ELE Times

Texas Instruments showcases energy-efficient and smart semiconductor solutions at electronica India 2025

Explore TI’s comprehensive portfolio of analog and embedded processing semiconductors for energy infrastructure, automotive and connected appliances

Texas Instruments (TI) is demonstrating its leading semiconductor innovations for energy infrastructure, automotive and connected appliances at electronica India, September 17-19, in Bengaluru, India. TI’s exhibit in Hall 3, booth D11 at the Bangalore International Exhibition Centre showcases the latest advancements in applications such as HVAC fans, vacuum cleaners and electric 2-wheelers.

“At electronica India 2025, TI is showcasing how our latest semiconductor innovations are enabling energy-efficient, smart and secure solutions that are essential for building a more sustainable future,” said Santhosh Kumar, president and managing director, TI India. “TI’s comprehensive portfolio of analog and embedded semiconductors, combined with our industry-leading technologies and system-level expertise, enables customers to design intelligent systems that are accelerating energy savings at scale across industries.”

New ultra-low-cost, real-time MCUs

At the tradeshow, TI is debuting the most affordable devices in its C2000 real-time microcontroller portfolio (MCU), which enable engineers to design products with industry-leading performance at a lower cost. The F28E120SC and F28E120SB MCUs deliver smoother, quieter and more efficient motor performance in a wide range of home appliances and power tools.

The new F28E120SC MCU is featured in two on-site demonstrations, including:

- Noise reduction in appliance fans: See how the F28E120SC MCU can control a high-voltage three-phase motor and run a total harmonic distortion reduction algorithm, enabling engineers to reduce noise and improve efficiency in a fan for heating, ventilation and air-conditioning system.

- High-speed sensorless motor control in vacuum cleaners: Explore how the F28E120SC MCU can use sensorless FOC software to control a low-voltage vacuum motor, enabling high efficiency, smooth and stable startup, and reduced peak currents. Booth visitors will be able to quickly and easily spin the motor up to 150,000rpm.

Reimagine safe and efficient electric two- and three-wheelers

TI is also showcasing how its comprehensive product portfolio and reference designs enable innovation across the electric vehicle ecosystem. This includes LED drivers for lighting systems, processors for displays and entertainment, battery management technologies, motor control solutions and more.

Notable demonstrations include:

- 750W light electric vehicle charger: See a 750W light electric vehicle charger powered by the UCC25661-Q1 LLC controller optimal for e-bikes, scooters, and other light electric vehicles. This charger features TI’s patented input power proportional control (IPPC) technology, which provides consistent, stable charging even when batteries are nearly empty.

- Efficient electric vehicle charging with F29x C2000 MCUs: Explore how a single F29xC2000 MCU can power a highly compact 11kW electric vehicle charging system. This design combines both high and low voltage power conversion in one stage, achieving remarkable efficiency (97.6%) while taking up minimal space. The system delivers 5.5 kilowatts of power per liter of volume, helping make electric vehicles more practical with faster charging in smaller, more affordable charging units.

- High-voltage battery management system: Learn about smarter battery management with TI’s high-voltage battery management system (BMS) technology that enhances safety and reliability for large battery packs. This complete solution includes both hardware components and software tools that help manufacturers build better battery systems more quickly.

- CC35xxE wake word detection: Explore Edge AI audio capabilities with 3rd Party Sensory’s TrueHandsfree library on TI’s CC3551 Wi-Fi 6 and Bluetooth LE 5.4 wireless MCU. This can be activated using voice command wake word, which helps to control the Edge IoT device.

- High power density adapters with integrated GaN: See a tiny yet powerful 65W charger with two USB ports using TI’s integrated GaN technology. These chargers pack more power into less space (2.3W per cubic inch), making them significantly smaller than traditional chargers while delivering the same performance. This means more convenient, portable charging solutions for laptops, phones, and other devices.

The post Texas Instruments showcases energy-efficient and smart semiconductor solutions at electronica India 2025 appeared first on ELE Times.

From Space to Earth: How Semiconductor Technology Powers Environmental Discovery

Changing geophysical systems are observed from frost in forests to shifting ice packs by satellites equipped with advanced semiconductors. For centuries, human beings have been trying to figure out how to connect environmental occurrences. Suppose a frost attack happens far away in the forest, only to be followed by a heavy storm that causes silt deposits in a harbor far away; then, such cause-effect patterns are nearly impossible to observe on the ground. Modern earth-observation satellites make these connections clearer than ever due to state-of-the-art imaging techniques and ruggedized semiconductor components built to reside in space.

There goes the big picture with imaging methods.

Optical, radar, and infrared imaging combine to provide a multidimensional view of Earth.

- Optical imagery may see changes in the visible spectrum weather, ash clouds, and landscape.

- Radar imaging penetrates clouds to get details of the ground, with synthetic aperture radar being a higher resolution system thanks to the usage of orbital motion to synthesize enormous antennas.

- Infrared and hyperspectral imaging convey the composition of the soil, atmosphere, and temperature variation.

Put together, these imaging methods track environmental change over time: predicting ice sheets shrinking, sea levels rising, or shifts in the ecosystem.

Making satellites that last

While the imaging isn’t new, the instrumentation has to be created so that components can withstand radiation, extreme temperatures, and years without maintenance. Here semiconductor classifications and packaging play a big role.

- QML Class V devices coated with hermetic ceramic are suitable for high-radiation environments with long-term operational reliability.

- QML Class P devices, on the other hand, use specialized plastic packaging, thus creating a balancing act between durability and small size, leading to more compact and capable satellites.

- Radiation-tolerant components satisfy low Earth orbit purposes with cost sensitivity, implementing proven resilience for their relatively reduced lifespans.

These classifications enable designers of satellites to take into consideration whether the mission requires long-term monitoring from geosynchronous orbit or urgently supplying large constellations in low Earth solutions.

Preparing for challenges to come

Satellites can constantly monitor Earth for years because to dependable, radiation-hardened semiconductors, giving scientists and decision-makers vital data. Researchers are better equipped to foresee potential hazards and make wise judgments when they can see how environmental interactions, such as temperature changes and soil chemistry, change over time.

The Earth is billions of years old, and we have only been measuring it for the smallest fraction of time, according to Jason Clark, systems manager for Space and Avionics at Texas Instruments. We are assisting scientists in preparing for the future by collaborating with them today.

(This article has been adapted and modified from content on Texas Instruments.)

The post From Space to Earth: How Semiconductor Technology Powers Environmental Discovery appeared first on ELE Times.

Wi-Fi 6/6E: Powering the Next Generation of Smart Factory Connectivity

Factories are becoming increasingly connected, with sensors, actuators, machines, and operator devices all demanding seamless, reliable, and low-latency communication. Traditional Wi-Fi struggled to keep up with such dense and demanding environments. Enter Wi-Fi 6 and Wi-Fi 6E the latest generations of Wi-Fi technology, designed not just for speed, but for efficiency, scalability, and resilience in tough industrial settings. With extended spectrum, better interference management, and enhanced capacity, Wi-Fi 6/6E is now well-positioned to meet the evolving needs of smart factory automation.

Wi-Fi 6: Designed for Industrial Demands

Built on the IEEE 802.11ax standard, Wi-Fi 6 supports both 2.4 GHz and 5 GHz bands, offering longer range and higher capacity compared to Wi-Fi 5. The addition of the 6 GHz spectrum under Wi-Fi 6E further boosts scalability by introducing dozens of new channels and reducing congestion.

Factory environments pose unique challenges: thick concrete walls, heavy machinery, and a growing number of connected devices that must communicate continuously with minimal latency. Wi-Fi 6 addresses these demands through features that improve efficiency, reliability, and power management, ensuring smooth operation in 24/7 industrial settings.

Key Features of Wi-Fi 6/6E for Smart Factories

- MU-OFDMA (multi-user orthogonal frequency division multiple access): Enables simultaneous communication with multiple devices, optimizing bandwidth use.

- MU-MIMO (multi-user multiple input multiple output): Supports multiple upload and download streams at the same time.

- 1024-QAM modulation: Packs more data into each symbol, boosting capacity.

