ELE Times

3 semicon-enabled innovations impacting our experience of the world

Courtesy: Texas Instruments

The chips that power today’s smartphones contain over 15 billion transistors; the semiconductors powering data centres can have hundreds of billions of transistors. Semiconductors drive and power breakthroughs across hundreds of critical and emerging industries, such as robotics, personal electronics and artificial intelligence. As semiconductors continue to enable the world to function and make life more convenient and safer, their role will only increase.

The importance of chips – and the electronics they’re enabling – has been made possible by years of semiconductor progress. Let’s review how semiconductor technologies are enabling three innovations in electronics that impact how we experience the world.

Innovation No. 1: Systems that operate safely around humans

“You might think humanoids are 3 to 5 years away. But really, humanoids are the present,” said Giovanni Campanella, general manager of factory automation, motor drives and robotics at TI, at a Computex speech.

Humanoids’ emergence is anything but simple. Robots that perform chores in homes, complete tasks in a factory, or even clean dishes in a restaurant kitchen must adapt in dynamic environments, where things change every second.

In order to build adaptable robots that can operate around humans in diverse settings, such as domestic or business environments, design engineers must leverage semiconductor technologies. Each of these technologies must work together to perform the actions of one safe and functional humanoid. Actuators in robots enable their movements. With sensing, the robot can perceive its surrounding environment, and a central computer acts as its brain, analysing and making decisions from that sensing data. Communication with the compute units and actuators happens in real time, so the humanoid can complete a task, such as handing an object to someone.

Innovation No. 2: Smaller, more affordable, smarter devices

Smartphones and laptops keep getting thinner and lighter. Medical patches provide continuous monitoring without external equipment. Devices are on a trajectory to fit into an individual’s life, increasing convenience and accessibility.

How are designers able to continually progress toward the trend of “smaller” and more convenient when last year’s newest smartphone was already the smallest ever?

Significant advances in component design are enabling this progress. An example of this was our launch of the world’s smallest MCU, reflecting breakthroughs in packaging, integration and power efficiency that allow more functionality to fit into dramatically smaller spaces.

“With the addition of the world’s smallest MCU, our MSPM0 MCU portfolio provides unlimited possibilities to enable smarter, more connected experiences in our day-to-day lives,” said Vinay Agarwal, vice president and general manager of MSP Microcontrollers at TI.

Due to semiconductors, headphones that were once clunky can now fit into a pocket and provide a premium audio experience. Smart rings instantly track health metrics like activity and heart rate without interrupting everyday activities. With devices like the world’s smallest MCU, the prevalence of smaller, more affordable electronics that seamlessly blend into an already-existing routine is expanding.

Innovation No. 3: AI everywhere

By 2033, the global AI market is expected to account for $4.8 trillion – 25 times higher than the $189 billion valuation in 2023. AI is already enabling smartphones to process images in real time, cars to monitor drivers and their surroundings, and medical devices to deliver precise insights, and with its projected growth, the possibilities of where else AI can appear seem endless.

But with the influx of power needed to process the massive amounts of data that AI requires – and the inevitable demand to process even more data – there must be supporting infrastructure.

This is why moving energy from the grid to the gate is crucial – by optimising every stage of the power chain, from the electrical grid to the logic gates inside computer processors, TI helps support widespread AI adoption while improving efficiency, reliability, and sustainability.

At the same time, the need for more power to process the computations that AI requires has reshaped system designs. Software-defined architectures have enabled products to adapt and deploy new AI capabilities without new hardware. Software is increasingly becoming an important driver of flexibility, differentiation, and energy efficiency in applications such as vehicles, robotic systems and appliances.

Even at the edge, we’re working with designers now to implement AI onto devices such as solar panels to detect potentially dangerous arc faults. But that’s only one way we’re supporting the increase of AI.

“We’ll continue developing those use cases that make sense,” said Henrik Mannesson, general manager of energy infrastructure at TI. “But we also recognise the need to build universal tools that enable customers to further innovate with edge AI.”

Conscluion:

From robots that can safely work alongside humans to ultra-compact devices that seamlessly integrate into daily life, and AI systems that scale responsibly from the edge to the cloud, semiconductor innovation is redefining how technology touches the world around us. These advances are not happening in isolation; they are the result of sustained progress in sensing, computing, power management, and software-driven design working in unison. As demand grows for smarter, safer, and more energy-efficient systems, semiconductors will remain the invisible backbone enabling engineers to turn ambitious ideas into practical, real-world solutions. In shaping what’s next, the smallest components will continue to have the biggest impact.

The post 3 semicon-enabled innovations impacting our experience of the world appeared first on ELE Times.

The Next Phase of Energy Storage: When Batteries Start Working with the Grid

Authoredby: Rajesh Kaushal, Energy Infrastructure & Industrial Solutions (EIS) Business Group Head, India & SAARC, Delta Electronics India

For decades, the electricity grid operated on a simple principle: power had to be generated at the exact moment it was consumed. Coal plants, gas turbines, and hydro stations were dispatched to follow demand, and the grid was built around predictability and centralised control.

That principle is now being fundamentally rewritten.

As renewable energy becomes central to India’s power system, variability has entered the equation at an unprecedented scale. Solar and wind generation do not follow traditional load curves, and their growing share is changing how grids must be designed and operated. In this new reality, energy storage, particularly Battery Energy Storage Systems (BESS), is moving from being a supporting technology to becoming a core grid asset.

We are entering the next phase of energy storage, where batteries no longer sit on the sidelines but actively work with the grid.

From Backup to Backbone

In its early years, energy storage in India was largely viewed as backup power, used during outages or in niche, isolated applications. That perception is changing rapidly.

Today, batteries are expected to play a much broader role:

- Smoothing renewable variability

- Managing peak demand

- Deferring transmission upgrades

- Providing frequency and voltage support

- Enabling faster and more resilient grids

According to projections from the Central Electricity Authority, India will require over 82 GWh of total energy storage by 2026–27, with BESS contributing nearly 35 GWh, rising to 411 GWh total by 2031–32, with batteries accounting for over 236 GWh.

These are not incremental additions. They signal a structural shift in how the power system will be planned, operated, and stabilised.

When Policy Meets Scale

A key indicator of this transition is policy clarity and rapidly declining costs.

Recent tariff-based competitive bidding shows that the cost of BESS has plummeted from around ₹10.18 per kWh to approximately ₹2.1 per kWh, assuming two daily cycles. Based on market trends and utilisation patterns, the cost at 1.5 cycles per day is expected to be around ₹2.8 per kWh. This aligns closely with average solar tariffs, making storage increasingly competitive.

India’s policy framework supports this transition:

- Viability Gap Funding schemes supporting 13,220 MWh of BESS capacity with ₹3,760 crore, and an additional 30 GWh with ₹5,400 crore support through the Power System Development Fund.

- Inter-State Transmission System (ISTS) charges waiver for co-located BESS projects for 12 years and graded waivers for non-co-located projects.

- The PLI “National Programme on Advanced Chemistry Cell (ACC) Battery Storage” aims to establish 50 GWh of domestic Advanced Chemistry Cell manufacturing capacity, including 10 GWh for grid-scale applications to reduce import dependency and future costs.

These mechanisms are accelerating adoption and enhancing affordability, shifting storage from pilot projects to mainstream system planning.

Storage Enters Grid Planning

Perhaps the clearest indicator of maturity is how storage is now treated in national planning.

Nearly 47 GW of BESS capacity has already been considered in India’s transmission planning horizon up to 2032. This is a profound change. Batteries are no longer “add-ons” installed after the grid is built. They are being planned alongside transmission lines, substations, and renewable corridors.

This integration unlocks new possibilities:

- Managing congestion without building new lines

- Firming renewable power at the point of injection

- Providing local grid support closer to demand centres

In effect, storage becomes a flexible, digital asset embedded within the physical grid.

When Batteries Start Talking to the Grid

The next phase of energy storage is not defined by chemistry alone. It is defined by intelligence.

A battery that simply charges and discharges on a timer is useful. A battery that communicates with the grid in real time is transformative.

