Новини світу мікро- та наноелектроніки

Advantest announces KGD test cell for power semiconductors

What’s LVGL, and how it works in embedded designs

Light and Versatile Graphics Library (LVGL) is steadily making inroads in the graphics realm by efficiently facilitating graphical user interface (GUI) designs in small, resource-constrained, and battery-powered devices such as wearables, e-bikes, navigation systems, instrument clusters, medical gadgets, and more.

Graphics IP suppliers are increasingly partnering with LVGL to optimize GPU performance and expand graphic processing capabilities for a wide range of embedded applications. But who’s LVGL? It’s the company behind the free and open-source graphics library for embedded systems; it helps developers create GUIs for microcontroller units (MCUs), microprocessor units (MPUs), and display processors.

Figure 1 LVGL has no external dependencies, which makes its porting incredibly simple.

LVGL, written in C, allows embedded developers to create modern and visually appealing user interfaces in embedded applications. It works with various processors and operating systems and enables developers to keep code size and memory usage to a minimum. It can be used with any RTOS and bare-metal setup and quickly adapts to unique project needs.

What IP suppliers do is integrate their GPU solutions into LVGL’s graphics ecosystem; so, developers can build sleek, responsive interfaces without compromising on performance or power efficiency. The integration of LVGL into GPUs is transforming the embedded UI landscape in resource-constrained devices like MCUs.

Design case studies

Take the case of Think Silicon, a supplier of ultra-low-power GPU IPs for embedded systems and an Applied Materials company. It’s teaming up with LVGL to develop high-performance, low-power graphics libraries for MCUs. As a result, the software development kit for its NEMA GPUs will be able to accelerate LVGL’s graphics library by up to 5x compared to software-only rendering.

Figure 2 Think Silicon has combined LVGL’s lightweight open-source graphics library with its NEMA GPU-Series.

VeriSilicon, a Shanghai, China-based supplier of embedded GPUs, has also partnered with LVGL to facilitate seamless integration of 2D, 2.5D, and 3D content in embedded applications. In conjunction with LVGL’s graphics library, VeriSilicon aims to advance 3D rendering capabilities in the GUI designs.

Actions Technology, a Zhuhai, China-based firm developing chips for AIoT applications, has incorporated VeriSilicon’s GPU into its smartwatch system-on-chip (SoC) design. Tim Zhang, GM of Actions Technology’s Wearable and Sensing Business Unit, acknowledges the importance of LVGL’s graphics technology contribution in delivering rich 3D graphics in its smartwatch SoC.

![]()

Figure 3 Actions Technology has incorporated VeriSilicon’s LVGL-enabled GPU in its smartwatch SoC.

Embedded GPUs are now serving a wide range of applications, from wearables and infotainment to micro-mobility and AIoT. Here, the integration of LVGL in GPUs enables users to create visually appealing UIs across a wide variety of hardware platforms.

Related Content

- Re-imagining Imagination Technologies

- GUI Development: Embedding Graphics

- CAST launches graphics acceleration IP cores

- Imagination outstrips all other GPU IP suppliers

- Two-digit nanosecond latency CXL IP addresses GPU memory expansion

The post What’s LVGL, and how it works in embedded designs appeared first on EDN.

Coherent, SkyWater and X-Fab all agree preliminary terms for US CHIPS Act funding

Securing EMI Resilience with Software-Driven Smart Electronic Fuses

By: Giusy Gambino, Sebastiano Grasso, and Filippo Scrimizzi STMicroelectronics

Integrated smart power devices are becoming increasingly crucial in automotive systems due to their ability to combine power management with advanced diagnostic and protection features. When a fault occurs, these features enable the connected control unit to react promptly and effectively, protecting both the vehicle and its occupants. Smart power devices are often responsible for critical tasks within a vehicle and are gradually replacing conventional components such as fuses and relays, and switches.

Electronic fuses, a prominent type of smart power device, are particularly remarkable for their reliability under harsh environmental conditions, including high operating temperatures and mechanical stress. Additionally, they have to withstand various forms of electromagnetic interference (EMI) that can affect their normal functionality. This is especially crucial in safety-critical applications like airbag control modules or Anti-lock Braking Systems (ABS), where precise operation is vital to avoid hazardous conditions and ensure functional safety.

Testing Procedure for EMI

To ensure the correct operation of electronic products, they need to be tested for electromagnetic emissions that may negatively affect nearby equipment. These emissions fall into two categories:

- Conducted noise, which travels through supply or data/control cables.

- Radiated noise, which propagates through free space.

CISPR 25 is the standard developed for vehicles and boats to protect on-board receivers from such emissions. It outlines both limits and methods of measurement for equipment on board.

Conducted emission limits typically cover a frequency range of 150 kHz to 200 MHz, although this range may extend down to 9 kHz. The limits are defined in terms of average, quasi-peak and peak values.

Peak detection retains the peak value of each harmonic in an emitted signal, indicating the worst-case scenario. Average detection provides the average amplitude of each signal component across its period. Quasi-peak detection weighs each component based on its repetition rate: the faster the repetition rate, the higher the weight given to that component.

