment. This data network forms the backbone of the smart factory.

RF connectors that allow such high frequencies are manufactured to exact requirements. The bodies and contacts of the connector are machined to ensure consistent dimensions, and the plastic materials used for the dielectric are chosen for their stability. The result is a connector that delivers a consistent impedance profile and low losses, even at the highest frequencies.

Still, the physics of higher frequencies means that connectors have become smaller. For instance, the ever-popular SMA connector, which has provided many years of service in industrial applications, is limited at higher frequencies. Newer designs, such as the 2.92mm coaxial connector, can deliver up to 40GHz, while the SMPM is capable of even higher frequencies up to 65GHz.

From Automotive to AutomationDesigners of the latest AMRs can benefit from technology developed for the automotive industry. The introduction of electrification, advanced driver assistance systems (ADAS), and self-driving vehicles has seen a growing demand for robust RF connector systems that can withstand the harsh conditions vehicles face. This reliability is critical for AMRs that travel beyond the factory walls. Optimizing AMRs will require high-performance RF connectors to provide communications with the latest 5G network when they are away from the factory network. These autonomous robots will also need small and robust antenna connectors for use with global positioning and global navigation satellite systems (GPS and GNSS).

The key to all these communication systems will be RF connectors designed for the industrial world’s tough conditions. However, the smaller connectors that are capable of the higher frequencies required for effective communication can be vulnerable in these demanding conditions. Precision manufacturing and robust design will be vital, as will design features that reduce the stress on cables, such as edge-launching and angled PCB mounting connectors.

ConclusionA wide range of industries have employed the latest AMRs. Their ability to work without supervision makes them ideal for use in hazardous situations where they perform tasks that are too dangerous for a human worker. While their primary use is currently in industrial settings, the use cases for AMRs could be as diverse as scientific research or disaster relief, and even in the vacuum of space or on the battlefield.

Industrial AMRs will free human workers from the need to supervise repetitive tasks. These devices must share information, navigate, and communicate through various environments, from the home to the factory and beyond. RF technology provides AMRs with the wireless links they need to accomplish these tasks. To deliver communication signals, designers will require the latest RF connectors that offer high performance in some of the most demanding conditions in the world.

David Pike

David Pike

The post RF Connectors for Autonomous Mobile Robots appeared first on ELE Times.

STMicroelectronics unveils new generation of silicon carbide power technology tailored for next-generation EV traction inverters

- Smaller, more efficient products to ramp-up in volumes through 2025 across 750V and 1200V classes, will bring the advantages of silicon carbide beyond premium models to mid-size and compact electric vehicles.

- ST plans to introduce multiple silicon carbide technology innovations through 2027, including a radical innovation.

STMicroelectronics, a global semiconductor leader serving customers across the spectrum of electronics applications, is introducing its fourth-generation STPOWER silicon carbide (SiC) MOSFET technology. The Generation 4 technology brings new benchmarks in power efficiency, power density and robustness. While serving the needs of both the automotive and industrial markets, the new technology is particularly optimized for traction inverters, the key component of electric vehicle (EV) powertrains. The company plans to introduce further advanced SiC technology innovations through 2027 as a commitment to innovation.

“STMicroelectronics is committed to driving the future of electric mobility and industrial efficiency through our cutting-edge silicon carbide technology. We continue to advance SiC MOSFET technology with innovations in the device, advanced packages, and power modules,” said Marco Cassis, President, Analog, Power & Discrete, MEMS and Sensors Group. “Together with our vertically integrated manufacturing strategy, we are delivering industry leading SiC technology performance and a resilient supply chain to meet the growing needs of our customers and contribute to a more sustainable future.”

As the market leader in SiC power MOSFETs, ST is driving further innovation to exploit SiC’s higher efficiency and greater power density compared to silicon devices. This latest generation of SiC devices is conceived to benefit future EV traction inverter platforms, with further advances in size and energy-saving potential. While the EV market continues to grow, challenges remain to achieve widespread adoption and car makers are looking to deliver more affordable electric cars. 800V EV bus drive systems based on SiC have enabled faster charging and reduced EV weight, allowing car makers to produce vehicles with longer driving ranges for premium models. ST’s new SiC MOSFET devices, which will be made available in 750V and 1200V classes, will improve energy efficiency and performance of both 400V and 800V EV bus traction inverters, bringing the advantages of SiC to mid-size and compact EVs — key segments to help achieve mass market adoption. The new generation SiC technology is also suitable for a variety of high-power industrial applications, including solar inverters, energy storage solutions and datacenters, significantly improving energy efficiency for these growing applications.

Availability

ST has completed qualification of the 750V class of the fourth generation SiC technology platform and expects to complete qualification of the 1200V class in the first quarter of 2025. Commercial availability of devices with nominal voltage ratings of 750V and 1200V will follow, allowing designers to address applications operating from standard AC-line voltages up to high-voltage EV batteries and chargers.

Use cases

ST’s Generation 4 SiC MOSFETs provide higher efficiency, smaller components, reduced weight, and extended driving range compared to silicon-based solutions. These benefits are critical for achieving widespread adoption of EVs and leading EV manufacturers are engaged with ST to introduce the Generation 4 SiC technology into their vehicles, enhancing performance and energy efficiency. While the primary application is EV traction inverters, ST’s Generation 4 SiC MOSFETs are also suitable for use in high-power industrial motor drives, benefiting from the devices’ improved switching performance and robustness. This results in more efficient and reliable motor control, reducing energy consumption and operational costs in industrial settings. In renewable energy applications, the Generation 4 SiC MOSFETs enhance the efficiency of solar inverters and energy storage systems, contributing to more sustainable and cost-effective energy solutions. Additionally, these SiC MOSFETs can be utilized in power supply units for server datacenters for AI, where their high efficiency and compact size are crucial for the significant power demands and thermal management challenges.