Advanced power electronics, grid-forming inverters, and intelligent control systems allow BESS to:

- Respond instantly to frequency deviations

- Stabilise weak grids with high renewable penetration

- Coordinate with solar and wind plants to deliver dispatchable power

- Support black start and islanding operations

This is where energy storage stops being passive infrastructure and starts behaving like an active grid participant.

At Delta, our energy infrastructure approach is built around this convergence, where power electronics, automation, and digital control come together. Batteries are no longer isolated assets. They operate as part of a wider ecosystem that includes inverters, energy management systems, EV charging infrastructure, and grid interfaces.

Beyond Utilities: Storage Touches Everyday Life

While much of the discussion around BESS focuses on utilities and large-scale projects, the impact of grid-integrated storage is far broader.

For industries, it means improved power quality and reduced exposure to peak tariffs.

For cities, it means greater resilience during extreme weather events.

For renewable developers, it means predictable revenues and bankable projects.

For consumers, it ultimately means a cleaner, more reliable power supply.

Energy storage is becoming an invisible enabler, rarely noticed when it works well, but critical to system reliability when it is absent.

India’s Unique Opportunity

India’s energy transition is happening at a scale and speed few countries have attempted. Peak demand continues to rise, renewable capacity is expanding rapidly, and electrification is accelerating across transport, industry, and households.

This creates a unique opportunity. Instead of retrofitting storage into an aging grid, India can design a future-ready system where renewables, batteries, and digital infrastructure are integrated from the outset.

But success will depend on how well technology, policy, and execution align:

- Clear market signals for ancillary services

- Standards for grid-forming and hybrid systems

- Long-term visibility for manufacturers and developers

- Skill development for operating a more complex, digital grid

A Grid That Thinks, Responds, and Adapts

The next phase of energy storage is not only about adding battery capacity. It is about how the grid itself is designed and operated.

Future power systems will need to sense conditions in real time, respond quickly to changes in demand and supply, and adapt to increasing variability from renewable sources. When batteries are fully integrated into grid operations, they can support frequency regulation, peak management, and network stability more effectively than standalone assets.

India has already begun moving in this direction. Energy storage is being considered within transmission planning, renewable integration strategies, and market mechanisms. The focus now shifts from adoption to optimisation: how efficiently storage can be deployed, controlled, and scaled to deliver maximum system value.

In the years ahead, the grid’s role will extend beyond power delivery. It will increasingly manage energy flows dynamically, with storage playing a central role in enabling reliability, flexibility, and long-term sustainability.

The post The Next Phase of Energy Storage: When Batteries Start Working with the Grid appeared first on ELE Times.

TOYOTA Selects Infineon’s SiC Power Semiconductors for its New, “bZ4X”

Infineon Technologies announced that CoolSiC MOSFETs (silicon carbide (SiC) power MOSFETs) have been adopted in the new bZ4X model from Toyota, the world’s largest automaker. Integrated into the on-board charger (OBC) and DC/DC converter, the SiC MOSFETs leverage the material’s advantages of low losses, high thermal resistance, and high voltage capability to help extend driving range and reduce charging time.

“We are very proud that Toyota, one of the world’s largest automakers, has chosen Infineon’s CoolSiC technology. Silicon carbide enhances the range, efficiency and performance of electric vehicles and is therefore a very important part of the future of mobility,” said Peter Schaefer, Executive Vice President and Chief Sales Officer Automotive at Infineon. “With our dedication and our commitment to innovation and zero-defect quality, we are well-positioned to meet the growing demand for power electronics in electromobility.”

Infineon’s CoolSiC MOSFETs feature a unique trench gate structure that reduces normalised on-resistance and chip size, enabling reductions in both conduction and switching losses to contribute to higher efficiency in automotive power systems. In addition, optimised parasitic capacitance and gate threshold voltage enable unipolar gate drive, contributing to the simplification of drive circuits for automotive electric drive train and supporting high-density, high-reliability design for OBC and DC/DC converters.

The post TOYOTA Selects Infineon’s SiC Power Semiconductors for its New, “bZ4X” appeared first on ELE Times.

STMicroelectronics expands strategic engagement with AWS, enabling high-performance compute infrastructure for cloud and AI data

STMicroelectronics has announced an expanded strategic collaboration with Amazon Web Services (AWS) through a multi-year, multi-billion USD commercial engagement serving several product categories. The collaboration establishes ST as a strategic supplier of advanced semiconductor technologies and products that AWS integrates into its compute infrastructure, enabling AWS to provide customers with new high-performance compute instances, reduced operational costs, and the ability to scale compute-intensive workloads more effectively.

As part of this expanded relationship, ST will work with AWS to optimise electronic design automation (EDA) workloads in the cloud. AWS’s scalable compute power enables silicon design acceleration, parallelises design tasks, and gives engineering teams the flexibility to handle dynamic compute demands and speed products to market.

Commercial Agreement

This engagement covers a broad range of semiconductor solutions leveraging ST’s portfolio of proprietary technologies. ST will supply specialised capabilities across high-bandwidth connectivity, including high-performance mixed-signal processing, advanced microcontrollers for intelligent infrastructure management, as well as analogue and power ICs that deliver the energy efficiency required for hyperscale data centre operations.

The collaboration will help customers reduce the total cost of ownership and bring products to market faster. ST’s specialised technologies help AWS address the increasing demands for compute performance, efficiency, and data throughput required to support growing AI and cloud workloads.

Jean-Marc Chery, ST President & CEO, commented: “This strategic engagement establishes ST as an important supplier to AWS and validates the strength of our innovation, proprietary technology portfolio, and proven manufacturing-at-scale capabilities. Our advanced semiconductor solutions will directly power AWS’s next-generation infrastructure, enabling its customers to push the boundaries of AI, high-performance computing, and digital connectivity. This collaboration positions us ideally for further scale-up across multiple market segments, from data centre infrastructure to AI connectivity, positioning ST at the centre of the AI revolution.”

ST has issued warrants to AWS for the acquisition of up to 24.8 million ordinary shares of ST. The warrants will vest in tranches over the term of the agreement, with vesting substantially tied to payments for ST products and services purchased by AWS and its affiliates. AWS may exercise the warrants in one or more transactions over a seven-year period from the issue date at an initial exercise price of $28.38.

The post STMicroelectronics expands strategic engagement with AWS, enabling high-performance compute infrastructure for cloud and AI data appeared first on ELE Times.

GaN Benefits in Motor Controls

By: Ester Spitale, Technical Marketing Manager, STMicroelectronics and Albert Boscarato, Application Lab Manager, STMicroelectronics

GaN benefits in different applications

The major challenge of power electronics today is dealing with the growing need for improved efficiency and power performance, and at the same time, the constant pursuit of cost and size reductions.

The introduction of Gallium Nitride (GaN) technology, a relatively new wide bandgap compound, moves in this direction, as it becomes increasingly available commercially, its use is growing tremendously.

With a better figure-of-merit (FOM), on-resistance RDS(on), and total gate charge (QG) than silicon counterparts, High-electron-mobility transistor (HEMT) devices based on gallium nitride (GaN) also offer a high drain to source voltage capability, zero reverse recovery charge and very low intrinsic capacitances.

The first application where GaN technology has spread is power conversion: GaN represents the leading solution for improving efficiency, making it possible to meet the most stringent energy requirements. The capability to work at higher switching frequencies enables higher power densities, and therefore reduction of the system dimensions, weight and cost.

Size and energy efficiency are also crucial in electronic motor designs: minimising conduction and switching losses in the drive is key for reducing energy waste.

Performance improvement in motor drivers relying on classic silicon MOSFETs and IGBTs is becoming more difficult as silicon technology approaches theoretical limits for power density, breakdown voltage, and switching frequency. Due to their superior electrical characteristics, GaN transistors are a valid alternative to MOSFETs and IGBTs in high-voltage motor control applications.