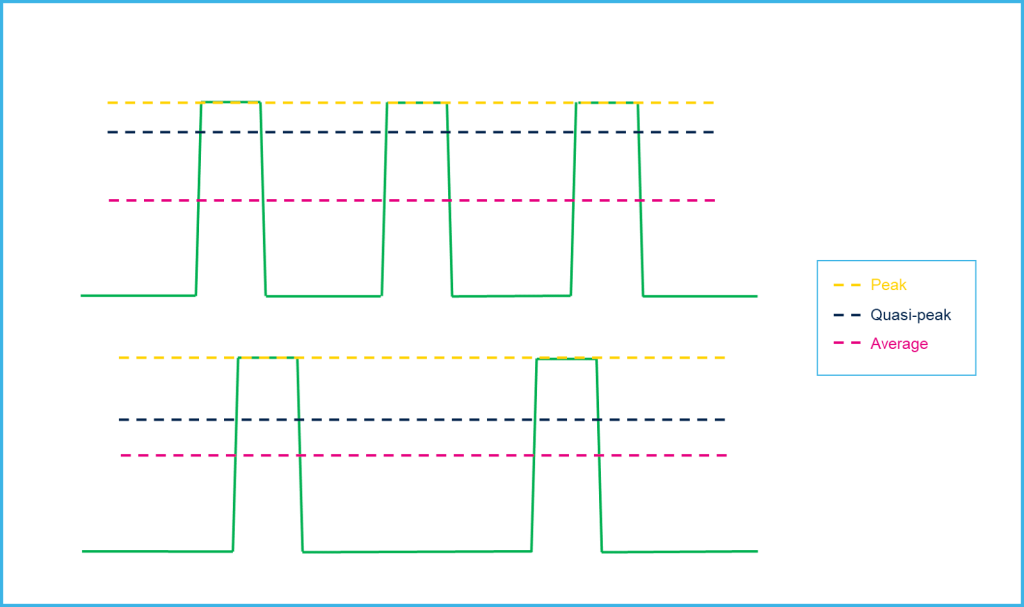

The output response of the three detectors to two similar pulsed signals is shown in with the top one having a higher repetition rate.

Output response of average, peak and quasi-peak detectors.

Output response of average, peak and quasi-peak detectors.

The above picture shows that the quasi-peak detector has a higher voltage output when the event occurs more frequently.

