ELE Times

R&S advances AI-RAN testing using digital twins in collaboration with NVIDIA

Rohde & Schwarz will showcase a new milestone in AI-driven wireless system testing at MWC Barcelona. The testbed, developed in collaboration with NVIDIA, integrates hardware-in-the-loop site-specific channel emulation using the NVIDIA Sionna Research Kit, enabling testing of AI-RAN applications under realistic channel conditions. The demonstration highlights the long-term collaboration of Rohde & Schwarz and NVIDIA, focusing on prototyping and validation of AI-RAN innovation with cutting-edge test and measurement solutions.

Evolving from prior proofs-of-concept in advanced neural receiver design – including custom constellations for pilotless communication – the new testbed advances from link-level validation to system-level verification using the full 5G NR protocol stack.

Powered by a single NVIDIA DGX Spark, the NVIDIA Sionna Research Kit runs a software-defined 5G RAN based on OpenAirInterface, while supporting AI inference workloads that comply with the strict real-time constraints of wireless systems. To showcase the flexibility of the research platform, a novel AI/ML-enhanced link adaptation algorithm has been integrated into the end-to-end system. It dynamically adjusts the downlink modulation and coding scheme (MCS) to optimise spectral efficiency and link reliability. The AI-driven link adaptation can learn not only site-specific propagation characteristics but also user equipment-specific behaviour on the fly, emphasising the need for end-to-end testbeds that capture these effects.

The testbed integrates the R&S SMW200A vector signal generator featuring dynamic channel emulation capabilities and the FSW signal and spectrum analyser. Jointly, these instruments enable the emulation of complex site-specific radio channels, seamlessly interfacing with the NVIDIA Sionna RT differentiable ray-tracing software. This closed-loop setup enables researchers and developers to evaluate the performance of novel AI-driven RAN features under dynamic, site-specific RF conditions – all without leaving the lab.

Gerald Tietscher, Vice President Signal Generators, Power Supplies and Meters at Rohde & Schwarz, said: “We’re excited to continue our ongoing collaboration with NVIDIA with this latest proof-of-concept for testing AI-enhanced base stations for both 5G-Advanced and 6G under realistic propagation conditions. Leveraging digital twin technology and ray tracing, this approach aims to bridge the gap between AI-driven wireless simulations and real-world deployment, facilitating more efficient and accurate testing of next-generation receiver architectures.”

Soma Velayutham, global industry business development lead for telecommunications at NVIDIA, said: “Synthetic data generation is transforming the way we train and validate AI-RAN systems by ensuring accuracy, scalability, and privacy, especially in settings of sparse data. Rohde & Schwarz, leveraging the NVIDIA Sionna Research Kit, exemplifies how industry-leading expertise and innovative technology can come together to accelerate progress in this critical field.”

The post R&S advances AI-RAN testing using digital twins in collaboration with NVIDIA appeared first on ELE Times.

NanoXplore & STMicroelectronics deliver European FPGA for space missions, first to qualify to new European ESCC 9030 standard for space applications

NanoXplore, the European leader in the design of SoC FPGA and radiation-hardened FPGA technologies, and STMicroelectronics, a global semiconductor leader serving customers across the spectrum of electronics applications, announce the qualification of NG-ULTRA for space applications. This radiation-hardened SoC FPGA has been designed specifically for space applications, including low- and medium-earth orbit constellations, and is set to be used in numerous satellite equipment systems, including flagship missions such as Galileo, Copernicus, and potentially IRIS.

“The ESCC 9030 qualification for the NG-ULTRA is a historic step. It proves that Europe now masters the entire production chain for cutting-edge digital components tailored to the requirements of both deep-space and new space constellations. Thanks to the support of the ESA, CNES, and the European Commission (via DG-DEFIS), NanoXplore & STMicroelectronics are securing EU strategic autonomy while making European satellites more competitive than ever.” — Édouard Lepape, CEO, NanoXplore.

“Space applications require a robust sovereign supply chain, radiation-hardened and cost-optimised chips. ST is leveraging its expertise in GEO and LEO platforms with proven FD-SOI technology, hardening expertise, manufacturing, advanced packaging and quality assurance assets in Europe to enable NanoXplore’s NG-ULTRA to the New Space market,” said Thomas Goust, Division General Manager of Space Division, RF & Optical Communication sub-group at STMicroelectronics.

First product certified to ESCC 9030 for the European New Space industry

This qualification marks a major industrial and technological milestone for the European space ecosystem: NG-ULTRA is the first product qualified to ESCC 9030, a new European standard dedicated to high-performance micro-circuits in flip-chip’ed on organic substrate or plastic package. This standard delivers the reliability required for space applications while enabling a transition away from traditional ceramic-packaged solutions – well-suited for deep-space but heavier and more expensive – marking a key step forward for constellations and higher-volume missions.

The “new space” dynamic (constellations, Low and Medium Earth Orbits, higher volumes) is transforming requirements for onboard digital equipment and driving a shift in scale: there is a simultaneous need for greater computing power, controlled power consumption, and contained costs compatible with large-scale deployments. NG-ULTRA addresses this challenge by enabling more data to be processed directly in orbit (edge computing), thereby limiting transmission bottlenecks between space and ground.

NG-ULTRA targets strategic functions such as on-board computers, data management and routing between sub-systems, image and video processing (real-time compression and encoding), Software Defined Radio (SDR) – enabling remote evolution of communication modes, and onboard autonomy (detection, recognition, supervision).

A secure, European supply chain

Beyond performance, this program embodies a strategic ambition to secure a sovereign and sustainable European supply chain for long-duration missions by reducing critical dependencies. For NG-ULTRA, the industrial framework combines design, manufacturing, assembly, and testing capabilities across European sites, with the aim of reconciling competitiveness, volume production, and space-grade reliability.

In addition to its own R&D and design center in Paris, Grenoble and Montpellier, NanoXplore leverages various STMicroelectronics facilities in Europe, including the Grenoble R&D and design center, the 300mm digital fab of Crolles, the space-specialist packaging facility in Rennes (France), the test and reliability site in Grenoble (France) and Agrate (Italy) and additional redundant qualified sites in Europe.

Technical specifications

With an “all-in-one” SoC (System on Chip) architecture designed specifically for platform and onboard computing applications, NG-ULTRA combines a multi-core processor with programmable hardware on a single chip. This architecture allows for greater design agility, reduces electronic board complexity and component count, and optimises latency, mass, and power consumption.

NG-ULTRA is built on STMicroelectronics’ 28nm FD-SOI digital technology platform, recognised for its advantages in energy efficiency, resistance to space radiation and advanced architecture features. Combined with a unique advanced radiation hardening technology, the NG-ULTRA is built to survive the thermal cycles, shocks, and vibrations of launch and long-term orbital life so as to ensure best-in-class performance and durability in the harsh space environment throughout the mission lifetime.

The NG-ULTRA has been designed to operate reliably in harsh radiation environments, offering a Total Ionising Dose (TID) tolerance of up to 50 krad (Si) to ensure long-term performance. It also demonstrates strong resilience to single-event effects, with Single Event Latch-up (SEL) immunity tested up to 65 MeV·cm²/mg and Single Event Upset (SEU) immunity validated for Linear Energy Transfer (LET) levels exceeding 60 MeV·cm²/mg.

NG-ULTRA integrates a full SoC based on quad-core Arm Cortex R52 and provides high computational capability (537k LUTs + 32 Mb RAM) to address the most complex onboard computer requirements.

Its streamlined architecture drastically reduces PCB complexity and system mass—two of the most critical constraints in space design. By minimising the component count, the NG-ULTRA simultaneously lowers total power consumption and project costs while increasing overall system reliability.

In addition, the SRAM-based architecture of the NG-ULTRA enables an adaptive hardware approach, allowing for unlimited on-orbit reconfiguration. This “hardware-as-software” flexibility allows operators to update functionality post-launch, adapt to evolving communication standards, or optimise the chip for different mission phases. The NG-ULTRA thus provides a future-proof platform that extends the operational relevance of assets long after they leave the launchpad.

To facilitate adoption, NG-ULTRA is also available as an evaluation kit — a complete prototyping platform that allows to rapidly validate performance and interfaces, reduces integration risks, and accelerates software and onboard logic development prior to flight-board production.

The post NanoXplore & STMicroelectronics deliver European FPGA for space missions, first to qualify to new European ESCC 9030 standard for space applications appeared first on ELE Times.

Top Seven Tech Trends in the semiconductor sector for 2026

In 2026, a new class of intelligent machines will emerge. Several of the trends we’ve identified are natural extensions of those we highlighted at the start of 2025, with the new year’s advancements driven by the widespread deployment of existing technologies. Industrial sectors, robotics, automotive, consumer electronics and smart homes will all benefit from increased autonomy, underpinned by the specialised silicon platforms and advanced processing that will make this a reality.