- Longer OFDM symbols and guard intervals: Enhance range and resilience in harsh environments.

- BSS coloring: Reduces interference between devices sharing the same channel.

- Target Wake Time: Improves battery life for wireless sensors by allowing them to “wake” only when needed.

The 6 GHz expansion in Wi-Fi 6E, now available across the US, Canada, South Korea, and partially in Europe, further reduces congestion and doubles available capacity—critical for dense factory floors.

Real-World Benefits in Industrial Automation

- Battery-powered sensors gain extended life and reliability thanks to Target Wake Time and reduced interference.

- Control systems and actuators benefit from low latency and consistent quality of service, even when handling small but critical data packets.

- Mobile operator tools like tablets and handheld terminals experience seamless roaming and stable connectivity.

- Augmented reality (AR) devices such as smart glasses achieve higher data rates and responsiveness, supporting new digital workflows.

- Extended range ensures robust coverage across large and challenging factory layouts.

Wi-Fi Meets Bluetooth and Cellular

Looking ahead, smart factories will not rely on a single wireless technology. Wi-Fi 6/6E will coexist with Bluetooth for low-power connections and with 4G/5G cellular networks for wide-area communication. Together, these technologies create a flexible, scalable, and future-proof foundation for Industry 4.0.

(This article has been adapted and modified from content on Ublox.)

The post Wi-Fi 6/6E: Powering the Next Generation of Smart Factory Connectivity appeared first on ELE Times.

Xcelium Distributed Simulation Delivers Up to 3× Faster Multi-Die Verification

As multi-die and chiplet-based systems gain traction in AI, mobile, automotive, and high-performance computing, traditional simulation methods are hitting performance limits. To address this challenge, Cadence has introduced the Xcelium Distributed Simulation App, designed to accelerate verification workflows and cut down bottlenecks. With speedups of up to 3×, the new solution helps design teams handle complex multi-die systems more efficiently and cost-effectively.

The Xcelium Distributed Simulation App, available within the Xcelium Logic Simulator, partitions large simulations into smaller, independent tasks that can run in parallel across server resources. This distributed approach eliminates the long runtimes associated with monolithic simulations, enabling teams to achieve faster turnaround times without compromising accuracy.

Key advantages include:

- Up to 3× faster performance in multi-die system simulations.

- Improved hardware efficiency, reducing compute costs by as much as 5×.

- Seamless testbench reuse, so teams can extend single-die verification environments to multi-die projects with minimal overhead.

Early adopters are already seeing results. At Samsung Semiconductor, Garima Srivastava’s verification team reports smoother workflows and faster execution by leveraging existing testbenches for multi-die designs.

Alok Jain, Corporate VP of R&D at Cadence, emphasized the impact:

“With the Xcelium Distributed Simulation App, we are redefining verification performance for multi-die systems. It’s about giving our customers the speed and scalability they need to meet next-generation design demands.”

This new capability reinforces Cadence’s leadership in advanced verification, helping customers stay ahead as the industry shifts to larger, more complex architectures.

(This article has been adapted and modified from content on Cadence Design Systems.)

The post Xcelium Distributed Simulation Delivers Up to 3× Faster Multi-Die Verification appeared first on ELE Times.

Rethinking AI Networking: Myths vs. Reality

As artificial intelligence infrastructure scales at breakneck speed, outdated assumptions about networking continue to circulate. Many of these myths stem from technologies designed for much smaller clusters, but the game has changed. Today’s AI systems are pushing into hundreds of thousands and soon, millions of GPUs. Old models simply don’t hold up.

Let’s take a closer look at the most persistent misconceptions about AI networking and why Ethernet has clearly established itself as the foundation for modern large-scale training and inference.

Myth #1: Ethernet Can’t Deliver High-Performance AI Networking

This one’s already been disproven. Ethernet is now the standard for AI at scale. Nearly all of the world’s largest GPU clusters built in the past year use Ethernet for scale-out networking.

Why? Because Ethernet now rivals and often outperforms alternatives like InfiniBand, while offering a stronger ecosystem, vendor diversity, and faster innovation. InfiniBand wasn’t designed for the extreme scale we see today; Ethernet is thriving with 51.2T switches in production and Broadcom’s new 102.4T Tomahawk 6 setting the pace. Massive clusters of 100K GPUs and beyond are already running on Ethernet.

Myth #2: You Need Separate Networks for Scale-Up and Scale-Out

That was true when GPU nodes were tiny. Legacy scale-up designs worked when you were connecting two or four GPUs. But today’s architectures often include 64, 128, or more GPUs within a single domain.

Using separate networks adds complexity and cost. Ethernet allows you to unify scale-up and scale-out on the same fabric, simplifying operations and enabling interface fungibility. To accelerate this convergence, we introduced the Scale-Up Ethernet (SUE) framework to the Open Compute Project, moving the industry toward a single AI networking standard.

Myth #3: Proprietary Interconnects and Exotic Optics Are Essential

Not anymore. Proprietary approaches may have fit older, fixed systems, but modern AI requires flexibility and openness.

Ethernet provides a broad set of choices: third-gen co-packaged optics (CPO), module-based retimed optics, linear drive optics, and long-reach passive copper. This flexibility lets you optimize for performance, power, and economics without being locked into a single path.

Myth #4: Proprietary NIC Features Are Required for AI Workloads

Some AI clusters lean on programmable, high-power NICs for features like congestion control. But often, that’s compensating for a weaker switching fabric.

Modern Ethernet switches, including Tomahawk 5 and 6, already embed advanced load balancing, telemetry, and resiliency — reducing cost and power draw while leaving more resources available for GPUs and XPUs. Looking ahead, NIC functions will increasingly integrate into XPUs themselves, reinforcing the strategy of simplifying rather than over-engineering.

Myth #5: Your Network Must Match Your GPU Vendor

There’s no reason to tie your network to your GPU supplier. The largest hyperscaler deployments worldwide are built on Ethernet.

Ethernet enables flatter, more efficient topologies, supports workload-specific tuning, and is fully vendor-neutral. With its standards-based ecosystem, AI clusters can scale independently of GPU/XPU choice-ensuring openness, efficiency, and long-term scalability.

The Takeaway:

Networking is no longer a side note; it’s a core driver of AI performance, efficiency, and growth. If your assumptions are rooted in five-year-old architectures, it’s time to update your playbook.

The reality is clear: the future of AI networking is Ethernet and that future is already here.

(This article has been adapted and modified from content on Broadcom.)

The post Rethinking AI Networking: Myths vs. Reality appeared first on ELE Times.

Why Electronics and Auto Manufacturers Struggle with Compliance in India

Electronics and automobile manufacturers, contributing 3% and 7.1% to India’s GDP respectively, are at the heart of the nation’s industrial growth. Yet, their progress is often slowed by a maze of compliance requirements from evolving labour codes and plant safety regulations to environmental certifications and state-specific laws. For many players, these overlapping obligations translate into delays, operational inefficiencies, and missed opportunities to scale.

To understand how compliance challenges are shaping the future of these sectors, and how technology like AI and RPA is redefining compliance management, ELE Times spoke with Munab Ali Beik, Head of Compliance Advisory at Core Integra. With over 20 years of experience navigating regulatory frameworks and driving digital compliance transformations, he provides deep insights into the hurdles manufacturers face, the reforms needed to unlock growth, and how smart compliance practices can strengthen India’s position as a global manufacturing hub.

Excerpts from the interview:

ELE Times: What are the most complex compliance requirements currently troubling electronics and automobile manufacturers in India?

Munab Ali Beik: For electronics and automobile manufacturers, the most complex compliance challenges today revolve around evolving labour laws, contractor & supplier compliances, shop floor regulations, health and safety requirements, unions and employee welfare norms. With the introduction of upcoming new labour codes, companies must realign HR policies, wage structures, obtaining registrations and working hours while maintaining strict adherence to health and safety standards. Shop floor compliance has become increasingly demanding, requiring detailed SOPs, audits, and documentation to manage risks associated with heavy machinery. Beyond this, manufacturers face intricate requirements around plant certifications, environmental regulations, product safety standards, certifications, audits and overall labour law compliance. Studies indicate that nearly 45–50% of players’ experience delays and operational inefficiencies due to these overlapping regulatory demands, highlighting the critical need for proactive compliance management.