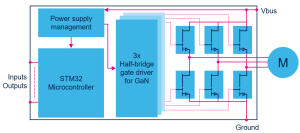

Simplified block diagram of a power inverter based on GaN transistors

Simplified block diagram of a power inverter based on GaN transistors

Fueling the next generation of motor inverters

GaN is promising important benefits even in applications operating at low frequencies (up to 20kHz). In the realm of home appliances, motor-driven systems such as washing machines, refrigerators, air conditioners, and vacuum cleaners rely heavily on motor inverters to control speed, torque, and efficiency. Unlike industrial servo or precision motors, the physical size of these motors is largely fixed due to mechanical and functional constraints. This means that the traditional approach of reducing overall system size by shrinking the motor itself is not feasible. Instead, improvements must be sought in the inverter and power electronics that drive these motors.

In this sense, it is important to point out that the benefit of GaN over traditional silicon transistors does not come from a single parameter that stands out. It is rather the sum of different aspects concatenating together.

GaN has a de facto negligible reverse recovery charge (Qrr) and low parasitic capacitances, which in turn enable working with slightly higher dV/dt. While the motor winding and insulation limit the maximum allowable dV/dt, GaN’s capability to operate at higher switching speeds allows designers to optimise switching edges carefully.

Moreover, a safe and drastic reduction of dead-time is also achievable without risking shoot-through faults. Time between high-side and low-side switching can be easily lowered by a factor of 10. This can improve inverter efficiency and reduce switching losses without compromising motor reliability.

As remarkable as it gets, the performance is not over yet. In fact, all these “little” improvements combined lead to what may be considered the most relevant of them all: the removal of the heatsink.

Kiss your heatsink goodbye

The considerable reduction in power dissipation allows designers to reduce or even remove bulky heatsinks in the inverter power stage. The assembly line may now require fewer steps in the manufacturing process. No heatsink also means no screws or mounting joints, thus avoiding mechanical failures that can appear when the appliance is already long in the field. An interesting potential saving of service and warranty costs.

The overall result is a more compact, lightweight, and cost-effective inverter design that fits better within the demanding and highly competitive space of the home appliances market.

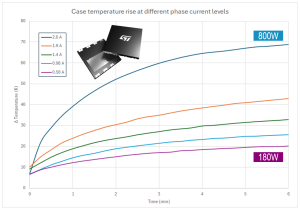

700 V GaN mounted on a motor inverter running without a heatsink

700 V GaN mounted on a motor inverter running without a heatsink

The waveforms show how smooth and cold a GaN can be. In the example above, the device under test has a typical RDS(on) of 80mΩ. The motor inverter runs at a switching frequency of 16 kHz, with a maximum dV/dt slightly under 10V/ns.

A power level of about 800 W can be safely achieved without incurring thermal runaway. The increase in temperature Δt is less than 70 °C, which leaves a good margin before reaching the maximum operating junction temperature (TJmax) of 150 °C.

This remarkable result is achieved without a heatsink, with GaNs mounted on and cooled down through a common 2-layer PCB.

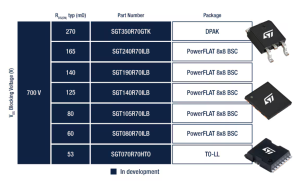

STPOWER GaN Transistors

STPOWER GaN Transistors are intrinsically normally off, p-GaN gate e-mode transistors that offer a zero reverse recovery charge. ST offers today seven part numbers rated 700 V breakdown voltage (VDS), with typical on-resistance RDS(on) ranging from 270 mΩ down to 53 mΩ in DPAK, PowerFLAT 8×8, and TO-LL packages.

The portfolio is rapidly growing, adding on different packages, RDS(on) and breakdown voltage levels.

The post GaN Benefits in Motor Controls appeared first on ELE Times.

Union Minister Ashwini Vaishnaw inaugurates TI’s new, world-class R&D centre

Texas Instruments (TI) officially opened its new, state-of-the-art product research and development (R&D) centre in Bengaluru at an event commemorating the company’s 40-year presence in India. As the first multinational company to establish an R&D centre in India in 1985, TI has been instrumental in shaping India’s semiconductor landscape for four decades. The new 550,000-square-foot centre features a collaborative workspace dedicated to developing world-class chip designs. The centre includes an end-to-end reliability lab equipped with advanced testing capabilities for various environmental conditions, along with many other integrated circuit design labs.

Inaugurated by Shri Ashwini Vaishnaw, Union Minister for Railways, Information & Broadcasting, Electronics & Information Technology, Government of India, alongside TI leaders, the new centre highlights the company’s strategic vision to propel semiconductor innovation and nurture world-class design talent. This expansion reinforces TI’s commitment to developing breakthrough analogue and embedded processing technologies while strengthening its support for the design ecosystem and its growing customer base in India.

Shri Ashwini Vaishnaw, Union Minister for Railways, Information & Broadcasting; Electronics & Information Technology, Government of India, said, “I congratulate Texas Instruments on the inauguration of this world-class R&D centre in Bengaluru. TI has been a true pioneer in India’s semiconductor journey and stood as a testament to consistently nurturing the design talent ecosystem in India. The company’s expanded investment reinforces India’s position as a global hub for semiconductor design, development and supports our vision of building an innovation-led nation.”

Santhosh Kumar, president and managing director, TI India, said, “As we celebrate 40 years in India, this milestone reflects TI’s rich legacy and our strong commitment to the future. TI India’s product development and design teams drive research and breakthrough innovations for customers worldwide. Our world-class engineers are central to pioneering the next generation of semiconductor advancements.”

The company recently opened an additional sales office to strengthen its partnership with Indian customers, while the new R&D facility builds on its innovation capabilities in the region. With thousands of employees in India, TI continues to expand its presence in the region.

The post Union Minister Ashwini Vaishnaw inaugurates TI’s new, world-class R&D centre appeared first on ELE Times.

Bridging the design-to-deployment gap: How India can lead the next wave of connected device innovation

Hareesh Ramana, Chief Experience Officer, Sasken Group & President, Borqs Technologies (a Sasken Group company)

India is making significant strides in electronics manufacturing with the aim of 38% value addition within five years. The device manufacturing ecosystem has grown to a significant scale, but it still depends heavily on designs and reference architectures developed elsewhere.

Building domestic capability in electronic device design, especially IoT/connected device design, is critical to India’s ambition of becoming a major electronics manufacturing hub. India’s ambition to reach 38% value addition in electronics manufacturing will be driven not only by scaling assembly but by strengthening device design and systems engineering, which can contribute as much as 30-35% of the total value creation.

Need for in-house design capabilities:

A growing model in India’s connected-device ecosystem is design-led, end-to-end IoT product development anchored locally, covering silicon integration, embedded software, connectivity stacks, and certification. Companies like Borqs Technologies (now part of the Sasken Group) exemplify this approach, offering full-stack IoT design capabilities from within India. For OEMs, this can shorten development cycles, improve control over system integration, and reduce dependence on externally sourced IP and engineering capacity, especially in critical connectivity and compliance stages. Expanding these capabilities across the industry can help India move beyond contract manufacturing and toward the higher-value innovation layer where devices connect to data, analytics, and services.

Time to market gap:

Many IoT projects stall because hardware, firmware, cloud platforms, connectivity, and certification are handled by separate vendors with misaligned priorities.

Over the past decade, India’s product development ecosystem has matured to address these challenges, evolving from a cost-centric outsourcing base into a design-led innovation hub. Global OEMs and platform companies increasingly view India as a partner for rapid prototyping and co-innovation, not just low-cost assembly. Several end-to-end product engineering companies in India exemplify this shift by delivering integrated IoT solutions that shorten development cycles and align with global OEM roadmaps.

Integration as a strategic capability

Connected devices are no longer standalone products; they are endpoints of digital services. The differentiator is therefore systems integration across silicon, hardware, software, connectivity, and lifecycle management. A unified, end-to-end engineering model can enable:

- Faster debugging by tightening the feedback loop between hardware and software teams

- Fewer integration issues by reducing handoffs across multiple vendors

- Quicker prototyping and validation through coordinated design and test cycles

- More predictable certification and production ramp by planning compliance and manufacturability early

- A single accountable partner from concept through delivery and lifecycle management

This is particularly vital for industrial-grade devices where reliability, security, and compliance define adoption. Indian engineering firms with cross-layer capabilities are increasingly enabling platform-driven approaches that allow module reuse across verticals like automotive, energy management, and logistics.