Roadmap

To accelerate the development of SiC power devices through its vertically integrated manufacturing strategy, ST is developing multiple SiC technology innovations in parallel to advance power device technologies over the next three years. The fifth generation of ST SiC power devices will feature an innovative high-power density technology based on planar structure. ST is at the same time developing a radical innovation that promises outstanding on-resistance RDS(on) value at high temperatures and further RDS(on) reduction, compared to existing SiC technologies.

ST will attend ICSCRM 2024, the annual scientific and industry conference exploring the newest achievements in SiC and other wide bandgap semiconductors. The event, from September 29 to October 04, 2024, in Raleigh, North Carolina will include ST technical presentations and an industrial keynote on ‘High volume industrial environment for leading edge technologies in SiC’. Find out more here: ICSCRM 2024 – STMicroelectronics.

The post STMicroelectronics unveils new generation of silicon carbide power technology tailored for next-generation EV traction inverters appeared first on ELE Times.

STMicroelectronics delivers industry’s first FIPS 140-3 certified TPMs for computer, server, and embedded systems

State-of-the-art protection certified to the latest standard for information security certification, globally recognized and mandatory for US federal procurement

STMicroelectronics has announced the FIPS 140-3 certification of STSAFE-TPM trusted platform modules (TPMs), the first standardized cryptographic modules on the market to receive this certificate.

The newly certified TPMs, the ST33KTPM2X, ST33KTPM2XSPI, ST33KTPM2XI2C, ST33KTPM2I, and ST33KTPM2A provide cryptographic asset protection to meet security and regulatory requirements for critical information systems. They are used in PCs, servers, and network-connected IoT devices, as well as medical and infrastructure high-assurance equipment. The ST33KTPM2I is qualified for long lifetime industrial systems. ST33KTPM2A commercialized under the name STSAFE-V100-TPM leverages an AEC-Q100-qualified hardware platform required for automotive integration.

FIPS 140-3 is the latest version of the federal information processing standards (FIPS) specifications for cryptographic modules, superseding FIPS 140-2. “All FIPS 140-2 certificates are scheduled to expire in September 2026,” commented Laurent Degauque, Marketing Director, Connected Security, STMicroelectronics. “By achieving FIPS 140-3, our TPMs are uniquely ready for new designs and let customers create secure, interoperable equipment with extended product and certification lifetimes.”

The products support use cases like secure boot, remote/anonymous attestation, and secure storage with an extended user memory of 200kBytes. In addition, each product supports secure firmware update to add new cryptographic algorithms like PQC and maintain state-of-the-art cryptographic asset protection.

The STSAFE-TPM devices are compliant with multiple industry security standards. These include Trusted Computing Group TPM 2.0 applicable to trusted platform modules, Common Criteria EAL4+, passing the CC framework’s most stringent vulnerability analysis (AVA_VAN.5), and now FIPS 140-3 level 1 with physical security level 3. They offer cryptographic services (ECDSA & ECDH up to 384 bits, RSA up to 4096 including key generation, AES up to 256 bits, SHA1, SHA2 and SHA3), standardized by TCG and compatible with software stacks under FIPS 140-3 certification.

ST also offers provisioning services to load device keys and certificates to reduce the total solution cost and time to market and to guarantee the security of the supply chain.

The post STMicroelectronics delivers industry’s first FIPS 140-3 certified TPMs for computer, server, and embedded systems appeared first on ELE Times.

Spectrum Instrumentation launches fast switching multi-tone DDS Instruments

Spectrum Instrumentation launches a family of DDS Generators named the 96xx series, forming a new product category in the company’s portfolio. The new DDS Instruments offer up to 50 sine wave carriers on one single output channel. This feature provides a new way for engineers and scientists to produce and independently control multi-tone sine signals. DDS, which is short for “Direct Digital Synthesis”, is a powerful technique for generating high-purity signals (typically sinewave cores, also called carriers or tones) with ultrafast switching between output frequencies and fine frequency resolution. The products can produce multiple tones, covering a broad range of operating frequencies up to 200 MHz. It makes them uniquely agile signal sources that are suitable for demanding applications in industries such as biomedicine, communications, semiconductors and quantum science.

Link to the product video (5 min): https://youtu.be/FEzjhXFNfF0

The 96xxs series comprises 12 different models in three different formfactors; PCIe cards, PXIe modules and Ethernet instruments. A single PCIe or PXIe card can produce up to 50 different low-phase-noise variable-frequency tones and is available with up to 4 channels. The stand-alone Ethernet instruments offer from 2 to 24 channels. For applications needing more than 50 tones, the larger NETBOX units support up to 300, or it is possible to connect multiple cards together with the Star Hub synchronization module to create systems with up to 400 tones. All models provide integrated output amplifiers with programmable signal amplitudes up to ±2.5 V into 50 Ohm loads, or ±5 V for high-impedance.

