Feed aggregator

Designing better listening experiences with multi-driver IEMs

Once primarily used by stage performers, modern in-ear monitors (IEMs) have expanded into the personal audio space over the past decade, transforming how we experience music, games, and digital content through unprecedented levels of sonic detail and spatial accuracy. This interest from audio enthusiasts, gamers, and a growing segment of consumers requires manufacturers to meet higher demands for premium sound.

At the heart of these immersive listening experiences lies a sophisticated engineering approach: multi-driver design. While traditional earphones rely on a single driver to reproduce all sounds, today’s premium IEMs employ arrays of specialized drivers, each precisely tuned to handle specific frequencies.

Leading manufacturers are pushing these boundaries further—from FiiO’s FA19 with its intricate 10-driver architecture to Earsonics’ EM96 featuring a refined three-way crossover system. As consumer demand for premium audio experiences grows, the multi-driver IEM market has evolved from its roots in the professional stage to become a pillar of high-fidelity personal audio.

This evolution brings both opportunities and challenges, requiring manufacturers to master complex acoustic engineering while delivering comfortable, practical designs for daily use. Success in this competitive landscape demands more than just adding drivers—it requires a deep understanding of how to harmoniously integrate these components to create superior listening experiences, requiring a deep understanding of acoustics, crossover integration, and component synergy.

To succeed in this evolving market, brands must navigate technical complexities in multi-driver design—ensuring seamless integration, optimizing crossovers, and balancing comfort with performance—without compromising on sound quality.

Why multi-driver designs?

Unlike single-driver IEMs, which are tasked with reproducing the entire frequency range within one transducer, multi-driver designs distribute the workload across specialized drivers. This approach mirrors full-sized speaker systems, where woofers, midrange drivers, and tweeters work together to create an immersive soundstage.

By assigning dedicated drivers to specific frequency ranges—such as bass, midrange, and treble—manufacturers can achieve exceptional clarity and depth. This targeted separation ensures each frequency range is handled by specialized drivers, reducing distortion and delivering a cohesive, high-fidelity listening experience.

A key component of modern multi-driver IEMs is the balanced armature (BA) driver. Originally developed for hearing aids, BAs have since become a cornerstone of in-ear audio due to their compact size and precision tuning capabilities. BAs use stationary coil and pivoting armature, which enables them to reproduce detailed frequencies with remarkable efficiency.

Figure 1 BAs are becoming critical for in-ear audio designs. Source: Knowles

Because of their small form factor and specialization, BAs are ideal for multi-way driver configurations, where multiple units work together to optimize frequency response, enhance clarity, and improve overall sound separation.

In fact, multiple BAs are the industry standard, though some manufacturers introduce alternative technologies—such as planar drivers, dynamic drivers, or even microphones—for novelty. Highly versatile and available in several variations for specialized applications, BAs can function in multiples or in tandem with other technologies, as often seen in hybrid-driver true wireless stereo (TWS) earphones.

Addressing design challenges

Integrating multiple drivers into an IEM presents both opportunities and engineering challenges. While multi-driver designs enable more refined tuning and enhanced performance, they require precise crossover implementation, seamless driver integration, and compact form factor solutions to deliver the best user experience. Manufacturers must balance sound quality, consistency, and ergonomic constraints while also delivering a competitive and signature sound experience.

- Crossover design

Multi-driver IEMs rely on crossover circuits to distribute frequencies across different drivers. Poorly executed crossovers can cause phase issues (cancellation of energy rather than addition and vice versa), frequency dips, and distortion, particularly in the midrange, where driver overlaps are most sensitive.

By strategically distributing the audio signal across multiple drivers, each driver operates within its optimal range, reducing the likelihood of distortion. This ensures that no single driver is overburdened, leading to cleaner, more accurate sound reproduction with better clarity and separation compared to single-driver IEMs.

For additional ease of integration, choosing multi-way drivers with pre-configured crossover implementations can reduce the complexity of designing systems from scratch and ensure clean performance upfront.

Figure 2 BAs allow finer control over the interaction between drivers. Source: Knowles

BAs are helpful for crossover design, as they enable finer impedance control, ensuring seamless transitions between drivers. Due to their stationary coil design, which can be wound with different impedances, BAs enable finer control over the interaction between drivers. Specialty BAs with closed-back designs can further reduce acoustic irregularities, producing more natural sound even in complex setups.

- Signature sounds

Modern IEM manufacturers distinguish themselves through unique sound signatures that define their brand identity. The precision and flexibility of multi-driver configurations enable manufacturers to create these distinctive audio profiles with unprecedented control. BAs play a pivotal role in signature sound development.