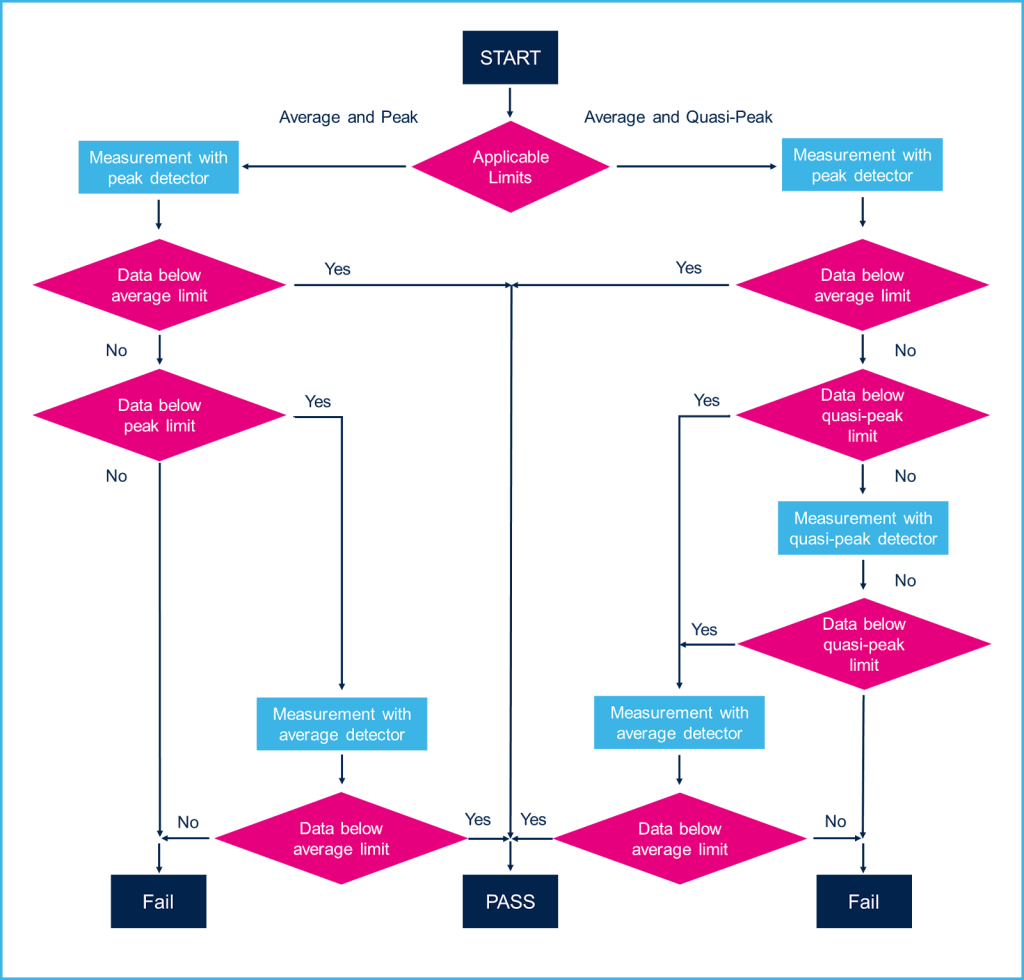

To determine the conformance of the Equipment Under Test (EUT) with the specified CISPR 25 limits, the following guidelines should be followed (Fig. 2).

Guidelines for conformance to CISPR 25 limits.

Guidelines for conformance to CISPR 25 limits.

In all cases, the EUT should conform to the average limit. For frequencies where both peak and quasi-peak limits are defined, the EUT should conform to either the peak or the quasi-peak limits, as specified in the test plan. For frequencies where only peak limits are defined, the EUT must conform to the peak limit.

For CISPR 25, emission limits are divided into Class 1, 2, 3, 4, and 5 products, specifying how to measure the noise using peak, quasi-peak, and average detection methods (Tabs. 1 and 2).

| Service/Band | Frequency MHz | Levels in dB (µV) | ||||

| Class 1 | Class 2 | Class 3 | Class 4 | Class 5 | ||

| Peak | Peak | Peak | Peak | Peak | ||

| BROADCAST | ||||||

| LW | 0.15 – 0.30 | 110 | 100 | 90 | 80 | 70 |

| MW | 0.53 – 1.8 | 86 | 78 | 70 | 62 | 54 |

| SW | 5.9 – 6.2 | 77 | 71 | 65 | 59 | 53 |

| FM | 76 – 108 | 62 | 56 | 50 | 44 | 38 |

| TV Band I | 41 – 88 | 58 | 52 | 46 | 40 | 34 |

| MOBILE SERVICES | ||||||

| CB | 26 – 28 | 68 | 62 | 56 | 50 | 44 |

| VHF | 30 – 54 | 68 | 62 | 56 | 50 | 44 |

| VHF | 68 – 87 | 62 | 56 | 50 | 44 | 38 |

| Service/Band | Frequency MHz | Levels in dB (µV) | ||||

| Class 1 | Class 2 | Class 3 | Class 4 | Class 5 | ||

| Average | Average | Average | Average | Average | ||

| BROADCAST | ||||||

| LW | 0.15 – 0.30 | 90 | 80 | 70 | 60 | 50 |

| MW | 0.53 – 1.8 | 66 | 58 | 50 | 42 | 34 |

| SW | 5.9 – 6.2 | 57 | 51 | 45 | 39 | 33 |

| FM | 76 – 108 | 42 | 36 | 30 | 24 | 18 |

| TV Band I | 41 – 88 | 48 | 42 | 36 | 30 | 24 |

| MOBILE SERVICES | ||||||

| CB | 26 – 28 | 48 | 42 | 36 | 30 | 24 |

| VHF | 30 – 54 | 48 | 42 | 36 | 30 | 24 |

| VHF | 68 – 87 | 42 | 36 | 30 | 24 | 18 |

LW stands for Long Waves

MW for Medium Waves

SW for Short Waves

TV Band I for TeleVision broadcast Band 1

CB for Citizens Band

VHF for Very High Frequencies.

The testing procedure ensures that both peak and average measurements are checked for compliance with Class 5 standards. If any measurements fail, the EUT is evaluated against a lower class.

Conducted Electromagnetic EmissionThe conducted Electro-Magnetic Emission (EME) is the noise current generated by the EUT that propagates through the harness to other components/systems or power grid. This noise current can be measured using either the voltage method or the current method.

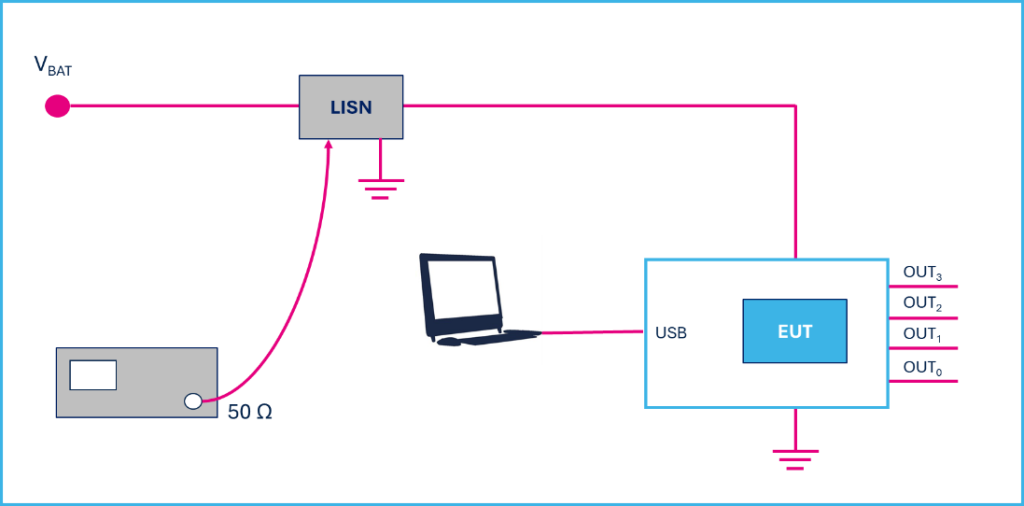

The voltage method is carried out with the measurement setup displayed in Fig. 3.