ELE Times: Why do almost half of manufacturers experience delays specifically due to compliance hurdles?

Munab Ali Beik: The delay is due to compliance hurdles because the regulatory landscape remains highly complex and fragmented. Frequent updates to labour laws and enterprise laws require constant adjustments, while machinery safety norms and employee welfare provisions add operational challenges. For companies operating multiple plants, the lack of uniformity across states further complicates compliance, state-specific laws, local regulatory requirements, and varying environmental norms necessitate separate processes and documentation. States have indicated that the Ease of Doing Business initiative may complicate the procedural implementations and understanding the simplified part of compliances. This patchwork of regulations, combined with limited coordination across jurisdictions, creates bottlenecks and inefficiencies, slowing operations and impacting manufacturers’ ability to scale effectively.

ELE Times: With electronics contributing 3% and automobiles 7.1% to India’s GDP, do you think regulatory overload is limiting their full growth potential?

Munab Ali Beik: Yes, absolutely. If compliance hurdles were streamlined, electronics and automobile manufacturers could devote far more resources to R&D, innovation, and building global competitiveness. These sectors have the potential to not only sustain but significantly increase their contribution to India’s GDP by boosting exports, enhancing localization, and developing advanced manufacturing ecosystems. Procedural bottlenecks currently divert focus from scaling production, investing in cutting-edge technologies, and optimizing supply chains. While India is making strides in improving ease of doing business, attracting larger foreign investments and sustaining growth requires simpler and more stable compliance frameworks. The central and state governments are set to relax certain provisions for the electronics and automobile manufacturing sectors to improve their performance. These relaxations pertain to auto-renewals, inspections, self-certifications, working hours, overtime, industrial disputes, subsidies, and promotional activities. Reducing regulatory overload would enable these industries to strengthen core operations, accelerate India’s emergence as a global manufacturing hub, and unlock untapped economic potential.

ELE Times: How can AI and RPA truly transform compliance management for manufacturing plants?

Munab Ali Beik: AI and RPA can revolutionize compliance management in manufacturing by automating repetitive tasks like payroll, attendance tracking, statutory filings, registers maintenance, returns filing, maintaining the data, Management information system and audit reporting. AI platforms provide real-time visibility, flag risks, and update changes in regulations automatically, while RPA ensures consistent workflows across HR, finance, and operations. This reduces errors, boosts efficiency, and frees management to focus on strategic priorities. Over time, digital compliance not only cuts costs, increase the efficiency, error free and improves safety monitoring but also strengthens governance and investor confidence.

ELE Times: What critical changes are required to make India a global manufacturing hub for electronics and automobiles?

Munab Ali Beik: To position India as a global manufacturing hub for electronics and automobiles, critical changes are needed in regulatory stability, ease of doing business, exemption from regulatory frameworks and policy clarity. Simplifying access to government schemes, enhancing transparency in labour laws, and streamlining compliance processes will reduce operational friction and build investor confidence. These measures will enable manufacturers to focus on innovation, scale efficiently, and compete globally, driving both domestic growth and export potential.

ELE Times: How is Core Integra evolving its AI/RPA tools to stay aligned with future compliance expectations?

Munab Ali Beik: We are continuously enhancing our AI and RPA capabilities through our compliance platform, Ctrl F, to stay ahead of evolving regulatory requirements. We leverage AI to track changing laws in real time, identify the impacts, flag risks, and automate documentation, filings, and reporting. By integrating RPA, we ensure consistency across multi-location operations, reduce manual errors, simplified the process and minimize administrative burdens. Alongside technology, we invest in R&D and advisory expertise to simplify complex regulations and provide proactive compliance updates. These innovations empower our clients to manage compliance efficiently, enhance operational oversight, and focus resources on scaling and innovation.

The post Why Electronics and Auto Manufacturers Struggle with Compliance in India appeared first on ELE Times.

Unlocking the Power of AI: A Strategic Guide for OEMs and ISVs

Artificial intelligence is no longer some faraway notion; it has become a strong and immediate agent of innovation. Whether in predictive analytics or generative design, AI remains instrumental in the means by which OEMs and ISVs conceive, produce, and maintain their products. However, promising this technology is, majority of companies cannot speed away from experimentation into value-driven and large-scale application.

This guide demystifies the AI technologies reshaping the industry, illuminates their real-world applications, and lays down a commercially viable roadmap for OEMs and ISVs to embrace AI with confidence and clarity.

Understanding Artificial Intelligence

AI refers to the development of computer systems capable of performing tasks traditionally requiring human intelligence. These systems process vast amounts of data, recognize patterns, and make decisions with minimal human intervention. AI spans a wide spectrum from rule-based automation to advanced deep learning algorithms capable of generating content, interpreting speech, and predicting outcomes.

While AI has existed for decades, the surge in computational power, cloud infrastructure, and data availability has accelerated adoption across industries. Today, AI is no longer optional it is an essential enabler for companies striving to remain innovative and competitive.

The Different Types of AI:

Natural Language Processing (NLP)

NLP enables machines to understand, interpret, and generate human language. It powers chatbots, virtual assistants, translation tools, and sentiment analysis systems. OEMs and ISVs are integrating NLP into products to create voice-enabled interfaces, enhance customer engagement, and extract insights from unstructured data such as emails, reviews, and social media.

Machine Learning and Predictive Analytics

Machine Learning (ML) allows systems to learn patterns from data and make predictions without explicit programming. Predictive analytics, a major ML application, helps anticipate trends, detect anomalies, and optimize operations. For instance, predictive maintenance reduces downtime by forecasting equipment failures, while cybersecurity solutions use ML to detect threats in real-time.

Generative AI

Generative AI is the next frontier. Unlike traditional ML, it creates new content—ranging from text and images to design prototypes. For OEMs and ISVs, this translates into automated documentation, rapid product prototyping, and personalized customer experiences. Generative AI not only streamlines workflows but also fosters creativity and innovation.

Addressing the Challenges of AI Adoption:

Despite its potential, AI adoption comes with hurdles-

Bias and Fairness: AI models trained on biased datasets risk producing unfair or inaccurate outcomes. Businesses must prioritize transparency and accountability in AI systems.

Integration Complexity: Legacy infrastructure, siloed data, and fragmented workflows often complicate AI integration.

Data Security and Privacy: AI systems process sensitive business and customer information, making strong data governance and compliance with privacy regulations critical.

Continuous Adaptation: AI models require constant monitoring, retraining, and refinement to remain accurate in dynamic business environments.

Deploying AI Strategically for OEMs and ISVs:

To move beyond pilots and achieve scalable impact, businesses should approach AI strategically:

- Align AI with Business Goals – Identify specific areas where AI can enhance value, such as automation, customer engagement, or operational efficiency.

- Ensure Data Readiness – High-quality, structured data is the backbone of AI success. Companies must invest in robust data collection and management systems.

- Leverage Cloud and AI-as-a-Service – Cloud-based platforms lower barriers to entry by offering scalable AI tools without requiring deep in-house expertise.

- Collaborate with AI Experts – Partnering with specialized providers accelerates adoption and optimizes solutions for industry-specific needs.

- Commit to Continuous Improvement – Regularly monitor performance, retrain models, and evolve AI capabilities alongside business needs.

The Future of AI in Business:

AI’s evolution is accelerating. Explainable AI (XAI) is enhancing transparency, allowing businesses to understand and trust AI-driven decisions. Edge AI is bringing intelligence closer to data sources, enabling real-time decision-making in IoT and remote deployments. Together, these innovations are making AI more practical, ethical, and impactful.

For OEMs and ISVs, investing in AI today is not just about keeping pace it’s about leading the transformation. Those who strategically integrate AI will unlock new opportunities in product development, customer engagement, and operational efficiency, securing a decisive competitive edge.

Conclusion:

AI is no longer experimental it is a strategic imperative. From NLP-driven customer engagement to predictive maintenance and generative design, the opportunities for OEMs and ISVs are vast. By aligning AI adoption with business goals, addressing data and integration challenges, and committing to continuous refinement, companies can unlock the full potential of AI.