Specialty BAs engineered for specific acoustic tasks—such as extended treble or enhanced midrange—allow manufacturers to tailor sound signatures precisely. Each BA configuration can be customized to achieve different target sound signatures in a multi-driver layout, making it easier for manufacturers to create distinctive audio profiles without extensive R&D time.

Figure 3 BAs can be engineered for specific acoustic tasks. Source: Knowles

Multi-way drivers can deliver pre-tuned frequency ranges, alleviating the work of internal teams and enabling faster progression in product development. Selecting multi-way BA models with dedicated drivers optimized for bass, midrange, and treble reduces the need for extensive manual tuning. Properly tuned BAs ensure each driver operates within its ideal range, avoiding common issues like frequency dips or distortion in the midrange.

The multi-driver designs also offer manufacturers greater flexibility in tuning their unique signature sound. By integrating newer technologies and adjusting the crossover points of different driver types, engineers can define specific characteristics—such as enhanced bass, detailed midrange, or sparkling highs—to make their output one-of-a-kind.

- Form-factor flexibility

Despite advancements in miniaturization, integrating multiple drivers into a compact, ergonomic earpiece remains a challenge. Comfort and versatility are essential for an optimal user experience, and sound quality must be balanced with design and functionality.

The compact size of BAs offers greater flexibility in placement within an earpiece, freeing up valuable space for designing with multiple drivers. This enables the incorporation of specialty BAs—engineered for high impact in exceptionally small sizes—maximizing room for additional drivers and advanced crossover designs.

Unlike other driver types, which require larger enclosures for optimal functionality, BA drivers are significantly smaller. They also have adjustable port placements. This allows multiple units to be arranged within the same IEM shell.

Pre-configured multi-way BA configurations help manufacturers create ergonomic, form-fitting IEMs without needing large nozzles or vents. These factors allow for a more minimalist design, making it easier to achieve a comfortable form factor.

4 Scalability across multiple markets

As demand for high-performance in-ear monitors continues to grow across various listener segments, manufacturers must develop scalable solutions that cater to a wide range of users. Achieving this requires flexible driver configurations that maintain high sound quality standards while accommodating different price points.

One of the most effective ways to achieve this scalability is through multi-way driver configurations and hybrid technology. By combining drivers, manufacturers can fine-tune crossover points to create sound profiles suited for different applications. This versatility allows brands to produce IEMs that offer precise, high-fidelity audio at multiple tiers—whether for entry-level consumer models or high-end audiophile monitors.

Reliability and consistency in production also play a crucial role in meeting market demand. Automated manufacturing processes ensure tight tolerances, reducing batch-to-batch inconsistencies in multi-driver designs. Additionally, the availability of pre-configured multi-way BA systems simplifies product development, allowing manufacturers to expand their product lines efficiently without extensive redesigns.

By leveraging these scalable design strategies, companies can provide high-quality IEMs across various market segments, ensuring a balance between performance, affordability, and accessibility without compromising sound integrity.

IEMs shaping personal premium sound

Multi-driver designs have redefined what’s possible in IEM performance, enabling richer, more detailed soundscapes than ever before. Through advancements in BA technology and thoughtful integration of multiple drivers, manufacturers are overcoming traditional limitations to meet the rising demand for premium audio experiences.

For research and development teams in the personal audio space, mastering the complexities of multi-driver design is crucial for maintaining competitiveness in today’s rapidly evolving market. If done well, new IEM designs could shape the future of personal premium sound.

Cristina Downey is senior electroacoustic engineer for R&D at Knowles Corp.

Related Content

- Audio design and technology

- TWS reference design features hybrid dual speaker

- Hear This: ‘Ear-Worn Computing’ Around the Corner

- Exploring Trends and Opportunities for True Wireless Audio

- Understanding superior professional audio design: A block-by-block approach

The post Designing better listening experiences with multi-driver IEMs appeared first on EDN.

Delta Launches its New Collaborative Robots for the Indian Smart Manufacturing Market at ELECRAMA 2025

The showcase also includes a new 240kW DC fast EV charger designed to foster e- mobility for India’s sustainable cities

Delta, a global leader in power management and a provider of IoT-based smart green solutions, announced today its participation in ELECRAMA 2025 under the theme of Smart Manufacturing by launching its new D- Bot series Collaborative Robots (Cobots) in the Indian market. These 6-axis cobots boast payload capacities up to 30 kg, and speeds as fast as 200 degrees per second, thus, designed to empower industries with smarter, more efficient production processes, such as electronics assembly, packaging, materials handling, and even welding. At the event, Delta will also unveil its new 240kW DC Fast EV Charger and the Industrial Power-protect Transformer-based UPS – further strengthening its commitment to energy conservation and the development of sustainable cities across India.