AI and advanced technologies and product development:

Advanced technologies like AI, IoT, automation, digital twins, and cloud computing are transforming product development. AI-driven analytics reduce manual testing cycles, while digital twins simulate device behaviour under real-world conditions, enabling faster iteration and higher reliability.

Demand for software-defined vehicles, smart energy infrastructure, automated factories, and connected appliances is accelerating globally. Multinationals are expanding design centres and co-innovation programs in India to build products for both developed and emerging markets.

For India, the opportunity lies in moving beyond contract manufacturing to the high-value layer where devices meet data, analytics, and services. Mastery over sensors, edge intelligence, connectivity stacks, and lifecycle platforms can enable the country to capture a far greater share of the global electronics economy.

The coming decade will reward ecosystems that can bridge the design-to-deployment gap with reliability and speed. India has the talent, digital infrastructure, and entrepreneurial energy to lead this shift. The next step is an integrated approach that unites design, engineering, and manufacturing into a single innovation continuum.

The post Bridging the design-to-deployment gap: How India can lead the next wave of connected device innovation appeared first on ELE Times.

ST Foundation Continues Expansion of Digital Literacy Initiatives in India; Honours IFCCI ‘CSR Project of the Year’ Recognition

The ST Foundation, the non-profit corporate arm of STMicroelectronics, hosted a media briefing late January 2026 to outline its strategic expansion in India and celebrate the recent recognition of its flagship “Digital Unify” program. Dedicated to bridging the global digital divide since 2001. The Foundation’s mission has taken on critical urgency in India, where over 400 million people remain excluded from essential digital services.

Addressing the 400 Million Divide

With global data from the 2025 ITU Connectivity Report indicating that 2.2 billion people lack basic digital access, the ST Foundation has positioned India as a central focus for its “Digital Unify” (DU) initiative. The program uses a “train-the-trainer” model and local partnerships to ensure sustainable, community-owned growth.

Impact in Asia and India

In Asia alone, the foundation has 96 Digital Unify Labs, serving about 26,000 beneficiaries per year at a cost of less than $10 per student trained.

The Foundation in India was officially registered in 2018, having reached more than 180,000 trainees to date and having established over 56 Digital Unify Labs across the country.

Key Program Impact and Expansions:

- Education for Vulnerable Children: Since 2022, the “Basic Coding” program has reached over 2,500 children aged 9–13 in slum areas, providing many with their first-ever exposure to digital devices.

- Rehabilitation for Incarcerated Individuals: In partnership with the India Vision Foundation, the “Introduction to Computer Basics” (ICB) course has trained over 3,300 incarcerated people across Uttar Pradesh and Delhi (including Central Jail Rohini) to aid in their eventual reintegration into society.

- Empowering the Visually Impaired: A specialised ICB4VI pilot recently trained 17 visually impaired girls in digital skills. The Foundation is now preparing to scale this model nationwide.

Digital Unification and Cyber Concerns

The Foundation has not only been providing underprivileged people with digital literacy but has also helped them with understanding the basic risks of cyber-attacks, briefings on cybersecurity and internet safety.

Award-Winning Impact

The briefing also highlighted the Foundation’s recent accolade as the “CSR Project of the Year” at the 7th Indo-French Chamber of Commerce & Industry (IFCCI) CSR Conclave & Awards. This award recognises the program’s effectiveness in turning the digital access gap into tangible opportunities for education and employment.

By: Shreya Bansal, Sub-Editor

The post ST Foundation Continues Expansion of Digital Literacy Initiatives in India; Honours IFCCI ‘CSR Project of the Year’ Recognition appeared first on ELE Times.

R&S drives connections and innovations at MWC Barcelona 2026

Rohde & Schwarz will exhibit its extensive portfolio of next generation of wireless technologies, under the motto, “Enabling Connections, Empowering Innovations”, at the Mobile World Congress 2026 in Barcelona, Fira Gran Via, hall 5, booth 5A80 from March 2 to 5, 2026.

The path from 5G to 6G

For a seamless evolution from 5G to 6G, Rohde & Schwarz offers future-ready test solutions for mobile devices and networks. Among the many innovative solutions, the CMX500 one-box signalling tester stands out throughout multiple demos, addressing today’s and tomorrow’s testing challenges.

- Paving the way for 6G, Rohde & Schwarz showcases carrier aggregation combining FR1 and FR3 frequency ranges with its CMX500 one-box signalling tester. The demonstration validates end-to-end device behaviour across the aggregated spectrum. FR3 (7.125 to 24.25 GHz) has been identified by industry and research as a “sweet spot” for combining wide-area coverage with high capacity. Equipped with the new, upgradeable RFU18 board for the CMX500, the tester covers up to 18 GHz, giving users enough headroom for FR3 evolution and a future-ready path for testing next-generation networks.

- Another setup addresses virtual signalling testing. Based on the CMX500, Rohde & Schwarz demonstrates a new approach of shift-left testing, allowing R&D engineers to find design flaws early in their mobile radio modem chips before costly silicon fabrication. This early SDR-based validation will significantly cut time-to-market for 6G devices.

- Ray tracing simulates real-world signal propagation environments, making it a valuable technique for AI receiver testing for future 6G devices. Rohde & Schwarz will showcase the CMX500 as it creates a digital twin of signal propagation within its test environment by leveraging the VIAVI

ray tracing engine. This enables controlled and reproducible validation of complex scenarios with high measurement precision, facilitating site-specific optimisation of radio links and reducing the need for tedious field tests.

ray tracing engine. This enables controlled and reproducible validation of complex scenarios with high measurement precision, facilitating site-specific optimisation of radio links and reducing the need for tedious field tests. - Rohde & Schwarz also advances 5G and emerging 6G testing with its AI-based toolset AI Workplace for the CMX500, massively enhancing testing productivity. TechAssist uses natural language to control the CMX500, enabling rapid test-scenario setup and status/configuration queries, while an upgraded ScriptAssist with a new interface simplifies and accelerates scripting for R&D protocol and application testing as well as instrument automation. Visitors can experience these AI-powered tools in action within various setups at MWC 2026.

- Mobile XR and personal AI devices like smart glasses and wearables are key for 5G-Advanced and 6G-enabled immersive 3D communications. Delivering compelling, low-latency experiences will require rigorous, realistic testing. Rohde & Schwarz will demonstrate an end-to-end testbed centred around the CMX500, addressing AI on RAN and XR testing challenges with its ability to emulate 4G, 5G and Wi-Fi networks, applying both RF and IP impairments to reproduce real-world conditions such as interference and congestion.

- 6G ISAC (Integrated Sensing and Communication), which leverages mobile networks for object detection, is rapidly gaining traction. Rohde & Schwarz will demonstrate new capabilities of its R&S AREG800A, including the emulation of micro-Doppler signatures – in addition to distance, speed and RCS – to support object classification, such as drones.

- For testing base stations and network infrastructure, Rohde & Schwarz showcases the PVT360. It meets the requirements for testing FR1/FR2, small cells and O-RU in a single box. For the verification of frequency converting antennas used in SATCOM, NTN or 5G and 6G applications, visitors can learn about CATR-based over-the-air test chambers, enabling fast OTA-testing of phased antenna arrays.

- With the first off-the-shelf commercial mobile devices now available for 5G broadcast, Rohde & Schwarz lets visitors explore seamless rich data distribution transmission to mobile devices, innovative applications like venue casting, emergency alerts and advanced solutions for terrestrial positioning, navigation and timing.

From ground to orbit with NTN

As terrestrial and satellite-based networks converge, it becomes increasingly complex to simulate real-world conditions while meeting 3GPP requirements, for instance, when it comes to handovers within orbits, between orbits or from space to ground. As NTN technology matures alongside 5G and towards 6G, overcoming significant technical hurdles is key to realising NTN’s potential.

- Rohde & Schwarz has upgraded its CMX500 one-box signalling tester, supporting NR-NTN, NB-NTN and Direct-to-Cell (D2C/DTC) technologies in a single platform. The tester creates a digital twin of the sky, simulating orbits, bands and impairments like Doppler shifts and fading. Combined with smart features like the Constellation Insights Tool, it allows engineers to visualise satellite constellations, analyse coverage gaps and observe trajectories.