(This article has been adapted and modified from content on Arrow Electronics.)

The post Unlocking the Power of AI: A Strategic Guide for OEMs and ISVs appeared first on ELE Times.

Electronica India and productronica India 2025: India’s Powerplay in Electronics, set to propel the future of electronics manufacturing

- Marking the event’s biggest international participation to date, the edition brings together 6,000+ global brands from over 50 countries, featuring pavilions from Germany, Japan, Taiwan, and more.

- A dynamic meeting ground for collaboration and innovation spanning Start-Up and SME zones, conferences, podcasts, forums, and buyer–seller programs.

- Cricket icon Rohit Sharma leads the campaign, embodying India’s spirit of innovation, teamwork, and emerging global leadership in electronics.

India is steadily strengthening its position in the global electronics landscape, moving from being a participant to becoming a key driver of innovation and manufacturing. This momentum comes to life at the co-located trade fairs, electronica India and productronica India, returning to the Bangalore International Exhibition Centre (BIEC) from 17–19 September 2025.

This year’s edition reflects the scale of India’s electronics growth journey. Spread across 60,000 square meters, the fairs will feature 6,000+ global brands and participation from 50+ countries. From semiconductor design and embedded systems to electronic components and production technologies, the platform will spotlight innovations driving electric mobility, smart displays, and Industry 4.0, reinforcing India’s growing role in global electronics manufacturing.

In a move that links national pride with technological prowess, cricket icon Rohit Sharma has been named the face of the event, embodying the theme, “India’s Powerplay in Electronics.” It’s a fitting analogy Sharma’s leadership, innovation, and teamwork on the field resonate with the very ethos driving India’s electronics sector.

Bhupinder Singh, President IMEA, Messe München and CEO, Messe Muenchen India, said:

“These trade fairs underscore India’s global ambitions in electronics manufacturing. This year marks a record international participation for the event, with representation from over 50 countries and dedicated pavilions from Germany, Japan, Taiwan, and more. The platform brings together industry leaders, policymakers, and innovators to advance design-led innovation and modern manufacturing. With Rohit Sharma as the face of this edition, they embody the scale, energy, and vision driving India’s Powerplay in Electronics.”

Dr. Reinhard Pfeiffer, CEO of Messe München, added:

“The significance of these trade fairs lies in uniting every layer of the electronics ecosystem from global industry leaders to agile startups, from government stakeholders to academia. Hosting this convergence in Bengaluru underscores India’s fast rise as a key technology hub and its growing influence on global innovation trends. For Messe München, this edition represents a milestone in our mission to foster cross-border collaboration and create a truly global platform for innovation and growth.”

The event’s gravitas is underscored by powerful alliances with Government of Karnataka as State Partner and support from premier industry associations including the Electronic Industries Association of India (ELCINA), India Cellular & Electronics Association (ICEA), Electronics City Association ofIndia (ELCIA), Consortium of Electronic Industries in Karnataka (CLIK), Taiwan Printed Circuits Association (TPCA), Korea Printed Circuits Association (KPCA) and Global Industry Association (GEA) other association names.

Rajoo Goel, Secretary General of ELCINA, underscores:

“What excites us is the balance between today’s opportunities and tomorrow’s vision. With pioneering start-ups, global pavilions, semiconductor design focus, extensive representation of components and materials value chain as well as buyers and sellers converging, these trade fairs reflect the fast maturity of our industry. ELCINA is proud to partner in building an ecosystem where policy, innovation, and collaboration come together and where India’s electronics manufacturing is stepping into genuine global leadership.”

At the heart of this year’s buzz are 18 pioneering start-ups, backed by the Government of Karnataka and Startup Karnataka, unveiling breakthrough innovations across the electronics value chain and highlighting India’s deep-tech and semiconductor strength. Adding momentum, the India Semiconductor Conclave will convene global leaders and policymakers to drive India’s design-led chipmaking ambitions onto the world stage.

Karnataka Innovation and Technology Society expressed pride in supporting electronica India and productronica India 2025 in Bengaluru. This support underscores Karnataka’s commitment to advancing a design-led and manufacturing-led future in electronics and semiconductors. By fostering innovation, attracting global investments, and empowering start-ups, the state continues to create an environment where technology thrives, talent flourishes, and India strengthens its position as a global leader in electronics. electronica India and productronica India 2025 will go beyond traditional displays with:

- Innovation Forum – spotlighting breakthrough ideas in sustainability, Japanese tech trends, asset tracking, e-tolling, and future navigation.

- Buyer–Seller Forum – driving 2,000+ structured meetings with procurement leaders from Honda, Pricol, BHEL, BEL, Lava, Foxconn, and more across PSUs, automotive, consumer electronics, mobility, and industrial sectors.

- Industry-led Conferences – a series of focused forums including the CEO Forum, eFuture, eMobility, Capital Goods & Automation, India PCB Tech, and the India Semiconductor Conclave.

- Live Podcast Series – featuring conversations with industry thought leaders and innovators, adding dialogue to the show floor.

Together, these programmes blend demonstration, deal-making, and dialogue—underscoring India’s Powerplay in Electronics as it ignites Bengaluru.

The post Electronica India and productronica India 2025: India’s Powerplay in Electronics, set to propel the future of electronics manufacturing appeared first on ELE Times.

Power Electronics Market Trends: SiC & GaN Technologies Reshape Industry Outlook

The power electronics sector is set to start a final stage of growth as it is expected to have an evaluated market value of USD 51.73 billion by 2025, reaching USD 67.42 billion by 2030. A steady CAGR of 5.4% stems from a steady increase in demand for energy efficiency, renewable integration, and semiconductor advanced technology.

The Growth Drivers:

The positive momentum of the market is born out of interlinked phenomena:

Clean Energy Imperative

As the world tries to go carbon-neutral, renewable energy systems, including solar photovoltaic and wind farms, go mainstream. Power electronics, hence, are used in these systems to enable efficient energy conversion, grid integration, and real-time management.

Electrification of Transport

With EVs and HEVs no longer considered niche, the demand is now rising for high-performance inverters, converters, and battery-management systems. The transition is fueled by policy, consumer interest, and vehicle-electrification technology advances.

Semiconductor Innovations

Wide-bandgap materials such as silicon carbide (SiC) and gallium nitride (GaN) are reshaping design possibilities. These materials enable devices that are smaller, faster, more efficient, and capable of operating at higher temperatures making them invaluable for modern automotive, industrial, and renewable applications.

Smart Infrastructure and Connectivity

With the development of smart grids, connected mobility, and smart manufacturing, there is a greater demand for the precision operation of power. Power electronics underpin these systems to foster efficiency, safety, and interoperability.

Though on a positive trending path, the sector faces engineering challenges, chiefly in the design and packaging of SiC devices, which mandate careful thermal and structural management.

Market Segmentation Insights:

Automotive & Transportation: Fastest Growing Segment

This industry segment shall witness the highest CAGR during the forecast period. Vehicle electrification, growing ADAS features, integration of infotainment systems require advanced power electronics focusing on efficiency and reliability, which are only further underlined with the march toward autonomous and connected vehicles.

Power ICs: Market Leader

Power ICs will maintain their position as the largest share commanded due to their extensive uses in consumer electronics like smartphones, laptops, and tablets; industrial and automotive applications. They become vital for reducing energy loss, extending battery life, ensuring high performance, and reliability of systems.

Regional Insights:

Asia-Pacific region is considered to be the center of the global market and hence is projected to remain dominant. The key drivers behind its domination are:

Percentagewise: Strong power electronics manufacturing systems in China, Japan, South Korea, and Taiwan.

Rapid urbanization and industrialization in emerging economies such as India, Vietnam, and Indonesia.

Generous government aids for the adoption of EVs and the deployment of renewable energy.

Asia Pacific then stands as a global supplier and a major consumer of power electronics, given the establishment of an industrial base and growing domestic demand.