Fig. 3 Measurement setup for voltage method conducted EME

Fig. 3 Measurement setup for voltage method conducted EME

where:

LISN stands for Line Impedance Stabilization Network.

Experimental ResultsThe experimental data have been collected for the STi2Fuse product VNF9Q20F, which is a 4-channel monolithic electronic fuse fully programmable through serial peripheral interface (SPI). This device embeds sophisticated digital protection and diagnostic mechanisms, which include a unique i2t feature for harness protection.

The following testing conditions have been considered:

- VBAT = 13 V

- TAMB = Room temperature

- All channel in Fail Safe mode (off)

- Channel 2 driven by direct input with DC (5 V) and PWM (100 Hz, 50% duty cycle) loaded with 27 W + 5 W bulbs.

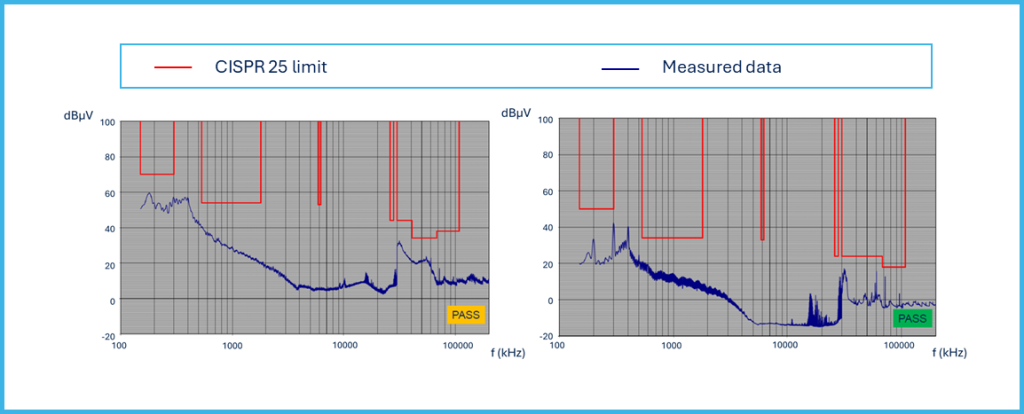

When channel 2 is turned on and it is driven by direct input with 5 V DC voltage and a PWM signal with 100 Hz frequency and 50% duty cycle, the noise detector measurements for peak and average methods are shown in Fig. 5 and compared with CISPR 25 limit relevant to class 5.

Fig. 5 Comparison between noise measurement with channel 2 turned-on and CISPR25 limit for peak detection (on the left side) and average detection (on the right side).

Fig. 5 Comparison between noise measurement with channel 2 turned-on and CISPR25 limit for peak detection (on the left side) and average detection (on the right side).

The electronic fuse VNF9Q20F is able to pass all the limits imposed by CISPR 25 for both peak and average limits in class 5.

ConclusionsThe EMI behavior of a smart electronic STi2Fuse device has been investigated, demonstrating compliance with the CISPR 25 standard under class 5 specifications.

The STi2Fuse products are critical components in modern vehicles, providing overcurrent protection and ensuring the safe operation of electrical circuits. Compliance with the CISPR 25 standard, particularly under class 5 specifications, is essential for these devices to ensure they do not interfere with other components and equipment within the vehicle.

References[1] VNF9Q20F, 4 channel high-side driver with STi2Fuse protection for automotive power distribution applications.

[2] CISPR 25:2021 International Standard, Vehicles, boats and internal combustion engines – Radio disturbance characteristics – Limits and methods of measurement for the protection of on-board receivers, Edition 5.0, Dec. 2021.

[3] R. Letor, R. Crisafulli, Smart Power devices and new electronic fuses compliant with new E/E architecture for autonomous driving, AEIT International Conference of Electrical and Electronic Technologies for Automotive (AEIT AUTOMOTIVE), 02-04 July 2019

The post Securing EMI Resilience with Software-Driven Smart Electronic Fuses appeared first on ELE Times.