- Rohde & Schwarz also supports NTN conformance and carrier acceptance testing, offering the highest number of validated test cases for NR-NTN according to 3GPP Rel.17. In cooperation with Samsung, validations were conducted across all three test domains: RF, RRM and PCT. At MWC 2026, visitors will not only be able to experience these test cases but also see a demonstration of Viasat’s test plan for NB-NTN, covering protocol, performance and RF test scenarios.

Industry collaborations to accelerate AI-RAN

AI is becoming an integral part of the RAN, enabling performance optimisation, improved energy efficiency and more autonomous operations. As a member of the AI-RAN Alliance, Rohde & Schwarz continues industry collaboration and provides reliable test equipment for navigating interoperability in this evolving landscape.

- Rohde & Schwarz and Nokia Bell Labs have collaborated on an AI/ML-based 6G base station radio receiver employing Digital Post Distortion (DPoD) to recover distorted uplink signals. DPoD improves link budget, preserves coverage and reduces the need for dense site deployments, lowering costs. DPoD also reduces mobile device complexity and power consumption. The testbed at the Rohde & Schwarz booth, comprising the R&S SMW200A vector signal generator and the newly launched FSWX signal and spectrum analyzer will showcase the improved performance of Nokia’s AI receiver for uplink signals with different distortion levels.

- In collaboration with NVIDIA, Rohde & Schwarz will exhibit its latest proof-of-concept, also leveraging digital twin technology and high-fidelity ray tracing. This approach creates a robust framework for testing AI-enhanced base stations for both 5G-Advanced and 6G under realistic propagation conditions. This integration aims to bridge the gap between AI-driven wireless simulations and real-world deployment, facilitating more efficient and accurate testing of next-generation receiver architectures.

Next-generation Wi-Fi experience

Wi-Fi 8 sets new expectations for consistent, ultra-high-reliability and quality connectivity. Designed to handle a growing number of connected devices and demanding applications like XR or industrial IoT, IEEE 802.11bn employs ever more complex MIMO (Multiple-Input, Multiple-Output) scenarios. Rohde & Schwarz enables manufacturers with its solution portfolio, from R&D to production.

- The CMX500 one-box signalling tester is now equipped with comprehensive Wi-Fi 8 capabilities. The tester’s flexibility and embedded IP test capabilities make it a versatile solution for a broad range of Wi-Fi 8-specific tests, such as dRu (distributed resource unit), introducing distributed resource allocation, and UEQM (unequal modulation) where different MIMO layers use different modulation schemes, as well as 320 MHz channel bandwidth.

- To navigate the technical complexities of Wi-Fi 8 throughout the entire device lifecycle – from development to production – Rohde & Schwarz will exhibit the CMP180 radio communication tester, designed for testing in non-signalling mode with advanced capabilities and broad bandwidth support. The CMP180 combines two analysers and generators for efficient testing of 2×2 MIMO Wi-Fi 8 devices.

- For high-end MIMO signal generation and analysis tasks in R&D, Rohde & Schwarz will display the R&S SMW200A vector signal generator and the newly launched FSWX signal and spectrum analyser. With its outstanding standard EVM performance and in combination with its cross-correlation feature, the FSWX discovers details of Wi-Fi 8 signals that have been hidden up to now and offers new margins for optimisation. Its multichannel architecture makes the FSWX well-suited for analysing complex scenarios like multi-user MIMO (MU-MIMO).

Automotive connectivity testing

Vehicle manufacturers are integrating increasing levels of wireless connectivity to enable new user experiences, safety features and higher levels of autonomous driving. Rohde & Schwarz offers precise test solutions that cover all wireless technologies used in the automotive industry, from 5G and ultra-wideband to C-V2X and GNSS.

- With NG eCall becoming mandatory for vehicles sold in Europe starting in 2026, Rohde & Schwarz will demonstrate compliance testing capabilities using the CMX500 one-box signalling tester and R&S SMBV100B vector signal generator. The test solution also supports the upcoming Chinese automotive GNSS test standard, GB/T 45086.1 2024, expected to be mandatory for the Automotive Emergency Call System in 2027, with automated testing.

- Non-terrestrial networks have the potential to provide ubiquitous automotive connectivity and require enhancements to key components such as the chipsets, TCU and antennas. Trade show visitors can discover at MWC 2026 how the company’s comprehensive NTN test solutions can help the automotive industry create the always-connected vehicle.

Solutions for mission-critical communications and spectrum monitoring

Mission-critical communications (MCX) support public safety, first responders and emergency services by providing extremely reliable, low-latency and secure communications even in adverse conditions. Rohde & Schwarz will showcase its integrated solutions for testing devices and mobile networks, facilitating the ongoing migration to 3GPP-compliant broadband mission-critical services.

- The QualiPoc platform will be demonstrated with new capabilities for MCX testing. This smartphone-based solution allows detailed performance assessment of MCX private and group calls, including measurement of 3GPP-defined MCX KPIs. New features include direct MCX app control and the ability to measure quality of service (QoS) and quality of experience (QoE) for public safety communications. The R&S LCM, an autonomous monitoring probe, and the R&S TSMS8, the fastest network scanner, will also be on display, further expanding capabilities for both business and mission-critical networks.

- Rohde & Schwarz will also exhibit a protocol conformance test solution to verify that MCX devices and client software implementations adhere to 3GPP specifications.

- Expanding its spectrum monitoring portfolio, Rohde & Schwarz will launch two new products at MWC Barcelona 2026: These solutions will enable regulatory authorities, network operators and public services in over 100 countries to actively protect the electromagnetic spectrum and address evolving monitoring challenges. The new devices will enhance capabilities in interference hunting and regulatory compliance.

Endpoint security, network visibility and secure network solutions

Robust security solutions deliver seamless and reliable communications experiences. Rohde & Schwarz subsidiaries will also present their innovative solutions supporting the wireless ecosystem.

- The Rohde & Schwarz Networks & Cybersecurity division, comprising the subsidiaries Rohde & Schwarz Cybersecurity and LANCOM Systems, provides endpoint security, secure networks and high-quality cryptography. With products “Engineered in Germany”, they ensure trustworthy, reliable and secure data transfer, specialising in the public, critical infrastructures, defence, health, retail and SME verticals. At MWC 2026, Rohde & Schwarz Cybersecurity will showcase the Layer 2 encryptor R&S SITLine ETH NG and the R&S ComSec solution enabling secure mobile working with sensitive data on iPhones and iPads. LANCOM Systems will present an overview of its Wi-Fi 7 access point portfolio, the latest 5G router models and firewalls.

- As networks become more distributed, encrypted and dynamic, network visibility becomes indispensable. At the Rohde & Schwarz booth, visitors will experience how the ready-to-deploy, DPI-powered R&S Probe Observer delivers deep network visibility, precise real-time traffic analytics and actionable intelligence. Developed by ipoque, a Rohde & Schwarz company, this deep packet inspection (DPI) software probe analyses network traffic at the application level, enabling operators to understand, optimise, and control their networks while supporting faster detection, diagnosis and resolution of network and service issues.

Rohde & Schwarz will showcase its comprehensive portfolio of test and measurement and industry solutions at Mobile World Congress 2026 at Fira Gran Via in Barcelona, in hall 5, booth 5A80. Trade magazine editors and press representatives visiting the event are invited to schedule briefings with their press contact at Rohde & Schwarz.

The post R&S drives connections and innovations at MWC Barcelona 2026 appeared first on ELE Times.

EVs, Software and the Grid: Why the Real EV Challenge Is Infrastructure, Not Vehicles

Speaking at the Auto EV Tech Vision Summit 2025, Mohammadsaeed Mombasawala laid bare a reality the EV industry often skirts around—electric vehicles are evolving fast, but the ecosystem supporting them is dangerously lagging.

Opening his address with a provocative question—“Is EV done and dusted?”—Mombasawala was quick to answer it himself: far from it. Innovation in EVs is accelerating, but the real battleground is no longer the vehicle alone. It is charging infrastructure, grid readiness, and software-defined architectures that will decide the success or failure of the transition.

Charging Anxiety Will Not Be Solved with AC

According to Mombasawala, EV charging anxiety cannot be addressed with slow, AC charging solutions. The industry is inevitably moving towards high-power DC fast charging, with capacities of 50 kW and above becoming the new norm.