Jimmy Yiin, Delta’s Executive Vice President of Global Business Operations, said, “India is a key market for Delta, and we are committed to driving its industrial and energy transformation with our advanced solutions. Delta’s strategic investment in the Krishnagiri facility underscores our dedication to local innovation, manufacturing excellence, and sustainability. Through this investment, we aim to strengthen India’s self-reliance in smart manufacturing and energy infrastructure while contributing to global industry standards.”

Benjamin Lin, President of Delta Electronics India, stated, “Delta is proud to showcase our innovative smart manufacturing solutions at Elecrama 2025. Our focus has always been on delivering solutions that advance industries to become more efficient, sustainable, and resilient. The new solutions we are introducing – from the D-Bot Cobots to the Ultron IPT Series UPS – are designed with these values in mind, and we are committed to driving the transition to smart and sustainable manufacturing across India and beyond.”

Across the Delta booth, visitors will engage on a journey with a live demonstration of intelligent infrastructure across Industrial Automation, EV Charging, Smart Building Automation Solutions, Data Centers, Smart Energy Infrastructure, ICT Infrastructure, and many more innovative solutions.

Newly-Launched Smart Green Solutions by Delta at ELECRAMA 2025 are:- D-Bot Series Collaborative Robots (Cobots) are an integral part of Delta’s broad portfolio of Smart Manufacturing Designed for smart factory automation and equipped with advanced safety mechanisms, these cobots detect contact and instantly reverse movement to prevent accidents, ensuring safe human-robot collaboration. With payload capacities ranging from 6 kg to 30 kg, 6-axis flexibility, speeds up to 200 degrees per second D-bot provides precision, efficiency, and rapid deployment across industries in a broad range of applications that require smart manufacturing capabilities, including packaging, pick and place, electronics assembly, materials handling, welding, machine tending, and more. Moreover, these D-Bot series cobots integrate seamlessly with Delta’s VTScada SCADA system, DIATwin digital twin platform, machine vision systems, and more, to help customers upgrade the productivity, reliability, and efficiency of their factories.

- 240kW DC Fast EV Charger – A high-speed dual-vehicle charging solution developed locally by Delta India’s own R&D and engineering These advanced EV charger boasts 95% efficiency, OCPP compatibility, and wired/4G GSM connectivity, ensuring fast, seamless EV charging for commercial applications, fleet operators, and public charging networks.

- Industrial Power-protect Transformer-based UPS (IPT series)- It redefines power reliability with Zig-zag transformer, advanced PFC converter, and exceptional short-circuit protection. With IP43 optional enclosure protection, it ensures robust performance and optimizes frontend investment for harsh industrial environments.

Delta is also showcasing a wide range of cutting-edge solutions across its key business verticals:

Industrial Automation SolutionsDelta is also showcasing articulated and SCARA robots at ELECRAMA 2025, delivering high- speed pick-and-place capabilities and smart screwdriving solutions for mobile phone manufacturing. Additionally, Delta is featuring its Next-Gen CNC Controllers for precise motion control, PMa Synchronous Reluctance Motor MSI for energy savings, Active Power Filter APF3000 for clean power with THDi below 5%, and the Fan, Pump, and Compressor Solution with Fluid Industry Drive VP3000, integrating IE4/IE5 MSI motors for enhanced performance. Delta also offers VTScada SCADA software for Industry 4.0 by optimizing smart manufacturing and energy management through real-time monitoring, control, and predictive maintenance.

EV Charging SolutionsDelta continues to drive India’s EV charging ecosystem and showcasing, high efficiency charging solutions, designed for residential, commercial, and fleet applications. The AC Cordset 3.3kW offers a compact home charging solution, while the AC Miniplus 7.4kW provides smart connectivity-enabled AC charging. The 240kW DC Fast Charger allows simultaneous charging of two EVs with 95% efficiency and OCPP compatibility, making it ideal for commercial applications, parking lots, service stations, and bus depots. As a total solutions provider, Delta commonly integrates power conditioning systems (PCS), battery energy storage systems (BESS), solar PV inverters, and EV chargers, enabling renewable energy- powered EV charging infrastructure for smart cities.