Industry Panorama:

The market consists of well-established technology giants as well as specialized players. Major companies include Infineon Technologies AG, Texas Instruments Incorporated, ON Semiconductor, STMicroelectronics, Analog Devices, Inc., Mitsubishi Electric Corporation, Renesas Electronics Corporation, Toshiba Corporation, Fuji Electric Co., Ltd., and Vishay Intertechnology, Inc.

Such firms intend to strengthen their market positions with product innovations, partnerships, acquisitions, and increased capacity. Investing heavily in R&D with special emphasis on SiC and GaN technologies, they are shaping the next generation of energy efficient systems.

Future Outlook:

Power electronics’ contribution to a cleaner, smarter, and more connected society will define the market by 2030. The industry is situated at the nexus of technological innovation and energy change, powering everything from electric vehicles to regulating renewable energy flows and supporting the gadgets we use on a daily basis.

In this situation, businesses that can expand production, overcome material constraints, and innovate for efficiency will not only prosper but also establish the standards for a sustainable electronics future.

The post Power Electronics Market Trends: SiC & GaN Technologies Reshape Industry Outlook appeared first on ELE Times.

Analog Electronics: The Timeless Backbone of Modern Sensors

Introduction: The “Old” Tech Powering the “New” World

In today’s electronics ecosystem, conversations are dominated by artificial intelligence, edge computing, and ultra-fast wireless networks. Yet, behind every groundbreaking innovation, there lies a quieter but indispensable player i.e., analog electronics. While digital may dominate headlines, it is analog that ensures real-world phenomena which can be captured, conditioned, and processed.

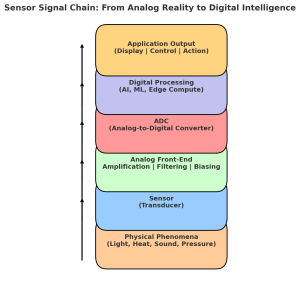

As engineers often remind themselves, “Nature is analog. Everything else is an approximation.” No matter how sophisticated a digital system is, its accuracy and reliability hinge on the quality of the analog front-end. From radar in advanced driver-assistance systems (ADAS) to MEMS accelerometers in smartphones, and from biomedical wearables to industrial IoT nodes, analog electronics forms the first link in the sensor signal chain.

Why All Sensors Speak Analog First

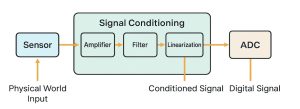

Every physical phenomenon light intensity, sound waves, heat, vibration, or radio frequency (RF) radiation exists in analog form. Sensors are essentially transducers, converting these continuous signals into measurable electrical quantities. But before such data can be digitized and analyzed by processors or AI algorithms, it must pass through an analog front-end (AFE).

The AFE includes key blocks such as instrumentation amplifiers, filters, linearization circuits, and signal conditioning modules that prepare raw sensor outputs for analog-to-digital conversion (ADC). Without robust analog conditioning, even the most advanced digital processors would be “blind” to the real world.

As Walt Maclay, CEO of Voler Systems, puts it: “Digital processing is only as good as the analog electronics feeding it. Garbage in, garbage out applies more to sensors than anywhere else.”

Core Functions of Analog in Modern Sensors

- Signal Amplification

Many sensors output signals in the microvolt or millivolt range, easily drowned by noise. Instrumentation amplifiers and low-noise amplifiers (LNAs) boost these signals while preserving fidelity. For example, electrocardiogram (ECG) sensors require amplifiers with high common-mode rejection ratios (CMRR) to extract meaningful heart signals from noise-laden environments. - Filtering

Real-world signals are messy. Analog active and passive filters remove unwanted noise and interference before digitization. In radar systems, bandpass filters ensure only the target frequency range is processed, dramatically improving signal-to-noise ratio (SNR). - Linearization & Biasing

Many sensor outputs are nonlinear by nature. Analog circuits implement linearization techniques that correct these distortions, making sensor behavior predictable. Similarly, biasing ensures transducers operate in optimal ranges. For example, in thermistors, resistance-to-temperature curves must be linearized before meaningful temperature data is derived. - Conversion Readiness

Analog circuits prepare signals for ADC compatibility by ensuring proper voltage levels, impedance matching, and bandwidth. Without this step, digitization could lead to clipping, aliasing, or resolution loss.

Case Studies: Analog at Work in Emerging Applications

- Automotive ADAS

ADAS relies heavily on radar and LiDAR sensors, where real-time performance is non-negotiable. Analog front-ends amplify weak RF echoes, filter them for interference, and feed precise signals to high-speed ADCs. Even a microsecond delay can mean the difference between safe braking and a collision.

- Biomedical Devices

Wearable medical devices like glucose monitors and ECG patches demand ultra-low-power, high-precision analog circuits. Here, analog electronics extend battery life while ensuring clinical-grade accuracy. An error of even 1 mV in amplification could translate into misdiagnosis.

- Industrial IoT

Factories rely on thousands of sensors for vibration monitoring, predictive maintenance, and process automation. Analog circuits in these environments must withstand electrical noise, temperature fluctuations, and mechanical stress. Unlike fragile digital logic, robust analog designs ensure reliability under extreme industrial conditions.

- Environmental Monitoring

Long-term stability is critical in air-quality monitors, soil sensors, or weather stations. Analog circuits designed for low drift and high linearity guarantee consistent data for years without recalibration.

Analog’s Edge Over Digital in Certain Tasks

While digital processing offers flexibility, analog holds an edge in critical aspects:

- Zero Latency: Analog signals propagate at the speed of physics — no clock cycles required. For radar-based collision avoidance, this deterministic performance is irreplaceable.

- Power Efficiency: Analog front-ends consume far less power than equivalent digital circuits, making them essential in wearables and IoT nodes where every microamp counts.

- Reliability under Harsh Conditions: Analog circuits continue functioning in extreme environments — radiation, high temperatures, or electromagnetic interference — where digital logic often fails.

As Bob Dobkin, co-founder of Linear Technology, famously said: “Analog will never die, because the world is analog.”

Integration Trends: Analog in the Age of SoCs and SiPs

The industry is increasingly moving towards system-on-chips (SoCs) and system-in-packages (SiPs) that integrate both analog and digital functions. For instance, today’s MEMS inertial sensors often include on-chip AFEs, ADCs, and digital processors in a single package. This integration reduces footprint, improves signal integrity, and supports miniaturization for wearables, drones, and autonomous systems.

However, integration does not eliminate the need for analog expertise. Instead, it requires engineers to design mixed-signal systems where the interplay between analog and digital domains is carefully managed. Issues like thermal drift, bandwidth matching, and parasitic effects remain squarely in the analog domain.

Conclusion: Analog as the Permanent Foundation

In the race towards digital transformation, analog electronics is often overlooked. Yet, it is precisely analog that determines how effectively digital systems can sense and respond to the physical world. Whether in self-driving cars, medical diagnostics, or industrial automation, analog remains the timeless backbone of modern sensors.

For engineers, the message is clear: mastering analog design is not a relic skill, but a future-proof investment. The more complex and interconnected systems become, the more critical it is to ensure rock-solid analog foundations.

As the electronics pioneer Barrie Gilbert once noted: “You can digitize data, but you cannot digitize reality. Reality is, and will always be, analog.”

The post Analog Electronics: The Timeless Backbone of Modern Sensors appeared first on ELE Times.

Generative Artificial Intelligence Boosts Chip Yields and Slashes Manufacturing Defects

In 2021, car manufacturers worldwide halted production because a single one-dollar microcontroller was unavailable. The wait time for advanced semiconductors jumped from 12 weeks to over 26 weeks, revealing how fragile the global supply chain had become. The yield losses and manufacturing defects are not just technical issues-they are strategic challenges affecting procurement leaders, supply chain managers, and even national economies.

Meanwhile, demand for semiconductors continues to grow relentlessly. Global consumption is expected to increase at a compound annual growth rate of 7 to 8 percent through 2030, while production capacity is only growing at about 5 percent per year. This mismatch makes every wafer incredibly valuable. Even a modest 2 percent improvement in yields at advanced technology nodes could free up around 150,000 wafers annually, which translates into billions of dollars of extra supply.