But charging speed alone is not enough. He highlighted the emergence of plug-and-play charging, where vehicles authenticate themselves automatically through preloaded scripts and cloud connectivity—eliminating the need for RFID cards or manual authentication. In this model, the vehicle communicates with the charger via the cloud, pre-authorises itself, and begins charging seamlessly, reflecting the deeper convergence between EVs and software-defined vehicles (SDVs).

Vehicle-to-Grid: Opportunity Born from Crisis

One of the most critical trends Mombasawala pointed to was Vehicle-to-Grid (V2G) —using EVs not just as consumers of electricity, but as mobile energy sources capable of feeding power back into the grid.

This, he explained, is not just a technological curiosity, but a necessity born from a looming crisis. “I have done the calculation myself,” he noted. If all vehicles in Delhi were replaced with EVs and charged using 50 kW fast chargers, the grid would require 7,000 MW of additional power just to charge vehicles within 5–8 minutes. No grid today is prepared for that kind of load”.

The implication is stark: while EV adoption is racing ahead, grid infrastructure is nowhere close to ready.

The Grid Is the Real Bottleneck

Mombasawala warned that without serious innovation and investment in electrical infrastructure, a rapid EV transition could destabilise the power system itself.

“If we transition the whole country by 2030 at this pace, the grid will collapse,” he cautioned. The issue is no longer just EV range anxiety—it is national power security. Without infrastructure upgrades, consumers may find themselves unable to charge vehicles and facing power shortages at home.

Electrical engineers, he stressed, have a monumental role ahead—not just in vehicles, but in re-architecting the grid to handle electrified mobility at scale.

Software-Defined Vehicles: Complexity Beneath the Surface

While SDVs are often discussed as sleek, updatable platforms, Mombasawala highlighted the hidden complexity beneath the headlines. Today’s vehicles contain hundreds of ECUs communicating through multiple discrete protocols. The industry urgently needs standardisation, moving towards Ethernet-based architectures to manage growing data and control demands.

He also pointed to emerging semiconductor trends such as chiplets, where optics and semiconductors are packaged together in a single die—underscoring how vehicle electronics are becoming more sophisticated and tightly integrated.

Why the Cloud Is Non-Negotiable

A recurring theme in his address was the absolute necessity of cloud backends for SDVs. With millions of vehicles requiring continuous updates, feature upgrades, and service enhancements, localised solutions are no longer viable. “There is no red reset button,” he reminded the audience. Without cloud-based services, upgrading and managing vehicle software at scale becomes impossible.

AI, Data Centres and the Limits of In-Vehicle Intelligence

One of the most sobering insights came from Mombasawala’s discussion on AI in SDVs. Advanced vehicle functions—braking behaviour, acceleration profiles, comfort tuning—will increasingly rely on AI models trained on massive datasets. But these models cannot be trained inside vehicles.

To put scale into perspective, he cited how companies like Meta use around 600,000 GPUs, while Elon Musk’s Grok reportedly uses 800,000 GPUs in a single data centre. Even with such resources, training models can take weeks. Training safety-critical vehicle systems like braking could require 6–8 weeks per iteration, and continuous retraining as new data arrives.

This underscores a key reality: SDVs are as much a data-centre problem as they are an automotive one.

Beyond the Hype

Mombasawala concluded by grounding expectations around SDVs. While the stories sound exciting, real-world vehicle control systems only stabilise through negative feedback loops, making their design and validation far more complex than popular narratives suggest. The EV transition, he implied, will not be won by flashy announcements alone. It will require deep engineering, infrastructure investment, and a sober understanding of system-level constraints.

As the industry pushes ahead, his message was clear: the future of EVs depends not just on better vehicles, but on grids, software, clouds, and engineers rising together.

The post EVs, Software and the Grid: Why the Real EV Challenge Is Infrastructure, Not Vehicles appeared first on ELE Times.

Silicon Shield: Role of Semiconductors in Modern Warfare

Courtesy: Orbit & Skyline

War has always been part of human history, and true global peace still seems far away. While modern wars may look intense on TV screens, they are generally far less deadly and destructive than what the world has seen in the past. For example, in February 1945, during the bombing of Dresden, Germany, Allied planes dropped unguided bombs aimed at disrupting supply lines. However, the attack triggered a firestorm that killed about 25,000 people and destroyed most of the city, even though it wasn’t a major military target. In contrast, recent conflicts around the world have used far more advanced weapons but resulted in fewer casualties. As military technology evolved from gunpowder to tanks to nuclear weapons, wars became shorter, though still devastating. World War-2 remains the deadliest, with an estimated 70–80 million lives lost.

Today, most battles are fought remotely using advanced weapons that strike deep into enemy territory while keeping one’s own forces out of harm’s way. Modern air battles are fought primarily in the Beyond Visual Range (BVR) domain. The era of vintage fighter planes engaging in close-range dogfights is long gone. Today’s fighter jets are equipped with missiles capable of striking targets nearly 200 km away, far beyond visual sight. To detect and track such distant targets, they rely on advanced AESA (Active Electronically Scanned Array) radars and are supported by airborne AEW&C (Airborne Early Warning and Control) systems that serve as eyes in the sky. These BVR engagements are made possible by sophisticated electronic systems, sensors, and radars, all of which depend on complex semiconductor technologies to enable their advanced capabilities.

The shift in battlefield tactics has reduced civilian harm and damage. This is mainly due to precise, guided weapons powered by semiconductor-based integrated circuits (ICs) that enable smart targeting and real-time tracking. Semiconductors, which revolutionised smartphones and satellites, have also made weapons smarter, faster, and more accurate. These ICs are key to guided missiles, radars, drones, and surveillance systems, processing huge amounts of data quickly for precise targeting, adaptive routes, and secure communication. Such electronics have moved warfare from blunt attacks to focused, strategic strikes.

Rise of Precision Warfare

Warfare has significantly transformed from the close-combat battles of the past to today’s reliance on unmanned systems like missiles and drones. A century ago, weapons such as tanks, rifles, and grenades, primarily mechanical and chemical systems, were designed for maximum destruction, often resulting in heavy casualties with little concern for collateral damage. Modern armies no longer use inaccurate, unguided weapons that can cause accidental damage and political problems, especially with the world watching closely. Such mistakes can harm their goals.

Today, nations prioritise precision and control in military operations through smart, guided weapons. These rely on semiconductor components for navigation, guidance, surveillance, and reconnaissance, enhancing effectiveness and enabling shorter, more focused missions. Precision weapons allow defence forces to deliver targeted strikes with minimal collateral damage, signalling intent without triggering full-scale conflict. This strategy provides several key advantages:

- Targeted Messaging: Precision strikes focus on military assets, deterring adversaries without full-scale war.

- Escalation Control: Pinpoint accuracy neutralises threats efficiently, avoiding prolonged conflicts.

- Reduced Civilian Casualties: Minimal unintended damage preserves legitimacy and prevents escalation.

- Strategic Deterrence: Precise attacks discourage aggression by keeping critical assets vulnerable.

Semiconductor Technologies in Advanced Weapon Systems

Semiconductor technologies are essential in modern weapon systems, enhancing precision, range, guidance, navigation, surveillance, and electronic warfare. Here are some examples of how various semiconductor technologies (Silicon, GaN, MEMS, FPGAs, Sensors, etc.) are used in modern weapon systems:

Electronics warfare and Radar: Electronic warfare (EW) and radar systems, built on different semiconductor technologies, form the key driver of battlefield dominance. Integrated circuits (ICs) fabricated using technologies such as CMOS, GaN, GaAs, and SiGe enable operation across low-frequency digital domains and high-frequency bands—from L-band to millimetre-wave. These technologies support critical functions like signal detection, response generation, and countermeasures, enabling fast RF transmission, real-time processing, and agile control essential for modern EW and radar systems.