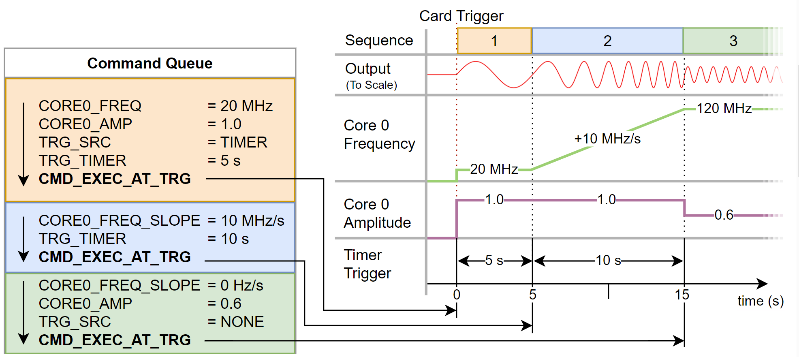

Extremely fast parameter changesThe speed at which these products can change the characteristics of a tone is what makes them different to conventional signal generators. Fully programmable, changes can be made using simple commands almost instantly. New settings for a tone’s frequency, amplitude and phase as well as amplitude slopes and frequency slopes can be initiated during runtime, or via preloaded sequences of DDS commands. Millions of DDS commands can be stored in the on-board memory. Setting changes can be triggered externally, or by an internal timer, or immediately on command. No transition jitter or glitches appear and the timing resolution for sequencing commands is as small as just 6.4 nanoseconds.

DDS controls waveforms in Test and Measurement, Communications and QuantumThe 96xx series DDS generators provide an easy and programmable way for users to produce trains of waveforms, frequency sweeps or finely-tuneable references of various frequencies and profiles. Applications can be found in industrial, medical and imaging systems, network analysis or even communication technology where data is encoded using phase and frequency modulation on a carrier. Another application is the control of lasers through AODs and AOMs, as often used in quantum experiments. Laser control can be made at very high speeds with just a few simple commands – this is in contrast to the more processing-intensive method that uses an Arbitrary Waveform Generator (AWG) and demands large data array calculations. Issuing a small series of slope commands, the user can control advanced functions like s-shaped or custom-shaped frequency transitions, custom pulse envelopes, AM or FM modulation and more.

In DDS-mode, only a few commands are needed to, for example, generate a sine wave (orange block), accelerate the frequency (blue block) and lower the amplitude (green block).

Easy system integration

In DDS-mode, only a few commands are needed to, for example, generate a sine wave (orange block), accelerate the frequency (blue block) and lower the amplitude (green block).

Easy system integration

Running under Windows or Linux operating systems, the 96xx series DDS generators can be programmed using programming examples for C++, Python, C#, JAVA, LabVIEW, MATLAB and others as well as a high-level Python API‘s that provide an easy way to control the products.

Two instruments in oneShould there ever be a need to generate more complex waveforms, the 96xx series can also be converted into a fully functional AWG. A firmware option is available that switches the DDS Generator into an AWG, allowing the replay of arbitrary waveforms on all active channels synchronously. Operating modes such as Single Shot, Loop, Single Restart, Multiple Replay, Gated Replay, Streaming (FIFO) or Sequence Replay are all supported.

The post Spectrum Instrumentation launches fast switching multi-tone DDS Instruments appeared first on ELE Times.

AI-enabled COMs for medical technology

Maximilian Gerstl, congatec Product Line Manager and AI expert, and Zeljko Loncaric, congatec Market Segment Manager Medical and Infrastructure

AI in medical technology supports health professionals and enhances diagnostic accuracy. As AI algorithms must process vast amounts of data in real-time, there is a need for high-performance computing solutions such as conga-TC700 Computer-on-Modules (COMs). These COMs are powered by Intel Core Ultra processors, which uniquely integrate CPU, GPU, and NPU on a single chip.

Medical device manufacturers have consistently been at the forefront of innovation and technological progress. As early adopters, many have embraced and utilized AI systems for decades, well before widespread general acceptance.

The availability of increasingly powerful hardware components and the development of advanced algorithms enabled device manufacturers to use AI methods to significantly improve medical imaging and data analysis in the 1990s.

The emergence of machine learning for training AI algorithms in the 2000s led to even more sophisticated image analysis and the development of high-performance computing systems in fields like radiology. Since the 2010s, device manufacturers have made further strides in image processing and big data analysis.

Modular concept for medical devicescongatec’s modular concept is particularly well-suited for a wide range of medical devices that can benefit from AI integration. This includes high-performance imaging equipment such as MRI and CT scanners (Fig 1), as well as more compact devices like ultrasound, X-ray, endoscopy equipment, and mammography screening devices.

Fig 2: Portable ultrasound devices are one of the most common applications of COMs in medical technology.

Fig 2: Portable ultrasound devices are one of the most common applications of COMs in medical technology.

Beyond diagnostic devices, Computer-on-Modules also play a crucial role in therapeutic equipment such as ventilators (Fig 3). In these systems, they enable intelligent algorithms that automatically determine optimal ventilation settings for patients. In addition, these algorithms continuously analyze critical patient data and adjust parameters like respiratory rate, tidal volume, and oxygen supply.

The development, application, and significance of AI in medical technology have gained substantial momentum over the past decade. This progress is driven not only by continuous advances in computer technology but also by optimizations in AI algorithms.

Fig 3: Computer-on-Modules are even used in compact devices such as ventilators.

MRI scans in under a minute

Fig 3: Computer-on-Modules are even used in compact devices such as ventilators.