Data Center, Telecom & Mission-Critical Infrastructure SolutionsDelta is transforming data center infrastructure with high-efficiency solutions such as the 33kW 1OU ORv3 Power Shelves, which achieve 97.5% efficiency to ensure stable power for AI servers. The InfraSuite Data Center Infrastructure Solutions helps data centres achieve PUEs below 1.2, reducing energy losses, especially with Delta’s with new liquid cooling solutions. Delta’s 18kW High-Power Rack-Mounted Systems support network communication and AI servers with 97.5% energy conversion efficiency, while the DC Power Converter achieves 98.3% efficiency, meeting the high-power demands of AI GPUs. Delta also has DC first solution with UPS, Busway, Cooling, and containerized data centre solutions for reliable, efficient infrastructure support.

Delta’s telecom power solutions include Power Distribution Units (PDU), HE Rectifiers, and Outdoor Cooling Cabinets, ensuring network efficiency and reliability. Additionally, Delta’s Mission-Critical Infrastructure Solutions (MCIS) portfolio features the Active Harmonic Filter (AHF), iCool Row, Li-Ion Battery Solutions, and IPT for next-gen power transmission.

EV Powertrain SolutionsDelta is also advancing EV Powertrain Solutions with compact, high-efficiency power solutions for electric two- and three-wheelers. These include On-Board Chargers (OBCM), DC/DC Converters, OBG, and EVCC products, which support bi-directional charging and V2X integration to enhance EV functionality.

Smart Building Automation SolutionsDelta revolutionizes buildings through integrated smart solutions, combining energy-efficient HVAC control, smart lighting, and AI-powered video surveillance. Our comprehensive building portfolio includes industry-leading brands such as LOYTEC, Delta Controls, VIVOTEK, March Networks and Amerlux, delivering advanced technologies that optimize both energy use and operational performance.

Commitment to SustainabilityDelta remains dedicated to sustainability through high-efficiency energy solutions. Between 2010 and 2023, Delta’s products and solutions deployed worldwide saved customers an estimated 45.5 billion kWh of electricity, equivalent to reducing carbon emissions by nearly 23.84 million tons. Additionally, from 2006 to 2024, Delta has built 35 green buildings and 2 certified green data centers worldwide, reinforcing its commitment to energy conservation and sustainability.

Visit Delta at ELECRAMA 2025Experience live demonstrations and interact with Delta’s latest innovations at Booth #A3B4, Hall 16. Discover how Delta is driving smart manufacturing with its advanced robotics, automation, and energy solutions.

The post Delta Launches its New Collaborative Robots for the Indian Smart Manufacturing Market at ELECRAMA 2025 appeared first on ELE Times.

An old project where I replaced the IC in an IR RGB strip controller with something I can program myself and eventually upgrade. It's been running in production for 1.5 years by now

| Last pic is the original IC that I turned into a pin-compatible IC with the ATtiny45. Figuring out the pin mapping was a fun challenge. All the code is mine, including the IR decoding which took me 3 iterations to make it reliable and non-blocking. My plan is to eventually use a better wireless comm technology than IR :) [link] [comments] |

💥 Вакансії в НАЗК

5 нових вакансій в НАЗК: шукаємо дизайнера, спеціалістів з міжнародного співробітництва, HR, ІТ

LED ON - OFF ... A simple circuit

| submitted by /u/SpecialistRare832 [link] [comments] |

Aspiradora atma con placa controladora quemada

| submitted by /u/Objective-Concept905 [link] [comments] |

Weekly discussion, complaint, and rant thread

Open to anything, including discussions, complaints, and rants.

Sub rules do not apply, so don't bother reporting incivility, off-topic, or spam.

Reddit-wide rules do apply.

To see the newest posts, sort the comments by "new" (instead of "best" or "top").

[link] [comments]

Logisim: shift register

| See how to make a simple 4 bits short register on Logisim [link] [comments] |

Cutting-Edge Innovations in Flexible Electronics Transforming Next-Generation Devices

The emergence of flexible electronics is revolutionizing traditional rigid circuitry by enabling stretchable, ultra-thin, and lightweight electronic devices. These advances are transforming key sectors such as wearable technology, biomedical instrumentation, IoT, and next-gen display systems. Rapid breakthroughs in nanomaterials, conductive polymers, and advanced fabrication techniques are accelerating the adoption of flexible electronics across multiple industries.