Generative AI addresses these challenges by creating optimized designs in advance, anticipating potential defects, and enhancing scheduling in wafer fabrication. It is reshaping the economics of the semiconductor industry- improving yields, reducing inconsistencies, and strengthening supply chains’ reliability.

The Yield Challenge in Semiconductor Manufacturing

Chip manufacturing involves more than 1,000 steps, from photolithography to etching. At advanced nodes of three nanometres and below, tiny atomic-level variations can make wafers unusable. With single-wafer costing over 16,000 dollars, any loss in yield directly cuts profit margins.

Every percentage point of yield improvement is like adding a new fabrication plant without capital investment, said Sanjay Mehrotra, CEO of Micron Technology.

How Generative AI Creates Strategic Value

Generative models such as Generative Adversarial Networks (GANs), Variational Autoencoders (VAEs), and foundation models go beyond predictive analytics: they generate better alternatives. Four applications stand out:

- Design Optimization

Generative AI evaluates thousands of layout variations to identify configurations that reduce defects. Synopsys, working with Taiwan Semiconductor Manufacturing Company (TSMC), reported a 15 percent yield improvement using AI-driven design space exploration. Faster design cycles and quicker delivery to customers follow. A European fabless design company leveraged generative AI for design optimisation and achieved ROI in just 18 months, reducing wafer scrap, accelerating revenue realization, and lowering operational costs.

- Defect Prediction

AI generates synthetic wafer maps to train inspection systems before defects appear. American-based KLA corporation reported 25–30 percent improvement in defect detection, resulting in more usable wafers and faster production cycles. Samsung implemented AI-based yield learning to cut line failure rates by 12 percent, decreasing buffer inventory needs and improving delivery reliability.

- Assistance with Lithography

AI supports mask patterns generation to minimize distortions through Inverse Lithography Technology (ILT) and Optical Proximity Correction (OPC). Intel reported a 40 percent reduction in edge-placement error, increasing first-pass yields.

- Supply Assurance and Fabric Scheduling

Generative AI simulates thousands of scheduling scenarios, balancing tool usage, and maximizes throughput. A Taiwanese fabless company reduced wafer cycle times from 20 to 17 days using AI scheduling, ensuring timely chip delivery in a competitive market.

It also strengthened broader supply chain resilience. Global Foundries applied predictive analytics to reduce recovery times during material shortages by 30 percent, helping procurement meet client demand during disruptions.

Industry Case Studies and Outcomes

- Samsung Foundry – AI-based Yield Learning- It reduced the cut line failure rates by 12 percent, lowering buffer inventory requirements and improving delivery reliability for customers.

- Global Foundries – Predictive Supply Chain Analytics: Using predictive analytics, it improves supply chain resilience and cuts recovery times during material shortages by 3 percent, enabling procurement teams to meet client demands.

- European Fabless Design Company – Design Optimisation: Employing generative AI for layout optimisation, the company achieved return on investment (ROI) in just 18 months. By decreasing wafer scrap, speeding revenue realisation, and reducing operational cost.

Strategic Procurement and Supply Chain Value

Generative AI serves the dual role. On the shop floor, it functions like examining billions of flaw patterns to increase yields. In the boardroom, it mitigates risk, strengthens supply continuity, and protects margin.

Predictive insight facilities by generative AI can help with lead time optimisation, multi-sourcing strategy guidance, and supplier negotiations, and align contractual requirements with actual fab performance, ensuring reliable capacity guarantees.

SEMI CEO Ajit Manocha stated that generative AI is not just yield enhancement-, it lowers process variability, increases predictability, and strengthens overall operational resilience.

Challenges to Adoption

Despite its transformative potential, adopting generative AI in the semiconductor industry presents several challenges:

Ø Data confidentiality: It remains the key concern because the processed data is so proprietary and difficult to share across ecosystems.

Ø Computational intensity: It requires a substantial amount of computational equipment to train sophisticated AI generative models.

Ø Explainability gaps: To foster confidence, engineers and procurement teams need AI advice to be transparent.

Ø Change management: To fully realise value, Fabs must retrain process engineers, educate procurement specialists in AI literacy, and link data science teams across silos.

The Road Ahead: Toward Autonomous and Resilient Fabs

Next-generation semiconductor factories are increasingly relying on generative AI as central intelligence. Emerging trends include:

- Autonomous fabs: It leverages generative AI to modify recipes in real time to reduce yield loss and improve efficiency.

- Collaborative ecosystems: Design firms, equipment manufacturers, and fabs share AI models to optimize production and supply chain resilience.

- Zero-defect manufacturing: While idealistic, generative AI is making substantial progress towards achieving it, bringing fabs closer to near-perfect yield and consistency.

Strategic Imperatives for Leaders

The path forward is clear for procurement executives, semiconductor leaders, and strategy decision makers:

- Scale AI across operations: Transition from pilots to full integration in scheduling, lithography, electronic design automation, and inspection workflow.

- Leverage AI in procurement: Use insights for contract negotiations, supplier diversification, and lead time predictability.

- Invest in people and collaborations: Integrate the expertise of supply chain managers, data scientists, and strengthen collaboration with AI solution providers and academic institutions.

Conclusion

Generative AI is transforming chip manufacturing. It boosts yields, cuts defects, and improves production scheduling. More importantly, it helps leaders make supply chains stronger, margins steadier, and delivery times more predictable.

Companies that embrace AI first will unlock extra capacity, protect supply continuity, and gain a clear competitive edge. Every wafer counts, and every week of lead time matters. Generative AI ensures neither is wasted.

The post Generative Artificial Intelligence Boosts Chip Yields and Slashes Manufacturing Defects appeared first on ELE Times.

Welcome to the Indian era of global technology

India is emerging as the big Global South trade story as it pursues favorable relations with most of the world’s major economies. Simultaneously, it has highlighted the complexity and fragility of the global order as the world grapples with intensifying great power competition, the rise of regional actors, and a growing erosion of trust in multilateral institutions. India’s economic growth has been the envy of other nations.

Under this background, Donald Trump issued a strong directive to Silicon Valley’s titans to stop hiring Indians. Why? Because the Indian intellect has evolved from being America’s secret weapon to becoming its most feared competitor. Donald Trump delivering can only be described as a declaration of intellectual war.

Indians – the talent pool and intellectual force has quietly, methodically, and brilliantly infiltrated every corner of American technological supremacy. But without Indian minds, Silicon Valley doesn’t just slow down, it stops. But why are Indians being targeted that have consistently outperformed, out-innovated, and out led every other group in tech space?

The point is that Indians don’t just work in American tech, they run it. Indians constitute just 1% of the U.S. population, yet they represent over 36% of all high-skill immigrant entrepreneurs. They hold 72% of all H-1B visas. They founded more than 25% of billion-dollar startups.

Indians occupy CEO positions at companies worth a combined $2.5 trillion. The intellectual domination speaks itself, Sundar Pichai, Satya Nadella, Shantanu Narayan and Parag Agrawal are the real gems. Indian minds aren’t just participating in America’s tech revolution, they’re leading it.

Under their leadership, these companies haven’t just grown, they’ve transcended their American origins to become truly global forces. And that’s the real threat, because when you can no longer control the minds that drive your most valuable companies, you’ve lost more than economic leverage, you’ve lost technological sovereignty. Here Trump talks about intellectual nationalism and protecting American technology supremacy.

Every major technological breakthrough of the past two decades has Indian fingerprints all over it – be it the rise of artificial intelligence, cloud computing, smartphone revolution and coding the software. This is about intellectual capital that has become irreplaceable. The fear isn’t just about Indian success in America; it’s about India’s independence from America.

Today’s Indian professionals aren’t just seeking American opportunities; they’re creating alternatives to American systems. They’re not just joining tech companies, they’re founding them. They’re not just moving to Silicon Valley; they’re building Silicon Valley back home. Bangalore has become Asia’s tech capital. Indian unicorns are solving problems that American companies haven’t even identified yet. From Paytm revolutionizing digital payments to Flipkart challenging Amazon to Ola competing with Uber, Indian innovation is no longer derivative, it’s original, it’s disruptive, it’s independent.

And the same independence terrifies Trump more than any foreign threat ever could. In such a case you’re no longer the only superpower in the room. You’re just another player in a multipolar game.