MRI scans in under a minute

An innovative AI algorithm for magnetic resonance imaging (MRI) now enables scans to be completed in less than a minute, significantly reducing the time patients spend in the scanner. This advanced scanning process, known as upscaling or super-scaling, requires fewer images than traditional methods. The pre-trained AI interpolates a small number of individual images into a high-resolution overall image. Moreover, the AI can independently and accurately sharpen blurry areas within images.

AI-based endoscopy devices for more accurate diagnosesAI is also being integrated into endoscopy devices, for instance to alert doctors to potentially missed lesions during examination and directing their attention to specific areas of concern. High-performance inference is crucial to ensure that this happens in real-time and that trained models execute swiftly. AI-based endoscopy devices provide doctors with a powerful tool to achieve more accurate clinical results and deliver better patient care.

Historically, medical devices required either dedicated GPGPU computing accelerators (often integrated via the classic PCIe slot and relatively large and power-hungry) or smaller AI accelerator cards designed for an M.2 slot to achieve the necessary AI performance.

AI capabilities integrated into the chipToday, more and more processor manufacturers are adapting their chip portfolios to meet the demands of artificial intelligence. By integrating AI functions directly into their products, many medical applications can now be realized more easily, quickly, and at a lower total cost of ownership (TCO), eliminating the need for additional accelerator cards.

CPU, GPU, and NPU on one chip for the first timeThe first generation of Intel Core Ultra processors (Fig 4) exemplifies this trend. These processors uniquely combine a CPU, a particularly powerful GPU (graphics processing unit), and – for the first time – an NPU (neural processing unit) on a single chip. AI applications with high computing power demands can leverage the combined power of the CPU, GPU, and NPU, whereas AI models requiring high energy efficiency and high performance per watt can be optimized to run only on the NPU.

The new NPU in the Meteor Lake processors executes machine learning algorithms and AI inference with approximately 20 times greater energy efficiency compared to standard x86 instruction sets. For image classification tasks, applications can utilize the graphics unit as a general-purpose GPU (GPGPU), achieving performance levels comparable to discrete graphics units. This results in 1.9 times faster graphics or GPGPU processing, enabling a more detailed, meaningful, and immersive user experience.

These new AI features can be easily implemented using standardized Computer-on-Modules, particularly COM Express, without requiring developers to modify existing designs.

COMs provide high flexibilityThis is precisely why COMs are popular in medical technology among other industries. As AI and its applications continue to evolve, the flexibility of COM and carrier board solutions allows developers to adapt their products to new computing requirements with minimal integration effort and software modifications. They just need to follow two simple steps: unplug the old module, plug in the new one, done!

One such Computer-on-Module suitable for demanding edge AI workloads is the conga-TC700. This COM Express Type 6 Compact module, powered by Intel Core Ultra processors (codenamed Meteor Lake), integrates all the necessary AI functions for the applications previously discussed.

Generate findings automaticallyThe conga-TC700 is particularly well-suited for vertical medical markets and their applications due to its long availability of ten years and the ease of upgrading applications based on the open COM Express standard. It enables powerful real-time computing and offers high-performance AI functions for various medical applications, including surgical robots, diagnostic systems, and high-resolution diagnostic workstations for radiologists. The latter can automatically identify critical findings, providing valuable support to medical professionals.

Beyond the new edge AI capabilities of the Intel Core Ultra platform, Intel also offers the Intel Geti software framework. This comprehensive platform facilitates the creation of powerful computer vision models. Developers benefit from a unified ecosystem that spans from machine learning in the cloud to AI-accelerated edge devices.

Optimizing AI models with OpenVINOThe congatec COMs ecosystem is further enhanced by Intel’s open-source software toolkit, OpenVINO. This tool allows for the optimization and transfer of pre-developed, often hardware-specific AI models to the customer’s platform, regardless of where they were created. OpenVINO can also manage workload distribution, intelligently deciding which tasks should be handled by the CPU, GPU, or NPU for maximum efficiency.

Comprehensive support for medical device developerscongatec offers an extensive ecosystem and design-in services to simplify and accelerate application development. The offering includes evaluation, production, and application-ready carrier boards, as well as customized active and passive cooling solutions. congatec also provides a wide range of application development services, including extensive documentation, training, signal integrity measurements, shock and vibration tests for customer-specific system designs, temperature screening, and high-speed signal compliance testing.

ConclusionAI has been a long-standing focus in medical technology, predating its adoption in other industrial markets. In fact, AI is even being touted as the new operating system for medical devices. Recent advancements in semiconductor technology have yielded microprocessors with exceptionally high computing and graphics performance. Featuring integrated NPU units, they enable faster, more accurate diagnoses while consuming less energy than predecessors. When implemented through Computer-on-Modules, today’s AI-supported medical devices become highly future-proof, making it easy to integrate upcoming technologies by simply swapping the module.

The post AI-enabled COMs for medical technology appeared first on ELE Times.

OptiMOS™ 6 135 V and 150 V MOSFETs enable higher efficiency in drives and SMPS applications

Infineon Technologies AG expands its OptiMOS 6 MOSFET portfolio with the new 135 V and 150 V product families. The devices are designed to meet the requirements of drives and switched-mode power supply (SMPS) applications and complement the recently released launched OptiMOS 6 120 V MOSFETs. With the extended portfolio, Infineon offers its customers a wide range of alternatives to select the best-fit MOSFETs for various applications. Lower switching losses benefit applications like server SMPS, solar optimizers, high-power USB chargers, and telecom. Improved conduction losses are highly beneficial for motor inverters in e-forklifts and light electric vehicles (LEVs).