Advanced Materials Engineering for High-Performance Flexible Electronics Next-Gen Conductive Polymers and Hybrid NanocompositesTraditional silicon-based electronics are constrained by rigidity, necessitating the transition to flexible alternatives. Conductive polymers, such as poly(3,4-ethylenedioxythiophene) (PEDOT) and polyaniline (PANI), offer a balance between mechanical pliability and high electrical conductivity. Hybrid nanocomposites incorporating silver nanowires (AgNWs), graphene, and transition metal dichalcogenides (TMDs) enhance charge transport and mechanical durability.

Quantum Dot-Enhanced Flexible MaterialsQuantum dots (QDs) and perovskite nanocrystals are being explored for their tunable optical and electronic properties, significantly improving the performance of flexible photodetectors, OLED displays, and sensor arrays. Their integration into stretchable substrates facilitates the development of high-resolution rollable screens and energy-efficient lighting solutions.

Liquid Metal Interconnects for Stretchable ElectronicsGallium-based liquid metals provide dynamic electrical pathways with self-healing properties, ensuring resilience under mechanical stress. These interconnects are pivotal in deformable circuits, allowing uninterrupted performance even under extreme bending or stretching conditions.

Cutting-Edge Fabrication Techniques for Flexible Circuits Ultra-Precision Roll-to-Roll (R2R) ManufacturingRoll-to-roll (R2R) processing is a breakthrough in large-scale flexible electronics production, enabling continuous fabrication of stretchable circuits with micron-level precision. This method significantly reduces production costs while maintaining high-throughput scalability for applications such as flexible RFID tags and sensor arrays.

Multi-Material 3D Printing for Integrated ElectronicsRecent advancements in 3D printing have enabled additive manufacturing of complex electronic architectures using conductive, insulating, and dielectric inks. Multi-material 3D printing facilitates the direct integration of flexible electronics into biomedical implants, conformal antennas, and wearable devices.

Disruptive Applications of Flexible Electronics in Next-Gen Technologies Biocompatible Electronic Skins and Neural InterfacesUltra-thin electronic skins (e-skins) with embedded sensors enable seamless real-time health monitoring. These biocompatible devices are crucial for applications such as non-invasive glucose monitoring, prosthetic feedback systems, and brain-machine interfaces (BMIs) for neuroprosthetic applications.

Foldable AMOLED Displays and Holographic ProjectionsLeading display manufacturers are leveraging flexible organic light-emitting diodes (AMOLEDs) to create ultra-thin, foldable, and rollable screens. Future innovations include holographic projection-based flexible displays that enhance augmented reality (AR) and virtual reality (VR) experiences.

Self-Powered IoT Sensors and Sustainable ElectronicsFlexible electronics integrated with energy-harvesting solutions such as triboelectric nanogenerators (TENGs) and biofuel cells are driving self-powered IoT deployments. These technologies significantly enhance smart packaging, environmental sensing, and remote monitoring systems with minimal energy consumption.

Overcoming Challenges in Flexible Electronics DevelopmentDespite remarkable progress, several technical barriers persist:

- Material Optimization: Enhancing the mechanical resilience of stretchable conductors without compromising electronic properties remains a critical challenge.

- Hybrid Integration with Rigid Components: Seamless interfacing between flexible circuits and conventional silicon-based microelectronics demands innovative interconnection techniques.

- Reliability Under Dynamic Deformation: Ensuring long-term stability under cyclic bending, twisting, and stretching is essential for real-world applications.

- Power Management: Next-gen energy storage solutions such as ultrathin supercapacitors and flexible lithium-ion batteries are being explored to meet the power demands of flexible electronic systems.

Flexible electronics is poised to redefine the landscape of consumer electronics, healthcare, and IoT ecosystems. As materials and fabrication techniques continue to evolve, the widespread commercialization of these technologies will drive innovation in wearable computing, adaptive displays, and biocompatible devices. The next decade will witness a convergence of AI, quantum electronics, and flexible circuits, paving the way for unprecedented advancements in intelligent, sustainable, and seamlessly integrated electronic systems.

The post Cutting-Edge Innovations in Flexible Electronics Transforming Next-Generation Devices appeared first on ELE Times.

Breaking Boundaries with Ultrawide Band (UWB) Technology: A Deep Dive into High-Precision Wireless Communication

Introduction: The Evolution of UWB in Wireless Systems

Ultrawide Band (UWB) technology has emerged as a disruptive force in wireless communication, offering ultra-low latency, high data rates, and centimeter-level precision localization. Unlike conventional narrowband and wideband systems, UWB operates over an exceptionally broad spectrum (>500 MHz), enabling unparalleled spatial awareness and secure connectivity. Its applications span IoT, automotive, smart devices, and industrial automation, making it a foundational element in next-generation wireless ecosystems.