Pleasant surprise finding a raspberry pi while hacking a random device

| Still need to find the voltage this thing runs on, I think it's at least 30v [link] [comments] |

Just finished writing automatically updated KiCad library with all the basic/prefered JLCPCB parts and 3D models - thought I'd share!

| submitted by /u/CD_FER [link] [comments] |

Found a bunch of Radio Shack parts from 40+ years ago that I never used

| submitted by /u/Rocky_Mountain_Way [link] [comments] |

Nixie tubes are so unique and beautiful. I'm almost 5 years into running this clock and my goal is 20 on the original tubes.

| submitted by /u/lxl_Arctic_lxl [link] [comments] |

Weekly discussion, complaint, and rant thread

Open to anything, including discussions, complaints, and rants.

Sub rules do not apply, so don't bother reporting incivility, off-topic, or spam.

Reddit-wide rules do apply.

To see the newest posts, sort the comments by "new" (instead of "best" or "top").

[link] [comments]

A mono amplifier for a school project

| submitted by /u/DrawingDoggo [link] [comments] |

Navitas showcasing GaN and SiC technologies at CES 2025

Beauty is in the eye of the beholder

Take a close look at this power audio amplifier that dates back to 1961 (Figure 1). This image is a still extracted from a YouTube video by a group called “The Spotnicks” playing their version of “Ghost Riders In The Sky”. (Try not to laugh too hard when you see them in their space suits.)

Figure 1: Image of an amplifier featured in a YouTube video with eight 6L6GB beam power tetrode tubes.

Sporting eight 6L6GB beam power tetrode tubes, this thing was clearly pushing the limits of the state-of-the-art at that time but notice the gorgeous appearance, the emphasis on gold coloration and the mirror-like reflection. This amplifier was meant as a work of art to be seen, particularly on stage, not just listened to.

After I looked on in dazed admiration for a while, I noticed something. One of the seven-pin-miniature tube shields on the left is not gold colored. Somewhere along the line I suspect, one of those tubes had to be replaced and its tube shield got lost somehow. A replacement shield was used instead, which left the amplifier with something of a beauty mark.

When you play that video, you’ll see that more than one of these amplifiers was in service during the performance.

Enjoy!

John Dunn is an electronics consultant, and a graduate of The Polytechnic Institute of Brooklyn (BSEE) and of New York University (MSEE).

Related Content

- Vacuum tube negative resistance

- Friday Fun: Test Those Tubes

- Electronics of our youth

- Self-contained TV receiver uses 24 transistors

- Remembrance of chips past

- Gone but Not Forgotten

The post Beauty is in the eye of the beholder appeared first on EDN.

VisIC and AVL partner on GaN inverters for EVs

Securing AI Models: Safeguarding the Future of Innovation

As artificial intelligence (AI) adoption accelerates, the urgency to protect AI ecosystems grows proportionally. In 2025, the world will witness a concentrated push to address critical concerns surrounding the security of Large Language Models (LLMs) and other advanced AI systems. These efforts will focus on safeguarding data confidentiality, ensuring integrity, and upholding privacy, which are essential to sustaining innovation and trust in AI technologies.

The Rise of AI and Its Risks

AI technologies, particularly LLMs, have revolutionized industries with their ability to process vast amounts of data, generate human-like text, and make intelligent predictions. However, their immense potential also introduces vulnerabilities. Cyber threats targeting AI systems are becoming more sophisticated, with adversaries exploiting weaknesses to steal intellectual property, manipulate outputs, or compromise sensitive data. For instance, adversarial attacks can subtly manipulate input data to mislead AI models, while data poisoning can corrupt training datasets, leading to flawed or biased predictions.

Additionally, as LLMs like ChatGPT or GPT-4 are deployed widely, the potential for misuse grows. These models, if not adequately safeguarded, could be manipulated to generate harmful content, leak proprietary information, or amplify misinformation. Thus, securing AI systems is no longer an afterthought; it is a fundamental requirement for ethical and reliable AI deployment.

Data Confidentiality and Privacy

Data confidentiality is at the heart of AI security. Training LLMs often requires enormous datasets, some of which may include sensitive or proprietary information. Ensuring that this data remains secure and private is a complex but crucial challenge. Robust encryption protocols, federated learning, and differential privacy techniques are emerging as key solutions. These methods enable AI systems to learn from data without exposing individual records, thereby reducing the risk of data breaches.

Federated learning, for example, allows models to train across decentralized devices without transferring data to a central repository. This approach not only enhances privacy but also minimizes attack vectors, as no single point of failure exists. Meanwhile, differential privacy adds statistical noise to datasets, protecting individual data points while preserving the overall utility of the model.

Ensuring Model Integrity

Model integrity is another critical focus area. Attackers may attempt to tamper with the parameters of an AI model to alter its behavior or introduce biases. To counteract this, organizations are turning to techniques like robust model architectures, regular audits, and tamper-evident mechanisms. Blockchain technology, for instance, is being explored to maintain immutable records of model versions, ensuring any unauthorized modifications are detectable.

Furthermore, explainable AI (XAI) is gaining traction as a means to enhance model transparency and trust. By making AI decision-making processes interpretable, XAI can help identify anomalies or unexpected behavior that might indicate tampering or misuse.