Compared to the previous generation (OptiMOS 5 150 V MOSFETs), the new product families offer a reduction in on-state resistance RDS(on) of up to 50 percent, while the FOMg is reduced by 20 percent. With the very low RDS(on), their improved switching performance and excellent EMI behavior, both new families deliver unparalleled efficiency, power density, and reliability. A faster and softer body diode delivers an up to 59 percent lower Qrr, less overshoot and ringing.

The OptiMOS 6 135 V and 150 V MOSFETs are available in a variety of packages to provide customers with a range of options for best-fit products. This broad package portfolio includes TO-220, D2PAK 3-pin, D2PAK 7-pin, TOLL, TOLG, TOLT, SuperSO8 5×6 and PQFN 3.3×3.3.

The post OptiMOS™ 6 135 V and 150 V MOSFETs enable higher efficiency in drives and SMPS applications appeared first on ELE Times.

New CEA-Leti Technology Improves DC-DC Converter Efficiency and Paves the Way to Piezoelectric Converters Without Transformers

‘This Type of Converter Is Now Compatible With a Much Wider Range of Applications, Such as TVs, Phones, Tablets and Electrical Tools.’

Building on its earlier breakthroughs introducing a new way of converting electrical power using piezoelectric resonators and developing a dual-bridge piezoelectric resonator converter, CEA-Leti has paved the way to isolating piezoelectric converters without transformers.

The new topology of dual-bridge isolated piezoelectric resonator converter (DB-IPRC) provides isolation using two independent piezoelectric resonators. The improved version of the DC-DC converter significantly improves efficiency, while maintaining the converter isolation principle.

The results were reported in a paper, “Switching Assisting Circuit Improving the Efficiency of DC-DC Converters Based on Piezoelectric Resonators”, presented in this summer at PCIM Europe 2024.

The paper notes that “for a 200 V to 120 V conversion, the converter shows an efficiency of 96.2 percent with the inductive assisting circuit, 94.3 percent with the piezoelectric one and 87.4 percent without any assisting circuit. The (piezoelectric resonator) assisting circuit offers a gain in efficiency over a smaller operating range than the inductance, but leads to a flatter converter.”

Building on 2023 BreakthroughsThe work expands on previous results reported by CEA-Leti in the August 2023 issue of “IEEE Transactions on Power Electronics” in the article, “A New Isolated Topology of DC–DC Converter Based on Piezoelectric Resonators”. The article says that the new topology “uses the natural isolation of piezoelectric resonators to isolate the converter’s output from the input and vice-versa.”

The use of piezoelectric resonators instead of inductors in power conversion “will lead to a dramatic reduction in the size of power converters,” explained Ghislain Despesse, a co-author of the PCIM paper and the earlier article. “Our results make it possible to extend this type of compact conversion to isolated converters. So this type of converter is now compatible with a much wider range of applications, such as TVs, phones, tablets and electrical tools.”

“For many people, piezoelectricity is associated with energy harvesting and the idea of low power,” Despesse said. “But in power conversion, piezoelectrics operate at high frequencies, greater than 100kHz, with no limits in terms of input power. That makes it possible to reach power levels of several hundred watts. The range of applications is therefore very broad, with most converters having a rated power of less than 100W.”

The post New CEA-Leti Technology Improves DC-DC Converter Efficiency and Paves the Way to Piezoelectric Converters Without Transformers appeared first on ELE Times.

New Bosch radar-based assistance system used for first time by KTM

- Six new Bosch radar-based convenience and safety features now available worldwide

- New generation of rider assistance functions with front radar used for the first time by KTM

- Bosch Accident Research estimates that assistance functions could prevent up to one in six motorcycle accidents on German roads alone

Thanks to Bosch, motorcyclists can now feel even safer in the saddle: the technology company has unveiled six new radar-based assistance systems, including five world-firsts. According to Bosch Accident Research, these could help prevent not just one in seven, like earlier systems, but as many as one in six accidents on German roads alone. Bosch already revolutionized the motorcycle market back in 2020 with its support functions for motorcyclists. Of the six new assistance functions, four will be unveiled in a new model from leading European motorbike manufacturer KTM in November 2024 and are set to enter production in 2025. “Bosch’s declared aim is to make motorcycling even safer and more comfortable by employing innovative new technologies – without diminishing riding enjoyment,” says Geoff Liersch, head of Two-Wheeler & Powersports at Bosch. “The new functions mark yet another step in this direction, and we’re delighted to have KTM as a customer.” The manufacturer will incorporate the four Bosch rider assistance functions that use front radar. This is not the first time Bosch and KTM have worked together: in 2013, the two companies collaborated on the successful launch of the MSC motorcycle stability control system. „We’re very satisfied with the longstanding collaborative relationship between our development teams, and we’re excited that KTM is the first to put these new functions to use,” says Stefan Haist, Lead KTM Chassis Control System – Street Development.

Bosch assistance systems provide more support on two wheels Adaptive cruise control – stop and go (ACC S&G)For two-wheelers, traffic jams can be strenuous as well as dangerous. Riders have to constantly apply the clutch, use the brakes, and then start moving again. To make this task easier, Bosch launched ACC adaptive cruise control back in 2020. Once the desired speed has been set, this system constantly matches the vehicle’s speed to the flow of traffic while maintaining the necessary safe distance from the vehicle in front. Bosch has now taken this technology to a new level to offer increased riding comfort with its new ACC S&G function, which can bring the motorcycle to a controlled standstill in order to support the motorcyclist. This works best with an automatic transmission such as the one used in KTM’s new bike, which will be the first to incorporate this new function. If their motorcycle comes to a halt, there is no need for riders to use the clutch; they can set their bike in motion simply by pressing a button or briefly activating the throttle as soon as the vehicle in front starts moving.