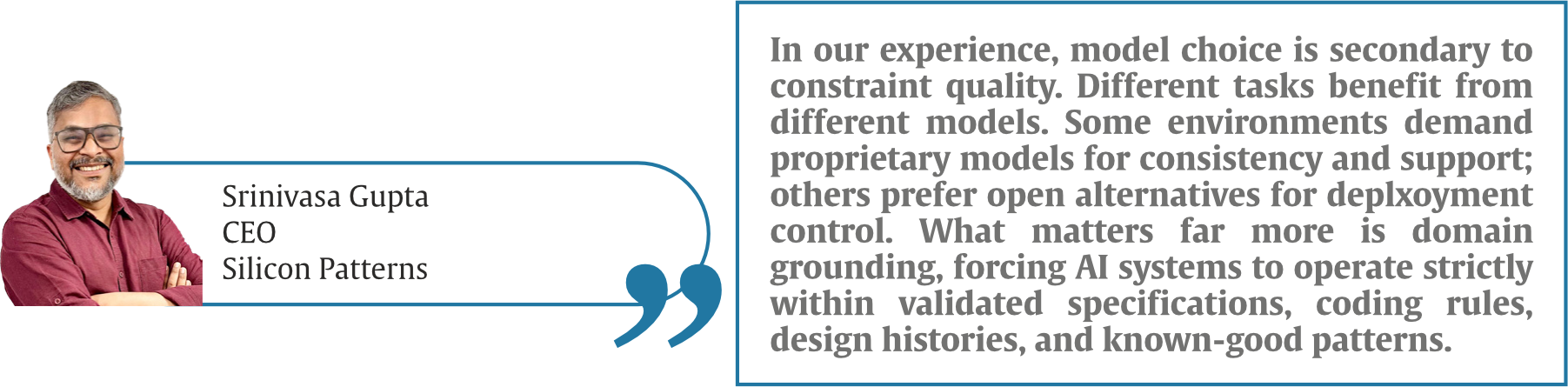

The foundation will continue to be semiconductor material innovation. Silicon carbide (SiC), gallium nitride (GaN) and silicon photonics will support increasing demands for efficient power conversion, thermal management, and data transmission. Architectural advances in neural processors, imaging sensors, microcontrollers and microprocessors will enhance the capabilities of autonomous and intelligent systems. Security of these systems will remain in sharp focus. In summary, our view for 2026 is: smarter machines will be built on faster and more secure semiconductor technologies.

The foundation will continue to be semiconductor material innovation. Silicon carbide (SiC), gallium nitride (GaN) and silicon photonics will support increasing demands for efficient power conversion, thermal management, and data transmission. Architectural advances in neural processors, imaging sensors, microcontrollers and microprocessors will enhance the capabilities of autonomous and intelligent systems. Security of these systems will remain in sharp focus. In summary, our view for 2026 is: smarter machines will be built on faster and more secure semiconductor technologies.

Edge AI innovation continues to be the lynchpin connecting these trends. In 2025, we saw the momentum of more AI finding its way to the edge. For 2026, this momentum accelerates, as embedded AI finds its way into almost every category of device and sensor. These edge AI and TinyML-enabled devices will benefit from enhanced awareness and analytical capabilities, in turn enabling them to act more autonomously. We will also see the emergence of more domain- and application-specific AI chips, optimised for workloads in different environments and sectors.

The next evolution of robotics (see below), industrial systems, automobiles, smart home technology, consumer devices, and more will be supported by powerful and energy-efficient AI at the edge. In turn, these will become more active participants and partners in every aspect of our lives.

2. Robots start speaking a different languageLarge language models (LLMs) – AI trained on massive text datasets – have been dominant in the AI discussion of recent years. As highlighted last year, these advancements, along with those in neural processing, allowed machines to “think” better. A new type of model will help turn thinking into action in 2026. New large action models (LAMs), sometimes called vision-language-action (VLA) models, are enabling robots to interpret their surroundings, make decisions, and perform tasks in the physical world, which some are calling “embodied AI”.

LAMs supporting robotic inference will drive the widespread emergence of edge AI-powered cobots working alongside humans, deployments of humanoid robots, and autonomous industrial systems that act independently with advanced sensing and motor control. The combination of enhanced intelligence and dexterity will pave the way for robotics to move from factories into retail, hospitality, and the home.

LAMs supporting robotic inference will drive the widespread emergence of edge AI-powered cobots working alongside humans, deployments of humanoid robots, and autonomous industrial systems that act independently with advanced sensing and motor control. The combination of enhanced intelligence and dexterity will pave the way for robotics to move from factories into retail, hospitality, and the home.

Last year, we predicted how the ability to use traditional semiconductor technologies would help advance the development of quantum computing. This has been the case, and the coming year will see quantum computers based on FD-SOI processes move from the lab to deployment. However, in 2026, the quantum-related priority for all organisations will relate to one topic: cybersecurity.

Cybercriminals are already preparing to add quantum computing to their armoury through cryptographically-relevant quantum computers (CRQCs). They are harvesting encrypted data today, confident that quantum computing will provide the power to access it in the future, which poses a real and immediate risk to every organisation. Post-quantum cryptography (PQC) provides a solution; PQC algorithm standards are being established and made available to preemptively secure devices and software. The time to act is now.

4. A tipping point for autonomous vehicles?Self-driving taxis provide the highest profile examples of the progress of autonomous vehicles, underpinned by advances in LiDAR, AI-enabled cameras, and integration with infrastructure. The number of cities around the world allowing the use or trial of so-called “robotaxis”, notably in the US and Asia, grew significantly in 2025, suggesting positive momentum. Challenges remain, with Level 4 autonomy remaining restricted to controlled environments (Level 5 being complete autonomy in any environment) and major manufacturers scaling back timelines to full autonomy.

Consumer confidence is also a barrier to adoption, though studies have shown that acceptance is far higher following use. With the opportunities increasing for consumers to experience the benefits, along with technological enhancements and efficiencies, 2026 should see progress accelerate.

5. Homes become even smarter, better connected and more secureIn 2026, several trends will converge to transform domestic technology. Edge AI, advances in connectivity protocols such as Matter and Thread, and approaches to security adopted from the commercial environment will make our homes smarter, better connected, and more secure.

Improving the collection and sharing of data between domestic devices, along with increased intelligence at the edge, will act as a force multiplier, delivering what analyst Gartner has defined as “ambient intelligence”. Among other benefits, this will allow for the creation of domestic digital twins, a concept we touched on in 2025 as an opportunity in every sector, optimising the efficiency of our homes.

As smart homes become more intelligent and connected, cybersecurity will be an increasing concern. We expect to see principles crossing over from commercial environments to the home, and in particular, best practices such as a Zero Trust approach to security in smart home technologies.

6. The integration of satellite and terrestrial networksAs we predicted in 2025, there has been no slowdown in the desire to launch more satellites into space, and particularly those low Earth orbit (LEO) satellites forming part of the communications mega-constellations. 2026 will see advancements in how these satellites are used to provide truly global connectivity. For communications network operators, the decision between traditional terrestrial networks and the growing mega-constellations of low Earth orbit (LEO) satellite networks is no longer “either/or”, but “both”. Mobile network operators are already integrating LEO networks as backhaul, filling coverage gaps in earth-based networks or to improve connection speeds.

This integrated use of networks will continue in 2026, creating a unified “network of networks” managed by AI and advancing towards goals for seamless global connectivity. The economic and educational benefits to previously unconnected parts of the globe will be huge, with significant additional enhancements to connectivity across worldwide consumer, commercial and industrial sectors.

7. A revolution in imagingImaging technology provides the foundation for many of the innovations that allow devices to operate more effectively and efficiently. Yet the central concept of lenses as stacks of curved glass to refract light has remained unchanged for centuries. Metasurface technology shifts this paradigm by recreating optical functions on perfectly flat, ultra-thin layers patterned with nanostructures. Imaging becomes smaller, less costly, and more flexible wherever it is embedded. Imaging improvements will impact every area of life, work, and industry, from more spatially-aware robotics and automobiles, to more secure devices, from enhanced photography to applications that vastly improve power efficiency.

2026 wrappedTechnology rarely moves in straight lines, but the direction is becoming clearer. The trends emerging for 2026 indicate a world shaped by greater autonomy, deeper intelligence, stronger intelligence and more, all shaped by advances in semiconductor technologies. The opportunity for organisations that understand these trajectories early enough is not simply to react but to shape what comes next. The systems designed today will define how people live, work and connect in the years to come.

The future is already taking form; it’s a matter of how boldly we choose to build it.

The post Top Seven Tech Trends in the semiconductor sector for 2026 appeared first on ELE Times.

R&S and Broadcom showcase first Wi-Fi 8 RF signalling tests, paving way for next-gen connectivity

Rohde & Schwarz, in collaboration with Broadcom, is set to display its CMX500 multi-technology multi-channel signalling tester at MWC Barcelona 2026 with newly added Wi-Fi 8 (IEEE 802.11bn) testing capabilities. The setup at the Rohde & Schwarz booth (5A80) will validate a prototype Wi-Fi 8 device from Broadcom, showcasing physical layer features unique to Wi-Fi 8.

Addressing UHR challenges with the CMX500

As Wi-Fi transitions beyond increasing throughput, the IEEE 802.11bn amendment introduces crucial advancements focused on delivering consistent, high-quality connectivity across a diverse range of dense environments. It is designed to handle the growing number of connected devices and the increasing demands of applications like VR/AR, 8K streaming, and industrial IoT.