A Multi-Stakeholder Approach

Securing AI models requires collaboration across industries, governments, and academia. Policymakers must establish clear guidelines for AI governance and data protection, while researchers and developers work on advancing technical safeguards. Companies deploying AI systems must prioritize regular security assessments and adopt best practices for risk management.

Public awareness also plays a vital role in fostering responsible AI use. Educating users about potential threats and mitigation strategies can help minimize risks associated with AI adoption.

Conclusion

As we move into 2025, securing AI ecosystems will be a defining challenge for the tech industry. By addressing issues of confidentiality, integrity, and privacy, stakeholders can build robust AI systems that not only drive innovation but also inspire trust. The future of AI depends not only on its capabilities but also on the strength of the safeguards we put in place today.

The post Securing AI Models: Safeguarding the Future of Innovation appeared first on ELE Times.

Delta to Provide Made-in-India High-efficiency Rectifiers to ThunderPlus for its Fast Chargers for Low Voltage 2W and 3W EVs

Delta Electronics India has announced the signing of an MOU with ThunderPlus, a leading two-wheeler (2W) and three-wheeler (3W) electric vehicle (EV) charging solutions provider. Under the aforementioned agreement, Delta will provide advanced high-efficiency 4kW rectifier modules, made at its new large manufacturing site in Krishnagiri, Tamil Nadu, to support ThunderPlus’ fast chargers for the low voltage market, specifically designed for 2W and 3W EVs.

Mr. Niranjan Nayak, Managing Director, Delta Electronics India, said, “Delta’s corporate mission is ‘To provide innovative, clean, and energy-efficient solutions for a better tomorrow’. Hence, our collaboration with Thunder Plus underscores Delta’s goal to contribute to India’s EV transition by delivering cutting-edge, locally manufactured solutions. Our fast-growing R&D capabilities in Bengaluru and manufacturing in Krishnagiri have been instrumental to this milestone.”

Ms. Manjula Girish, Business Head – EV Charging Infrastructure, Delta Electronics India, “Our 4kW rectifiers are a testament to Delta’s commitment to innovation and sustainability. Engineered with high energy efficiency of up to 93% and manufactured at our state-of-the-art Krishnagiri facility, these rectifiers exemplify the synergy between cutting-edge technology and localized manufacturing. ThunderPlus’ decision to integrate our rectifiers into their EV chargers highlights the trust in Delta’s capability to deliver superior performance and value. This partnership is a significant step toward enabling robust and energy-efficient charging solutions for India’s growing EV ecosystem.”

Mr. Rajeev YSR, CEO – Thunder Plus, highlighted, “This collaboration with Delta Electronics brings world-class technology to India’s low-voltage EV charging market. Our customizable chargers cater to the unique requirements of OEMs and end-users, ensuring efficient and seamless integration with their operations. Together, we are building the foundation for a robust and sustainable EV charging infrastructure in India.”

This endeavor brings together Delta’s technological expertise in power solutions and ThunderPlus’ market leadership in EV charging systems. The chargers, developed with Delta’s advanced 4kW rectifier modules featuring energy efficiency up to 93%, are customizable and designed to meet India’s diverse requirements, making them a game-changer for the local EV market.

India’s EV sector is witnessing unprecedented growth, with the adoption of 2W and 3W EVs driving much of the demand. This Make in India chargers are tailored to the low-voltage segment under this partnership we aim to reduce charging downtime, alleviate range anxiety, and boost the productivity of EV users.

Thunder Plus, a leading provider of EV charging solutions in India, has already on-boarded OEMs in the 2W and 3W segments. These chargers are equipped with advanced co-branding opportunities, reflecting the synergy between both organizations. The partnership ensures that the chargers are developed to meet global standards while being tailored to the Indian market.

The post Delta to Provide Made-in-India High-efficiency Rectifiers to ThunderPlus for its Fast Chargers for Low Voltage 2W and 3W EVs appeared first on ELE Times.

Quantum sensors used to move prosthetics

Digitizers by Spectrum Instrumentation used to detect extremely small and fast nerve signals

For controlling prosthetics, the body’s signals must be detected to move the artificial limb. At the moment, implanting electrodes is the most common technique but this is invasive and electrodes can deteriorate or move position. A completely different approach is now developed by the multidisciplinary consortium QHMI in Stuttgart, Germany, using quantum sensors to detect the incredibly small and fast nerve signals. The ultrasensitive quantum magnetometers will be carried outside the body measuring the neural signals through the skin. At this stage, the scientists are using Spectrum Instrumentation’s ultrafast digitizers (M5i.3357) and Arbitrary Waveform Generators (M4x.6631) to characterize the signals and to finally design the required Application Specific Integrated Circuits (ASICs) and Photonic Integrated Circuits (PICs).