At the front end, GaN-based high electron mobility transistors (HEMTs) in monolithic microwave integrated circuits (MMICs) deliver high-power RF amplification with good thermal efficiency, key for long-range radar and jamming. These are paired with low-noise amplifiers (LNAs), often made using SiGe BiCMOS or pHEMT processes, to ensure high sensitivity and signal integrity. RF switches and phase shifters, built on SOI or RF MEMS, enable dynamic beam steering in AESA radars, allowing electronic scanning without moving parts.

High-speed analogue-to-digital (ADC) and digital-to-analogue converters (DAC), typically CMOS or bipolar, digitise wideband signals for baseband processing. Radiation-hardened FPGAs and DSP cores handle FFTs, beamforming, and adaptive filtering. PLL synthesisers and VCOs, using SiGe or advanced CMOS, provide low-jitter, frequency-agile clocking critical for threat detection and deception. Together, these semiconductor components form the backbone of radar and EW systems, delivering precision, speed, and resilience in modern electromagnetic warfare.

Guidance and Navigation: In modern missiles and drones, guidance and navigation rely heavily on semiconductor-based components that ensure precision and reliability even in challenging environments. At the core of these systems are inertial navigation systems (INS), which use MEMS accelerometers and gyroscopes to measure motion and orientation without external signals, crucial for operation in GPS-denied conditions. These are often integrated into compact IMUs (Inertial Measurement Units) that fuse data in real time to calculate position and velocity. When GPS signals are available, GNSS receiver chips provide absolute positioning by processing satellite signals, with advanced modules incorporating anti-jamming and anti-spoofing features to maintain accuracy under electronic warfare. Complementing these are digital signal processors (DSPs) and microcontrollers (MCUs), which handle sensor data processing, flight control algorithms, and real-time decision-making. These systems typically utilise semiconductor technologies such as CMOS for GNSS and signal processing ICs, MEMS processes for inertial sensors, and advanced packaging to integrate these functions in compact, rugged modules. Together, these semiconductor components enable autonomous, accurate, and adaptive navigation critical to modern missile and UAV operations.

Explore how we at Orbit & Skyline help global FABs and system integrators by supporting GaN process optimisation, enabling better RF and radar performance. Read our related post on GaN in semiconductors here.

Surveillance and Reconnaissance: Surveillance and reconnaissance systems today use many types of semiconductor technologies for sensing, data processing, and secure communication. CMOS and CCD image sensors are used in electro-optical and night vision equipment. For thermal and FLIR imaging, infrared detectors made from materials like InGaAs, HgCdTe, and InSb are combined with special Readout ICs (ROICs). In radar systems, GaN HEMT chips are used in power amplifiers to send signals efficiently, while SiGe or pHEMT-based LNAs help in receiving weak signals clearly.

High-speed ADCs and DACs made using CMOS or BiCMOS are used to convert radar signals, including those from Synthetic Aperture Radar (SAR), into digital form for further analysis. SAR provides clear images even at night or in bad weather. Systems use FPGAs, SoCs, and AI chips, often made with advanced FinFET technology, to process this data quickly. AI edge ICs make fast, low-power decisions on the spot. DRAM and SRAM store sensor data, while secure MCUs and RF transceivers enable encrypted, high-speed communication. Together, these semiconductor parts help satellites, aircraft, and drones deliver accurate, real-time battlefield information.

Tiny Chips, Big Defence

Semiconductors also serve as a shield for nations, not just for those using advanced weapons, but especially for those that develop them. While many countries can buy defence systems, only a few can design and manufacture the complex semiconductor ICs inside them. These ICs are classified as commercial, military, or space-grade, with increasing reliability and performance demands. Military systems often operate in extreme conditions from -40°C to 150°C, requiring robust, fail-proof chips. Access to such military-grade ICs is restricted by various regulations and export controls. Hence, having a domestic, secure semiconductor manufacturing ecosystem is critical. Without it, countries risk supply-chain disruptions during strategic needs. These ICs function as sensory organs; eyes, ears, and brains of missiles, drones, and UAVs, and are essential for mission success.

A nation with precision-strike capabilities can deter adversaries from engaging in prolonged conflict, something seen very clearly in recent global conflicts. These semiconductor-driven systems form a “Silicon Shield,” reducing the impact of warfare on civilians and infrastructure. Compared to the devastation of the World Wars, recent conflicts have seen far less destruction, underlining the value of precision weapons in enabling restrained and strategic military actions.

The post Silicon Shield: Role of Semiconductors in Modern Warfare appeared first on ELE Times.

Silicon Photonics: The Lightspeed Revolution That Will Transform AI Computing

Courtesy: Lam Research

Lam Research is setting the agenda for the wafer fabrication equipment industry’s approach to a silicon photonics revolution, driving the breakthroughs in Speciality Technologies that will enable sustainable AI scaling through precision optical manufacturing.

The artificial intelligence boom has created an energy crisis that threatens to consume more electricity than entire nations. As data centres race to keep pace with AI’s insatiable appetite for computational power, technology leaders like Lam are shaping a fundamental shift that could redefine how we think about high-performance computing. One solution lies in replacing the electrical interconnects that have powered computing for decades with something far more efficient: light.

AI’s Energy Crisis: Why Power Demand Is Surging in Data Centres

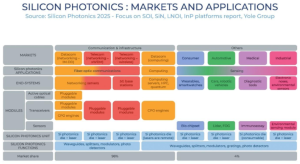

Goldman Sachs projects a 160% increase in data centre power demand by 2030, reaching 945 terawatt-hours annually — equivalent to Japan’s entire electricity consumption.

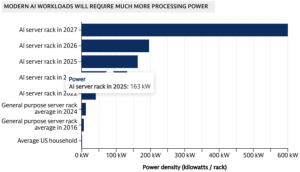

The problem runs deeper than software inefficiency. According to Bloomberg, AI training facilities house hundreds of thousands of NVIDIA H100 chips, each drawing 700 watts, nearly eight times the power consumption of a large TV. Combined with cooling systems, some hyperscale facilities now require as much power as 30,000 homes, driving tech companies to seriously consider dedicated nuclear plants.

Source: Nvidia. Apart from average estimates, power data for racks are based on Nvidia specifications. 2025 and later are estimates. AI server racks refer to GPU racks. General-purpose racks refer to CPUs.

Source: Nvidia. Apart from average estimates, power data for racks are based on Nvidia specifications. 2025 and later are estimates. AI server racks refer to GPU racks. General-purpose racks refer to CPUs.

The Paradigm Shift

Meeting this challenge requires a fundamental change in how chips are designed and connected. Silicon photonics—using light to transmit data—has the potential to provide dramatic improvements in speed and efficiency over traditional electrical interconnects. Precision optical manufacturing makes this shift possible, enabling scalable processes that can support the next era of energy-efficient, high-performance computing.

Silicon photonics represents a fundamental reimagining of how data moves within computing systems. Instead of pushing electrons through copper wires, this technology uses photons—particles of light—to carry information through silicon waveguides that function like nanoscale fibre optic cables, integrated directly onto chips.

The efficiency gains are dramatic. Optical interconnects consume just 0.05 to 0.2 picojoules per bit of data transmitted, compared to the much higher energy requirements of electrical interconnects over similar distances. As transmission distances increase, even within a single package, the energy advantage of photonics becomes overwhelming.

TSMC has published several research papers on silicon photonics since late 2023. The company has announced public partnerships with NVIDIA to integrate optical interconnect architectures into next-generation AI computing products. Lam is leading the industry’s approach to the transition to silicon photonics. As a technology leader with deep expertise in precision manufacturing, we are defining the roadmap for silicon photonics production, working closely with leading foundries and fabless companies to address the unique challenges presented by optical interconnects.

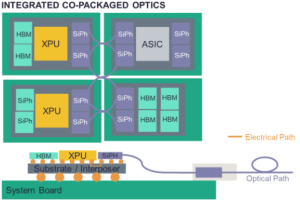

According to Yole Group, the market for silicon photonics is expected to grow from $95 million in 2023 to more than $863 million in 2029, with a 45% annual growth rate that reflects the technology’s expected rapid commercial adoption.

The Limits of Copper: Why Traditional Interconnects Can’t Scale With AI

At the heart of this energy crisis lies a fundamental bottleneck that has been building for years. While computing performance has advanced at breakneck speed, the infrastructure connecting these powerful processors has not kept pace. Hardware floating-point operations (FLOPS) have improved 60,000-fold over the past two decades, but DRAM bandwidth has increased only 100-fold, and interconnect bandwidth just 30-fold over the same period.