Wi-Fi 8 builds upon the foundation of Wi-Fi 7, retaining core physical layer parameters like supported frequencies up to 7.125 GHz, channel bandwidths up to 320 MHz and 4096QAM modulation, as well as Multi-Link-Operation (MLO). However, to achieve its UHR goals, IEEE 802.11bn introduces a suite of innovative PHY and MAC layer technologies that present new testing hurdles. At MWC 2026, visitors can experience how to address key testing challenges associated with Wi-Fi 8 with the enhanced testing capabilities of the CMX500 one-box signalling tester, one of the most versatile mobile device test platforms in the market, which supports many of the demanding features of Wi-Fi 7 and Wi-Fi 8 today.

For example, Wi-Fi 8 uses distributed resource units (dRU) to overcome power spectral density (PSD) limits. With dRU measurement,s users can validate their device’s effectiveness in boosting uplink transmit power and improving connection reliability. Another technology is unequal modulation (UEQM), where throughput is improved in difficult reception scenarios by allowing each MIMO link to use a different modulation scheme. With UEQM analysis, users can assess the ability of the test device to adapt the modulation accurately, using the specified modulation of coding scheme (MCS) combinations. With comprehensive signalling mode tests, covering a broad range of Wi-Fi 8 features, users can perform in-depth analysis of performance characteristics.

Future-ready platform for all cellular and non-cellular standards

The CMX500 is a modular, powerful one-box signalling tester enabling comprehensive multi-technology testing. It covers LTE and NR in SA/NSA modes, NR-NTN, NB-NTN, Direct-to-Cell (D2C/DTC) testing and WLA, N, including Wi‑Fi 7 and Wi‑Fi 8. Consequently, the CMX500 allows R&D engineers of wireless devices to comprehensively test their design’s operation in both cellular and non-cellular standards of the latest generation in a single instrument setup.

Rohde & Schwarz will present the CMX500 one-box signalling tester, validating a Wi-Fi 8 device from Broadcom and other comprehensive test solutions for next-generation WLAN at MWC Barcelona 2026 at the Fira Gran Via in Barcelona, in hall 5, booth 5A80.

The post R&S and Broadcom showcase first Wi-Fi 8 RF signalling tests, paving way for next-gen connectivity appeared first on ELE Times.

Keysight launches next-gen Infiniium XR8 Oscilloscopes for faster analysis, clearer insights, and a compact design

Keysight Technologies introduced its next-generation Infiniium XR8 Real-Time oscilloscopes, designed to accelerate high-speed digital and compliance testing while improving efficiency and insight for modern electronics development.

As interface standards such as USB, DisplayPort, and DDR rapidly evolve and scale in speed and complexity, engineers face tighter margins, higher data rates, and compressed development timelines. These pressures result in longer validation cycles, reduced noise tolerance, and growing lab constraints. The Infiniium XR8 addresses these challenges with a completely new hardware and software architecture optimised for today’s high-speed digital applications and emerging standards, helping engineering teams condense days of testing into hours.

The XR8 integrates newly designed front-end ASIC technology and an integrated ADC and DSP digital engine to preserve signal integrity, improve timing accuracy, and deliver consistent, repeatable measurements across high-speed serial, memory, and mixed-signal designs. These capabilities are essential for debugging and validating today’s high-speed interface, where small impairments in signal quality can directly impact system performance and compliance margins.

A redesigned mechanical architecture further enhances usability by reducing system power consumption, improving thermal efficiency, and minimising acoustic noise with a compact footprint. Engineers can deploy high-performance oscilloscopes in space-constrained labs and dense validation environments while maintaining a stable, low-noise operation.

Powered by Keysight’s new Infiniium 2026 software platform, the XR8 delivers faster response time, improved stability, and streamlined workflows for high-speed digital and compliance testing. The modern user experience features flexible waveform windows, enhanced visualisation, and productivity tools such as drag‑and‑drop functionality and an integrated SCPI recorder. Optimised multithread processing and memory management enable engineers to fully leverage Keysight’s measurement science, delivering enhanced jitter decomposition, PAM analysis, and advanced equalisation for deeper insight and faster validation.

Together, the new hardware and software architecture enable:

Maximised test margin and signal integrity

Intrinsic jitter as low as 13 fs rms and noise performance below 130 µV at 8 GHz bandwidth provide exceptional fidelity and preserved compliance margin, enabling confident validation of high-speed interfaces including USB4v2, DisplayPort 2.1, and DDR5.

Accelerated compliance testing efficiency

A new ADC and DSP digital engine combined with Infiniium 2026 software accelerates acquisition, analysis, and reporting by up to three times, dramatically reducing validation cycles and improving overall test throughput.

Compact, quiet, and flexible lab deployment

Lower power consumption, enhanced thermal design, and reduced acoustic noise create a smaller, more flexible platform that can be positioned closer to the device under test while supporting comfortable, distraction-free daily engineering workflows.

Jun Chie, Vice President, Keysight Product Management, said: “Our customers are under intense pressure to validate increasingly complex, high-speed designs on compressed schedules. The Infiniium XR8 directly addresses that reality, preserving signal fidelity, accelerating compliance workflows, and reducing lab constraints in a single, streamlined platform. It’s about giving engineers back time, confidence, and productivity when they need it most.”

“As India strengthens its leadership in AI data centres, 5G-Advanced, next-generation computing, and aerospace and defence, signal integrity measurement challenges are becoming increasingly complex,” said Girish Baliga, General Manager, Industry Marketing, Keysight India. “The Infiniium XR8 oscilloscope delivers the precision and performance required to accelerate innovation while ensuring accurate, high-speed validation. As India advances its ‘Make in India’ vision and expands its global R&D footprint, demand for ultra-high-speed digital test solutions continues to grow. The XR8 empowers local engineering teams with the confidence and efficiency needed to bring world-class technologies to market faster.”

The post Keysight launches next-gen Infiniium XR8 Oscilloscopes for faster analysis, clearer insights, and a compact design appeared first on ELE Times.

R&S showcases its comprehensive embedded systems test solutions at embedded world 2026

Rohde & Schwarz will present its advanced test and measurement solutions for the embedded industry at embedded world Exhibition & Conference in Nuremberg, Germany. Visitors can find the T&M expert at booth 4-218 in hall 4 of the Nuremberg Exhibition Centre from March 10 to 12, 2026. There, they can delve into the company’s innovations designed to help engineers enhance device energy efficiency, expedite EMC compliance within the design process, speed up digital protocols debugging, and meet required regulatory standards for wireless interfaces.

Next generation oscilloscopes

At Embedded World, Rohde & Schwarz will showcase its ever-growing range of next-generation oscilloscopes, from MXO 3 to MXO 5, all powered by the same next-generation MXO-EP ASIC technology from Rohde & Schwarz, originally introduced with the MXO 4 in 2022. The latest addition, the compact MXO 3, comes with up to eight channels and offers a combination of features that rival higher-class oscilloscopes, such as a real-time capture rate of up to 99% and hardware-accelerated functionality on math, spectrum and zone trigger.

Ensuring reliability in power electronics

Combined with high voltage, current and optically isolated probes (R&S RT-ZISO), the eight-channel models of MXO 3 and MXO 5 extend their capabilities to power electronics applications. For power conversion, the instruments’ eight channels and 18-bit HD mode provide critical visibility into complex systems like motor drives and inverters, enabling precise measurements for efficiency and optimisation. Furthermore, they simplify power sequencing analysis with simultaneous multi-channel observation and deep memory of up to 500 Mpts, enabling longer recording durations and precise analysis of small signal events. Additionally, their fast spectrum analysis capability makes them excellent tools for quickly identifying EMI issues and noise sources.

EMI testing for embedded systems

Every electronic product and component is likely to emit conducted or radiated electromagnetic emissions. Especially for densely packed embedded systems, early debugging helps to isolate and correct EMI issues and accelerates time-to-market. As a leader in EMC testing, Rohde & Schwarz will present solutions that integrate EMI testing into the product design process. Visitors can learn how to use the R&S EPL1007 EMI test receiver in fast, accurate and reliable EMI pre-compliance and compliance measurements up to a frequency range of 7.125 GHz. The instrument offers device developers and conformance test houses the flexibility to upgrade with evolving needs – from preselection, including a preamplifier, up to a full CISPR 16-1-1 compliant test receiver.

Verifying signal integrity of digital designs

All hardware elements on a board layout are potential causes of signal degradation. To test the signal integrity on a PCB, Rohde & Schwarz will showcase its R&S ZNB3000 vector network analyser at embedded world, covering up to 40 GHz. This VNA, part of the new midrange family offering instruments with a maximum frequency range of up to 54 GHz, has redefined the standard for speed, precision and versatility with its industry-leading dynamic range, fast measurement speed, and scalable upgrades, perfectly suited for signal integrity applications. Visitors can experience the instrument’s advanced de-embedding techniques, which facilitate characterising the test fixture, extracting the S-parameters and de-embedding the test fixture in a user-friendly manner, with the signal quality visualised by a simulated eye diagram.