The Core Principles of UWB: Wideband Spectrum and Low Power Consumption Wideband Transmission Characteristics and Spectral EfficiencyUWB operates within 3.1 GHz to 10.6 GHz under FCC regulations, leveraging ultra-short pulses (<2 ns) to achieve high time-domain resolution. Unlike frequency-hopping or spread-spectrum techniques in Wi-Fi and Bluetooth, UWB transmits data over a large frequency range, resulting in improved spectral efficiency, reduced interference, and higher penetration through obstacles.

Pulse-Based Modulation: Precision Through Impulse Radio (IR-UWB)UWB employs Impulse Radio (IR-UWB) modulation, encoding data into ultra-short pulses rather than continuous waveforms. This enhances resilience against multipath fading and allows accurate time-of-flight (ToF) calculations for centimeter-level positioning accuracy—critical for localization applications in smart infrastructure and real-time tracking.

Advanced UWB Signal Processing and Protocol Enhancements High-Precision Ranging and Time Synchronization AlgorithmsUWB implements sophisticated ranging techniques such as:

- Two-Way Ranging (TWR): Measures the round-trip time of pulses to determine distance with minimal latency.

- Time Difference of Arrival (TDoA): Enables multi-anchor localization by analyzing phase shifts and signal arrival disparities, refining positioning accuracy for industrial and AR/VR applications.

- Angle of Arrival (AoA): Extracts angular data for robust direction-finding, optimizing navigation for autonomous systems.

- Adaptive Filtering Techniques: UWB dynamically adjusts signal parameters, mitigating cross-talk and interference in dense environments.

- Spread Spectrum & Low Probability of Intercept (LPI): Wideband transmission ensures low-power spectral density, making UWB resilient against eavesdropping and jamming, enhancing cybersecurity for financial transactions and digital key applications.

- Keyless Entry & Secure Vehicle Access: UWB outperforms traditional RFID/NFC by preventing relay attacks, ensuring encrypted authentication.

- Advanced Driver Assistance Systems (ADAS): UWB fusion with LiDAR and radar enhances in-vehicle monitoring, parking automation, and collision avoidance.

- Real-Time Location Systems (RTLS): UWB-enabled asset tracking in warehouses ensures precise inventory management and operational efficiency.

- Wireless Sensor Networks (WSNs): Low-latency UWB communication supports edge AI-powered automation in smart factories and industrial robotics.

- Non-Invasive Monitoring: UWB’s ultra-low power properties enable next-gen biomedical imaging and wireless body area networks (WBANs).

- Contactless Vital Sign Detection: UWB radar systems monitor respiration and heart rate, enhancing telemedicine and elderly care.

Despite its technical superiority, UWB adoption faces hurdles:

- Global Regulatory Compliance: Limited standardization across regions impacts seamless deployment.

- Coexistence with Legacy Wireless Systems: Hybrid UWB-Bluetooth Low Energy (BLE) architectures mitigate compatibility issues in consumer electronics.

- Power Consumption Trade-offs: Ultra-low power UWB chipsets leveraging AI-driven optimizations improve battery life for mobile and IoT applications.

As AI-driven signal processing enhances UWB’s accuracy and efficiency, its role in autonomous navigation, AR/VR interfaces, and smart wearables will grow. With 6G networks integrating UWB for high-precision wireless sensing and localization, the next decade will witness unprecedented advancements in ubiquitous connectivity and spatial intelligence.

Conclusion: UWB as the Backbone of Hyper-Connected SystemsUWB is revolutionizing wireless communication by delivering unmatched precision, security, and energy efficiency. As industries embrace AI-augmented UWB solutions, its applications will extend across smart cities, industrial automation, and immersive digital experiences, shaping the future of intelligent connectivity.

The post Breaking Boundaries with Ultrawide Band (UWB) Technology: A Deep Dive into High-Precision Wireless Communication appeared first on ELE Times.

U heard it that we are flexing micro controllers?

| Flex in the comments⬇️ [link] [comments] |

RS-485: The Communication Protocol that Keeps on Giving

Courtesy: Analog Devices

When it comes to reliable, long-distance communication protocols, RS-485 has stood the test of time. Industrial automation is one of many industries that still rely on this tried-and-true protocol, despite the rise of modern alternatives such as Ethernet, Gigabit Multimedia Serial Link (GMSL), and low-voltage differential signaling (LVDS).