Group ride assist (GRA)Group riding in a staggered formation is popular among motorcyclists, though it can be challenging with ACC, because the function expects the motorcycles riding in front to be in the middle of the lane. GRA is a useful addition to ACC; using an algorithm, it detects when a group is riding in a staggered formation and regulates the speed to automatically maintain the same distance from the motorcycles in front. In this way, the function assists riders in achieving a natural group formation. When not riding in groups, the GRA system works the same as ACC.

Riding distance assist (RDA)When traffic is flowing smoothly and RDA is activated, it helps maintain an appropriate distance from vehicles in front and thus prevent rear-end collisions. With ACC, a desired speed must be set; but when RDA is activated, the motorcycle can be controlled as normal via the throttle grip. While riding, the system automatically reduces the vehicle’s acceleration or applies the brakes as and when required. Riders can set the desired distance from the vehicle in front beforehand. If they wish, they can also use a switch to deactivate the function or apply the throttle to override the deceleration generated by the RDA system. This enables the function to blend naturally and comfortably into the dynamic flow of riding.

Emergency brake assist (EBA)Hazardous situations on the road require not only a rapid response but, in many cases, emergency braking. Every second counts when it comes to preventing collisions and avoiding potentially serious consequences. EBA is triggered when the system detects a risk of collision and the rider doesn’t brake hard enough. In this case, the function actively increases the wheel brake pressure further to reduce the bike’s speed as quickly as possible.

Rear distance warning (RDW)Even in a car, it can be hard to keep a constant eye on traffic approaching from behind; but on a motorcycle, it requires an extra level of concentration.

RDW monitors the situation behind the rider and flashes a warning on the display if another vehicle gets too close. Based on this warning, the rider can take mitigating action to prevent a rear-end collision.

Rear collision warning (RCW)RCW warns vehicles behind the motorcycle when a rear-end collision is imminent, for example by activating the hazard warning lights. In this way, the function protects motorcyclists from accidents caused by having to brake unexpectedly or by a vehicle failing to see them – whether waiting at traffic lights, sitting in a traffic jam, or riding in free-flowing traffic.

These new functions supplement Bosch’s worldwide portfolio of radar-based assistance systems, thus expanding the “sensory world” of the motorcycle. In addition to basic safety features, increasing importance is also being given to convenience and experience features that focus on the motorcycle and take real-life riding situations into consideration – functions that ensure not only safety and convenience, but also unmatched riding enjoyment.

The post New Bosch radar-based assistance system used for first time by KTM appeared first on ELE Times.

10 Major Lithium-ion Battery Companies in USA in 2024

The United States of America is one of the lithium-ion battery powerhouses in the world. Besides the domestic lithium-ion manufacturing companies, it has the presence of all major lithium-ion companies from across the globe.

Market-size of lithium-ion batteries in the United States of America

The United States of America is one of the largest lithium-ion batteries market in the world. Speaking specifically about the market-size of the lithium-ion batteries in the USA, it was worth US$ 13.7 billion in 2023. By 2032, its market size is expected to be worth US$ 71.6 billion. Hence, from 2023 to 2032, the market-size of lithium-ion batteries in the USA is expected to witness a Compound Annual Growth Rate (CAGR) of 20.1%.

Ranking of the United States of America in the world as per the market size of lithium-ion batteries

As per the BloombergNEF’s ranking, China has the largest market of lithium-ion batteries in the world. It is followed by the United States of America. Hence, the USA has the second largest lithium-ion market in the world.

10 Major Lithium-ion Companies in the USA in 2024

The 10 major lithium-ion manufacturing companies in the world are as follows:

- Tesla, Inc.

It is an American multi-national company. It manufacturers batteries for cars and home power storage, solar panels, and electric automobiles.

It was incorporated in July, 2003, as Tesla Motors. It was named so after a Serbian-American inventor, Nikola Tesla.

Its head-office is in Austin, Texas.

It invests hugely in developing new lithium-ion technologies. For instance, in 2016, it had set-up a five-year research and development collaboration with Dalhousie University.

It has also acquired many battery manufacturing companies in the past. For instance, Maxwell Technologies, Hibar Systems, and Springpower International.

Its lithium-ion batteries are known for using majorly two types of cathodes. First, nickel-cobalt-aluminium (NCA) cathodes. And second, lithium-iron-phosphate (LFP) cathodes.

Its lithium-ion batteries are known world-over for their high quality and durability.

For the production of lithium-ion batteries, it has established its Gigafactories across the world. They are in Austin, New York, Nevada, Fremont, Shanghai, and Berlin-Brandenburg. Besides these, it is also establishing a new Gigafactory at Neuvo Leon, Mexico.

- EnerSys

It is among the leading lithium-ion battery companies in the world. It supplies lithium-ion batteries to customers in more than 100 countries of the world.

Its manufacturing process is certified as per the ISO 9000, ISO 9001-2015, ISO 14001-2015, ISO 13485-2016, AS9100D, and IATF 16949.

It is headquartered in Reading, Pennsylvania. Besides, it has two regional headquarters. One in Zug, Switzerland. And the other in Singapore.

It manufacturers the famous NexSys® iON series of lithium-ion batteries. They are produced using Nickel-Manganese-Cobalt (NMC) chemistry.