Testing of high-speed interfaces

High-speed digital interfaces are integral to electronic designs, with increasing data rates and integration density posing new challenges at the IC, board and system level. Trade show visitors will learn at the Rohde & Schwarz booth about powerful signal integrity test tools for system verification, debugging, and compliance testing for different high-speed busses. Rohde & Schwarz will showcase, for example, 1GBASE-T Ethernet compliance testing using the R&S RTO6 oscilloscope and related equipment to ensure that a 1 Gigabit Ethernet (1GbE) physical layer (PHY) transceiver meets the specifications outlined in the IEEE 802.3 standard. In a different setup, Rohde & Schwarz will showcase its R&S RTP164B oscilloscope for signal integrity testing on a multitude of standards, including DDR5 and USB3.2.

When it comes to automotive interfaces, the emerging standards, including Automotive Ethernet, OpenGMSL or ASA (Automotive SerDes Alliance), bring new challenges for design. Rohde & Schwarz already supports all of these new standards and will showcase comprehensive validation using the R&S RTP164B oscilloscope, featuring signal integrity debugging and automated compliance on ASA, as well as protocol decoding of 10Base-T1S to ensure robust and reliable link performance.

Battery life testing

Battery life is critical for battery-powered devices. Rohde & Schwarz will demonstrate in real time how the features of smart devices affect their power consumption. The setup is based on the R&S NGU source measure unit emulating a battery. The integrated analysis tool captures and visualises current across sleep-to-active transitions. In another application on battery testing with the R&S NGM202, cells will be charged and discharged to characterise battery behaviour and build accurate battery models.

Wireless connectivity testing

Embedded systems increasingly incorporate wireless connectivity as a core function. Thorough testing is essential to ensure reliable performance, interoperability and compliance with industry standards. The complexity of these standards requires specialised test equipment and expertise. The CMP180 radio communication tester from Rohde & Schwarz contains two analysers, two generators and two sets of eight RF ports in a single box and supports many cellular and non-cellular technologies across R&D, pre‑conformance and mass production. At embedded world, visitors will experience the CMP180 testing both Bluetooth LE and Wi-Fi 8 devices.

The platform already supports physical layer testing for the new Bluetooth LE Channel Sounding and new Bluetooth LE High Data Throughput (HDT) feature, a cornerstone for the next generation of Bluetooth Low Energy (LE), offering increased capacity, better energy efficiency, improved spectrum efficiency and enhanced reliability. Wi-Fi 8, based on the IEEE 802.11bn standard, sets new expectations for consistent, ultra-high-reliability and quality connectivity. Designed to support a growing number of connected devices and demanding applications like XR and industrial IoT, the CMP180 helps engineers navigate the technical complexities of 802.11bn throughout the entire device lifecycle in non-signalling mode with its advanced capabilities and broad bandwidth support.

Efficient production lines with tailored solutions

For production tests at component, module and system level, Rohde & Schwarz will showcase a rack-mounted test and measurement configuration, featuring the rack-optimised MXO 5C oscilloscopes and the PVT360A performance vector tester. This setup will demonstrate how tailored Rohde & Schwarz test solutions contribute to a production environment built for reliable validation, streamlined workflows and maximised throughput.

These and other test solutions for the embedded industry can be found at the Rohde & Schwarz booth 4-218 in hall 4 at the Embedded World Exhibition & Conference from March 10 to 12, 2026, in Nuremberg, Germany.

The post R&S showcases its comprehensive embedded systems test solutions at embedded world 2026 appeared first on ELE Times.

Toxics Link study Finds a Long Road to Circularity in India’s E-waste EPR Model

A new report by an environmental group, Toxics Link, reveals significant structural gaps in India’s Extended Producer Responsibility (EPR) framework for e-waste. The study, titled “Long Road to Circularity,” warns that while the EPR model is a cornerstone of waste management, it currently fails to capture a vast range of critical minerals essential for India’s green transition.

The Extended Producer Responsibility (EPR) framework mandates the recovery of only four metals—gold, copper, iron, and aluminium—leaving critical metals untapped. A vast range of valuable and critical metals, including neodymium, dysprosium, and lithium, are essential to strengthening resource security but is currently overlooked and lost.

In light of these concerns, the report examines current e-waste regulations and highlights critical challenges limiting their effective implementation. The report also underscores persistent issues, including low consumer awareness, poor financial traceability of e-waste flow and limited monitoring capacities. The study identifies several operational gaps. Key findings from the report include:

- The EPR portal currently lacks data on total market players and leaves small-scale manufacturers, online sellers, and grey-market importers outside the system.

- Information regarding non-compliance penalties and environmental compensation remains unavailable for the 2023–24 and 2024–25 fiscal years.

- Detailed data is accessible only to operators, resulting in limited public visibility into system performance.

- The current regulation does not identify and place responsibility on any individual stakeholder for the setting up of collection centres, thus making it extremely difficult for consumers to deposit their waste in the authorised e-waste stream.

- No incentive to producers and manufacturers adopting “green” product designs or for recyclers implementing high-quality, advanced recovery processes.

“While Extended Producer Responsibility is a cornerstone of India’s e-waste management framework, the principle alone cannot deliver the desired outcomes. It must be complemented by an effective and robust waste collection system, integrating the informal sector and the development of high-tech recycling facilities along with public awareness for advancing system transparency”, Satish Sinha, Associate Director, Toxics Link.

The report suggests the following key recommendations to plug some of the gaps in the

present system:

- Enhance system accountability and transparency by making data accessible to the

public. - Strengthen reverse supply chains and collection mechanisms to streamline the flow

of e-waste. - Expand consumer awareness on the advantages of e-waste recycling and the

importance of using authorised collection channels. - Integrate the informal sector into the e-waste management ecosystem.

Together, these measures can help build a stronger and more effective e-waste

management system.

The post Toxics Link study Finds a Long Road to Circularity in India’s E-waste EPR Model appeared first on ELE Times.

ESGDS’ AI platform slashes data processing time by 98% with MongoDB Atlas

ESG Data & Solutions (ESGDS) is a fast-growing Indian technology company. It builds tools to enable banks, investors, and other financial groups to track and analyse a company’s performance on Environmental, Social, and Governance (ESG) issues.

With a vast range of covered topics and multiple providers employing different types of methodologies and taxonomies, ESG data sets are notoriously difficult to work with.

Because these analyses guide critical research and investment decisions, ESGDS developed ESGSure—a bespoke research platform built on MongoDB Atlas—to address the challenge.

THEIR CHALLENGE: Overcoming the relational model limitations to unlock AI scale

ESGSure collects points from over 20,000 companies and investors—these include annual reports and corporate filings, news, and client-specific questionnaires. The platform also tracks a range of other publicly available sources, including news articles, compliance records, and sanctions lists, among others. These resources come in various formats, including videos, PDFs, transactional data in APIs, and more.

Before moving to MongoDB Atlas, ESGDS relied on several other databases, including relational databases such as PostgreSQL and Pinecone for vector search workloads. As the use cases and data sets expanded, ESGDS encountered limitations.

“Our platform needs to process massive, diverse, and unstructured data sets, so we can then use a combination of large language models (LLMs), real-time data, and vector search capabilities to deliver AI-driven granular, personalised, and actionable insights for investors,” said Arun Doraisamy, Co-Founder and Chief Technology Officer at ESGDS. “We needed more flexibility, to reduce complexity, and do that at scale. This meant moving away from a relational model and onto a database model that fit our needs.”

Several limitations drove ESGDS to seek a new database:

- Lack of flexibility and scalability: Rigid legacy relational databases lacked the schema flexibility required to dynamically store and update ESGDS’s rapidly evolving datasets. This resulted in inconsistent insights that hindered analysts’ and investors’ ability to make timely and accurate data-driven decisions. Additionally, a lack of elastic scalability throttled ESGDS’s ability to handle continuous data growth, compromising its ambitious expansion plans.

- Delayed data insights: Stale data is a significant challenge for the ESG data analysis industry—by the time it is collected and analysed, ESG data can be up to a year old. To add to this challenge, manual ESG data review in ESGDS’s legacy database took an average of 2 to 3 days per company. ESGDS wanted to automate these processes to provide investors with real-time insights.

- Complex security and compliance: ESGDS manages sensitive, private datasets for its clients. Ensuring secure storage, data encryption, and compliance with ESG frameworks and regional requirements, such as GDPR, has become increasingly complex. With expansion into highly regulated countries on its roadmap, ESGDS knew this challenge would become acute.

- Limited global portability: ESGDS needed a data platform that would easily and efficiently power growth plans across Europe, Asia Pacific, and North America. It had to support a reliable, multi-cloud, and multi-region infrastructure.

“We needed a modern, flexible model with built-in AI capabilities that could meet our complex needs, and keep evolving to support our ambitious growth and diversification goals,” said Doraisamy.

The post ESGDS’ AI platform slashes data processing time by 98% with MongoDB Atlas appeared first on ELE Times.

Keysight Unveils 3D Interconnect Designer for Chiplet and 3DIC Advanced Package Designs

Keysight Technologies introduced 3D Interconnect Designer, a new addition to its Electronic Design Automation (EDA) portfolio. The solution addresses the mounting complexity of designing 3D interconnects for high-chiplet and 3DIC advanced packages used in AI infrastructure and data centre applications.