This creates what engineers call the “memory wall,” a constraint where data cannot move between processors and memory fast enough to fully use the available computing power. In AI applications, where massive datasets must flow seamlessly between graphics processors, high-bandwidth memory, and other components, these interconnect limitations become critical performance bottlenecks.

The solution that worked for previous generations—simply shrinking copper interconnects and packing them more densely—is reaching physical limits. As these copper traces become smaller and more numerous, they consume more power, generate more heat, and introduce signal integrity issues that become increasingly difficult to manage. Each voltage conversion in a data centre’s power delivery system introduces inefficiencies, and copper interconnects compound these losses throughout the system.

Modern AI architectures require what engineers call “high access speeds within the stack.” Chips become thinner, interconnects evolve from through-silicon vias (TSVs) to hybrid bonding, and memory modules must connect directly to graphics processors at unprecedented speeds. But when that high-speed memory connection has to traverse copper tracks on a circuit board to reach another processor, much of the bandwidth advantage disappears.

Silicon Photonics Meets AI: Co-Packaged Optics for Next-Gen Performance

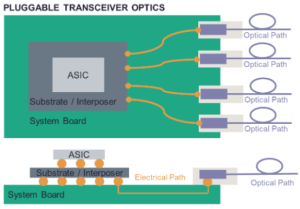

Silicon photonics is not entirely new; it has powered telecommunications networks for years through pluggable transceivers that connect data centre racks. These proven systems use silicon photonic dies combined with separate lasers and micro-lens technologies packaged into modules that can be easily replaced if they fail.

But AI’s demands are pushing photonics into uncharted territory. Instead of simply connecting separate systems, the technology must now integrate directly with processors, memory, and other components in what engineers call “co-packaged optics.” This approach promises to bring optical interconnects closer to the actual computation, maximising bandwidth while minimising energy consumption.

The challenge is reliability. While pluggable transceivers can be easily swapped out if they fail, co-packaged optical systems integrate directly with expensive graphics processors and high-bandwidth memory, making them a more reliable option. If an optical component fails in such a system, the repair becomes exponentially more complex and costly. Early implementations from major chip developers are still in pilot phases, carefully assessing long-term reliability before full-scale deployment.

Accelerating Adoption: How Industry Timelines Are Moving Faster Than Expected

Industry roadmaps that once projected capabilities for 2035 are already being met by leading manufacturers. The combination of urgent market need, massive investment, and three decades of accumulated photonics research has created what amounts to a perfect storm for commercialisation.

The implications extend far beyond data centres. As optical interconnects become more cost-effective and established, they have the potential to revolutionise everything from autonomous vehicles to edge computing devices. The same technology that enables sustainable AI scaling could ultimately transform how electronic systems communicate across virtually every application.

Source: Yole Group

Source: Yole Group

The Future of Computing Is Optical Interconnects for Sustainable AI Growth

The question is how quickly it can be implemented and scaled. With leading manufacturers already investing billions and pilot systems entering data centres, the light-speed future of computing is no longer a distant possibility. Companies like Lam, through our customer-centric approach and advanced manufacturing solutions, enable this transformation by providing the precision tools that make commercial silicon photonics possible.

Silicon photonics represents a fundamental technology shift that could determine which companies lead the next phase of the digital revolution. Just as the introduction of copper interconnects enabled previous generations of performance scaling, optical interconnects have the potential to break through the barriers that threaten to constrain AI development.

For an industry grappling with the sustainability challenges of exponential AI growth, silicon photonics offers a path forward that doesn’t require choosing between performance and environmental responsibility. By replacing electrical inefficiency with optical precision, this technology could enable the continued advancement of AI while dramatically reducing its environmental footprint.

The revolution is just beginning, but one thing is clear: the future of high-performance computing is increasingly bright, and Lam is at the centre of it.

The post Silicon Photonics: The Lightspeed Revolution That Will Transform AI Computing appeared first on ELE Times.

AI-Augmented Test Automation at Enterprise Scale

Courtesy: Keysight Technologies

Enterprise test automation does not break because teams lack tools.

It breaks when browser-level automation is asked to validate systems far beyond the browser.

At enterprise scale, software quality depends on the ability to test entire user journeys across the full technology stack, from web and APIs to desktop, packaged applications, and highly graphical systems, without fragmenting tooling or multiplying maintenance effort.

This distinction explains why Keysight Technologies was positioned as a Leader in the 2025 Gartner Magic Quadrant for AI-Augmented Software Testing Tools, recognised for both Ability to Execute and Completeness of Vision.

Gartner defines AI-augmented software testing tools as solutions that enable increasingly autonomous, context-aware testing across the full software development lifecycle. In practice, that definition only matters if it holds up in complex, regulated enterprises.

One notable deployment is American Electric Power (AEP).

Why Browser-Only Automation Hits a Ceiling at Enterprise Scale

Most enterprises already use Selenium successfully for its intended purpose.

Browser automation works well when:

- The system under test is web-based

- Interactions are DOM-driven

- The scope is limited to UI flows

Problems emerge when enterprises attempt to extend browser-centric automation to validate full end-to-end systems that include:

- Highly graphical or non-DOM interfaces

- Desktop or packaged applications

- Field mobility tools and operational systems

- Integrated workflows spanning UI, APIs, and backend logic

At that point, teams are forced to stitch together multiple tools, frameworks, and scripts. The result is not resilience-it is complexity, fragmentation, and rising maintenance cost.

The issue is not Selenium.

The issue is using a single-layer tool to validate multi-layer systems.

What Gartner Means by AI-Augmented Software Testing

According to Gartner, the market is moving toward platforms that combine and extend automation capabilities, rather than replacing them.

Modern AI-augmented testing platforms are expected to:

- Orchestrate testing across UI, API, and visual layers

- Combine browser automation with image-based and model-based techniques

- Abstract complexity so teams test behaviour, not implementation details

- Reduce maintenance through models, self-healing, and intelligent exploration

- Scale across cloud, on-premises, and air-gapped environments

This is not an argument against existing tools.

It is recognition that enterprise testing requires a unifying layer above them.

Enterprise Reality: Complexity, Scale, and Risk at AEP

AEP operates one of the largest electricity transmission networks in the United States, serving 5.5 million customers across 11 states. Its software landscape includes:

- Customer-facing web applications

- Financial and billing systems

- Highly graphical, map-based field mobility applications

Before modernising its testing approach, AEP faced a common enterprise constraint:

- Browser automation covered part of the estate

- Critical operational systems remained difficult to validate

- Manual testing persisted in high-risk workflows

- Defects continued to escape into production

The challenge was not adopting another tool.

It was testing the full system end-to-end, consistently, and at scale.

How AEP Scaled Full-Stack, AI-Driven Testing

AEP began where confidence was lowest.

Rather than extending browser automation incrementally, the team selected a highly graphical, map-based field mobility application-a system that sat outside the reach of traditional browser-only approaches.

Using AI-driven, model-based testing, the application was automated end-to-end, validating behaviour across visual interfaces, workflows, and integrated systems.

That success changed internal perception.

As AEP’s Lead Automation Developer and Architect explained, proving that even their most complex system could be tested reliably shifted the conversation from “Can we automate this?” to “How broadly can we apply this approach?”

The key was not replacing existing automation, but extending it into a unified, full-stack testing strategy.

Measured Results: Time, Defects, and Revenue Impact

Once deployed across teams, the outcomes were measurable:

- 75% reduction in test execution time

- 65% reduction in development cycle time

- 82 defects identified and fixed before production

- 1,400+ automated scenarios executed

- 925,000 exploratory testing scenarios discovered using AI

- 55 applications tested across the organisation

- $1.2 million in annual savings through reduced rework and maintenance

In one instance, AI-driven exploratory testing uncovered 17 critical financial defects that had escaped prior to validation approaches. Resolving those issues resulted in a $170,000 revenue increase within 30 days.

This is not broader coverage for its own sake.

It is risk reduction and business impact.

Empowering Teams Beyond Test Engineers