The speciality of these batteries is that they are ideal for applications in heavy-duty operations. Besides, they recharge at a very fast pace, are very durable and have low-upkeep. These qualities lower down the operational costs and make the entire production process very economical.

Owing to all these qualities, its lithium-ion batteries are used in appliances that find applications in grids, telecommunications, medical safety, and climate change. Besides, it is a major producer of lithium-ion batteries for energy storage solutions.

- Panasonic Holdings Corporation

It is a Japanese multinational electronics company. It was established in 1918.

Back then, it was called Matsushita Electric Housewares Manufacturing Works. It was established at Fukushima, Osaka, Japan. It was renamed as Matsushita Electric Industrial Co., Ltd., in 1935. Similarly, it was renamed as Panasonic Corporation in 2008. In 2022, it became a holding company and was renamed as Panasonic Holdings Corporation.

Its head-office is at Kadoma, Osaka, Japan.

The lithium-ion batteries are manufactured by Panasonic Holdings Corporation’s constituent company, Panasonic Energy Co., Ltd. It was incorporated in April, 2022. It is also based out of Osaka0, Japan.

It manufactures a wide range of lithium-ion batteries. Its cylindrical lithium-ion batteries are used in automotive. Besides, they are used as primary batteries and in storage battery modules.

- LG Energy Solution, Ltd.

It is a lithium-ion battery manufacturing company headquartered in Seoul, South Korea.

It was founded in December, 2020, when LG Chem Energy Solution Business Division, which had started its operations in 1992 shut down its operations in 2020, and transformed into a new company- LG Energy Solution, Ltd.

Its specialisation is the production of lithium-ion batteries for electric vehicles.

- Duracell, Inc.

It is a wholly-owned subsidiary of Berkshire Hathaway since 2016.

It manufacturers lithium-ion batteries in a range of sizes. A few such models are known as CR2, 123, 245, and 1/3N. Besides, it manufacturers lithium coin button batteries in a range of products- 2016, 2025, 2032, and lithium-ion button batteries such as LR44, 364, 362/361, 371/370, 377. Also, it manufacturers special lithium-ion batteries such as MN21, CR2, 123, 223, 245, 1/3N, AAAA.

It manufacturers ultra-light lithium ion batteries in three ranges- 28L, 223, and 245.

One of its premium and most famous products is the Duracell High Power Lithium 123 batteries. Its special feature is that they are made up of high-purity lithium. They have long guarantee and lasting power for a range of devices. For instance, sensors, smoke detectors, photo flash, keyless locks, flashlights, electronic dog collars, and bike accessories.

- Volkswagen Group

It is a world-famous automotive company. It is based out of Wolfsburg, Germany. Its American subsidiary company is named Volkswagen of America, Inc. Its head-office is based out of Reston, Virginia. It has established its advanced manufacturing facility at Chattanooga, Tennessee.

Its speciality is that it manufactures very high-quality solid-state lithium-ion batteries for a wide range of applications. It manufactures these lithium-ion batteries by its battery innovation start-up QuantumScape.

- Contemporary Amperex Technology Co., Limited (CATL)

It is a Chinese battery manufacturer and technology company. It was founded in 2011. It specializes in the manufacturing of lithium-ion batteries for use in three domains- electric vehicles, energy storage systems, and battery management systems (BMS).

It has established a lithium-ion battery manufacturing facility in Detroit, a city in the Michigan province of the USA. This plant supplies lithium-ion batteries to all the world-renowned car manufacturers. For instance, BMW, Daimler, Jaguar Land Rover, and Volkswagen.

- Wanxiang A123 Systems Corp.

It is a subsidiary of the Chinese Wanxiang Group Holdings. It was established in 2001 by three people- Bart Riley, Ric Fulop, and Yet-Ming Chiang.

It specialises in the manufacturing of nano-iron phosphate lithium-ion batteries. They are used in a wide range of applications- both appliances and energy storage devices.

- Lithion Battery, Inc.

It is head-quartered in Nevada, Henderson, USA. It has its production facilities in eight different locations across the world.

It has established a highly advanced manufacturing and testing facility for lithium-ion batteries at Henderson, Nevada, USA. It is dedicated to the production of lithium-ion cells and battery pack.

Its manufacturing process adheres to the Battery Council International (BCI) standards.

It manufacturers highly differentiated lithium iron phosphate cells, modules, and battery packs.

10. Toshiba Corporation

It is a Japanese multi-national company. It is head-quartered at Minato City, Tokyo, Japan.

It manufacturers the world-famous SCiB lithium-ion batteries. It uses lithium titanium oxide as anode. This enables it to achieve its desirable characteristics. For instance, long life, fast charging, safety, and high input/ output power.

lithium-ion batteries. It uses lithium titanium oxide as anode. This enables it to achieve its desirable characteristics. For instance, long life, fast charging, safety, and high input/ output power.

Its SCiB lithium-ion batteries are used in a wide range of applications. Such as automobiles, vehicle, power plants, elevators, and other industrial and infrastructure applications.

lithium-ion batteries are used in a wide range of applications. Such as automobiles, vehicle, power plants, elevators, and other industrial and infrastructure applications.

The post 10 Major Lithium-ion Battery Companies in USA in 2024 appeared first on ELE Times.