Today, India operates its own space program that lands on the moon at a fraction of NASA’s cost. It runs its own digital payment system that processes more transactions than Visa and MasterCard combined. It develops its own AI models trained on Indian languages, solving India’s problems. This is technological independence. The truth is uncomfortable but undeniable.

The Indian mind has become so valuable, so essential, so irreplaceable that even suggesting its absence sends shockwaves through the entire American tech ecosystem. It’s not the beginning of Indian exclusion from American tech. It’s the acknowledgement that Indian inclusion has been so successful, so complete, so transformational, that it now threatens the very narrative of American technological exceptionalism.

Google’s search algorithms, refined by Indian mathematicians, Microsoft’s cloud infrastructure, designed by Indian engineers, Apple’s chip designs, optimized by Indian developers, Amazon’s logistics networks, managed by Indian operations experts, Tesla’s autonomous driving systems, powered by Indian AI researchers are such examples of Indian’s contribution to the US’s technology supremacy. The Indian mind has already reshaped American technology so fundamentally that any attempt to reverse it would be like trying to un-invent the Internet. You can’t separate Indian intelligence from American innovation anymore.

The future belongs to minds that can adapt, innovate, and excel, regardless of geography, politics, or prejudice. The future belongs to talent that creates value wherever it goes and builds bridges wherever it lands. The future belongs to the Indian intellect that has proven its worth. Trump’s fear of Indian talent isn’t India’s problem to solve. It’s America’s competitive disadvantage to manage. Welcome to the new reality. Welcome to the Indian era of global technology.

Devendra Kumar

Editor

The post Welcome to the Indian era of global technology appeared first on ELE Times.

Road to Alternate Battery Solutions: Beyond Lithium for a Sustainable Future

As the world moves towards its ambitious climate friendly goal of net-zero emissions by 2050, transport sector, which contributes between 15% to 25% of total global GHG emissions according to varying estimates, will be closely monitored. Transition from ICE vehicles to Electric Vehicles (EVs) on a large scale is imperative in this regard.

The International Energy Agency (IEA), in its recently released report ‘Global EV Outlook 2025’ estimated that globally, EV sales crossed 17 million in 2024, reaching a sales share of more than 20% of total automotives sold. With China leading the way amounting to half of global electric sales, and new markets emerging in Asia and Latin America, electric cars are expected to exceed a share of 40% of total share by 2030 under current policy settings.

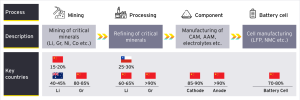

Along with growth in EV sales, the demand for batteries have also gone up, accounting for 950GWh in 2024. The battery makes up about 40% of an EV’s total cost, with lithium as the main element in most batteries worldwide. A Lithium-ion battery (LIB) is made up of a graphite anode, with lithium salt as the electrolyte and a cathode consisting of Lithium compounded with Nickel, Cobalt or Manganese. Consequently, conventional lithium-ion batteries are commonly referred to as NMC batteries, denoting their composition of nickel, manganese, and cobalt.

Supply Chain imbalances of LIBs:

While reserves of these minerals are present in a broad geography of Latin America, Australia, Africa and others, the down stream supply chain of processing and battery manufacturing is heavily skewed in favour of China.

EY research shows China’s hold over processing of EV components encompasses 80-90% of global share. At the same time with giants like CATL, China houses over 70-80% of global LIB manufacturing. Over the years these giants have innovated and reduced the use of Nickel and Cobalt in LIBs and produced Lithium iron phosphate (LFP) batteries on a large scale.

NMC batteries, which are still prevalent in the US and Europe provide an energy density advantage over the LFP batteries, which are in turn cheaper and are widely used in China. The energy density of LFP battery packs is about one-fifth lower by mass (Wh/kg) and one-third lower by volume (Wh/L) than that of NMC battery packs. This advantage, however, is partly offset by LFP’s capability to reach 100% state of charge when required without significant degradation, whereas NMC batteries are typically limited to 80% to preserve long-term performance. The NMC batteries are preferred for operating in colder climates and over long ranges. Whereas enhanced performance level of LFP batteries and the given cost advantages have made them popular in the mass markets.

Global Lithium Constraints:

Primarily Lithium, often referred as ‘white gold’ is extracted from two sources across the globe. Firstly, there are minerals like spodumene, petalite, and lepidolite and secondly from Lithium salts like Lithium hydroxide, Li carbonates and Li chlorides which are highly available in lakes across the Andes mountains.

Parts of Argentina, Bolivia and Chile form the Lithium triangle with large proportion of world’s Lithium reserves. However, an nationalization drive over these reserves seems to proliferate in the Latin American countries, akin to what took place vis-à-vis oil sector with the formation of OPEC in the 1960s introducing new complexities on global supply chains.

Then there is also research going on Absorption type aluminium based direct Lithium extraction, which can reduce water drainage, but such methods are at low Technical Readiness levels (TRL)

Finding a way around the ‘White Gold’:

These dynamics have compelled governments and automakers to look at alternatives to Lithium. Some of the alternate EV battery technologies considered are as follows:

| Battery Technology | Anode Active Material (AAM) | Cathode Active Material (CAM) | Electrolyte |

| Sodium Ion Battery (SIB) | Hard as well as soft Carbon easily available from Crop residue or Agri waste | Sodium ions such as layered oxides | Salts such as sodium hexafluorophosphate (NapF6) |

| Zinc manganese Dioxide battery | Zinc metal, 80% of which globally available is from recycled products | Oxygen from air | Aqueous solution of Potassium hydroxide

(KOH) |

| Aluminium-Air battery | Solid Aluminium metal | Oxygen from air | High pH solution of KOH, NaOH or even NaCl. |

| Hydrogen Fuel Cell (HFC) | Hydrogen gas | Oxygen from air | KOH or NaOH |

The metals other than Lithium that are mostly used in metal ion or metal air batteries are widely available but TRLs of 7-9 as required for commercial EVs are yet not achievable with these technologies. However, technologies like Al-air batteries are inducted in other applications like medical devices. Metal air batteries have higher energy density and lower cost than LIBs but have persistent design challenges.

Batteries with solid electrolytes called solid state batteries are looked upon with high optimism even with low TRLs. Electrolytes used in them are mostly oxides, sulphides or polymer electrolytes.

While HFCs are in use commercially, but their production methods remain debatable. Production of hydrogen through electrolysis of water called green hydrogen is still limited compared to blue hydrogen (produced from methane) and grey hydrogen (produced from capturing hydrogen from fossil fuel).

Reducing Dependence through Recycling

A major source of Raw material extraction is Urban mining, which involves extracting valuable materials from E-Waste contributing to a circular economy. According to Global E-waste monitor, we might see E-waste production levels of 82 million tonnes globally by 2030 providing huge recycling potential. Although inefficient recycling mechanisms hinder urban mining potential. A systematic process of collecting, sorting and dismantling E-waste followed by methods like Pyrometallurgy (Smelting), Hydrometallurgy (Chemical separation) and Biometallurgy (Biological separation) must be integrated at ground level.

It is to be remarked that Alternative battery solutions won’t reduce the share of LIBs and LFPs in EVs immediately just as EVs won’t suddenly replace ICEs on roads. A coordinated strategy working on conventional sources while building resilience through alternatives is the need of the hour for a just climate transition.

The post Road to Alternate Battery Solutions: Beyond Lithium for a Sustainable Future appeared first on ELE Times.

Reimagining Human-Machine Interaction: Force Sensing as the New Frontier in HMIs

Introduction- From Mechanical Inputs to Force-Sensitive Interfaces

Human–Machine Interfaces (HMIs) have transformed dramatically in the past few decades. Early systems relied on mechanical switches, levers, and tactile buttons, robust but limited in design flexibility. The capacitive touch revolution brought sleek glass panels, multi-touch gestures, and sealed surfaces to smartphones, automotive dashboards, and industrial equipment.

However, capacitive technology has well-known drawbacks: poor performance in humid environments, false triggers, difficulty working with gloves, and limited ability to distinguish intentional versus accidental touches. Engineers have long sought the next leap in interaction technology.