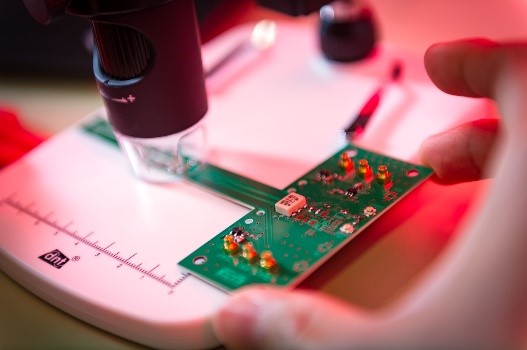

Pic 2: A test PCB with custom integrated circuits and the quantum sensors

Pic 2: A test PCB with custom integrated circuits and the quantum sensors

Prof. Dr. Jens Anders of the University of Stuttgart, who is in charge of the project ‘Cluster4Future QSens’ and a leading scientist of the QHMI consortium, explained, “This is one of the first real-world applications for quantum sensor probes as there is no other way to non-invasively detect such tiny magnetic changes that are in the order of 10 to 100 picoTeslas for muscles: that is six orders of magnitude smaller than the Earth’s magnetic field. Our tests show that our sensors are sensitive enough that they can detect neural signals to muscles through the skin. Even a small amount of remaining, say, lower arm muscle can in principle be used for this. We are working on even greater sensitivity for the femtoTesla magnetic changes we need to measure to detect signals within the brain without breaking the skin.”

At the heart of this technology is an optically detected, magnetic resonance (ODMR) device made of a tiny slice of diamond. The diamond is doped with so-called nitrogen-vacancy centers (NV centers), which have a net electron spin and, therefore, behave like tiny bar magnets. When green laser light is shone on them, they produce a red fluorescence signal. By applying a suitable microwave magnetic field, this fluorescence signal is very sensitive to external magnetic fields, which can be used to measure neural signals with utmost precision.

Pic 3: Checking the ASICs on the test PCB with a microscope

Pic 3: Checking the ASICs on the test PCB with a microscope

The microwave magnetic fields required to control the NV center spins are generated using suitable coils driven by a microwave transmitter. The baseband signals for this transmitter are generated using an Arbitrary Waveform Generator (AWG) to provide the required phase and amplitude modulation of the carrier signal that make the excitation signal more robust against experimental nonidealities. The resulting fluorescence signals, which carry the information of the neural magnetic fields, is then captured by a photodiode, amplified, filtered and digitized for advanced signal processing.

Spectrum’s cards were chosen by the team for several reasons. First, they have an extremely high dynamic range and good noise performance which is vital for such tiny signals. Second, they are very fast, so they can capture the fast signals associated with advanced pulsed excitation schemes, which can require bandwidth beyond 100 MHz. Third, they offered a great value in terms of performance / price. And lastly, the five-year warranty provides peace of mind that a critical component of the research is good for five years as it is almost impossible to obtain funding to replace a failed piece of equipment.

The digitizer flagship M5i.3357 with 10 GS/s sampling rate and 12 bit resolution and the bestseller AWG M4x.6631 with 1.25 GS/s output rate and 16 bit resolution.

The digitizer flagship M5i.3357 with 10 GS/s sampling rate and 12 bit resolution and the bestseller AWG M4x.6631 with 1.25 GS/s output rate and 16 bit resolution.

The quantum sensor probes are currently matchbox-sized and, in the future, will be around one cubic centimeter and go to a control box that is roughly the size of a large matchbox that houses the processing electronics and the battery. The aim is to use microelectronic and photonic integration to shrink the control box further and extend the battery life to give a day of use before recharging. It is hoped that prosthetics will start becoming available in three to four years.

The post Quantum sensors used to move prosthetics appeared first on ELE Times.

Ampere and STMicroelectronics collaborate on powerbox with long term supply for silicon carbide

- Multi-year agreement between STMicroelectronics and Renault Group secures Ampere’s supply of Silicon Carbide power modules

- Collaboration on powerbox and cooling systems for the inverter to get the best efficiency for Ampere’s new generation electric motors

- Agreement aligned with Ampere’s strategy of working upstream with its partners to design the best solutions for each one of its EV technologies

Ampere, the intelligent electric EV pure player born from Renault Group and STMicroelectronics, a global semiconductor leader serving customers across the spectrum of electronics applications, has announced the next step in their strategic co-operation, starting in 2026, with a multi-year agreement between STMicroelectronics and Renault Group on the supply of Silicon Carbide (SiC) power modules, as part of their collaboration on a powerbox for the inverter for Ampere’s ultra-efficient electric powertrain. Ampere and STMicroelectronics worked together on the optimization of the power module, the key element in the powerbox, to get the highest performance and best competitiveness in the e-powertrain, leveraging Ampere’s expertise in EV technology and STMicroelectronics’ expertise in advanced power electronics.

“This agreement is the result of the intensive work carried out with STMicroelectronics. By working upstream together, we were able to optimize and secure the supply of key components for our electric powertrains, to offer high-performance EVs with increased range and optimized charging time. It perfectly aligns with Ampere’s strategy to master the entire value chain of power electronics for its e-powertrain, leveraging STMicroelectronics’ expertise in power modules,” said Philippe Brunet, SVP Powertrain & EV engineering, Ampere.