New Family of Voltage-Controlled Saw Oscillators with Ultra-Low Phase Noise Performance for Radar Applications

Microchip’s VCSO 101765 devices are available in 320 MHz and 400 MHz with a small form factor

Mission-critical applications like radar and test and measurement require specialized components with precise frequency control and ultra-low phase noise to enhance signal clarity, stability and overall system performance. To provide the aerospace and defense market with specialized technology for generating precise signals and frequencies, Microchip Technology today announces its new 101765 family of Voltage-Controlled SAW Oscillators (VCSOs) designed to deliver ultra-low phase noise and operate at 320 MHz and 400 MHz.

The 101765-320-A VCSO delivers ultra-low phase noise performance of 166 dBc at 10 kHz offset and a 182 dBc floor. Low phase noise is crucial for improving the lower limit of detection in radar and other sensing applications. These devices are optimal for radar and instrumentation systems such as Active Electronically Scanned Array (AESA) that demand high fidelity in critical phase-locked loop timing applications.

Available in a small form factor, 1 inch × 1 inch hermetic Kovar package, the VCSOs are designed for applications where Size, Weight, Power and Cost (SWaP-C) are important factors. The VCSOs are offered with supply voltages from 4.75–15.75V and a supply current of 111 mA to provide a power-efficient timing solution.

“Microchip continues to deliver ultra-low phase noise and high-performance timing products at a competitive price point to meet the needs of our customers,” said Leon Gross, corporate vice president of Microchip’s discrete products group. “Customers can choose Microchip for their timing needs and select other components for their application including FPGAs, MPUs, MCUs, RF, power management, security and connectivity.”

For aerospace and defense customers who require a higher degree of reliability, the 101765 VCSOs are available with MIL-PRF-38534 screening. The screening process is designed to ensure only the highest reliability components are used in critical applications where failure is not an option, such as in military and aerospace systems.

The 101765 VCSO family is a fresh addition to Microchip’s family of SAW products for aerospace and defense applications, which are designed to offer levels of high reliability for robust and mission-critical environments. They are available in a wide range of package options for ruggedized applications and support a center frequency range from 30 MHz to 2.7 GHz. Additionally, Microchip can address ITAR, EAR, and classified specifications for hardware to meet the customer’s security requirements.

Development ToolsThe VCSO devices are supported by the 101765-320-A-N-S-TB and 101765-400-B-N-S-TB test boards to enable customers to test the parts during the design phase.

Pricing and AvailabilityThe VCSO 101765-320-A and 101765-400-B are available now for purchase. For additional information and to purchase, contact a Microchip sales representative or authorized worldwide distributor.

The post New Family of Voltage-Controlled Saw Oscillators with Ultra-Low Phase Noise Performance for Radar Applications appeared first on ELE Times.

EDOM Technology Creates Resource Exchange Platform to Help Developers Quickly Get Started with AI Applications Using NVIDIA Jetson

Focusing on the development needs of edge AI applications, EDOM Technology has set up a microsite specifically designed to provide the latest hardware information and software development kits (SDKs) offered with the NVIDIA Jetson platform for edge AI and robotics. The microsite also provides rich content such as solution examples for diverse application scenarios, ecosystem partner resources, market information, etc., which can help developers to easily implement various innovative projects on the Jetson platform.

EDOM Technology has been an authorized distributor of the NVIDIA Jetson platform for over 20 years. NVIDIA Jetson offers complete systems-on-module (SoMs), including CPU, GPU, memory, various accelerators, built-in power management, and a variety of high-speed interfaces and external peripheral connections. The Jetson family of SoMs provides different levels of performance and energy efficiency to meet the development needs of different projects. From software services to hardware resources, NVIDIA Jetson modules have a complete set of compatible products, which can help developers obtain corresponding resources and accelerate project development.

In addition to various NVIDIA Jetson software and hardware resources, EDOM Technology’s microsite links to NVIDIA’s online forum, allowing developers to discuss and interchange ideas, solve development problems, and accelerate project progress. Manufacturers or developers who want to join the Jetson platform ecosystem can establish contact through the website to obtain corresponding technical support or development assistance.

Jeffrey Yu, CEO and President of EDOM Technology, said: “Our new exchange platform for NVIDIA Jetson meets the various needs of developers, helps solve the problem of resource dispersion, and ensures that developers can continue to obtain the latest technology information and trends. With years of collaboration with NVIDIA, EDOM Technology assembles a comprehensive and prosperous network of hardware and software resources, providing curated information on the latest AI models, libraries & SDKs from NVIDIA Metropolis, Isaac and Holoscan, from the cloud to the edge, and solutions for applications including robotics, vision AI, edge computing, and generative AI. Whether you are a novice developer or an experienced expert, you can find suitable tools to get started quickly according to your own needs.”

NVIDIA Metropolis offers powerful developer tools to supercharge vision AI applications, making the world’s most important spaces and operations safer and more efficient. NVIDIA Isaac is an AI robot development platform that offers more acceleration libraries and optimized AI models for robotics applications, like autonomous mobile robots and robotic arms. The NVIDIA Holoscan SDK provides a sensor processing platform with an optimized library for data processing and AI, especially for low-latency video processing applications, like medical devices.

By creating the microsite and integrating it with the NVIDIA Jetson AI Lab, EDOM Technology provides developers with a one-stop solution to help users get started quickly on generative AI and complete projects smoothly. In addition, users who log in to the website and subscribe to the newsletter through the “Lucky Draw Form” before the end of September 2024 will have a chance to win an NVIDIA Jetson Orin Nano developer kit.

The post EDOM Technology Creates Resource Exchange Platform to Help Developers Quickly Get Started with AI Applications Using NVIDIA Jetson appeared first on ELE Times.