As chiplet architectures are increasingly adopted, engineers face complex 3D interconnect designs for multi-die and stacked-die applications, which traditional workflows struggle to handle efficiently. As a result, teams spend significant time manually optimising the interconnects that include vias, transmission lines, solder balls, and micro-bumps while ensuring signal and power integrity in densely packed systems. This results in more design spins and longer product development cycles, creating a bottleneck that can delay product launches and increase development costs.

Keysight EDA software streamlines the process with a dedicated workflow for designing and optimising 3D interconnects accurately. The tool handles complex geometries, including hatched or waffled ground planes, which are critical to overcome manufacturing and fabrication constraints, especially silicon processes such as interposers and bridges, in advanced package designs. By enabling engineers to quickly design, optimise, and validate 3D interconnects used in chiplets and 3DICs, it minimises iterations and speeds time-to-market.

Key benefits include:

- Accelerates Design Cycles: Streamlined automation removes time‑consuming manual steps in 3D interconnect design, minimising errors and boosting first‑pass success

- Reduced Compliance Risk: Validates designs against emerging standards such as UCIe and BoW, ex VTF (Voltage Transfer Function), early in the lifecycle, reducing the risk of late-stage failures that lead to costly redesigns

- Predicts Performance Accurately: Electromagnetic-based simulation provides precise electrical analysis of printed circuit boards (PCB) and package 3D interconnect designs

The solution integrates with Keysight’s EDA tools as well as supporting the standalone version, enabling teams to incorporate 3D interconnect design and optimisation into existing workflows. When combined with Chiplet PHY Designer, engineers can design and optimise 3D interconnects specifically for chiplets and three-dimensional integrated circuits (3DICs), ensuring accuracy and reducing costly iterations in multi-die systems.

Nilesh Kamdar, EDA Design and Verification General Manager at Keysight, said:

“With today’s complexity, manual 3D interconnect design and optimisation have become a significant bottleneck. By streamlining the process and providing early insights into potential issues like signal and power integrity, we’re enabling engineers to get products to market faster and deliver compliant designs on tighter timelines.”

The post Keysight Unveils 3D Interconnect Designer for Chiplet and 3DIC Advanced Package Designs appeared first on ELE Times.

Jodi Shelton, CEO of GSA – Launches A Bit Personal, a New Podcast Offering Rare, Candid Conversations with the Most Powerful Tech Leaders

Jodi Shelton, Co-Founder and CEO of the Global Semiconductor Alliance and Shelton Group, announced the launch of A Bit Personal, a new leadership-focused podcast that pulls back the curtain on the people shaping the future of global technology. Premiering today, the podcast offers an intimate, cinematic look at the personal stories, values, failures, and defining moments of the industry’s most powerful leaders – stories rarely heard beyond earnings calls and keynote stages.

Unlike traditional technology podcasts focused on products and platforms, A Bit Personal centres on the human behind the hardware. Through trust-based, unscripted conversations, Shelton encourages guests to share candid reflections on leadership, ambition, vulnerability, and the moments that shaped who they are today.

“These are the most fascinating people I know, and I can’t wait for you to hear their stories,” said Shelton. “This is A Bit Personal, and it’s going to be good.”

The inaugural season features nine weekly episodes and includes hard-hitting, first-of-their-kind conversations with industry icons such as NVIDIA Founder and CEO Jensen Huang and AMD Chair and CEO Lisa Su. Future episodes will further spotlight a female-led perspective in a traditionally male-dominated industry, with an upcoming series focused on women CEOs and their leadership journeys.

“Over the course of my career, I’ve had a front-row seat to the semiconductor industry’s evolution,” Shelton added. “The leaders who drive economic prosperity and human advancement have become public figures and cultural celebrities. The world wants to know who they are and what drives them. With A Bit Personal, I’m offering listeners a seat at the table – moving past product launches to explore the personal stories, values, failures, and triumphs of the boldest visionaries defining tomorrow.”

Produced with a film-forward, cinematic approach, the podcast blends creative visuals, behind-the-scenes moments, and deeply personal storytelling to deliver what Shelton describes as “not your father’s tech industry podcast.”

New episodes of A Bit Personal release weekly on Thursdays and are available on YouTube and all major podcast platforms. Listeners can also follow along for news and updates on A Bit Personal’s Instagram, TikTok, LinkedIn and X channels. Additionally, Jodi’s podcast A Bit Personal is planning to interview the CEOs of Indian semiconductor companies in its upcoming season. Guest announcements and appearances will be revealed gradually—stay tuned.”

The post Jodi Shelton, CEO of GSA – Launches A Bit Personal, a New Podcast Offering Rare, Candid Conversations with the Most Powerful Tech Leaders appeared first on ELE Times.

Is SDV Really an Automotive or Just A Software-based machine That Moves?

Speaking at the Auto EV Tech Vision Summit 2025, Rajeev Ved, Chief Growth Officer at Sasken Technologies Limited, took the Software-Defined Vehicle conversation away from surface-level features and into something far more foundational. While much of the industry debate revolves around autonomy levels, over-the-air updates, or larger infotainment screens, Ved stepped back and asked a more fundamental question: What does a car even mean in an SDV world?

For decades, automobiles have been sold through emotion. Freedom of mobility. Control over one’s journey. Aspiration for safety, performance, and status. These emotional anchors have shaped marketing, engineering priorities, and customer expectations alike. According to Ved, the SDV does not erase these emotions—it amplifies them. Adaptive driving systems increase control, predictive maintenance enhances reliability, and connected ecosystems elevate convenience. The “joy of driving” becomes algorithmically refined.

Software that Happens to Move

But beneath that emotional amplification lies a deeper transformation. An SDV is no longer merely a car with software added on. It is software orchestrating a machine, continuously connected to cloud systems, infrastructure, homes, offices, and other vehicles. At that point, the question shifts: is it a car enhanced by software, or is it a rolling software platform that happens to move from point A to point B?

Building such a vehicle, Ved argued, cannot be achieved by layering code over legacy architectures. It requires constructing the stack from the ground up. He described four foundational layers that together define a true SDV architecture.

The 4 Layers of SDV Architecture

In his address, Rajeev outlines what he described as the four architectural layers required to build a true Software-Defined Vehicle. At the foundation sits the Operational Foundation Layer—the tightly integrated hardware–software core that governs the vehicle’s mechanical systems. Here, distributed ECUs are consolidated into centralized domain controllers, allowing braking, propulsion, safety, and powertrain functions to operate as coordinated software-driven systems. Built above this is the Data & Intelligence Layer, where the vehicle continuously ingests sensor data, processes it at the edge, connects through V2X ecosystems, and interacts with cloud backends—transforming the car into a connected computational platform rather than an isolated machine.

Layered on top is the Services & Monetization Layer, where connectivity enables feature-on-demand models, adaptive insurance, predictive maintenance, and new lifecycle revenue streams. In this framework, the vehicle evolves from a one-time hardware product into a dynamic digital platform. At the apex lies the UI/UX & Infotainment Layer—the digital cockpit that defines the customer interface through immersive screens, augmented experiences, and ecosystem integrations. According to Ved, control of this layer will determine who ultimately owns the user relationship in the SDV era, making it one of the most strategically contested fronts in automotive transformation.

Cross-sectoral Expertise

Yet Ved cautioned that while the architecture evolves, foundational disciplines remain non-negotiable. Mission-critical standards, safety validation frameworks, and robust embedded software practices continue to underpin the stack. What changes is the scale of data pipelines, edge compute capabilities, cloud APIs, and monetization frameworks layered on top. Building for the SDV era requires expertise not only in automotive systems but in distributed computing, AI integration, and scalable digital services.

Conclusion

The larger implication of his address was clear. The SDV shift is not a feature race. It is a structural redesign of how vehicles are conceived, built, monetized, and experienced. Cars are evolving into distributed compute nodes, data platforms, and service ecosystems. The industry’s challenge is not merely to digitize the automobile, but to architect it as a layered, interoperable, and continuously evolving system.

The Software-Defined Vehicle is not an upgrade cycle. It is the redefinition of mobility itself.

The post Is SDV Really an Automotive or Just A Software-based machine That Moves? appeared first on ELE Times.