The new Core Interface blog series will explore industrial automation technology (IAT) such as building automation, process control, instrumentation, fleet management, and more, beginning with a four-post mini-series exploring what exactly has given the RS-485 communication protocol such staying power. First, we’ll showcase key features and benefits of RS-485 in IAT and beyond. Later, we’ll touch on some unique use cases and highlight ADI solutions that leverage RS-485 to add value for our customers.

Applications of RS-485The RS-485 protocol remains a staple in industries that prioritize stability, longevity, and proven performance over cutting-edge technologies. This robust, cost-effective, and established protocol is naturally attractive to industries that are conservative about adopting new standards, such as:

- Industrial Automation: RS-485 is widely used in factory and process automation for connecting programmable logic controllers (PLCs), sensors, and actuators. The long-distance capability and resistance to electrical noise make it ideal for noisy industrial environments.

- Home Automation: RS-485 is also popular in home and building automation, where it connects devices like thermostats, lighting systems, and security controls.

- Motion Control: In environments that require precision control of motors and machinery, RS-485 shines for its reliability and real-time communication capabilities.

The RS-485 standard, also known as TIA/EIA-485, enables robust performance in environments prone to electrical noise over long distances—hence its popularity for industrial and commercial applications. This immunity to noise is one of the protocol’s core strengths, but it offers many advantages besides.

Balanced Differential SignalingRS-485 transmits and receives data using two wires carrying equal but opposite signals. Any external noise typically affects both lines equally as long as the wires are close together with matched impedances.

Balanced differential signaling improves noise immunity by canceling out interference that is common to both lines. The receiving end only reads the difference between the two signals, ignoring any noise. This ensures reliable communication even in electrically noisy environments such as factories where motors and other equipment can often generate electro-magnetic interference.

Full-Duplex and Half-Duplex ModesRS-485 supports both full-duplex and half-duplex communication. In full-duplex, data can be transmitted and received simultaneously, but it requires two pairs of wires. Half-duplex, on the other hand, uses a single pair of wires for both transmission and reception, alternating between the two. This makes RS-485 highly versatile, allowing engineers to choose the best mode for their application’s needs.

Number of Transceivers on the BusStandard RS-485 can support up to 32 transceivers on a single bus (or as high as 256 nodes with modern transceivers). This capability makes it ideal for multi-device communication networks in systems like factory automation or building controls, where several devices need to communicate over a single bus.

Common-Mode RangeAnother vital feature of RS-485 is its wide common-mode range. The system can tolerate a voltage difference of at least -7V to +12V between the grounds of devices on the same bus. This resilience ensures stable communication across devices that may not share a common ground or are subject to differing electrical potentials, which can be common in industrial setups.

Data Rate Vs. Distance Trade-OffStandard RS-485 can support data rates up to 10 Mbps over short distances and slower speeds over longer distances (up to 1.2 km). This makes it suitable for applications that require different combinations of speed and range.

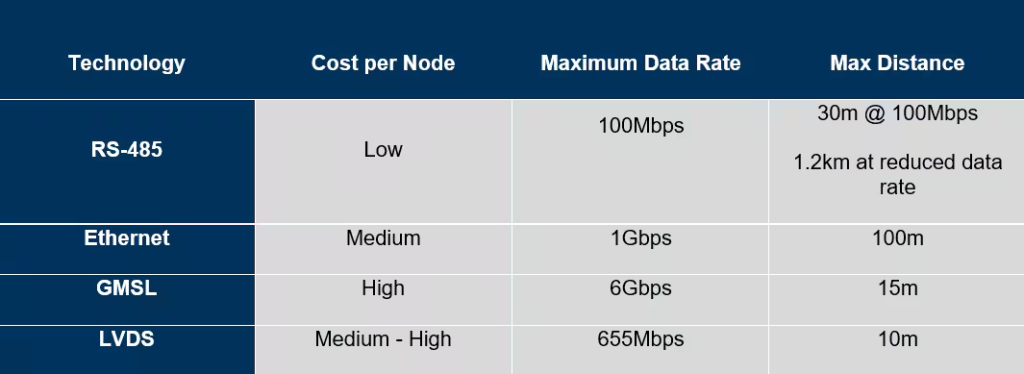

Value: Function Features Vs. CostRS-485 remains a cost-effective choice compared to modern alternatives like Ethernet, GMSL, and LVDS. Although these newer protocols offer higher data rates and more advanced features, RS-485 provides an excellent balance of performance and cost for many industrial applications. Below is a rough comparison of nodes for different technologies. As you can see, while Ethernet, GMSL, and LVDS excel in high-speed data transfer, their higher node costs and shorter transmission ranges limit their suitability for industrial systems with longer-distance, lower-data-rate needs.