“ST is at the cutting edge of the development of advanced power electronics enabling the mobility industry to improve the performance of electrified platforms. With the optimization of these higher-efficient products and solutions to meet Ampere’s performance requirements, and our vertically integrated silicon carbide supply chain, we are supporting Ampere’s strategy for its next generation of electric powertrain,” said Michael Anfang, Executive Vice President Sales & Marketing, Europe, Middle East and Africa Region, STMicroelectronics. “ST and Ampere share a common vision for more sustainable mobility and this agreement marks another step forward in improved power performance to further contribute to concrete improvements to carbon emissions reduction by the mobility industry and its supply chain.”

Power modules, composed of numerous silicon carbide chips, manage and convert electrical power from the battery to drive the electric motor. They play a crucial role in the efficiency of the electric powertrain and battery range, as well as energy regeneration features, making them a key element of the efficiency of an electric car. They also contribute to the smoothness and responsiveness of driving.

STMicroelectronics and Ampere have collaborated on a powerbox for the supply of energy to Ampere’s new generation of electric motors. The powerbox is designed for optimum performance-size ratio across Ampere’s line-up, on 400 Volt battery EV vehicles, and for Segment C-EVs with 800 Volt batteries, enabling greater autonomy and faster charging. 800 Volts is one of the key levers to achieve the 10%-80% quick charge in 15 minutes or less. This agreement is fully aligned with Ampere’s strategy to master the entire value chain of the electric vehicle, particularly by working further upstream with its partners and ensuring the best efficiency at each step.

As an integrated device manufacturer (IDM), STMicroelectronics ensures quality and security of supply to serve carmakers’ strategies for electrification. The collaboration with Ampere on the silicon carbide power modules and powerbox demonstrates STMicroelectronics’ leadership and system-level experience of advanced power electronics, including its packaging expertise.

Additional Technical Information

The powerbox combines three SiC-based power modules, an excitation module, which provides the necessary electrical excitation to the motor or generator for controlling the magnetic field within the motor, and a cooling baseplate designed to dissipate heat from the back side of the power module, simplifying the thermal management and cooling process.

The post Ampere and STMicroelectronics collaborate on powerbox with long term supply for silicon carbide appeared first on ELE Times.

Never buy cheap test leads

| submitted by /u/mikeblas [link] [comments] |

Wireless combo modules offer global connectivity

Silicon Labs’ SiWx917Y series of Wi-Fi 6 and Bluetooth LE 5.4 modules provides plug-and-play simplicity with global RF certifications, helping to accelerate development. Intended for battery-powered IoT devices, these energy-efficient modules integrate an Arm Cortex-M4 application processor and antenna in a small 16×21×2.3-mm package.

![]()

The SiWG917Y variant enables customers to run all application code on the device’s Arm Cortex-M4 core. In contrast, the SiWN917Y allows customers to execute applications on a separate MCU, while the module manages Wi-Fi 6 and BLE 5.4 communication tasks. Intelligent power management supports connected sleep mode, consuming as little as 20 µA with Target Wake Time (TWT) and a 60-second keep-alive interval.

The wireless subsystem includes a 160-MHz network processor, baseband DSP, analog front-end, RF transceiver, and power amplifier. The application subsystem features a 180-MHz Cortex-M4 processor with a floating-point unit (FPU) for peripheral and application tasks. This dual-core architecture separates applications and wireless stacks to optimize performance and ensure timely processing.

Wireless modules in the SiWx917Y series are now generally available for purchase.

Find more datasheets on products like this one at Datasheets.com, searchable by category, part #, description, manufacturer, and more.

The post Wireless combo modules offer global connectivity appeared first on EDN.

MPU controls multi-axis motors in real time

Renesas’s RZ/T2H microprocessor, its most advanced for industrial equipment, enables precise control of robot motors with up to nine axes. The device’s application processing and real-time performance make it well-suited for programmable logic controllers (PLCs), motion controllers, distributed control systems, and computerized numerical controls (CNCs). It also supports a variety of network communications, including industrial Ethernet with Time Sensitive Networking (TSN).

The RZ/T2H features four Arm Cortex-A55 CPUs (up to 1.2 GHz) for application tasks and two Cortex-R52 CPUs (up to 1 GHz) for real-time processing. Each R52 core is equipped with 576 KB of tightly coupled memory (TCM). The RZ/T2H also supports 32-bit-wide LPDDR4-3200 SDRAM for external memory, enabling high-performance tasks like Linux applications, robot trajectory generation, and PLC sequence processing.

To support multi-axis motor control, the RZ/T2H provides 3-phase PWM timers, delta-sigma interfaces for current measurement, and encoder interfaces. Peripheral functions for motor control are connected to the Low Latency Peripheral Port (LLPP) of the Cortex-R52 for fast access.

The RZ/T2H microprocessor is now available through authorized Renesas distributors.

Find more datasheets on products like this one at Datasheets.com, searchable by category, part #, description, manufacturer, and more.

The post MPU controls multi-axis motors in real time appeared first on EDN.