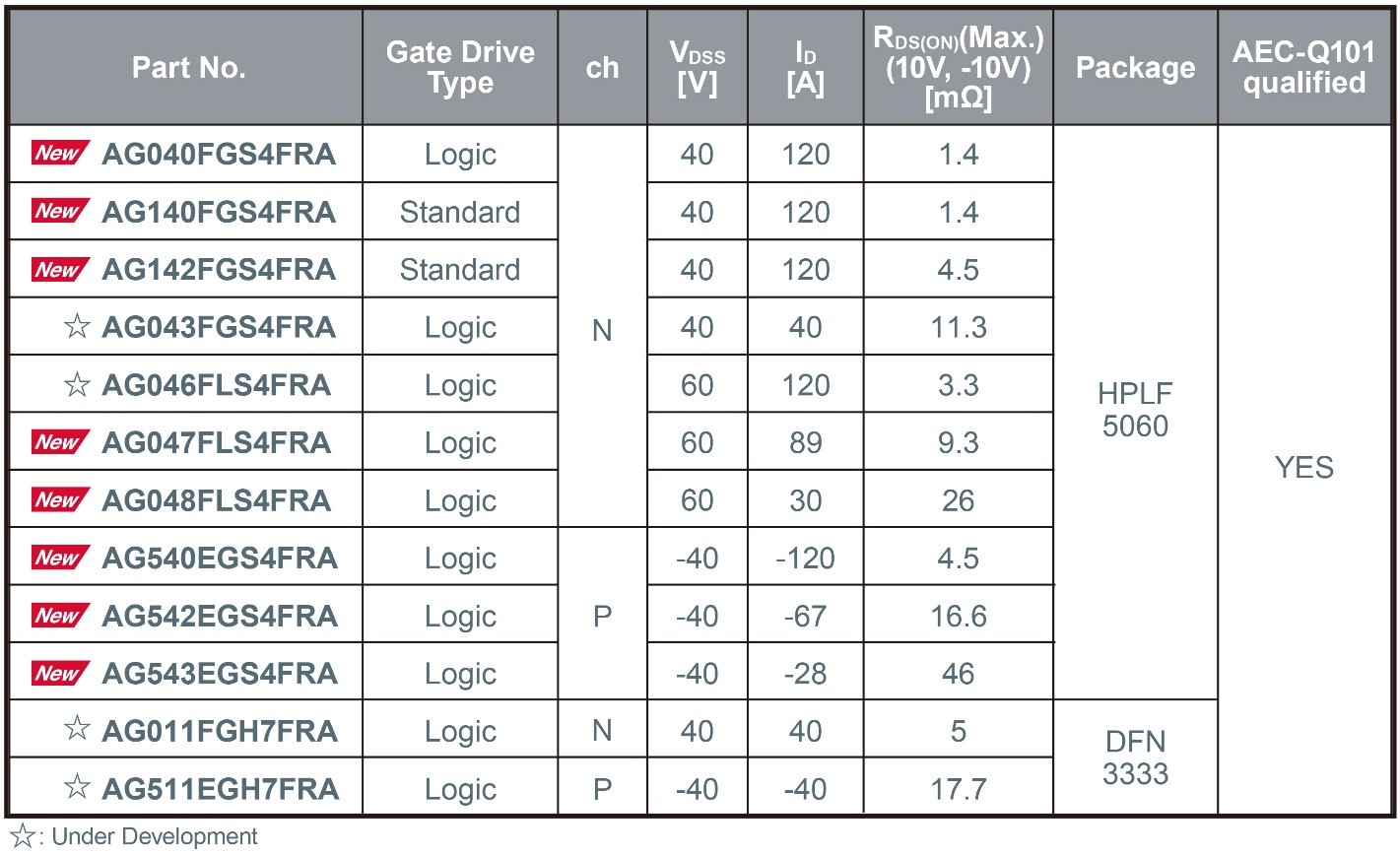

ROHM’s New Compact, Highly Reliable Package Added to Automotive 40V/60V MOSFET Lineup

ROHM has expanded its lineup of low-voltage (40V/60V) MOSFETs for automotive applications – such as main inverter control circuits, electric pumps, and LED headlights – by introducing the latest products adopting the new HPLF5060 package (4.9mm × 6.0mm).

In recent years, automotive low-voltage MOSFETs have been trending toward smaller packages, such as the 5060-size and even more compact options. However, this miniaturisation introduces significant challenges for achieving reliable mounting, primarily due to narrow terminal spacing and leadless designs.

To address these issues, the new HPLF5060 package offers a smaller footprint compared to the widely used TO-252 package (6.6mm × 10.0mm) while enhancing board-mount reliability through the adoption of gull-wing leads. Additionally, the use of copper clip junction technology enables high-current operation, making the HPLF5060 an ideal solution for demanding automotive environments.

Mass production of new products using this package began in November 2025 (sample price: $3.5/unit, excluding tax). Online sales have also started, and the products are also available for online purchase through online distributors such as DigiKey and Farnell.

In addition to expanding the lineup of products using this package, mass production of the smaller DFN3333 (3.3mm × 3.3mm) package, which employs wettable flank technology, is scheduled to begin around February 2026. Furthermore, development has commenced on a TOLG (TO-Leaded with Gull-wing) package (9.9mm × 11.7mm) to further expand the lineup of high-power, high-reliability packages.

The post ROHM’s New Compact, Highly Reliable Package Added to Automotive 40V/60V MOSFET Lineup appeared first on ELE Times.

The Rise of the AgentEngineer: How AI is Orchestrating the Future of Chip Design

While traditional Electronic Design Automation tools have been faithfully executing commands for decades, today’s agentic AI systems are rewriting the rulebook by thinking, iterating, and problem-solving autonomously across entire design workflows. Picture this: specialised AI agents functioning like a virtual design team—complete with their own CEO, CTO, and engineering specialists—orchestrating everything from RTL generation to physical design verification in feedback-driven loops that don’t just respond to errors, they anticipate and resolve them. This isn’t your standard chatbot-writes-some-code scenario; we’re talking about multi-agent architectures powered by Large Language Models that refuse to call it a day until every simulation passes. As the semiconductor industry grapples with a workforce crisis that threatens to bottleneck innovation, these AI systems are emerging as more than assistants; they’re becoming co-designers capable of exponentially multiplying engineering productivity. To understand how industry leaders are navigating this transformation from AI-assisted to AI-orchestrated design, we reached out to companies at the forefront of this revolution.

Architecture to Autonomy: Building Multi-Agent AI Systems for Chip Design

The semiconductor design floor is witnessing an unprecedented transformation where intelligent agents collaborate, critique, and refine work autonomously, like a seasoned design team operating at machine speed.

The Multi-Agent Architecture

Industry implementations structure these systems around specialised agent roles: RTL generation specialists handle code synthesis, verification agents scrutinise design correctness, and physical design agents optimise layouts. The orchestration framework manages task routing and dependencies, ensuring coherent workflow progression. Critically, these agents don’t replace existing EDA platforms; instead, they orchestrate them, invoking synthesis runs and analysing timing reports with minimal human intervention.

LLM Selection and Domain Adaptation

Behind these agents run Large Language Models serving as inference engines. The industry has split between proprietary models like GPT-4 and Claude, which offer robust reasoning capabilities, and open-source alternatives such as DeepSeek-Coder and Llama variants, providing customisation flexibility for high-volume workloads.

Raw LLMs produce generic code, but semiconductor design demands precision. Organisations implement two adaptation strategies: Retrieval-Augmented Generation (RAG) connects LLMs to design rule manuals, timing libraries, and verified IP repositories, grounding outputs in proven patterns. Domain-specific fine-tuning retrains models on millions of lines of verified RTL, enabling them to recognise design intent from terse specifications and suggest synthesis-aligned optimisations.

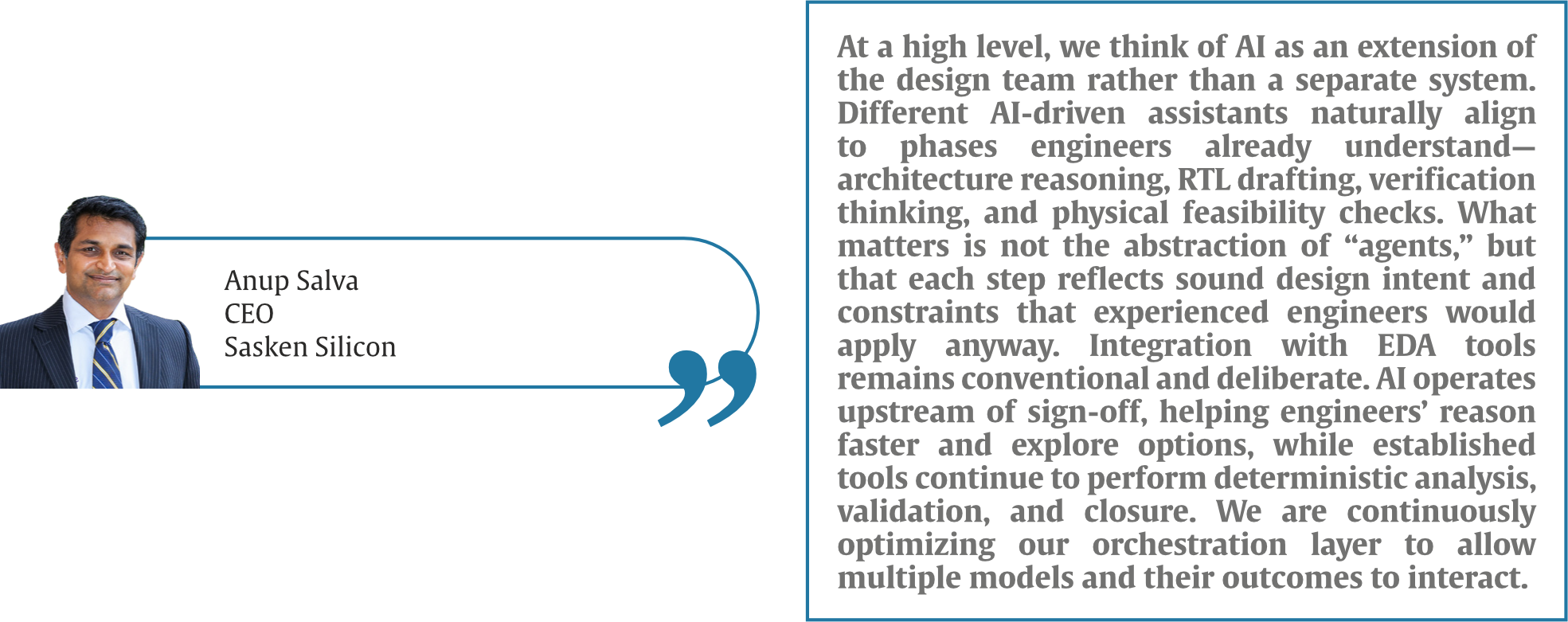

Talking about choosing the “right” LLM,

Addressing Code Hallucination

The critical challenge remains code hallucination, plausible but incorrect outputs. Industry leaders deploy multi-layered validation: formal verification integration, simulation-in-the-loop refinement cycles, constraint-guided generation, and mandatory human review checkpoints for critical path logic. As one verification lead noted, AI-generated RTL receives the same scrutiny as junior engineer code, but iterates at 100x speed before human review.