Why RS-485 Remains a Strong ChoiceAlthough modern alternatives offer certain advantages, RS-485 remains a key player in many industrial applications due to its balance of reliability, simplicity, and cost-effectiveness. Its wide adoption across industries like automation, building control, and motion systems is a testament to its staying power.

With features like noise immunity, long-distance communication, and support for multiple transceivers, RS-485 provides an excellent solution for environments where stability and robustness are paramount. Pair this with innovative features from Analog Devices, Inc. (ADI)’s portfolio of transceivers that push RS-485 beyond the standard, and you have a robust solution for your connectivity needs.

The post RS-485: The Communication Protocol that Keeps on Giving appeared first on ELE Times.

Infineon CoolGaN power transistors enable SounDigital to reach higher fidelity in smaller amplifier systems

Manufacturers of cutting-edge audio equipment constantly seek to enhance sound quality while also meeting the growing demand for compact, lightweight, more integrated, and energy-efficient designs. At the same time, they must ensure seamless connectivity, cost-effectiveness, and user-friendly functionality, making audio product development more complex than ever. To overcome these challenges, SounDigital has integrated CoolGaN transistors from Infineon Technologies AG into its new 1500 W Class D amplifier, featuring an 800 kHz switching frequency and five channels. Infineon’s advanced GaN technology has improved the energy efficiency of the amplifier by five percent and reduced energy loss by 60 percent.

“We are excited to enhance the performance of our audio amplifiers using Infineon’s GaN power semiconductors, enabling us to inspire people and provide entertainment by amplifying music around the world,” said Juliano Anflor, CEO of SounDigital. “GaN transistors significantly enhances our overall system performance with minimized system cost and increased ease of use.”

“GaN technology is transforming the audio amplifier industry, providing unparalleled efficiency and performance,” said Johannes Schoiswohl, Head of the GaN Business Line at Infineon. “Infineon’s leading GaN solutions deliver superior sound quality, higher power density, and reduced energy consumption, enabling SounDigital’s audio systems to reach new levels of fidelity and performance.”

For its 1500 W Class D amplifier, SounDigital selected Infineon’s 100 V normally-off E- mode transistors: IGC033S101 in a PQFN-3×5 package and IGB110S101 in a PQFN-3×3 package. With their low on-resistance, the transistors are ideal for demanding high-current applications, enabling significant improvements in both sound quality and efficiency of SounDigital’s amplifier. The GaN-based amplifier also delivers high performance while reducing power dissipation by 75 W, allowing for a 50 percent smaller heat sink.

Additionally, the overall system size has been reduced by 40 percent without compromising performance. The audio quality has been further improved by the CoolGaN transistors, with total harmonic distortion (THD) reduced by 70 percent, enabling a more precise and detailed sound experience. At the same time, the idle current has been reduced by 40 percent, significantly improving energy efficiency.

The post Infineon CoolGaN power transistors enable SounDigital to reach higher fidelity in smaller amplifier systems appeared first on ELE Times.

University of Michigan awarded up to $7.5m to bring heat-resistant silicon carbide sensing and computing chips from lab to fab

I might have found the culprit.

| The Varactor diode in the photo seems to have marks of overheating. I came to this conclusion after observation with a flashlight on the back of the board. I was led to perform this visual inspection because I concluded that a stove's control board 098-01540-35 won't turn on due to a faulty G5Q-14 relay. I'll add more findings down the road of troubleshooting. [link] [comments] |

Делегація представників Програми розвитку Організації Об’єднаних Націй (ПРООН) в КПІ

Наш університет прийняв делегацію представників Програми розвитку Організації Об’єднаних Націй (ПРООН) в Україні.

SounDigital uses Infineon’s 100V normally-off E-mode CoolGaN transistors

First Solar announces final sale amount of 2024 Section 45X Advanced Manufacturing Production tax credits

Фінансово-бюджетний звіт за 2024 рік (МОН)

Геотрон: від студентського гуртка – до спеціалізованого центру

На XIII Міжнародному фестивалі інноваційних проєктів "Sikorsky Challenge 2024: інновації для миру і безпеки України" команда проєкту "Модульна система дистанційного розмінування "Імпактор" стала переможцем у номінації "Краще стартап-рішення". Автори розробки – члени студентського наукового гуртка "Геотрон".