That leap is force sensing the ability of HMIs to detect not just whether a surface is touched, but how firmly it is pressed. This evolution unlocks richer interaction, robust operation across challenging environments, and freedom from restrictive material choices. As Dr. Mark Weiser, often regarded as the father of ubiquitous computing, once said:

“The most profound technologies are those that disappear. They weave themselves into the fabric of everyday life until they are indistinguishable from it.”

Force sensing is enabling precisely this an interaction layer so intuitive and adaptable that it becomes invisible, yet indispensable.

Technology Fundamentals- How Force Sensing Works

Force sensing is fundamentally about converting mechanical load into an electrical signal. Two primary sensing principles dominate the market: piezoresistive and capacitive force sensing.

Piezoresistive Force Sensors

- Operate by measuring a change in electrical resistance when a material deforms under load.

- Typically use a full-bridge Wheatstone configuration, where four resistive elements form a balanced circuit.

- When force is applied, resistance changes unbalance the bridge, producing a measurable voltage signal.

- Advantages: High sensitivity, strong signal-to-noise ratio (SNR), good temperature compensation, suitability for MEMS fabrication.

- Considerations: Requires calibration to account for long-term drift and environmental conditions.

Capacitive Force Sensors

- Detect changes in capacitance caused by the displacement of conductive plates.

- Well-suited to applications where transparency or minimal deformation is required.

- Limitations: Susceptible to interference from humidity, dust, and certain materials; reduced performance with thick overlays.

MEMS Integration- Driving Miniaturization and Reliability

MEMS (Micro-Electro-Mechanical Systems) fabrication has transformed force sensing by enabling:

- Micron-scale sensing elements for compact integration.

- Tight tolerances and reproducibility, ensuring low hysteresis and predictable linearity.

- On-chip integration of low-noise amplifiers (LNA) and analog-to-digital converters (ADC), minimizing latency and reducing PCB real estate.

- Lower power consumption, which is vital for battery-powered devices.

By combining the sensing element, amplifier, and ADC into one package, designers can reduce complexity, improve EMC (Electromagnetic Compatibility), and speed up time-to-market.

Engineering Performance Metrics

Top engineers evaluating force sensors look beyond basic operation and focus on specific metrics:

- Sensitivity- The smallest detectable change in force; expressed in mV/V/N or equivalent.

- Linearity-The degree to which output correlates proportionally with applied load across the sensing range.

- Hysteresis– Difference in output between loading and unloading at the same force; lower values mean more repeatable performance.

- Power Consumption– Measured in µW or mW; critical for mobile and IoT devices.

- Temperature Stability– Resistance to thermal drift over wide operational ranges.

- Latency– The delay between applying force and obtaining a usable output; must be minimal for real-time feedback systems.

- Durability and Fatigue Life– How well the sensor maintains calibration after repeated load cycles.

Reference Example- Qorvo’s Integrated Force Sensor

Qorvo’s full-bridge piezoresistive MEMS force sensor exemplifies current best practice in integration:

- Architecture: MEMS sensing die + low-noise amplifier + on-chip ADC.

- Performance: Sensitivity up to 50× that of traditional capacitive sensing.

- Thermal Stability: Full-bridge layout compensates for temperature-induced resistance changes.

- Size: Compact footprint for easy integration in constrained spaces.

- Noise Reduction: Common-mode noise rejection inherent to Wheatstone bridge design improves measurement reliability.

This level of integration reduces external component count, simplifies PCB layout, and delivers predictable performance across demanding environments such as automotive cabins or factory floors.

Capacitive vs. Force Sensing – A Technical Comparison

| Aspect | Capacitive Sensing | Force Sensing |

| Pressure Detection | Detects touch only | Detects both light and firm presses |

| Material Options | Requires conductive/transparent surfaces | Works through metal, wood, plastic |

| Environmental Resistance | Sensitive to moisture, gloves, humidity | Performs in wet, dusty, or extreme conditions |

| False Triggers | Higher risk in contamination | Lower, needs deliberate pressure |

| Durability | Surface wear impacts function | Can be sealed for long service life |

Integration Considerations for Engineers

Force sensing delivers new possibilities, but integration requires careful planning:

- Overlay Material– The stiffness, thickness, and elasticity of the cover layer affect force transfer and sensor response.

- Mechanical Coupling– Poor coupling between the overlay and sensor leads to inconsistent readings.

- Calibration & Compensation– Initial factory calibration and in-field software compensation mitigate drift and account for production tolerances.

- Signal Conditioning– Filtering and amplification tailored to the application’s dynamic range are essential for maintaining high SNR.

- Power Management– Sleep modes, duty cycling, and event-driven activation preserve battery life in portable designs.

- Interface Protocols– Support for standard digital interfaces (I²C, SPI) ensures compatibility with a wide range of MCUs and SoCs.

Application Spectrum

Force sensing’s unique combination of precision, environmental resilience, and material flexibility makes it valuable across sectors:

1 Automotive

- Smart dashboards without mechanical buttons.

- Steering wheel controls that differentiate between light navigation and firm command inputs.

- Surfaces resistant to dust, vibration, and thermal cycling.

2 Wearables & Consumer Electronics

- Waterproof, gapless designs that still respond to fine pressure variations.

- Wearables that maintain tactile accuracy under sweat, rain, or glove use.

3 Industrial Controls

- Equipment interfaces operable with gloves, in oily or dusty conditions.

- High durability in mission-critical control systems.

4 Medical Devices

- Sterile, sealed surfaces for hospital environments.

- Precise force detection for surgical robotics and diagnostic equipment.

Market Dynamics & Growth Drivers

The demand for rugged, low-maintenance HMIs is accelerating, driven by:

- Industry 4.0 and increased automation.

- Automotive electrification, requiring cleaner, smarter control surfaces.

- Wearable health tech, where reliability and waterproofing are paramount.

- IoT proliferation, pushing for sensors with low power consumption and high integration.

Future Directions

Force sensing is evolving toward multi-modal, adaptive HMIs:

- AI-Assisted Sensing– Systems that learn individual user habits, adjusting sensitivity dynamically to reduce false positives.

- Sensor Fusion– Combining force sensing with capacitive, optical, and haptic elements for richer interaction profiles.

- Standardization Efforts– Creating performance benchmarks and interoperability guidelines to accelerate adoption.

- Ultra-Low-Power Designs– Extending sensor battery life into multi-year ranges for IoT nodes.

Conclusion-Toward a New Input Paradigm

Force sensing is not just a technical upgrade, it fundamentally changes how devices interpret human intent. For engineers, it represents:

- Greater control over input granularity (light vs. firm presses).

- The ability to design HMIs for challenging environments without sacrificing aesthetics.

- Reduced maintenance through sealed, wear-resistant surfaces.

As the technology matures, the combination of MEMS precision, integrated signal processing, and intelligent software adaptation could make force sensing a standard HMI layer in everything from cars to medical devices. In many cases, the future of interaction will not be whether a device was touched but how it was touched.

The post Reimagining Human-Machine Interaction: Force Sensing as the New Frontier in HMIs appeared first on ELE Times.

Transforming EVs at AutoEV Bharat 2025 – High Efficiency Power Electronic

Power electronics is the silent engine behind every electric vehicle for regulating and controlling the electrical flow powering motors and providing a level of drive.

AutoEV Bharat 2025 showcases the innovations in power electronics that make EVs more efficient, smaller, and better performing.

Inverters and converters lie in the heart of these technologies, the power electronics that convert DC power from the battery into AC power for the motor. By doing so, they allow exact control of the motor speed and torque, resulting in smooth acceleration, power-efficient energy use, and superb driving experience.

Today, an EV demands a high-density, compact level of power electronics. AutoEV Bharat 2025 highlights next-generation designs that shrink the size and weight of these components while maintaining power ratings. Smaller size, then, results in more space and better thermal efficiency, thus aiding in vehicle packaging.

Advanced motor controllers are coupled with these power electronics to dynamically control torque, regenerative braking, and direction of power. Based on predictive algorithms, these systems optimize performance under multiple driving situations, such as city stop-and-go, highway, and hilly terrain.