“Hallucination is not a mysterious AI problem. It is the result of under-specified intent. We deal with it the same way we deal with junior engineers: through validation gates. Every AI-generated output passes through linting, simulation, coverage analysis, and equivalence checks. Nothing bypasses human review for critical design decisions. Trustworthy output comes from engineering discipline applied to AI, not from believing AI will magically become trustworthy,” added Gupta.

The technical architecture is maturing rapidly, but the true test ahead is scaling from engineer assistance to autonomous subsystem design, determining whether agentic AI becomes indispensable infrastructure or remains an expensive experiment.

AgentEngineer Revolution: Transforming Roles and Multiplying Productivity

The automation wave reshaping semiconductor design isn’t just changing workflows—it’s fundamentally redefining what it means to be a design engineer in 2026.

Quantifiable Productivity GainsEarly adopters report transformative productivity metrics. RTL generation rates have surged from approximately 50-100 lines per engineer-day in manual workflows to 500-1,000+ lines with AI assistance—a 10x improvement when measured by functional complexity rather than raw line count. Time-to-tapeout reductions range from 20-40% for complex SoC projects, with verification cycles seeing the most dramatic compression.

“The biggest gains have come from reducing friction, not replacing engineers. Tasks that previously required multiple iteration initial RTL structure, verification scaffolding, and early debug hypotheses now converge faster. We typically see meaningful schedule compression in early and mid-design phases, allowing teams to spend more time on optimisation, corner cases, and RF-digital interactions. This has increased our capacity to take on more complex mixed-signal and SoC programs without sacrificing rigour,” explains Anup Salva, CEO, Sasken Silicon.

Verification coverage metrics tell an equally compelling story. AI-driven testbench generation achieves 85-95% functional coverage in initial passes compared to 60-70% with manual approaches, while bug detection rates during pre-silicon validation have improved by 30-50%. One design team reported identifying critical corner-case failures that traditional directed tests missed entirely, caught by AI agents exploring unconventional stimulus patterns.

Perhaps most significant: engineering teams report handling 2-3x more concurrent design projects without proportional headcount increases, effectively multiplying organisational capacity during an industry-wide talent shortage.

The Evolving Engineer RoleThe shift from manual RTL coding to AI-orchestrated design is forcing a fundamental role transformation. Traditional design engineers spent 60-70% of their time writing and debugging code. Today’s “AgentEngineers” allocate that time differently: 40% on high-level architectural specification and constraint definition, 30% on AI output validation and refinement, 20% on system integration and optimisation, and just 10% on direct coding for critical path logic AI cannot yet handle reliably.

Talking on the evolving role of Engineers in the AI era, Srinivas Gupta, CEO, Silicon Patterns, emphasises that, “AI is not eliminating engineering roles, it is exposing who is adding real value. The role of the engineer is shifting from manual construction to intent definition, supervision, and judgment. Writing RTL is no longer the bottleneck; understanding what should be written and why is. Effective training is not about teaching “prompt engineering.” It is about teaching engineers how to reason clearly, review outputs critically, and understand failure modes. The best learning happens when AI is embedded directly into real project workflows, spec reviews, verification bring-up, debug, not in isolation.”

New competencies are emerging as essential: prompt engineering skills to communicate design intent effectively to LLM agents, AI system supervision capabilities to recognize when autonomous agents are diverging from design goals, and elevated architectural thinking to work at higher abstraction layers. The most successful engineers are those who transition from implementation experts to design orchestrators—defining what to build while delegating how to build it.

Training for TransformationOrganisations are implementing structured transition programs. Technical training covers AI model capabilities and limitations, effective prompt crafting for design specifications, and verification strategies for AI-generated code. Just as importantly, cultural training addresses the psychological shift from individual contributor to AI collaborator, teaching engineers when to trust autonomous outputs and when human judgment remains irreplaceable.

The semiconductor workforce crisis that threatened industry growth is being addressed not through massive hiring campaigns, but through radical productivity multiplication—a smaller cohort of AgentEngineers accomplishing what previously required entire design teams.

Trust, Validation, and the Road to 2026: Overcoming Deployment Challenges

Agentic AI’s technical promise confronts harsh deployment realities. The path from laboratory demonstration to production tapeout demands solving trust, integration, and scalability challenges that determine whether this technology revolutionises the industry or remains confined to pilot projects.

The Three Critical Deployment ChallengesIntegration Complexity tops the challenge list. Legacy EDA environments weren’t architected for AI orchestration—tool licenses limit concurrent sessions, APIs lack programmatic access depth, and design databases struggle with AI agents’ iterative read/write intensity. Organisations report 6-12 month integration timelines just to achieve basic agent-tool interoperability.

Trust and Validation Frameworks represent the existential challenge. For tape-out critical stages—final timing closure, DFT insertion, physical verification—engineers demand confidence levels AI systems cannot yet guarantee. One design director noted, “We can’t ship silicon that passes simulation but fails in production because an AI agent hallucinated a clock domain crossing fix.”

Organisational Resistance manifests subtly but persistently. Experienced engineers trained over decades resist delegating design authority to probabilistic systems. Version control becomes contentious when distinguishing human versus AI contributions. Accountability questions arise when AI-generated blocks cause post-silicon failures.

Building Trust Through ValidationSuccessful deployments implement rigorous validation hierarchies. AI-generated RTL undergoes formal equivalence checking against specifications, simulation coverage thresholds exceed 95% before human review, and critical paths receive mandatory expert sign-off regardless of AI confidence scores. Human-in-the-loop checkpoints gate progression, with engineers retaining veto authority at every stage.

Observability tools provide transparency into AI decision-making—logging which training examples influenced specific design choices, tracking confidence metrics for generated code segments, and flagging low-confidence outputs for immediate human review.

The 2026 Automation RoadmapIndustry consensus positions current systems at Level 2 on the five-level autonomy scale: capable assistants requiring continuous supervision. Reaching Level 4—autonomous subsystem design with minimal oversight—demands breakthroughs across multiple fronts.

Enhanced LLM reasoning must progress beyond pattern matching to genuine architectural trade-off analysis, understanding power-performance-area implications of micro-architectural choices. Memory systems need expansion to manage entire SoC contexts rather than isolated module designs. Formal methods integration must advance from post-generation validation to constraint-guided generation, preventing invalid designs rather than detecting them.

On the India front, Anup Salva, CEO, Sasken Silicon, notes that, “India’s advantage lies in its depth of engineering intuition, especially in areas like RF, analogue, and system-level integration. These are domains where AI works best as a multiplier, not a replacement. Over the next few years, we expect higher automation in well-understood design spaces, but always guided by engineers who understand the underlying physics and architecture. Progress will be driven more by better problem formulation and design discipline than by radical new tools.”

The competitive landscape trajectory appears clear: by late 2026, agentic AI will likely transition from a competitive differentiator to table stakes. Organisations not deploying these systems risk falling behind on time-to-market metrics. Yet the dominant paradigm will remain hybrid human-AI workflows rather than full autonomy—engineers orchestrating AI agents rather than being replaced by them, at least through this decade.

by: Shreya Bansal, Sub-Editor

The post The Rise of the AgentEngineer: How AI is Orchestrating the Future of Chip Design appeared first on ELE Times.

IIIT Hyderabad’s Smart Approach To Sand Mining Enforcement, Incorporating AI in Trucks

‘Truck art’ or the hand-painted ‘Horn Ok Please’, ‘Use Dipper at Night’ and the ‘Buri nazar waale tera mooh kala’ are an integral part of Indian highways. These artistic expressions, which lighten up many a road journey, also find an extension in hand-painted registration plates. However, such unstandardised lettering can prove to be a challenge for automatic number plate recognition (ANPR) systems. Most commercial ANPR systems are designed for standardised license plates. ANPR systems play a crucial role in modern governance, helping authorities monitor traffic, enforce regulations, prevent illegal transport, and improve public safety. From toll booths to traffic violations, ANPR enables real-time vehicle tracking without manual checks.

A Unique Number Plate Problem

Hence, when the Telangana IT Department approached IIIT-H, seeking an ANPR solution for the Telangana Mineral Development Corporation (TGMDC), their requirement was very different from typical commercial use cases.TGMDC was on the lookout for a cost-effective, robust solution tailored to monitor sand mining trucks, primarily to curb illegal mining and transport. “Typical license plates are actually easy to detect,” explains Dr. Veera Ganesh Yalla, CEO of iHub-Data and Adjunct Faculty at IIIT-H. But in India, especially with trucks, plates are often hand-painted, inconsistent, and highly variable. “They might follow black lettering on a yellow background, but from vehicle to vehicle, their design, the style, everything is unique,” he says, making off-the-shelf solutions for their detection both ineffective and expensive.

Building Smart, Not From Scratch

Commercial systems are typically very expensive, with per-camera costs of licensing and maintenance running into tens of lakhs. Leveraging prior research from Prof. Ravikiran Sarvadevabhatla’s team at the Centre for Visual Information Technology, IIIT-H, where a prototype license plate recognition system had been developed, the iHub-Data team took the research forward into real-world deployment. “The lab tech was more like a research prototype, not really for scaling or translation. So we decided to take it and see what we could do,” Dr. Yalla recalls. The team studied the workflow, rebuilt and strengthened the handwritten character recognition component. What’s unique is that they integrated the analytics as a plug-in into an open-source platform. ”If anybody wants to plug in our license plate technology into their platform, they can do it without having to rewrite their entire platform from scratch,” he notes.

Real-life Deployment

Their solution, named Vahan Eye, was piloted at Chityal on the Vijayawada–Hyderabad highway, where the team installed cameras, laid cables, and deployed the system end-to-end. The deployment tracks trucks entering Telangana and cross-checks them against a whitelist of nearly 40,000 approved vehicles. Tweaked specially to suit the needs of TGMDC, the solution offers customised dashboards. Since September, the system has been running continuously. Despite challenges such as low lighting at night and festival-related obstructions such as garlands covering the number plates, the algorithm has proven robust and continues to improve with live data.

From PoC to Public Impact

Built by a lean team of fewer than five engineers and powered by modern deep learning models, Vahan Eye demonstrates how lab research can be translated into an affordable, field-ready public solution. “Our IP is that we really figured out how to solve this whole handwritten license plate character problem,” says Dr. Yalla. Currently, the team is working on customising the solution for the Police Department for automatic detection of traffic violations by 2-wheelers.

Dr. Yalla, who began his career in the video surveillance industry with classical machine learning solutions that used support vector machines, explains that with advances in deep learning, more powerful algorithms such as YOLO and RF-Detr are now being applied, leading to significantly improved performance and accuracy. As he puts it, the goal is clear: prove the technology works, make it accessible at a fraction of commercial costs, and enable scalable adoption across government departments.

The post IIIT Hyderabad’s Smart Approach To Sand Mining Enforcement, Incorporating AI in Trucks appeared first on ELE Times.

Applied Materials, CG Power, Lam Research, Larsen & Toubro, and Micron Join the IDTA

The India Deep Tech Alliance (IDTA) announced that Applied Materials, CG Power, Lam Research, Larsen & Toubro, and Micron Technology have joined the Alliance. These additions further strengthen IDTA’s cross-sector collaboration model, which brings together investors, corporates, and technology-enabling partners to mobilise capital, technical expertise, market access, and policy engagement for the advancement of Indian deep tech startups.

With the addition of these global and Indian industry leaders, IDTA now spans artificial intelligence, semiconductor equipment, memory, materials, infrastructure engineering, and power systems, creating an integrated platform to support investment, technology collaboration, talent development, and startup commercialisation. With the shared goal of accelerating the growth of India’s deep tech economy, IDTA Corporate Strategic Partners aim to leverage their expertise to provide strategic and technology counsel to other IDTA members and emerging startups. Strategic advisory and ecosystem collaborations may include:

- Manufacturing and scale-up guidance for lab-to-fab transitions and production readiness.

- Technical talks, training, and access to expert resources.

- Collaborative research discussions and ecosystem initiatives with startups, researchers, and industry.

- Private industry input to policy dialogues related to national priority technology sectors.

- Mentorship, network access, and co-development opportunities in concert with investors.

IDTA is an industry-led consortium formed to mobilise capital and company-building expertise to help India-domiciled deep tech startups scale globally. It was formed to expand private sector support for strategic technology sectors, complementing the Government of India’s Research, Development & Innovation (RDI) Scheme.

This latest membership expansion follows NVIDIA joining IDTA as a Founding Member and Strategic & Technical Advisor, underscoring the Alliance’s ambition to build globally relevant, India-anchored deep tech capabilities at scale. Since its founding in September 2025, IDTA has expanded to a commitment of more than $2.5B USD in venture funding to Indian deep tech startups over the next five years, including a dedicated $1B USD allocation to Indian AI startups to be invested over the next three years. IDTA venture capital members have deployed $110M USD into 50+ companies over the past six months.

“The entry of Applied Materials, CG Power, Lam Research, L&T, and Micron marks a pivotal step in moving India’s deep tech ambition from intent to execution,” said Arun Kumar, India Managing Partner of Celesta Capital and Chair of IDTA. “Together with NVIDIA’s role as a founding member and strategic advisor, this coalition brings unmatched depth across semiconductors, advanced manufacturing, infrastructure, and systems engineering. IDTA is designed to align capital, technology, and policy so that India can emerge not just as a participant, but as a trusted global hub for next-generation technologies.”

Quotes from New IDTA Corporate Strategic Partners:

Om Nalamasu, CTO, Applied Materials, said, “Applied Materials has a long history of working across industry, startups, academia, and research institutions to advance foundational technologies. As a materials engineering leader, we believe long‑term progress comes from sustained, ecosystem‑level collaboration. Through this alliance, we look forward to contributing our deep technology expertise to help build resilient ecosystems for India and the world.’’

Mr. Amar Kaul, Global CEO & Managing Director, CG Power, said, “India’s deep tech journey is entering a decisive phase, one where execution, industrial capability, and long-term partnerships will determine global relevance. CG Power’s participation in the India Deep Tech Alliance reflects our conviction that nation-building today requires strong, technology-led manufacturing ecosystems. Through IDTA, we look forward to contributing our expertise in industrial, power systems and semiconductors to create resilient and future-ready value chains that reinforce India’s position as a trusted global technology hub.”

Kevin Chen, Head of Lam Capital & Corporate Development, Lam Research, said: “Semiconductor manufacturing excellence depends on deep collaboration across equipment, materials, process technology, and talent. We look forward to engaging with IDTA to help Indian innovators navigate technology roadmaps, manufacturability, and global ecosystem linkages that accelerate from lab to fab.”

Prashant Chiranjive Jain, Head Corporate Centre, Larsen & Toubro, said: “The India Deep Tech Alliance represents a pivotal shift toward indigenous innovation. By synergising L&T’s engineering heritage with advanced capabilities in AI, design engineering, and quantum systems, we are committed to building a robust deep-tech ecosystem. We look forward to delivering cutting-edge solutions that position India as a global leader in the next generation of technology.”

Anand Ramamoorthy, Managing Director, Micron India, said: “Micron’s decision to join the India Deep Tech Alliance reflects our commitment to ecosystem-led collaboration to propel a vital economic engine for India. Micron’s technology and innovation expertise will play a vital role in helping advance globally competitive deep tech from India while aligning with IDTA’s support for the national RDI agenda and its focus on translating research into market impact.”

The post Applied Materials, CG Power, Lam Research, Larsen & Toubro, and Micron Join the IDTA appeared first on ELE Times.

Manufacturing Breakthroughs in Chip Packaging Are Powering AI’s Future

Courtesy: Lam Research

With all the attention being given to AI, it’s easy to overlook some of the core technologies enabling its capabilities. Sure, a lot more people have now heard about NPUs, GPUs and the businesses that make them, but what about the companies that enable these cutting-edge AI accelerators to be manufactured?

The Complexity of Modern Chipmaking

While most people may not realise it, chip manufacturing is incredibly challenging and requires the level of scientific breakthroughs that have powered humanity’s most advanced achievements. I mean, we’re talking about bending the laws of physics to build components that are a thousand times smaller than a grain of sand. Oh, and doing so millions of times over at incredibly high levels of quality and consistency. Plus, with the extra demands that GenAI workloads are putting on today’s latest chips, the challenges are getting even tougher.

That’s why companies providing the equipment and technologies that enable the manufacturing of these advanced chips play an essential role in driving the advanced AI capabilities we are all starting to experience.

Without their work to overcome technical challenges like the need for exascale computing, addressing the “memory wall” that can slow down AI accelerators, increasing power efficiency, and other issues that are necessary to maintain the Moore’s Law-like advances we’ve seen in these chips, the state of AI would not be where it is today. In particular, organisations like Lam Research, which build extremely complex, sophisticated machines that help process the raw silicon wafers that eventually become today’s most powerful semiconductor chips, play a big, though little-understood, part in big tech advancements like AI.

Building Next-Generation AI Chips Through Heterogeneous Integration